RR H-70-2 "Erosion and riprap requirements at culvert and storm

advertisement

'

RESEARCH REPORT H-70-2

EROSION AND RIPRAP REQUIREMENTS AT

CULVERT AND STORM-DRAIN OUTLETS

l-lydraulic Laboratory Investigation

by

J. P. Bohan

January 1970

Sponsored by

Conducted by

Office, Chief of Engineers, U . S. Army

U. S. Army Engineer Waterways Experiment Station, Vicksburg, Mississippi

AR M Y · M RC V I CKSBURG . M ISS.

This document has been approved for public release and sale; its distribution is unlimited

w

J 11-- ,_

IVIJ• fi-7D-

~

~,'J

FOREWORD

The experimental investigation reported herein was authorized by the Directorate of Military

Construction, Office, Chief of Engineers, 1 July 1963.

The study was conducted in the Hydrau-

lics Division of the U. S. Army Engineer Waterways Experiment Station during the period July

1963 to June 1969 under the direction of Mr. E. P. Fortson, Jr., Chief of the Hydraulics Division, and Mr. T. E. 1\\urphy, Chief of the Structures Branch.

Mr. J. L. Grace, Jr., Chief of the

Spillways and Conduits Section, provided supervision during the formulation and conduct of the

tests, analysis of data, and preparation of this report.

The tests were conducted by Messrs. G. A.

Pickering, E. C. Maschmeier, J. 0. Farrell, and C. R. Styron III, with the assistance of Engineering

Aides B. Perkins and C. Wright.

The data were analyzed by Messrs. Styron and J. P. Bohan.

This report was prepared by Mr. Bohan.

Directors of the Waterways Experiment Station during the investigation and preparation and

publication of this report were COL Alex G. Sutton, Jr., CE, COL John R. Oswalt, Jr., CE, and

COL Levi A. Brown, CE.

Technical Directors were Messrs. J. B. Tiffany and F. R. Brown.

Ill

CONTENTS

'

Page

FOREWORD

111

NOTATION

Vll

..

CONVERSION FACTORS, BRITISH TO METRIC UNITS OF MEASUREMENT .

SUMMARY

PART 1:

.

IX

XI

INTRODUCTION

1

Background . . . .

Purpose and Scope of Study

1

PART II:

EXPERIMENTAL FAC ILITIES

Description

.

Scale Relations

PART Ill:

2

.

.

.

.

5

.

.

5

5

TESTS AND RESULTS

8

Tailwater Conditions . . . .

Scour Hole Geometry . . . .

Riprap Protection Requirements

Effect of Culvert Shape on Scour Hole Geometry

PART IV:

DISCUSSION AND DESIGN RECOMMENDATIONS

8

8

11

13

14

LITERATURE CITED

18

SELECTED BIBLIOGRAPHY

18

TABLES 1 and 2

PHOTOGRAPHS 1-4

PLATES 1-20

v

NOTATION

A

Cross-sectional area of flow m a channel, ft2

B

Channel bottom width, ft

ds

Stone diameter required to prevent failure, ft

D

Depth of flow in channel, ft

00

Culvert diameter, ft

Ds

Depth of scour, ft

Dsm

Maximum depth of scour, ft

Fch

Froude number of flow in a channel, Fch

F0

g

Ls

Froude number of flow at the culvert

Acceleration due to gravity, ft/sec2

Length of scour, ft

Lsm

Maximum length of scour, ft

Lsp

Length of stone protection, ft

n

Manning's roughness coefficient

Q

Channel discharge, cfs

Uc

Discharge at which stone was displaced on the nprap blanket, cfs

S

Channel bottom slope, ft/ft

t

Test duration, min

T

Qj'\) gA3jT

outlet, F 0 = V 0/~

=

Top width of flow in a channel, ft

Vs

Volume of scour, ft3

V0

Average velocity of flow at the culvert outlet, fps

W5

Width of scour, ft

Wsm

Maximutn width of scour, ft

..

Vll

CONVERSION FACTORS, BRITISH TO METRIC UNITS OF MEASUREMENT

British units of measurement used in this report can be converted to metric units as follows:

Multiply

By

To

- - ---

Obtain

inches

2.54

centimeters

feet

0.3048

meters

square feet

0.092903

square meters

cubic feet

0.0283168

cubic meters

feet per second

0.3048

meters per second

cubic feet per second

0.0283168

cubic meters per second

feet per second per second

0.3048

meters per second per second

.

IX

SUMMARY

Investigations were conducted in experimental facilities to determine the characteristics of

scour below a culvert outlet discharging onto a horizontal blanket of cohesionless soil and to develop guidance for designing riprap protection downstream of culvert and storm-drain outlets.

Scour holes, produced by the discharge of various flows of several durations through culverts of

various shapes and sizes, were observed and contoured.

These data were obtained for several tail-

water conditions and were used to develop generalized expressions describing the maximum length,

width, depth, and volume of scour as functions of the flow duration and the Froude number of

flow at the culvert outlet.

Dimensionless scour profiles and cross sections, for low and high tail-

water conditions, were also developed.

Riprap blankets of various configurations and stone stzes were tested with several culvert

stzes and shapes and various tailwater conditions to determine when displacement or failure occurred.

The results were used to develop generalized relations to describe the stone size and

appropriate blanket configuration required to prevent blanket failure and soil erosion, respectively,

at a culvert or storm-drain outfall.

.

Xl

EROSION AND RIPRAP REQUIREMENTS AT CULVERT

AND STORM-DRAIN OUTLETS

Hydraulic Laboratory Investigation

PART I:

INTRODUCTION

BACKGROUND

1.

The lack of adequate means for estimating the extent of erosion to be anticipated

downstream of culvert and storm-drain outlets and the size of stone and extent of a riprap blanket sufficient to prevent such erosion can be readily verified by a cursory inspection of field installations.

Rather extensive and noteworthy surveys of conditions at culvert outlets have been

accomplished by Keeleyl in Oklahoma and Scheer 2 in Montana. During the course of the subject

model investigations, observations were made of the drainage and erosion control facilities of over

SO military installations throughout the continental United States in connection with a separate

but related study concerning field performance of drainage and erosion control facilities sponsored

by the Office, Chief of Engineers. The conditions of erosion observed throughout the field performance study support the observation reported by Keeley 1 that two general types of channel

instability can develop downstream from a culvert and/or storm-drain outlet, i.e. either gully scour

or a localized erosion referred to as a scour hole.

Distinction between the two conditions of

scour and prediction of the type to be anticipated for a given field condition can be made by a

comparison of the original or existing slope of the channel or drainage basin downstream of the

outlet relative to that required for stability as illustrated in fig. 1.

ORIGINAL GROUND (STABLE SLOPE)

~--.,..--rt--- - - - - - - - - - - : : : - - - - - - - - - - - - - -

SCOUR HOLE

h

FLOW.._

STABLE

SLOPE

GULLY SCOUR

Fig. 1.

Types of scour at culvert outlets

1

2.

Gully scour is to be expected when the Froude number of flow in the channel exceeds

that required for stability.

and progresses upstream.

It begins at a control point downstream where the channel is stable

If sufficient differential in elevation exists between the outlet and the

section of stable channel, the outlet structure will be completely undermined as shown in fig. 2.

'

--

"

-t\

..

Fig. 2.

Failure of outlet structure due to gully scour

Erosion of this type may be of considerable extent depending upon the location of the stable

channel section relative to that of the outlet in both the vertical and downstream directions.

3.

A scour hole or localized erosion is to be expected downstream of an outlet even if

the downstream channel is stable as shown in fig. 3a.

The severity of damage to be anticipated

depends upon the conditions existing or created at the outlet.

In some instances, the extent of

the scour hole may be insufficient to produce either instability of the embankment or structural

damage to the outlet.

