HP Compaq LE2202x 21.5-inch LED Backlit LCD Monitor

advertisement

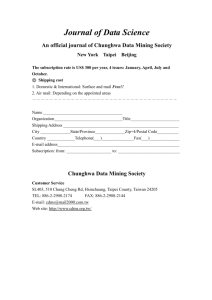

Product End-of-Life Disassembly Instr uctions Product Category: Monitors and Displays Marketing Name / Model [List multiple models if applicable.] HP Compaq LE2202x 21.5-inch LED Backlit LCD Monitor Name / Model #2 Name / Model #3 Name / Model #4 Name / Model #5 Purpose: The document is intended for use by end-of-life recyclers or treatment facilities. It provides the basic instructions for the disassembly of HP products to remove components and materials requiring selective treatment, as defined by EU directive 2002/96/EC, Waste Electrical and Electronic Equipment (WEEE). 1.0 Items Requiring Selective Treatment 1.1 Items listed below are classified as requiring selective treatment. 1.2 Enter the quantity of items contained within the product which require selective treatment in the right column, as applicable. Quantity of items Item Description Notes included in product Printed Circuit Boards (PCB) or Printed Circuit Assemblies (PCA) With a surface greater than 10 sq cm PWB-1425 and PWB-1431 and Fiberglass board 3 Batteries All types including standard alkaline and lithium coin or button style batteries 0 Mercury-containing components For example, mercury in lamps, display backlights, scanner lamps, switches, batteries 0 Liquid Crystal Displays (LCD) with a surface greater than 100 sq cm Includes background illuminated displays with gas discharge lamps LC Glass/ LAMP 1 Cathode Ray Tubes (CRT) 0 Capacitors / condensers (Containing PCB/PCT) 0 Electrolytic Capacitors / Condensers measuring greater than 2.5 cm in diameter or height 0 External electrical cables and cords DVI and VGA and Power cord 3 Gas Discharge Lamps 0 Plastics containing Brominated Flame Retardants weighing > 25 grams (not including PCBs or PCAs already listed as a separate item above) 0 Components and parts containing toner and ink, including liquids, semi-liquids (gel/paste) and toner Include the cartridges, print heads, tubes, vent chambers, and service stations. 0 Components and waste containing asbestos 0 Components, parts and materials containing 0 EL-MF877-00 Template Revision B Page 1 PSG instructions for this template are available at EL-MF877-01 refractory ceramic fibers Components, parts and materials containing radioactive substances 0 2.0 Tools Required List the type and size of the tools that would typically be used to disassemble the product to a point where components and materials requiring selective treatment can be removed. Tool Description Tool Size (if applicable) Description #1 Hand Description #2 Slotted Screwdriver Description #3 Philips Screwdriver Description #4 Hex Socket Screwdriver Description #5 3.0 Product Disassembly Process 3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment: 1. 2. 3. 4. 5. 6. 7. 8. To remove the screw for removing base and wall mount holes. AND release top、right and left side snaps of bezel to remove the bucket. Remove the keypad, key and lens, bezel and panel. Remove all the screws that fix the main board and power board and mylar. Press the tongue to remove the clip and back cover. To remove the screw for removing front cover and hinge. To remove all rubbers and screw. Destroy all boss pillars to remove the plate for removing base cover. 3.2 Optional Graphic. If the disassembly process is complex, insert a graphic illustration below to identify the items contained in the product that require selective treatment (with descriptions and arrows identifying locations). EL-MF877-00 Template Revision B Page 2 PSG instructions for this template are available at EL-MF877-01 L19RxCQ Disassembly Diagram Screw 1. To remove the screw for removing base. Base Screw 2. To remove the screws at wall mount holes. 3. Release top、right and left side snaps of bezel. 4. Remove the bucket. 5. Remove the keypad, key and lens. 6. Remove the bezel. 7. Remove the panel. Screw 8. Remove all the screws that fix the main board and power board. 9. Remove the main board and power board. 10. Remove the mylar. 11. Press the tongue. 12. Remove the Clip. 13. Remove the back cover. Screw 14. To remove the screw for removing front cover. 15. Remove the hinge. 16. To remove all rubbers. Screw 17. To remove the screw. Destroy 18. Destroy all boss pillars. 