ColumnClad System

advertisement

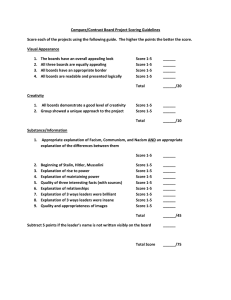

ZERO R ODP ZERO R GWP OZONE DEPLETING POTENTIAL GLOBAL WARMING POTENTIAL CI/SfB Rf 7 July 2005 (replaces September 2004 issue) Construction type Structural Steelwork Rockwool supports FIRAS accredited installers ColumnClad™ System Rigid fire protection solutions for structural steel columns and beams As part of the comprehensive FirePro range of fire protection products, the new Rockwool/Lafarge ColumnClad system is a fast and efficient method of providing fire protection to structural steel columns and beams. The square edged, gypsum based ColumnClad boards are extremely robust and impact resistant. The excellent moisture resistance properties of the board enables encasement assembly to take place earlier in the construction programme of the main building envelope. The board has a flat white mineral tissue surface which can be decorated directly or alternatively a thin plaster skim coat can be applied prior to decoration. The ColumnClad System has been tested and assessed by the Building Research Establishment (BRE) and subsequently reviewed by the Association for Specialist Fire Protection (ASFP), prior to inclusion in the ‘Yellow Book’. This publication is regularly reviewed to ensure that it reflects the current philosophies of steel protection and it is therefore recommended that the principles of the Yellow Book are closely followed when a ColumnClad system is designed and applied. The non-combustible boards are stapled or screw fixed to each other around the column or beam to form a frameless encasement system. The new ColumnClad board extends the current ‘tool box’ of Rockwool fire protection systems for structural steel columns and beams. Typical application showing the ColumnClad fire encasement system Advantages • • • • • • • • High impact resistance Quick and economical to install Moisture resistant Easy to decorate Column and beam applications Frameless system Up to 2hrs fire protection Euroclass A1 1 ColumnClad Performance and Properties The boards do not require a PVAC sealing coat prior to applying a decorative paint or plaster skim finish. Direct application may be applied to the board face subject to the following conditions: • Do not decorate boards if damp atmospheric conditions exist. • Boards must be dry and free of moisture. • Board faces must be clean and free of oil or grease marks. • All board joints should be reinforced with Lafarge jointing tape and filler. • Protective angle bead should be applied at external corners • Plaster skim finish applied once filler compound has set. Ceramic Tiling: Tiles can be applied using conventional tile adhesives without pre-treatment of the board. Board Fixings Fixing Options Composition and Manufacture ColumnClad boards are manufactured using synthetic additives, to provide superior fire and moisture resistant properties. 15mm and 20mm thick ColumnClad boards can be directly fixed to each other using proprietary 50mm chisel edged staples without the need for a supporting framework. (Alternatively 20mm boards may be screw fixed using Lafarge Grabber High Thread screws, without pre-drilling or counter sinking.) Board Characteristics Non combustible: BS 476 Part 4 Note: Only staple fixings should be used to fix single layer 15mm board encasements. Euroclass A1: BS EN 13501-1:2002 Components: Facings: Glass fibre non-combustible mineral tissue Frameless Staple fixing: Use a proprietary gas powered cordless staple gun, fitted with a guide attachment (Paslode make suitable models). The boards can be stapled together at max. 150mm centres to form a rigid encasement protection for columns and beams . Quality assured: To EN ISO 9002 : 2000 Moisture Content: < 2%: Appearance: White facings/Square edged board Frameless Screw Fixings: As an alternative to staple fixing, 20mm ColumnClad boards may be screw fixed together to form a rigid encasement using Lafarge Grabber High Thread Screws at max 300mm centres (see table below for sizes). Vapour Permeability: 15mm = 1.11g/MNS. 20mm = 0.85g/MNS. Thermal Conductivity: 0.30W/mK Surface Hardness(penetrometer): 600 N Impact resistance to BS 5234/2: 15mm severe duty/20mm severe duty Board Dimensions Thickness: mm 15 20 Board dimensions mm 1800 x 1200 1800 x1200 density kg/m3 900 900 wt./board wt./board/m2 boards/pallet kg 28 39 kg/m2 13.0 18.0 Double Layer Encasements Where 15mm and 20mm boards are required to form a double layer, apply the 20mm layer first. Board joints must be staggered between respective layers. Construction Single Layer 50 40 Fire Performance Reaction to fire classification: ColumnClad achieves an A1 classification in accordance with BS EN ISO 13501-1:2002. For the purposes of Approved Document ‘B’ this is equivelant to a