However, in many situations flow conditions produce scour of the extent

that embankment erosion (fig. 3a) as well as structural damage of the apron, end wall, and culvert

(fig. 3b) is evident.

4.

The observations and empirical methods developed by Keeley,l,3,4 which provide spe-

cific guidance relative to the conditions that produce gully scour or only a localized scour hole

as well as those required for stable channels in several Oklahoma soils, merit consideration and

application in general.

However, there still is a lack of guidance relative to the extent of the

scour hole to be anticipated downstream of culvert and storm-drain outlets.

for initiation of the subject study.

This is the basis

PURPOSE AND SCOPE OF STUDY

5.

The research reported herein has as its purpose the development of guidance for esti-

mating the extent of localized scour to be anticipated downstream of culvert and storm-drain

2

a.

Embankment instability

'

•

...

•

b.

Structural damage of apron, end wall, and culvert

Fig. 3.

Damage resulting from localized erosion

•

3

outlets as well as protective stone requirements sufficient to prevent such erosion.

A hydraulic

model was used to determine (a) the geometry of the scour hole formed by the discharge of

various rates and durations of flow from various sizes and shapes of culverts onto a horizontal

bed of sand under various depths of tailwater, (b) the conditions of discharge and tailwater

through and downstream of these culverts required to displace various sizes of crushed stone, and

(c) the configuration and extent of riprap blanket required

ditions.

to

prevent erosion under similar con-

Test results for various tailwater conditions were analyzed and are presented in terms of

dimensionless parameters involving the average velocity of flow and diameter of the outlet so that

the design engineer can readily and easily predict the geometry of the scour hole to be expected

and/or the size of stone and extent of riprap blanket required to prevent localized erosion.

4

PART II:

EXPERIMENTAL FACILITIES

DESCRIPTION

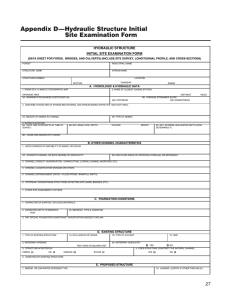

6.

Circular culverts with diameters of 0.125, 0.224, 0.333, and 1.000 ft* located at the

upstream end and center of a 16-ft-wide, 5.5-ft-deep, and 40-ft-long test flume (fig. 4) were used

t-----;;::::

------f

-

-

-

-

..

-

'

~

ION2

I•

40'

PLAN

~

~

ClJLVERT

BAFFLE- ._

:i:

.::·

s

'

II\

")

A

N

D ':;[; :,

i:I:

=·~;:;~;

·;_-·.::.

I ..

BRICK

END

SILL

);AILGATE

<ri

r--

•I

20'

'

II\

..A:

DRAIN

ELEVATION

Fig. 4.

Experimental facilities

to investigate scour downstream of a culvert outlet.

Circular, arch, rectangular, and box-shaped

sections of equal areas (cross-sectional area equal to that of the 0. 3 3 3-ft-diam circular culvert)

were used to investigate the effect of shape upon the scour characteristics.

7.

A horizontal sand bed, 3.5 ft deep, was provided for a length of 20 ft downstream of

the culvert.

Gradation of the material used for the sand bed was as shown in fig. 5.

The nprap

tests were conducted using uniformly graded crushed limestone in sizes ranging from 114- to 6-in.

diameters.

The stone was kept uniformly graded for ease in handling and storage.

was placed between the sand and riprap to prevent slumping of the riprap blanket.

A filter cloth

Standard de-

vices were used to measure discharge, velocity, and water- and soil-surface elevations.

SCALE RELATIONS

8.

*

In order to obtain some idea of the model scale effects, the 1.000-ft-diam culvert was

A table of factors for converting British units of measurement to metric units is presented on page ix.

5

U. S. STANDARD SIEVE SIZE

NO. 4

100

-~

NO. 10

NO. 40

I

I

I

I

I

I

i

!

eo

i

I

'

I

-w

>-

I

60

I

!

0:

w

I

I

I

I

I

lL.

40

I

I

ll.

I

20

I

I

I

I

I

I

I

i

I

I

I

I

I

li

I

I

I

I

I

I

I

i

I

0

10

6

I

ti

I

1:

I

I

I

I

I'

I

I

I

'I

!

i

II

I

I

\

I

I

I

I

II

II

I

I

II

I

I

I

I

I

I

I

I

I

I

I

[I

i

'

I

I

I

I

I

I'

w

u

0:

w

I

I

I

-z

z

It

It

I

aJ

1-

I

I

I

1J:

C>

~

I

I

\

NO. 200

I

I

4

2

1 .0

0.6

0. 4

0.2

I

I

I

\

I

I

It

0. 1

0.06

0.02

0.0 1

G RAIN SI Z E IN M ILLI M ETERS

Fig. 5.

Grain-size distribution of bed material

considered the prototype and the 0.3 3 3-, 0.224-, and 0.125-ft-diam culverts were referred to as

1 :3-, 1:4.46-, and 1 :8-scale models, respectively.

Th e 1:4.46 scale resulted from the fact that com-

mercially available tubing was used for the 0 .224-ft-diam culvert.

9.

The accepted equations of h ydraulic similitude , based upon the Froudian criteria, were

used to ex press mathematical relations between dimensio ns and h ydraulic quantities of the models

and prototy pe.

follo ws:

General relations for t ransference of model data to prototype equivalents are as

Dimension

10.

Ratio

Scale Relations

Length

Lr

1 :3

1:4.46

1:8

Area

Ar - L2r

1:9

1:19.89

1:64

Velocity

vr

-

Ll/2

r

1 :1.732

1:2.112

1:2.828

Discharge

<lr -

L5/2

r

1 : 15.6

1:42

1:181

The experimental data indicated that the proto type-t o-model scale ratws for the 0.3 3 3-

and 0.224-ft-diam culverts were valid; however, the data for the 0.125-ft-diam culvert did not correlate using the above relations.

For example, displacement of 1/ 2- to 3/4-in. stone downstream

of the 0.125-ft-diam culvert that simulated 5- to 6-in. st one d o wnstream of the 1.000-ft-diam

6

prototype culvert to a scale of 1:8 required simulated discharges 1.25 times those observed with

the prototype. The Reynolds number of flow at the culvert outlets for all of the circular culverts was calculated and was found to be 1 X 105 or greater for all tests of the 1.000-, 0.3 3 3-,

and 0.224-ft culverts. The Reynolds number of flow in tests of the 0.125-ft culvert was found

to be less than 1 X 105. It was concluded that the viscous effects were significant and that the

Reynolds number of flow in the model culverts should be of sufficient magnitude (apparently

:2: 1 X 105) to produce a resistance coefficient of the magnitude anticipated and attributed to

the prototype stone in a fully rough flow regime. This was accomplished with all but the 0.125ft-diam culvert, and therefore the unconservative results of tests obtained with the smallest (1 :8scale model) culvert were disregarded.

7

PART III:

TESTS AND RESULTS

TAILWATER CONDITIONS

11.

Tests indicated that all of the tailwater conditions investigated could be grouped into

two categones. Tailwater conditions of less than 0.5 0 0 above the culvert invert produced approximately the same flow pattern and scour hole geometry and will be referred to as minimum

tailwater conditions in this report; all tailwater conditions of 0.5 D0 ft and greater above the

culvert invert produced approximately the same flow pattern and scour hole geometry and will

be referred to as maximum tailwater conditions. Variations in the pattern of scour observed

with various tailwaters are shown in photograph 1.

12. These results agreed very well with those presented by Seaburn and Laushey5 which

indicate that for a constant discharge the velocity just downstream of a culvert outlet remains

constant for tailwater conditions from 0 to 0.5 D0 ft above the culvert invert. The velocity increases with increasing tailwater and reaches a constant maximum velocity again at a tailwater

approximately 1.0 D0 ft above the culvert invert.