19. To remove the plate for removing base cover. CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 Waste Electrical and Electronic Equipment Disassembly Report Model Name: 215FA04 V4 -1- CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 1. General Product Information 1.1 Product Description This applies especially to the following appendix: Appendix 1: Photos of tested sample LCD Monitor Panel/ 215FA04_V4 -2- CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 2. Assessment Results 2.1 Assessment Summary Product Name/ Model Name LCD Monitor Panel/ 215FA04 Total Weight (g) 1751.8(g) Combination :25 Screw :8 Lamp Set :2 Connection Technique Glued :32 Snap:6 Mini Plastic Nipper Slotted Screwdriver Philip Screwdriver Disassembly Tools Scissor Hand Recommended Disassembly Sequence See 2.5 Reuse/ Recycling Rate 70.2% Recovery Rate 70.2% -3- CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 2.2 Product Derivative Table Product Name/ Model Name LCD Monitor Panel/ 215FA04 Weight (g) Weight (%) Plastic (PMMA) 323.8 18.4 V Plastic (PET) 161.6 9.2 V Plastic (PC) 28.6 1.6 V Metal 665.4 37.9 V Fiberglass>10cm2 50.0 2.8 V LC Glass / Lamp 522.4 29.8 Total 1751.8 100.00 Derivative Reuse (%) Recycling (%) Incineration (%) Disposal (%) Plastic > 25 g Plastic<25g - - V 70.2 29.8 2.3 Product Derivative Summary Weight (g) Percentage of Weight (%) Reuse - - Recycling 1229.4 70.2 Incineration - - Disposal 522.4 29.8 Product Sample 1751.8 100.00 2.4 Test Result Required Reuse/ Recycling Rate Testing Reuse/ Recycling Rate 65% 70.2% Required Recovery Rate Testing Recovery Rate 75% - -4- CHUNGHWA PICTURE TUBES,LTD. 2.5 Recommended Disassembly Sequence 1.Remove the protector. 2. Remove PWB Screw. 3. Release all hooks around the metal frame to separate.. -5- Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 CHUNGHWA PICTURE TUBES,LTD. 4. Remove the Panel. 5. Separate Frame 6. Separate Film -6- Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 CHUNGHWA PICTURE TUBES,LTD. 7. Remove Protect Tape 8. Remove LGP and Back Cover. 9. Remove Lamp Set And Reflector. -7- Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 CHUNGHWA PICTURE TUBES,LTD. 10. Remove LGP Reflector. 11. Remove LED Light BAR. -8- Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 2.6 Lamp Disassembly method Sequence of Module Disassembly for Lamp Separation 1. Original condition 2. Remove the protector 3. Remove the screw 4. Remove bezel 5. Remove panel. 6. Remove frame. 8. Remove LGP. 9. Remove Reflector 7. Remove film 10. Remove LGP REF. 11. Remove LED BAR. -9- CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 2.7 Product Component Disassembly Assessment Summary Component Assessment-1 Component Name Protector Before After Weight (g) 4.0 Disassembly Tools Hand Connection Technique Combination :1 Glued Joint :2 Material(g) AL:4.0 Reuse Weight (g) Recycling Evaluation Recycling Weight (g) Incineration Weight (g) Disposal Weight (g) - 10 - 4.0 CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 Component Assessment-2 Component Name Metal Frame Front Before After Weight (g) 98.8 Disassembly Tools Slotted Screwdriver Hand Connection Technique Combination :1 Snap:6 Screw:0 Material(g) Metal:98.8 Reuse Weight (g) Recycling Evaluation Recycling Weight (g) Incineration Weight (g) Disposal Weight (g) - 11 - 98.8 CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 Component Assessment-3 Component Name Panel Before After Weight (g) 572.4 Disassembly Tools Scissor Hand Connection Technique Combination:5 Glued Joint :18 Material(g) LC Glass:522.4 Fiberglass:50.0 Plastic (PET):1.2 Reuse Weight (g) Recycling Evaluation Recycling Weight (g) 50.0 Incineration Weight (g) Disposal Weight (g) - 12 - 522.4 CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 Component Assessment-4 Component Name Backlight Unit Before After Weight (g) 122.6 Disassembly Tools Hand Connection Technique Combination:5 Glued Joint:6 Material(g) Plastic(PET): Reuse Weight (g) Recycling Evaluation Recycling Weight (g) Incineration Weight (g) Disposal Weight (g) - 13 - 122.6 CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 Component Assessment-5 Component Name LGP / Lamp Holder / Reflector/ Light bar Assembly Before After - 14 - CHUNGHWA PICTURE TUBES,LTD. Issue Date: 2011 / 03 / 09 Model Name: 215FA04_V4 Weight (g) 1048.4 Disassembly Tools Slotted Screwdriver Alloy Welding Scissor Hand Connection Technique Glued Joint :4 Combination :8 Lamp Set :2 Screw:4 Material(g) Light bar :11.2 Metal:551.0 PMMA:323.8 Plastic (PET):161.6 Screw:0.8 Reuse Weight (g) Recycling Evaluation Recycling Weight (g) Incineration Weight (g) Disposal Weight (g) - 15 - 1048.4