non-combustable product. Fire Resistance: The ColumnClad frameless encasement system provides up to 2 hours boxed fire protection to Structural Steel Sections when tested to BS 476 Part 21. Jointing and finishing is not a requirement to meet the fire protection levels given, however the inclusion of services should be considered with caution. Moisture Resistance Double Layer ColumnClad thickness 15mm 20mm 30mm (2 x 15mm) 40mm (2 x 20mm) Screw Length N/A 63mm N/A 63mm then 76mm Accessories All accessories are available throughout the UK from most Rockwool distributors Lightweight metal angle for board fixings at soffit and wall abutments. Size 25 × 25 × 0.8 (Lafarge reference MFC2525) Lafarge Grabber Self Tapping Screws – board fixing to lightweight metal angles. 32 × 6 gauge for single layer 15mm ColumnClad (Lafarge ref. 32DST5) 38 × 6 gauge for single layer 20mm ColumnClad (Lafarge ref. 38DST5) Lafarge Grabber High Thread Screws – alternative board/board fixing option for 20mm ColumnClad encasements. 63 × 8 gauge for single layer board applications (Lafarge ref. 63DHT5) 76 × 8 gauge for double layer board applications (Lafarge ref. 76GHT5) Proprietary 50mm board to board chisel edged staple fixings available from gas staple gun manufacturers. When tested to BS 1230, ColumnClad boards absorbed less than 5% water by weight after 2 hours total immersion. The ColumnClad boards can be subjected to moisture throughout their installation, prior to the building envelope being sealed. When wetted and allowed to dry, the board will regain its strength and fire resistance. Finishes The completed column (or beam) lining provides a robust impact resistant smooth surface that will accept most kinds of decoration. The boards can be left unjointed or alternatively a taping and jointing treatment or skim plaster coat can be applied to give a smooth seamless finish. 2 Table X. Section factor A/V (Hp/A) of structural steel I-sections for use only with Box encasements systems Section factors for Universal Columns Section Size (mm) 356 × 406 356 × 368 305 × 305 254 × 254 203 × 203 152 × 152 Mass per Metre (kg) 634 551 467 393 340 287 235 202 177 153 129 283 240 198 158 137 118 97 167 132 107 89 73 86 71 60 52 46 37 30 23 3 Sides Hp/A (m-1) 15 20 20 25 30 30 40 45 50 55 65 30 35 40 50 55 60 75 40 50 60 70 80 60 70 80 95 105 100 120 155 Section factors for Universal Beams 4 Sides Hp/A (m-1) 20 25 30 35 35 45 50 60 65 75 90 40 45 50 65 70 85 100 50 65 75 90 110 80 95 110 125 140 135 160 205 Section Size (mm) 914 × 419 914 × 305 838 × 292 762 × 267 686 × 254 610 × 305 610 × 229 533 × 210 457 × 191 457 × 152 406 × 178 406 × 140 356 × 171 356 × 127 305 × 165 305 × 127 305 × 102 254 × 146 254 × 102 203 × 133 Fixing self tapping Grabber screws at max. 300mm centres to lightweight metal angle 203 × 102 Mass per Metre (kg) 388 343 289 253 224 201 226 194 176 197 173 147 170 152 140 125 140 125 149 140 125 113 101 122 109 101 92 82 98 89 82 74 67 82 74 67 60 52 74 67 60 54 46 36 67 57 51 45 39 33 54 46 40 48 42 37 33 28 25 43 37 31 28 25 22 30 25 23 3 Sides Hp/A (m-1) 45 50 60 65 75 80 70 80 90 70 80 95 75 85 90 100 50 70 80 80 90 100 110 85 95 100 110 120 90 100 105 115 130 105 115 125 140 160 105 115 130 145 150 190 105 125 135 155 170 195 115 130 150 125 140 155 175 200 225 120 140 160 170 190 215 145 165 175 4 Sides Hp/A (m-1) 55 60 65 75 85 95 80 90 100 85 95 110 90 95 105 115 60 80 95 95 105 115 130 95 110 115 125 140 105 115 125 135 150 120 130 145 160 180 125 140 155 170 185 220 125 145 165 185 195 225 140 160 180 145 160 180 200 225 260 150 170 200 200 220 250 180 210 210 3 Design Considerations General ColumnClad boards are suitable for protecting structural steel columns and beams, with a section factor A/V (Hp/A) up to 260 calculated on the basis of box protection to 3 or 4 sides. Table 1 Hp/A table for 3 and 4 sided column fire encasement protection. Critical temperature 550°C 260 The ColumnClad board will protect universal column and beam sections listed in the ASFP Yellow book. 240 Establishing ColumnClad board thickness 220 In a fire, unprotected structural steel begins to lose its strength at temperatures around 550°C. Selection of the appropriate encasement is therefore essential. Further guidance can be found in Section 1 of the ASFP Yellow Book. To establish the correct board thickness required for steel column and beam encasements the specifier should follow the procedure set out below: 1) Locate the appropriate size and mass of the column or beam (for common sizes see table X on previous page). Read off its Hp/A Factor depending on whether 3 or 4 sided protection is required. 35 30 200 206 198 180 160 20 30 140 15 15 120 2) Establish the period of fire resistance required. 