SCOUR HOLE GEOMETRY

Test Procedure

13.

The sand scour tests were initiated usmg a 1.000-ft-diam culvert and a horizontal sand

bed molded to the invert of the culvert (fig. 6).

Fig. 6.

Several different discharges were passed through

Horizontal sand bed

8

the 1.000-ft-diam culvert, and it was observed that the scour hole extended to the model limits

for the higher discharges. For this reason and to check model scale effects, three smaller culverts

(0.333-, 0.224-, and 0.125-ft diam) were tested. A low flow and corresponding scour hole are

shown in photograph 2.

14.

The first phase of the sand scour investigation consisted of testing all of the circu-

lar culverts with several different discharges and test durations of 20 and 30 min for minimum

and maximum tailwater conditions, respectively. Typical flows and resulting scour holes for minimum and maximum tailwaters are shown in photograph 3. The test durations were arrived at by

conducting several tests with times varying up to 1 hour and observing that most of the scour

took place within the first 20 min of each test for minimum tailwater and the first 30 min of

each test for maximum tailwater.

15.

The scour hole was contoured after each test.

These data were used to obtain the

volume of scour and the maximum length, width, and depth of scour as shown in table 1.

After the scour hole was contoured, the sand bed was remolded prior to the next test.

16. The second phase of the sand scour investigation was conducted to determine the

effect of the duration of the test on the scour hole geometry. These tests were conducted

using the 0. 3 3 3-ft-diam culvert.

Two series of tests, with Froude numbers of flow at the cul-

vert outlet equal to 1.43 and 3.05, were conducted with minimum tailwater and a third test

series, with a Froude number at the culvert outlet of 3.05, was conducted with maximum tailwater.

During each test series the flow was stopped at various intervals and the scour hole con-

toured. The volume of scour and the maximum length, width, and depth of the scour hole were

obtained and are tabulated in table 1. The total duration of each of the test series was approximately 24 hours.

As indicated by the tabulated data, a stable condition was not reached

in this time period.

Data Analysis

17. Several attempts were made to generalize the data using dimensionless parameters.

The

plots which best satisfy the data are those of the Froude number versus the ratios of maximum

length of scour to the culvert diameter

diameter

Wsm/D0

,

Lsm/D 0

,

maximum width of scour to the culvert

maximum depth of scour to the culvert diameter

Dsm/00

,

and the vol-

Vs/D~ . The test duration data were best satisfied by plots of these same ratios versus the duration of the tests. These plots are shown in

ume of scour to the culvert diameter cubed

plates 1-5 for minimum tailwater conditions and in plates 7-11 for maximum tailwater conditions and will henceforth be referred to as the Froude number relations and the test duration

relations.

18.

Further analysis indicated that the Froude number relations and corresponding test

duration relations could be combined, yielding the following equations:

Minimum tailwater:

(1)

(2)

(3)

9

(4)

Maximum tailwater:

(5)

(6)

(7)

(8)

The technique used to develop these equations will be demonstrated with the graphs shown in

plate 3.

19. The test duration relation indicates that the data for Froude numbers of 1.43 and

3.05 are best fit by straight, parallel lines. It was assumed that the best fit for any other

Froude number would also be a straight line parallel to those for F 0 = 1.43 and 3.05 . The

equation of a straight line on this plot is

where a is the slope of the line and b is the Dsm/D 0 intercept at

the lines on this plot will be parallel, the slope is the same for every line.

t

= 1 .

Since all of

However, the

D5 m/D0 mtercept at t = 1 is variable and depends upon the Froude number. The Froude

number relation indicates that Dsm/D0 varies as the logarithm of the Froude number. The

curve shown on the upper plot of plate 3 is for a test duration of 20 min and the curve required is for a duration of I min.

The 1-min curve was obtained as follows:

Two points on the Froude number relation were selected (F0 = 1 and F 0 = 10)

and plotted on the test duration relation at t = 20 min. Since all curves on this

plot will be parallel, lines were drawn through the two plotted points, parallel to

the existing lines and through t = 1 min. At this point (t = 1 min) the Dsm1D 0

values were observed and plotted on the upper plot of plate 3 at F 0 = 1 and 10 .

A straight line was drawn between these two points and the equation of this line is

- 1.3 + 1.4 log F 0

This equation shows how Dsm/D 0 varies with the Froude number at

can be substituted into the equation

for

b , yielding,

10

t - 1 min

and therefore

The test duration plot indicates that

a - 0.1 .

The final equation is

0 sm

Do

or

(3 bis)

This same procedure was used to obtain equations 1 to 8.

These relations can be used to cal-

culate the expected length, width, depth, and volume of a scour hole for a known discharge, culvert size, flow duration, and tailwater condition.

20.

The next objective in the sand scour analysis was to develop a dimensionless scour

hole using the contour data.

A dimensionless profile along the center line of the culvert was

first constructed by plotting the ratio of the depth of scour to the maximum depth of scour

DsiDsm

versus the ratio of the length of scour to the maximum length of scour

Ls/Lsm .

This was done for both minimum (plate 6) and maximum (plate 12) tailwater conditions.

These

two plots indicated that the maximum depth of scour occurred at a distance 0.4 of the maximum

length of scour downstream of the culvert outlet for both tailwater conditions.

Dimensionless

cross sections were then plotted at this location for both tailwater conditions and are shown

in plates 6 and 12 for minimum and maximum tailwater, respectively.

The data satisfy these

plots quite well, especially considering the fact that the data were gathered by several different

individuals.

RIPRAP PROTECTION REQUIREMENTS

Types of Failure

21. Three types of nprap failure were considered:

(a) individual displacement of stones

on the blanket caused by inadequate stone size, (b) raveling of the ends of the blanket caused

by inadequate blanket size and scour in excess of the blanket thickness, and (c) movement of

material from below the blanket allowing the blanket to settle.

This latter type of failure is

caused by an inadequate filter below the blanket.

22. The first two types of failure have been investigated and the results are presented

below.

The third type of failure, blanket slumping, was not investigated but was prevented

during the testing by using a filter doth beneath the riprap blanket.

Stone Size

23. Tests were conducted to determine the stone size required to prevent failure (ds) or

displacement for various culvert sizes, discharges, and tailwater conditions.

The first problem in

this series of tests was to define this failure so that some type of standard could be referred

to for each test.

It was decided that the condition at which several stones were displaced from

the upper layer of the two-stone-diameter-thick blanket would be termed failure.

In several

cases only one or two stones were displaced and no other stone movement occurred.

was not considered failure.

was displaced.

This

On the other hand, in some cases a major portion of the blanket

The conditions termed failure herein did not permit displacement of the entire

11

blanket thickness for it is considered that it would be appropriate to be conservative in such a

laboratory investigation, smce a greater degree of turbulence is to be anticipated in the prototype

or field installations.

24. The tests that were conducted resulted in a list of stone sizes and corresponding discharges at which failure occurred for the different culvert sizes and tailwater conditions (see

table 2). Plots of the ratio of the stone diameter to the culvert diameter versus the Froude

number of flow at the culvert outlet for both minimum (plate 13) and maximum (plate 16)

tailwater conditions resulted in the best representation of the data. The relations obtained from

these plots are:

Minimum tailwater:

(9)

and

Maximum tailwater:

(10)

The stone size, therefore, depends upon the culvert diameter, Froude number of flow at the culvert outlet, and the tailwater condition.

Blanket Configuration

2 5. An appropriate rip rap blanket configuration was arrived at by a trial-and-error procedure. Several different configurations were tested, using the scour hole geometry data as a

guide and engineering judgment to determine whether the blanket was adequate. Once again a

standard had to be developed to use as a guide in determining whether a blanket was adequate.

