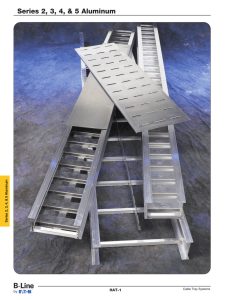

FITTINGS

advertisement