113 100 3) Refer to the adjoining tables to determine the ColumnClad board thickness required. Table 1: Column fire protection (550°C) Table 2: Beam fire protection (550°C) Table 2A: Beam fire protection (620°C) 96 80 60 Note: For castellated sections, adopt the above procedure then add 20% to the indicated thickness and specify the next highest board. 40 Example: Column fire protection 20 Requirement: 1 hour fire protection to 203 × 203 × 52 kg/m steel column with 4 sided protection 20 15 63 15 0 30 60 90 Fire Resistance Required (minutes) 120 Solution Section factor Hp/A = 125-1 (from table 1) Use single layer of 15mm ColumnClad Table 2 Hp/A table for 3 and 4 sided Steel Beams fire encasement protection. Critical temperature 550°C Table 2A Hp/A table for 3 sided steel beam fire encasement protection. Critical temperature 620°C 260 260 240 240 220 220 218 30 200 200 35 35 180 180 165 160 160 159 157 148 140 15 15 15 120 100 100 80 20 4 140 120 30 80 60 60 40 40 20 20 0 218 30 30 60 90 Fire Resistance Required (minutes) 120 0 15 20 30 60 90 Fire Resistance Required (minutes) 30 120 Installation – 4 sided frameless columns General The following notes are intended as general guidance only, addressing the basic sequence of installation. In practice consideration must be given to design criteria requiring specific project solutions. Cutting and fixing of ColumnClad boards To achieve a clean edge ColumnClad boards should be cut using a mechanical saw with suitable dust extraction. Boards can be staple fixed together at max. 150mm centres using a proprietary gas driven staple gun with an edge guide (Paslode make suitable models). Columns Frameless protection using ColumnClad noggins ColumnClad noggins are pre-cut and tightly friction fitted between the flanges on opposite sides of the column. The noggins are 100mm wide, fitted at max 1800mm centres, behind horizontal board joints, and at the top and bottom of the column section. ColumnClad boards are fixed to the noggins using 3 staples or screws. A 3mm air gap should be provided between the back of the ColumnClad board and the face of the steel flange. 50mm staples at 150mm centres ColumnClad boards staple fixed at 150mm centres For 4 sided column encasements: Always commence the cladding from the base of the column. ColumnClad boards are cut to widths and secured as shown. See figures C1 and C2. 1) Cut two full length ColumnClad boards equal to the flange width of the steel section, plus the thickness of board. 2) Cut one half length ColumnClad board equal to the depth of the steel section, plus the thickness of board, plus 6mm (for the air gaps at both flanges). Position the boards and staple fix board to board at max 150mm centres (alternatively, 20mm boards may be screw fixed at 300mm max. centres). 3) Cut a second half length board equal to the flange width plus the thickness of board. Position against the opposite flange and install fixings as stated above. 4) Continue boarding in the same manner, progressively working up the column. Ensure horizontal board joints are staggered on adjacent faces. Double layering Encasement For double layer boarding, install outer layer as per first layer, staggering board joints between layers. Cut outer boards to width making additional allowances necessary to cover the first layer. Note: Where 15mm and 20mm boards are required, apply the 20mm layer first. Board joints must be staggered between the respective layers. Additional Support Where web dimensions exceed 600mm additional support may be required for the encasement. For futher advice contact Rockwool. 3mm air gap Figure C1 ColumnClad board 100mm wide ColumnClad noggins at max 1.8m centres and behind abutting board joints Figure C2 4 sided protection to column. 3mm air gap between face of steel flange and board. ColumnClad noggins 100mm x 15-20mm wedged into the web at the head and base of the column and behind the horizontal board joints. Additional noggins are not required behind joints in the second layer of a double boarded encasement. 50mm chisel edged staples at 150mm centres. Fixing of boards using a proprietary gas powered cordless staple gun Stagger joints on adjacent sides by min. 300mm. 4 sided Column Encasements • 100mm wide ColumnClad noggins are tightly wedged between the • • • • steel flanges, at max. 1.8m centres, behind board jooints and at the head and base of the column. Facing boards are fixed to the noggins and each other using 50mm staples at 150mm centres. Adjacent boards should be half staggered. For double boarding, joints are staggered between layers. For column encasements, a 3mm air gap should be provided between the back of the board and the face of the column flange. 