The standard used was as follows: if the scour beyond the edges of a blanket was two or less

stone diameters deep, the blanket was adequate; if this scour depth exceeded two stone diameters, the blanket was inadequate. Tests of 20-min duration were run for several different

discharges and tailwater conditions.

26.

The blanket configurations were quite different for mm1mum and maximum tailwater

conditions. The jet from the culvert dispersed rapidly with minimum tailwater and required a

short, wide blanket; however, with maximum tailwater, the jet traveled a considerable distance

downstream and required a long, narrow blanket to prevent erosion.

With maximum tailwater

the jet also changed position from side to side, as shown in photograph 4.

27.

Tests indicated that the only parameter of the blanket configuration that changed sig-

nificantly with discharge was the blanket length.

A blanket width of three culvert diameters was

required at the culvert outlet for all conditions tested.

A flare of 1 on 2 (plate 15) was re-

quired to contain all discharges with minimum tailwater, while a 1-on-5 flare (plate 18) was

sufficient to contain all flows with maximum tailwater.

28.

For each test conducted, the blanket length was classified as adequate or inadequate

and the results were plotted with the blanket length, expressed as a number of culvert diameters,

12

versus the Froude number of flow at the culvert outlet for both tailwater conditions. The

adequate and inadequate blanket lengths can be divided quite well with the lines shown in plate

14 for minimum tailwater and plate 17 for maximum tailwater. The equations of these lines,

which define the required length of blanket to prevent raveling as defined in paragraph 21, are:

Minimum tailwater:

(11)

Maximum tailwater:

Lsp

=

D0 (8 + 55 log F 0 )

These relations are valid for Froude numbers greater than one.

(12)

A limited number of tests were

conducted with Froude numbers less than one and these indicated that a blanket length of approximately eight culvert diameters should be provided to contain the flow for both tailwater

conditions with Froude numbers less than one.

EFFECT OF CULVERT SHAPE ON SCOUR HOLE GEOMETRY

29.

The effect of culvert shape on the scour hole geometry was not investigated in detail.

A quick comparison was made by passing a discharge of 0.87 cfs through four differently shaped

culverts (circular, square, rectangular, and arch) with the same cross-sectional area (0.087 sq ft)

and by observing the scour hole. This was done for both minimum and maximum tailwater conditions, and the results indicated that the culvert shape had no significant effect on the scour

hole geometry.

30. The oscillating jet that was observed for flow from the circular culvert into maximum

tailwater (photograph 4) was also observed with flow from the square, rectangular, and arch

culverts. This oscillation was random and quite slow for all conditions except that in which

flow passed through the arch culvert into maximum tailwater after a scour hole had been

developed with minimum tailwater.

position about every 15 sec.

For this condition the oscillation was periodic and changed

Thus, it appears that the jet discharged from an arch culvert is less

stable than that from the other culverts investigated.

13

PART IV:

31.

DISCUSSION AND DESIGN RECOMMENDATIONS

In designing protection against erosion below culvert outlets, one must first know what

type of erosion to expect.

previously in this report.

Keeley 1 classifies erosion as gully scour or scour hole, as discussed

He states that gully scour may be expected in a cohensionless soil if

the Froude number of flow in the channel below a culvert outlet is 0.35 or greater.

This value

varies for different types of soil.

32. If one determines that gully scour will occur, the Froude number of flow in the

channel must be decreased.

This can be best accomplished by using one or more drop structures

to achieve considerable change in elevation and maintain a stable slope to the downstream conNo type of stilling device or blanket protection will prevent gully scour if the

trol point.

Froude number of flow in the downstream channel exceeds the critical value.

As indicated by

Keeley,! the ultimate depth of channel degradation to be anticipated at the outlet can be approximated.

The elevation of the invert of the control section (upstream limit of the stable

channel downstream) plus the product of the stable gradient and the distance from the control

section to the outlet will yield the elevation of the degraded channel to be anticipated at the

outlet.

This elevation compared with that existing at the outlet is a measure of the scour depth

which may ultimately develop.

3 3. Even if the Froude number of flow in a channel below a culvert outlet is less than

'

the critical value required for gully scour, a scour hole can be expected to develop.

The results

presented in this report can be used to determine the size of the scour hole expected for either

minimum or maximum tailwater conditions.

A decision must be made either to allow all or a

portion of this scour hole to form and provide the necessary structural protection or to prevent

erosion entirely.

34. If the location of the culvert is such that a scour hole is not objectionable, allowing

the scour hole to form may be a very economical solution to controlling erosion.

The scour

hole acts as an excellent energy dissipator; however, the culvert still must be protected against

undermining.

A cutoff wall will normally be used for this purpose and the dimensionless scour

holes presented in this report can be used to estimate the required depth to which a cutoff wall

must extend to prevent undermining.

The dimensionless scour hole for minimum tailwater, shown

in plate 6, indicates that erosion directly under a culvert outlet would be approximately 0. 7 as

deep as the maximum expected scour depth.

Thus it would be necessary to extend a cutoff wall

down to, at least, this depth to prevent undermining.

35.

A "plunge pool" (fig. 7) is another effective device which can be used to prevent

undermining of a culvert.

The plunge pool should be as deep and wide as the maximum ex-

pected depth and width of scour with the upstream slope protected with riprap.

This type of

protection requires much less riprap than a full blanket and will prevent erosion only near the

culvert (fig. 8).

36.

If a scour hole is undesirable, complete protection can be provided with a riprap blan-

ket, concrete apron, or a combination of these.

The blanket or apron configuration required

to provide protection can be determined with the technique outlined in this report.

The choice

between a riprap blanket and a concrete apron can be made after determining the stone size required for a riprap blanket.

The required stone size can be determined from equations 9 and

10 for minimum and maximum tailwater, respectively.

14

Examination of equation 9 indicates

Fig. 7.

Plunge pool or riprapped scour hole

Fig. 8.

Eroded plunge pool

that the stone size required for a Froude number of 2 is half the diameter of the culvert. Of

course, as the culvert size increases the stone size becomes unrealistically large and impractical,

in which case a concrete apron may be desirable with the same configuration as that required

for the riprap blanket. It would be uneconomical to extend the concrete apron or a riprap

blanket with the stone size determined from equations 9 or 10 the full length of the required

protection, since the degree of attack becomes less severe downstream. Thus, it is advisable to

gradually decrease the protection in a downstream direction. The dimensionless scour holes discussed herein can be used as a guide for determining the degree of attack along a channel.

These dimensionless scour holes (plates 6 and 12) indicate that the area of the most severe

attack is from the culvert outlet to a point approximately 0.6 or 0. 7 of the maximum expected

length of scour downstream; therefore, protection can be decreased downstream of this area. For

example, if a concrete apron is used below a culvert, grouted riprap can be placed beyond the

area of the most severe attack. A transition of loose riprap, decreasing in size in a downstream

direction, can be used between the grouted riprap and the natural channel. If a riprap blanket

is used, the stone size downstream of the area of the most severe attack may gradually decrease in size downstream to the end of the blanket.

37. For conditions in which the stone size of a nprap blanket is unrealistic or impractical and a concrete apron is exceedingly large, a stilling device may be the most economical

means of providing protection. Some commonly used energy dissipators are the St. Anthony Falls

stilling basin,6 the stilling well,7 and the U. S. Bureau of Reclamation Type VI stilling basin.8 A

laboratory study is presently getting under way at the U. S. Army Engineer Waterways Experiment

Station to develop simple stilling devices to be used at culvert outfalls for intermediate flow conditions where protection other than riprap and/or the most commonly used energy dissipators is

required.

38.

Design of culvert outlets, subjected to both mtmmum and maximum tailwater condi-

tions, requires good engineering judgment.

One suggestion of a sufficient blanket configuration

for this condition follows. The width of the blanket at the culvert outlet should be 30 0

wide and should flare 1 on 2 until the total width is equal to the greater of either the blanket

width required for minimum tailwater or the blanket width required for maximum tailwater.

From this point the blanket should extend downstream parallel to the culvert to a length equal

to the blanket length required for maximum tail water. This is illustrated in plate 19.

39. One very important factor of drainage design is deposition in the channel and culvert.

This condition may be a more severe problem than erosion, because the capacity of the channel

or culvert is reduced and maintenance (effort and cost) is required. The problem of deposition

can be reduced by providing more .stable channels, thus reducing erosion upstream of a drainage

facility. Keeley4 has observed some prototype drainage facilities in Oklahoma at which deposition has occurred. He suggests that deposition will occur if the Froude number in a channel is

less than a certain critical value, depending upon the sail type. Again, it is considered that the

results of Keeley 1,3 ,4 can be applied to design drainage channels in cohesionless soils such that

a Froude number of flow from about 0.15 to 0.35 is maintained and the channel downstream of

an outlet will not be subject to either deposition or erosion.

The graph shown in plate 20 was

developed (using the Manning formula) to provide guidance in selecting a satisfactory channel.

The parameters for a given channel may be calculated and plotted to determine whether the

Froude number for the channel is in the acceptable range. The plot shown is for a channel

16

side slope of 1 on 2. The same type of graph can be developed for other side slopes.

40. The results involving depth, width, length, and volume of scour; stone diameter;

outlet diameter; average velocity of flow; and tailwater depth were purposely presented in

terms of dimensionless parameters so that they can be readily and easily applied to predict

the geometry of the scour hole to be expected downstream of an outlet and to select the

size of stone and extent of riprap blanket required to prevent development of a scour hole.

judgment can and must be exercised to evall;late the need for and/or degree of protection

required at an outlet, such as no protection, prefabricated end section, end wall, small apron

and cutoff wall, protective stone blanket, grouted riprap blanket, concrete apron, or an energy

dissipater with either a protective stone blanket or concrete apron. Further, the outlet with

or without appurtenances must be provided with a stable channel downstream to prevent the

likelihood of gully scour and structural damage.

17

LITERATURE CITED

1.

2.

Keeley, J. W., "Soil Erosion Studies in Oklahoma; Part III, Culvert Oudet Conditions and

Downstream Channel Stability," 1963, U. S. Bureau of Public Roads, Oklahoma Division,

Oklahoma City, Okla.

Scheer, A. C., "Large Culvert Studies in Montana," 1968, Department of Civil Engineering

and Engineering Mechanics, Montana State University, Missoula, Mont.

3.

Keeley, J. W., "Soil Erosion Studies in Oklahoma; Part I, Water Erosion in Narrow Ditches

and Channels; Part II, Erosion Control Devices for Ditches and Channels," 1961, U. S.

Bureau of Public Roads, Oklahoma Division, Oklahoma City, Okla.

4.

, "Soil Sedimentation Studies in Oklahoma; Deposition in Culverts and

Channels," 1967, Federal Highway Administration, Bureau of Public Roads, Oklahoma Division, Oklahoma City, Okla.

5.

Seaburn, G. E. and Laushey, L. M., "Velocity of Culvert Jets for Incipient Erosion,"

Proceedings, Twelfth Congress of the International Association for Hydraulic Research, Vol 3,

Sept 1967, pp 1-8.

6.

7.

8.

Blaisdell, F. W., "Development and Hydraulic Design, Saint Anthony Falls Stilling Basin,"

Transactions, American Society of Civil Engineers, Vol 113, Paper No. 2342, 1948,

pp 483-520.

U. S. Army Engineer Waterways Experiment Station, CE, "Impact-Type Energy Dissipator

for Storm-Drainage Outfalls, Stilling Well Design," Technical Report No. 2-620, Mar 1963,

Vicksburg, Miss.

Beichley, G. L., "Progress Report No. XIII-Research Study on Stilling Basins, Energy Dissipators, and Associated Appurtenances-Section 14, Modification of Section 6 (Stilling

Basin for Pipe or Open Channel Outlets-Basin VI),'' Report No. HYD-572, june 1969,

Hydraulics Branch, Division of Research, U. S. Bureau of Reclamation, Denver, Colo.

SELECTED BIBLIOGRAPHY

Bradley, J. N. and Peterka, A. ]., "Hydraulic Design of Stilling Basins: Small Basins for Pipe

or Open Channel Outlets-No Tailwater Required (Basin VI)," Journal, Hydraulics Dil•ision,

American Society of Civil Engineers, Vol 83, No. I-IYS, 1957, pp 1406-1 - 1406-17.

Laushey, L. M., Ulrich, K., and Ofwona, M. P. , "Magnitude and Rate of Erosion at Culvert

Outlets," Proceedings, Twelfth Congress of the International Association for Hydraulics

Research, Vol 3, Sept 1967, pp 338-345.

Stevens, M. S., Scour in Riprap at Culvert Outlets, Ph. D. Dissertation, Colorado State

University, Fort Collins, Colo., Jan 1969.

18

Table 1

Summary of Sand St:our Tests

Culvert

Diameter

D0 , ft

Tail water

Condition

Do

Test

Uurauon

t , min

Dtscharge

Q , cfs

l•roude

Number at

Cuhert

Outlet, F0

Maxtmum

Length of

Scour

l"Sm • ft

Maxtmum

\\ tdth of

Scour

\\sm . ft

Maxtmum

Depth of

Scour

Dsm , ft

.us

\ olume

of cour

\'s ' ft3

Test Durations, 20 and 30 mm

1.000

20

0

0.333

0

20

4.710

5.500

6.280

7 070

7.850

9.420

11.800

1.06

1.23

1.41

1.59

1.76

2.12

2.64

13 .00

14 00

16 .00

17.00

17.00

20.00

EM I.

S.10

8.00

E.\11.

2.40

2.50

2.85

2.90

3.05

3.00

0.3 51

0.401

0.452

0.503

0.870

1.30S

1.740

1.23

I .41

1.58

1.76

3.05

4.58

6.10

4.00

3 so

4.00

5.00

7.50

10.00

12.00

3.30

2.80

2.50

3.50

5.50

8.00

8.00

0,68

0.70

0 .69

0.70

0.90

1.0!1

1.11

so.ss

F.\\1 . ·

EM I.

1..\11.

1.\\L

92.00

118.00

I S4.00

211\.00

260 00

3 76.00

465 .00

2.40

2.76

3.14

4 .H8

12.33

34.40

0.224

0

20

0.112

0.131

0.150

0.168

0.187

0.224

0.280

1.06

1.24

1.41

1.59

1.77

2.12

2.65

2.20

2.50

2.70

2.80

3.30

4.00

4 .50

1.10

1.25

1.10

1.15

1.40

1.90

2.15

0 .-1-8

0 .50

0.50

0.53

0.57

0.58

0.63

() 71

0.98

0 94

1.22

1.69

2.5S

3.32

0.333

1.0

30

0.410

0.450

0.870

1.300

1.740

1.-H

1.58

3.05

4.58

6.10

6.50

7.00

13 00

15.50

15.20

3 00

2 so

3.50

3.50

8.00

0.64

0.63

0.92

1.01

S.H

0.112

0.131

0.150

0.327

1.06

1.24

1.42

3.10

3.30

3 70

4.30

7.00

060

0.80

0.90

1.55

0.26

0.39

0.43

0.70

5.20

14.64

22.12

55.69

().28

0.67

0.89

4. 11

0.224

1.0

30

l.H

Extended Test Duration with 0.333 -ft·d•am Culvert

0.33 3

0

10

15

20

25

30

45

60

90

120

180

360

0.41

1.43

3.50

3.50

3.60

3.15

4.00

4.10

4 50

4.SO

5.00

5.00

5 50

9 00

1000

10 00

1.93

2.00

2.00

2.00

2.20

2 50

3 10

3.00

2.50

3.50

4.00

4.50

4.50

5.50

0.70

0.70

0.70

0.74

0.73

0.79

0.80

0.73

0.84

0.70

0.91

0.82

1.19

1.18

2.28

2.47

2.76

2.92

3.18

3.64

3. 70

4.23

4.58

5.62

6.57

9.08

12 89

14.48

0.87

3.05

7.00

7.50

7.50

7.50

8.00

10.00

12.00

18.00

18.00

18.00

4.00

5.00

5.50

5 50

5.50

8.00

0.84

0.88

0.90

0.94

1.00

1.06

1.22

1.44

1.47

1.55

I 0.42

12.19

12.33

I 4 .1 1

16.H

24 79

42.00

64 77

71.59

81.94

0.82

0.90

0.96

1.03

1.16

1.19

1.20

1.29

8.50

14.04

18.13

23.72

28.43

33.27

32.95

37.61

HU

900

1260

0

0.333

0.333

1.0

10

15

20

30

45

120

360

720

1020

1425

10

30

60

120

360

720

1080

1-HO

•

EML

=

exceeded model limits.