5 3 sided frameless column encasement 3 sided protection to steel columns Additional Support Single layer frameless protection For 3 sided column protection Lafarge lightweight metal angles are fixed to the wall flange of the steel on opposite sides to provide fixing points to ends of board. Position such that the face of the angles are level with the edges of the flange and secure using appropriate shot fired (or spot welded) fixings at max. 600mm centres. Where web dimensions exceed 600mm additional support may be required for the encasement. For futher advice contact Rockwool. 100mm wide ColumnClad noggins are then pre-cut and tightly friction fitted between both flanges at max. 1800mm centres and behind horizontal board joints. The ColumnClad encasement is fixed to the noggins using 3 staples or screws. 1) There are no special requirements for pressure resistance, such as lift shafts etc. Partitions Fixing Partitions and wall linings may be fixed directly to ColumnClad board, subject to the following conditions: ColumnClad boards are cut to widths shown in fig C3. 2) There are no special heavy duty or severe duty requirements as defined in recognised partition performance specification (e.g.BS 5234). The web encasement boards are cut to the depth of the steel section plus thickness of board plus 3mm (for the air gap tolerance between the board and flange). The Flange boards are cut to the same width as the column flange. Subject to these conditions, the partition ‘C’ stud or Track may be secured directly to the ColumnClad encasement using Redidriva fixings with Lafarge 38DHTS screws at max 600mm centres (see figs C5 and B4 below). The column is progressivly encased and adjacent boards are half staggered. The boards are fixed to each other at 150mm centres using 50mm × 10mm chisel edged staples, ensuring a clear 3mm air space is maintained between the back ColumnClad board and the steel column flange. The edges of the web encasement boards are fixed to the steel angles at 300mm centres using Lafarge self tapping Grabber screws (or equal approved, 32DST5 for 15mm boards and 38DST5 for 20mm boards). Screws should penetrate the angle by min. 10mm. 4 sided column encasement with partition abutment Figure C3 3 sided protection to column. Figure C5 Partition Abutment to Column Encasement Wall abutment 100mm wide ColumnClad noggins behind face board joints 3mm air space Redidriva fixing at 600mm centres. 25 x 25mm metal angle secured to column flange at 600mm centres ColumnClad screw fixed at 300mm centres to metal angle using self tapping screws 100mm wide ColumnClad noggins at 1.8m centres and behind board joints Lafarge 38DHT Screw Lafarge C stud 50mm frameless staple fixings at 150mm centres Board to board staple fix at 150mm centres 3mm air space Beam Soffit Figure B4 Partition Abutment Figure C4 Wall Abutment. Masonry wall Self tapping screws at 300mm centres 50mm long chisel edged staples. 3mm air space 25 x 25mm metal angle screw fixed to masonary wall Screw fixing appropriate to substrate at 600mm centres Wall plugs to be of non combustable type 50mm chisel edged staple fixings at 150mm centres Redidriva fixing at 600mm centres. 100mm wide ColumnClad noggins at 900mm centres and behind board joints. Partition track. Lafarge 38DHT Screw. 6 Fire encasement to beams Fire protection to steel beams – selecting the right system 3 sided protection to steel beams using ColumnClad When deciding on appropriate method of fire protection to structural beams, the specifier needs to be absolutely certain that selected system is both reliable and totally effective. Rockwool FirePro systems offer a wide selection of fire protection encasement solutions to structural steel beams. The 25mm × 25mm lightweight metal angle is shot fired or spot welded to the underside of the beam top flange at 600mm centres. 100mm wide ColumnClad noggins are tightly fitted between the top and bottom flanges at max. 900mm centres and behind vertical board joints. 100mm ColumnClad noggins are also fitted across the bottom flange of the beam at the location of board joints. Rockwool BeamClad (previously known as Conlit 150) has been proven in service over many years. BeamClad is light and easy to install and offers a variety of fixing options (see Rockwool FirePro BeamClad data sheet). Where beam encasements are required to achieve a high impact resistance, or direct decoration ColumnClad boards may also be used for these applications. Key to diagrams on this page A B C D E F G H Continuous 25x25mm lightweight metal angle shot fired or spot welded to top flange of beam. Encasement board fixed to metal angle at 300mm max. centres using Grabber self-tapping screws. ColumnClad encasement board (refer to tables 2 or 2A to determine thickness required). Ensure that adjacent board joints are staggered by at least 300mm. 100mm wide (15 or 20mm thicj) ColumnClad noggins friction fitted into web at max 900mm centres and behind vertical board joints. Stagger position of noggins on adjacent webs. ColumnClad encasement staple fixed to web noggins at max. 150mm centres. 