0.87

3.05

9.50

11 .50

13 so

14 50

15 50

16 so

15.50

16 50

EML

EML

EML

1:..\\L

3.50

3.00

3.00

4.50

4.00

4.00

4.00

~.00

Table 2

Stone Size Data

D0

,

ft

d5

,

ft

<lc , cfs

Tailwater Condition, 0 D0

0 .224

0.0625

0.0833

0.1250

0.1667

0.111

0.194

0.201

0.400

1.32

1.83

1.93

3.78

0.3 3 3

0.0833

0.1250

0.1667

0.2500

0.33 33

0.360

0.510

0.710

0.825

1.160

1.26

1. 79

2.49

2.90

4.06

1.000

0.0625

0.0833

0.1250

0.1667

0.2500

0.3333

0.4167

0.5000

0.240

0.790

1.700

3.210

4.090

7.470

8.980

9.100

0.53

0. 75

0.93

1.10

1.15

1.68

2.02

2.04

Tailwater Condition, 1.0 D 0

0.224

0.0625

0.0833

0.1250

0.1667

0.207

0.272

0.323

0.523

1.99

2.61

3.10

4.93

0.3 3 3

0 .083 3

0.1250

0.1667

0.2500

0.3333

0.580

0.810

0.925

1.000

1.310

2.04

2.84

3.24

3.50

4.59

1.000

0.0625

0.083 3

0.1250

0.1667

0.2500

0 .3333

0.4167

0.5000

4.190

4.600

5.710

7.880

8.380

9.100

10.200

12.100

0.94

1.03

1.28

1.77

1.89

2.04

2.29

2.71

a.

b.

Photograph 1.

Tailwater el 0 D0

Tailwater el 0.25 D 0

Variation of scour with tailwatcr. discharge 0.25 cfs (sheet 1 of 3)

c.

Tailwater el 0.50 D 0

d.

Tailwater el 0.75 D0

Photograph 1.

(sheet 2 of 3)

e.

Tailwater el 1.00 D0

Photograph 1.

(sheet 3 of 3)

•

a.

Flow from culvert, discharge 3.14 cfs

•

•

•

•

• ••• • •

•

•

•

•

•

• ••

• ••

•

'

I

..

•

• •

b.

Photograph 2.

•

•

....

Resulting scour hole

Typical flow condition and resulting scour, 1.000-ft-diam culvert

a.

Flow condition, m1mmum tailwater

b.

Photograph 3.

Scour hole, mm1mum tailwater

Flow condition and resulting scour hole for 0.224-ft-diam culvert,

discharge 0.131 cfs (sheet 1 of 2)

66646

c.

Flow condition, maxtmum tailwater

1

d.

Scour hole, maxtmum tailwarer

Photograph 3.

(sheet 2 of 2)

a.

b.

Flow concentrated at left (time - t)

Flow concentrated at right (time

Photograph ~.

=t

+ ~t)

Oscillating jet with max1mum tailv.:ater

40

I

I

I

I

I

'

I

I

I

l

I

I

~

_........ ~

30

~

~

--...

f--

20

0

0

~_;~

f--

0

10

0

~

~

~

(_--

!.---"

-

~

-

LEGEND

l .000-FT-DIAM CULVERT

0.333-FT-DIAM CULVERT

0.224-FT-DIAM CULVERT

0

0

~

6

-

~

I

I

0

2

I

I

l

I

5

4

FROUDE NUMBER, Fo= Vo/VgDo

3

I

I

7

I

I

B

9

10

100

50

ro== 3.os

0

Lsm

I 0.15

I

Do

b

0

D

fo::: /. 43

u

0

-u

0

1000

l-'

10

[)"

10

0

I!

0

I

0

50

100

500

TEST DURATION , t

1

M IN

5000

I 0 1 0 00

LENGTH OF SCOUR A SA

FUNCTION OF FROUDE NUMBER AND

TIME FOR MINIMUM TAILWATER

lJ

r

40

~

I

fTl

T

I

I

I

'

I

1

r

I

,__

1\)

-

30

~

1-

0

Wsm

Do

o j!:!_----

2 M

't :::: ::.;.-

20

,__

n

10

:

0

~

~

0

4

!::.

~

-

l--""

-

LEGEND

!::.

1.000-FT-DIAM CULVERT

0.333-FT-DIAM CULVERT

0.224-FT-DIAM CULVERT

0

0

!::.

a.

-

I

0

~

~ -

I

I

I

2

4

3

FROUDE NUMBER,F0

60

I

I

6

1

i

I

I

Fo:: 3.05

--,

I

I

'

Wsm

20

- !o.2o

Fo:: /.43

1-

Do

-

-""""

0

0

h

-

-

10

6

I

10

8

I

I

0

I

T

I

I

l

7

I

= V 0 /V9 Do

I

40

I

I

-

0

u

0

....

1000

10,0 00

0

~

50

5000

100

500

TEST DURATION,

t, MIN

WIDTH OF SCOUR AS A

FUNCTION OF FROUDE NUMBER AND

TIME FOR MINIMUM TAILWATER

4

I

l

I

l

I

l

I

I

I

--

1-

In

0

Q

-

"----

3

0

I-

0

6

2

:u

-

6

6

t::: 1 MIN

0

0

0

~

··-

t::: 20 MIN

0

6

6

6

0

0

6

--

0

-

~

I-

Dsm

Do

--- - -

-

I-

-

1.3+1.4 LOG F 0

LEGEND

-

-

--

1.000-FT-DIAM CULVERT _

0.333-F" T-DIAM CULVERT

0.224-FT-DIAM CULVERT

- -- 0

0

6

-

1-

I

I

0

I

3

2

I

I

I

4

FROUOE NUMBER,Fo = V 0

I

I

5

7

6

I

I

8

/.Jg Do

10

+ -- r-

--

-- I -

--

1-

5

----- r- - - f- - - - -- -

--

f.-

--

-f-

,..

-

v

)

-

f.0 :.:1 -

-

1-

·-

-

0

-

- -

-

Fo =~.OS

0

..... - 1-

I

r- r-

-

Fo:: J.43

- f-:_

n

I

0./0

-- -

--

---- --

-

-

-

-- -

1- -

- -

-

+--t-1000

I

10

-

-

.

0

f-

-

v

0

-

0

-

--- ~

1-

-

-

0

-

I

0

n

...:

- f.-

I-

-

- -- 1-- - 1-

u

v

n

-- -

I--

.

-

Do

- --

-

-

t-

F0 =10

Dsm

---

10

9

50

100

500

TEST DURATION, t

1

MIN

5000

10,0 00

DEPTH OF SCOUR AS A

FUNCTION OF FROUDE NUMBER AND

TIME FOR MINIMUM TAILWATER

2000

I

[

I

1000

1/

0

I

800

I

$f_

~,

600

~'J

p/

0

400

0

v

2

1\

I

7

0

6

0

200

0~

0

100

I

6p

80

I

of

6

60

40

I

I

-

LEGEND

I

0

1,000-FT•DIAM CULVERT -

0

0.333-FT·DIAM CULVERT _

6

0 . 224-FT-DIAM CULVERT

20

1

2

FROUDE NO.,

4

F0 :=

V

6

0

/1 go

8

10

0

VOLUME OF SCOUR AS A

FUNCTION OF FROUDE NUMBER FOR

MINIMUM TAILWATER

PLATE 4

10,000

5000

0

p

1000

o5

F; ~ 3- _.

...........

v

v

l?

I-'

....... I--'

/

~.40

v

v

I

0~

..,. I-'.....

500

L.,..../

~

~~

I..- ~

l.--6'

__./

I>

,t3 v

~

100

rr

h

_.jY

v

I-'

~

I..- 1---

p

~

~

v v0

v

.....

...,........ v

v

v-'" 10. 40

~

....... ~

I

0

0

0

../

~

~--"'

50

0

10

50

500

100

TEST DURATION , t. 1 MIN

1000

5000

VOLUME OF SCOUR AS A

FUNCTION Of TIME FOR

MINIMUM TAILWATER

. PLATE 5

FLOW ..,

Lo

_,-ORIGINAL GROUND LIN£

0

..

0.2

0

~ 0

0 0

v

0.4

Ds

Ds m

Oo

I

0.6

o¢

¢

0.8

0

00

6€l

~

,...

oo

0

,...

.......

6

0

0

0

1\

0

rv ......_ ~-....,..,

0

1.0

1.2

J -0

()f\

'"'

0.1

0

~

I

- [..7

/

~

6

6

I

0

6

6

6

0.5

0.4

0.3

0.2

lo _......

v

v

00

/

v

0./

vv

0

c--

0.7

0.6

0.8

0.9

1.0

LsfLsm

DIMENSIONLESS CENTER- LINE PROFILE

Ch

0

u

0.2

(J

6

r--_

0

0

,0.

I

--o....

0

~

i

0.4

~0

6

~ 0.6

Dsm

I

0.8

0

\

~

I

'

v

,___..,.

~

n

0

0

..o-- ~

6

f/

./

1\

1.0

I

rV

II

v

(')

I

0.8

LEGEND

0

0

6

~ [

-

I

0

1.0

€

L--cuLV£RT

~~

1.2

~ORIGINAL GROUND LIN£

1.000-FT-DIAM CULVERT

0.333-FT-DIAM CULVERT

0. 224·FT-DIAM CULVERT

0.6

0. 4

0.2

0

0.2

0. 4

Ws/Wsm

DIMENSIONLESS CROSS SECTION AT 0.4 L 5 m

0.6

0.8

1.0

DIMENSIONLESS

SCOUR HOLE GEOMETRY

FOR MINIMUM TAILWATER

80

I

I

I

I

I

I

I

I

I

-

f-

L---

60

-30~

._

40

~

~

20

0

I"'

~

------

~0

-

LEGEND

t.

0 . 333-fT- DIAM CULVERT

0.224-FT-DIAM CULVERT

0

t.

-

I

0

~

-~

l_..--- f..--

I

I

2

I

I

I

5

4

3

FROUDE NUMBER,Fo = V0

I

I

6

7

I

8

I

10

/V9 Do

100

r

Fo:: 3. 05

50

0

0

0

v

I

0./0

Lsm

Do

.

1000

10

10

50

100

500

TEST DURATION, t

1

MIN

5000

ro,o 00

LENGTH OF SCOUR A SA

FUNCTION OF FROUDE NUMBER AND

TIME FOR MAXIMUM TAILWATER

20

I

T

I

I

T

MIN

f-

10

0

f-

~

5

I

I

--------l.---

-

15

Do

I

-

f-

Wsm

I

..il"

-----

--~

~

~-

~

-

0

-

A

I

LEGEND

0

A

A

0.333-F"T-DIAM CULVERT

0.224-FT- DIAM CULVERT

A

-

f-

I

0

I

I

I

3

2

I

I

5

4

FROUDE NUMBER,Fo = V 0 /vg 0 0

I

I

6

7

I

8

I

10

40

zo

F0 =3.05

0

"

0

I

0.05

10

8

e

1000

4

10

50

100

500

TEST DURATION, t

1

MIN

5000

10, 0 00

WIDTH OF SCOUR AS A

FUNCTION OF FROUDE NUMBER AND

TIME FOR MAXIMUM TAILWATER

3000

v

I

..

2000

v

v

j1.70

~I

1000

v

1

~'l

It

800

I

I~

600

I

vs

1~/

400

o3

I

0

V'

6.

v

200

LEGEND

Do

0

6

6.

100

6.

80

I

60

Iv

I

0.333-FT•DIAM CULVERT

0.224-FT·DIAM CULVERT

I

"

!&.-

40

1

2

4

6

8

10

VOLUME OF SCOUR AS A

FUNCTION OF FROUDE NUMBER FOR

MAXIMUM TAILWATER

PLATE 10

10, 000

5 0 00

L.,..

1000

__.

0

500

-

~~

~

-l.---"

~

-

I<"

~ ---

v

v

v

-U'

1---"

...---ro.Jo

~

I

lb

100

50

0

10

50

100

TEST DURAT ION , t

1

500

MI N

1000

5000

VOLUME OF SCOUR AS A

FUNCTION OF TIME FOR

MAXIMUM TAILWATER

P L AT E II

lJ

r

~

Lo

fTl

I\)

0.2

FLOW.,.

~ORIGINAL

~I'\.

I

'\

0.6

6

\.

.A

I

I'

l

1.0

1.2

6

I

0

6

D""' ~

I

0

to..

0

~L

0

6_n

~

I

I

I

I

i

0.1

0

I

-

I

I ~ ""-

I

0.8

I

~

I

v

AD~

I

0 .4

Ds

Ds m

GROUND LINE

0.2

0.3

0.4

_g.. p- ~

-

v

/

/

y

v

v

6

Ll

t:.

6

~

0.5

0.7

0.6

0.8

0.9

1.0

0.8

1.0

LsfLsm

DIMENSIONLESS CENTER - LINE PROF ILE

0

.n

0

0.2

'

0.4

I

o.6

-

"'·~

I

Dsm

l-.--

\

'

'

I

Ds

CD

\

'

I

I

1.2

1.0

CULVERT

~

~I

_l

I

I

i

I

~

I

~

~

~

v

i

/

I

.

l

0.8

~

~

/

I

~

6

I

'

1.0

0

GROUND LINE

0

0

I

0.8

~ORIGINAL

0. 4

0.2

0

0.2

0.4

0.6

Ws/Wsm

LEGEND

0

6

0.333-f"T-DIAM CULVERT

0. 224-FT-DIAM CULVERT

DIM EN SIONLESS CROSS SECTION AT 0. 4 L sm

DIMENSIONLESS

SCOUR HOLE GEOMETRY

FOR MAXIMUM TAILWATER

1.0

I

M

l

I

I

I

I

I

0.9

I

I

I

I

I

cis= 0.25 Do F0 0.8

0.7

I

v

I

t::.

Jozs

II

0.6

t::.

d

~ 0.5

~

I""

Do

.....

0

0.4

Ot::.

0

v6

0.3

I

0.2

00

LEGEND

0

0

0

0

t::.