100mm wide ColumnClad noggins located at 900mm centres and behind soffit board joints. Board to board fixings using 50mm chisel edged staples at max. 150mm centres. Angle fixed to masonry at max. 600mm centres. Figure B1 Three sided encasement protection to beams. The face boards are cut to suit the depth of the beam plus twice the thickness of the soffit board and are screw fixed to the metal angle sections at 300mm centres using Lafarge self tapping Grabber screws (which should penetrate channel by min. 10mm). Face boards are fixed to noggins using 50mm deep staples at 150mm centres. Soffit boards are cut to suit the width of the beam flange plus 2mm and fixed to the fascia boards using 50mm staples at 150mm centres. The beam is progressively encased and adjacent boards are half staggered (see fig. B1). The encasement board should be cut to fit as tight as possible to the concrete soffit. Any gaps caused by the irregularity of the concrete surface should be filled with Lafarge Acoustic Sealant. Additional Support Where web dimensions exceed 600mm additional support may be required for the encasement. For futher advice contact Rockwool. 2 sided beam protection Figure B5 A A B C D B D C E E H F G F G Figure B2 Beam Isometric Figure B3 Beam Side elevation/section B A A D B C G E F C E D G F 7 Typical Specification Clauses Useful Contacts 1) The structural steel column/beam is to be fire protected using Rockwool ColumnClad board ……(a)mm thick to provide ……..(b) minutes fire resistance. (a) Insert ColumnClad board thickness (b) Insert period of fire resistance Paslode Impulse Stapler ref: IM200/50 S16 Staple and fuel pack: G516 × 50mm CH Contact ITM Construction Products Technical Helpdesk on 0141 342 1683 2) Board to board joints should be fixed using 50 × 10mm proprietary staples at 150mm centres or alternatively 20mm boards may be fixed with Grabber High Thread screws at 300mm centres. i Storage of Materials The recommendations of BS 8212:1995, Section 5, paragraph 31 must be complied with. The product must be stored in dry, well ventilated conditions with minimum temperature not less than 5°C. The boards should be kept off the floor and stored on timber pallets. Stock should be rotated, using oldest first. More information For further details visit our website at www.rockwool-firepro.co.uk. Site Conditions and Workmanship Temperature to be no less than 5°C. Site conditions to be in accordance with BS 8212:1995, Section 5, paragraphs 28 – 35. Workmanship in accordance with BS 8212 1995 and BS 8000: PT 8. Supply Available throughout the UK from Rockwool distributors. A list of distributors is available on request. Packaging ColumnClad boards are supplied shrink wrapped on timber pallets. Board Thickness 15mm 20mm Boards/pallet 50 40 Weight/pallet 1400kg 1560 kg Board Dimensions ColumnClad boards are manufactured in standard sizes of 1800 × 1200mm. Ordering When ordering please quote board thickness and area (m2) requirement. Minimum order quantity: 1 pallet load 15mm boards: 1 pallet = 108 m2 20mm boards: 1 pallet = 86.4 m2 Health and Safety Cutting ColumnClad with power tools generates dust and should be kept to a minimum. If significant dust is generated when working with the product, suitable respiratory protection should be worn, usually a dust mask. Heavy products should only be lifted in the correct way using mechanical handling equipment where necessary. Metal components should be cut and handled carefully to avoid cuts. Environment Rockwool products rely on trapped air for their thermal properties, which has neither ozone depleting nor global warming potential. Rockwool Limited Pencoed. Bridgend. CF35 6NY Email: info@rockwool.co.uk Web: www.rockwool-firepro.co.uk Rockwool Limited reserves the right to alter or amend the specification of products without notice as our policy is one of constant improvement. The information contained in this data sheet is believed to be correct at the date of publication. Whilst Rockwool will endeavour to keep its publications up to date, readers will appreciate that between publications there may be pertinent changes in the law, or other developments affecting the accuracy of the information contained in this data sheet. The above applications do not necessarily represent an exhaustive list of applications for ColumnClad. Rockwool Limited does not accept responsibility for the consequences of using ColumnClad in applications different from those described above. Expert advice should be sought where such different applications are contemplated, or where the extent of any listed application is in doubt. 8