1.000-F"T-DIAM CULVERT

0. 333-FT-DIAM CULVERT

0. 224-FT-DIM.A CULV ERT

0.1

0

0

0

0

2

3

F ROUDE NUMBER,

r0

=V

0 /

4

5

e

,J,-g-=D-0

STONE DIAMETER AS A

FUNCTION OF CULVERT DIAMETER AND

FROUDE NUMBER OF FLOW FOR

MINIMUM TAILWATER

PLATE 13

50

0 0

(X)

00

~

(X)

00

aD

--- - -

- -o

~

40

00

-

30

00

0

SUGGESTED CURVE

L sP =D0 (8+ 17 LOG FQ}-

aD

)

~

20

0

)

6

"J~

~

0

0

~

0

10

I

0

2

I

3

5

4

FROUDE NUMBER AT CULVERT OUTLET7 F0

= V0

6

7

8

9

10

/~

LENGTH OF STONE PROTECTION

0

0

6

ADEQUATE

INADEQUATE

ALMOST ADEQUATE

I

LENGTH OF STONE PROTECTION AS A

FUNCTION OF CULVERT DIAMETER AND

FROUDE NUMBER OF FLOW FOR

MINIMUM TAI LWATER

S::

0

-.J

IJ...

'

PLAN

0

0

2d5

ELEVATION

RECOMMENDED CONFIGURATION

OF RIPRAP BLANKET FOR

Ml NIMUM TAILWATER

PLATE 15

1.0 ~-------.--------.--------.---------r----~---.--------,

0.9 ~-------+--------4-------~--------~v~------+-------~

~

I

I

ds=0.25FQ 0 0 -0.150<) ~

0.8 ~-------+--------+-------~------~~--------+-------~

0

0.7~------+-------~-------+--~~--~--------+-------~

~0.25

0. 6 ~-------+--------+-------~~------~--------+-------~

ds 0.5

Do

~-------+--------+-----kr~~uf-----~--------+-------~

p

0.4

I

0.3

v

6

0

0

,l

0

lo

0.2 ~-------+--~----4-------~~-------+--------+-------~

LEGEND

0

0

0

1.000-FT-DIAM CULVERT

0

6

0. 333-FT-DIMv1 CULVERT

0. 224-FT-DIM.A CULVERT

0.1 ~------~--------~-------+--------4---------~-------4

0 ~--~~~--------~------~~-------L--------~------~

0

2

3

4

5

e

FROUDE NUMBER, F0

=V0 /

,JgD 0

STONE DIAMETER AS A

FUNCTION OF CULVERT DIAMETER AND

FROUDE NUMBER OF FLOW FOR

MAXIMUM TAILWATER

PLATE 16

so

0

v

0

0

00

/

40

~

\

SUGGESTED CURVE

ro

Lsp=Do (8+5SLOGFo)~

0

0

30

0

/

20

0

0

0

0

10

0

~

~

I.J

0

0

0

Do

DO

0

0

2

I

0

~

0

3

4

FROUDE NUMBER AT CULVERT OUTLET, F0

5

= V0

6

7

e

9

10

/-v'9Do

L ENGTH OF STONE PROTE C TION

0

0

1:i.

ADL: Q UAT E

INADEQUATE

ALMOST ADEQUATE

LENGTH OF STONE PROTECTION AS A

FUNCTION OF CULVERT DIAMETER AND

FROUDE NUMBER OF FLOW FOR

MAXIMUM TAILWATER

I

-.------

i30o

PLAN

ELEVATION

RECOMMENDED CONFIGURATION

OF RIPRAP BLANKET FOR

MAXIMUM TAILWATER

PLATE 18

\

\

\

\

\

I

I

I

I

I

I

I

'"'\

~

1-.:

~

~

......

\...

\

l't

II)

\

I

I

I

I

I

\

-..1

I

\

\

\

$

'"'\

~

1-.:

\

------r----+----I

\

\

\

\

\

\

\

I

I

I

I

I

I

I

~

\.:.

'

II)

-..1

\

\

I

I

\

\

\

I

I

I

I.

~

Wsp (MAX. T. W.)

Wsp (MIN. T.W.)

RECOMMENDED CONFIGURATION

OF RIPRAP BLANKET

SUBJECT TO MAXIMUM AND

MINIMUM TAILWATERS

PLATE 19

04

01

008

/ vv

/

V

-LV

/

,,

//

v

vv

v

/

/

v

0

B

_Q_

~gas

0001

/

o.oooaV

/

V

0.0006 1/

v

v

v

v

v

1/

v

v

I

I

v

V

v

o'

bv++-r~~~~~--~

/

0.0004 /

v

0

v

~

oooo2 r-r-/-+v-+v-t--1--t-t -t-:rf-V-+V-Hvl--+

1-+--+--t--r--t

v

vv

vv I

i

!

j

0 000 I L----l..L..--t~--L-L...u...J...-'--L..L.....J....l-l.-...L......l.---1.---L.--.L-...J

0 06 0.08 0 .10

04

06

08 10

CHARACTERISTICS OF

A TRAPEZOIDAL CHANNEL WITH

1- ON -2 SIDE SLOPES AS A

FUNCTION OF FROUDE NUMBER

PLATE 20

Unclassified

Security Claaairication

DOCUMENT CONTROL DATA- R & D

(Security cleadflcatlon of title, body of abatract and lnde1Cin

I. ORIGINATING ACTIVITY (Corporate author)

Q annotation muat be entered when the overall report Ia claaelfled)

Z.. REPORT SECURITY CLASSIFICATION

Unclassified

U. S. Army Engineer Waterways Experiment Station

Vicksburg, Mississippi

2b, GROUP

3. REPORT TITLE

EROSION AND RIPRAP REQUIREMENTS AT CULVERT AND STORM-DRAIN OUTLETS·

Hydraulic Laboratory Investigation

'

4. DESCRIPTIVE NOTES (Type of report and lnclualve datee)

Final report

e. AU THO RCSI (Firet name, middle lnlllal, Ia a I name)

Joseph P. Bohan

e. REPORT DATE

7a. TOTAL NO . OF PAGES

7b. NO. OF REFS

ll

53

January 1970

... CONTRACT OR GRII.NT NO.

Ga. ORIGINATOR'S REPORT NUM'BERCSI

Research Report H-70-2

b. PROJECT NO.

c.

Gb. OTHER REPORT NOCSI (Any other numbera that may be aeei(;Jed

lhl• report)

d.

10. QJSTRIBUTION STATEMENT

This document has been approved for public release and sale; its distribution is unlimited.

II· SUPPLEMENTII.RY NOTES

12. SPONSORING MILITARY ACTIVITY

Office, Chief of Engineers, U. S. Army

Washington, D. C.

11. ABSTRACT

Investigations were conducted in experimental facilities to determine the characteristics of scour below

a culvert outlet discharging onto a horizontal blanket of cohesionless soil and to develop guidance

for designing riprap protection downstream of culvert and storm-drain outlets. Scour holes, produced by the discharge of various flows of several durations through culverts of various shapes and

s1zes, were observed and contoured. These data were obtained for several tailwater conditions and

were used to develop generalized expressions describing the maximum length, width, depth, and

volume of scour as functions of the flow duration and the Froude number of flow at the culvert

outlet. Dimensionless scour profiles and cross sections, for low and high tailwater conditions, were

also developed. Riprap blankets of various configurations and stone sizes were tested with several

culvert sizes and shapes and various tailwater conditions to determine when displacement or failure occurred. The results were used to develop generalized relations to describe the stone size and

appropriate blanket configuration required to prevent blanket failure and soil erosion, respectively,

at a culvert or storm-drain outfall.

DD .'!-:••1473

IIIIC~LAC&a DD ~OIIIIM 1411, I JAN t4, WHICH . .

OaaGLIKTK ~01111 AIIIIMV ua&.

Unclassified

Security Claniflcatlon

I• .

LINK A

LINK B

LINK C

KEY WORDS

ROLE

WT

ROLE

WT

Culverts

Erosion

Rip rap

Storm sewers

.

.

•

c

.

•

Unclassified

Security Classification

ROLE

WT