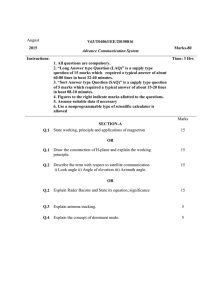

OptiMo® Field-Installable Products

advertisement

OptiMo® Field-Installable Products H I G H P R E C F A S T H G H I P R O D U C T I V I T Y I S E P E R F O R M A A N D N C E O P T I C A L P E R F O R M A N C E The HighProductivity Fiber-Optic Connector for HighPerformance Networks Start with productivity, end with optical performance using Ortronics OptiMo® field-installable connectors. Installing in just minutes—without the hassles and mess of epoxy or the uncertainties of hand polishing— OptiMo connectors are the fast way to terminate on site. Plus, excellent performance makes OptiMo field-installable connectors the fast fit for any application, right up through 10 Gigabit Ethernet. S A V I N G S A T E V E R Y S T E P OptiMo field-installable connectors speed optical installation time. You’ll benefit from high productivity — which translates directly into savings. N O E P O X Y : Minimize the time, eliminate wasted consumables, and the inconvenience of applying and curing epoxy and other adhesives. OptiMo connectors terminate with a simple, proven opto-mechanical splice. N O P O L I S H I N G : Our factory polished end-face provides optimum geometry for low insertion loss, low reflectance, and high bit rate transmission. M I N I M U M T O O L S : Our compact and economical tool kit contains all the common tools necessary to complete termination, including our unique “third hand” tool. N O C A P I T A L E Q U I P M E N T: With OptiMo field-installable connectors, you don’t need curing ovens, UV light sources, or polishing machines. You can terminate anywhere without worrying about power sources or charging batteries. F A S T I N S T A L L A T I O N : Terminate fibers in about a minute—much faster than epoxy-style connectors. Our fiber holder serves as a third hand, making it even easier to achieve quality results fast. R E D U C E D T R A I N I N G : The easy-to-learn, straightforward termination procedure means training is accomplished quickly and efficiently. Since the procedure is not craft dependent, even new installers get high-quality, consistent results from the start. P E R F O R M A N C E Y O U C A N C O U N T O N OptiMo field-installable connectors don’t sacrifice performance for convenience. C E R A M I C F E R R U L E : Ortronics OptiMo technology uses a precision ceramic ferrule for durability, temperature stability, and scratch resistance. F A C T O R Y- P R E P A R E D E N D - F A C E : Under controlled manufacturing conditions, Ortronics OptiMo technology creates a precision finish at the tip of each connector, with optimum end-face geometry for maximum performance. This ensures excellent optical transmission and eliminates the risk of error resulting from hand polishing in the field. CLEAVE THE FIBER S I N G L E M O D E O R M U L T I M O D E : Connectors are available for singlemode, 50/125-µm multimode, and 62.5/125-µm multimode fiber. 1 0 G I G A B I T R E A D Y : 10 Gigabit applications push the performance envelope in optical interconnections. OptiMo 50/125 connectors use an enhanced-fiber stub—the same fiber recommended for 10 Gigabit applications by TIA/EIA-568-B.3-1. Connectors are available for singlemode, 50/125-µm multimode, and 62.5/125-µm multimode fiber. INSERT THE FIBER R E L I A B L E : Unique hex crimp prevents torsional fatigue of the glass fiber. Interferometric inspections of the end-face ensure that apex, radius of curvature, and fiber protrusion/undercut meet the exacting tolerances required for optimum performance, low loss, and minimum reflectance. PULL THE PIN CRIMP A convenient tool kit holds all tools required for a high-quality termination. If you are already outfitted with fiber tools, an upgrade kit provides an economical path to OptiMo field-installable connectors. Termination of OptiMo fieldinstallable connectors is straightforward. Simply strip the fiber and cable, cleave the fiber, inspect the fiber, insert it into the connector, and pull the pin. Our unique “third hand” tool streamlines the process. Materials Ferrule Body Zirconia/ceramic High-impact plastic Specifications Style Fiber Types Insertion Loss Reflectance Durability Storage Temperature Operating Temperature Cable Retention LC, SC or ST 900-µm buffered or jacketed. See chart below for jacketed fiber conversion kits 0.3 dB (typical) -30 dB typical (multimode), -40 dB minimum (singlemode) 500 mating cycles (<0.3 dB change multimode, <0.2 dB singlemode) -40˚ to 40˚C (-40° to 104˚F) 0˚ to 55˚C (32˚ to 131˚F) TIA/EIA-568-B.3 Ordering Information Connectors Item Fiber (µm) ST ST SC SC LC LC ST SC LC 50/125 62.5/125 50/125 62.5/125 50/125 62.5/125 Singlemode Singlemode Singlemode Buffer Size (µm) 900 900 900 900 900 900 900 900 900 Part No. Single OR-205KAS9EA-50T OR-205KAS9EA-62 OR-205KAS9FA-50T OR-205KAS9FA-62 OR-205KAS9GA-50T OR-205KAS9GA-62 OR-205KAS9EA-09 OR-205KAS9FA-09 OR-205KAS9GA-09 25 Pack OR-205KAS9EB-50T OR-205KAS9EB-62 OR-205KAS9FB-50T OR-205KAS9FB-62 OR-205KAS9GB-50T OR-205KAS9GB-62 OR-205KAS9EB-09 OR-205KAS9FB-09 OR-205KAS9GB-09 Conversion Kits for Jacketed Fiber Item ST SC LC Description Used for ST installation on 2.4 to 3.0 jacketed fiber Used for SC installation on 2.4 to 3.0 jacketed fiber Used for LC installation on 2.0 jacketed fiber Part No. OR-20500236 OR-20500237 OR-20500267 Description Contains all tools necessary for complete OptiMo LC, ST and SC terminations: contractor bag, jacket strip tool, “nick-free” buffer strip tool, tweezers, waste bottle, marker pen, scissors,“third hand” tooling, microscope, fiber cleave tool, hex crimp tool w/die, LC, ST and SC Installation Instructions Same as OR-85400000-1, without cleave tool, crimp tool, or “nick free” buffer strip tool Same as OR-85400000-1, without fiber cleave tool Same as OR-85400000-1, without “nick-free” buffer strip tool Same as OR-85400000-1, without crimp tool Part No. OR-854A00000-1 Termination Kits Item Full Termination Kit Basic Kit Upgrade Kit 2 Upgrade Kit 3 Upgrade Kit 4 OR-854A00000-0 OR-854A00000-2 OR-854A00000-3 OR-854A00000-4 Individual Tools and Accessory Items Item Installation Tooling Fiber Cleaver Miller-type Buffer Strip Tool “Nick-Free” Buffer Strip Tool Inspection Microscope Crimp Tool with Die Cleaning Accessories ST Installation Manual SC Installation Manual LC Installation Manual Description Clamp and holder for LC, ST and SC* Cleave tool with proper cleave length stop* Buffer strip tool Buffer strip tool Cleave inspection scope* Crimp tool* Pre-moistened alcohol wipes (80 count), marker Part No. OR-60300126 OR-60300123 OR-60300124 OR-60300127 OR-60300128 OR-60300125 OR-854A00001 OR-71601376 OR-71601377 OR-71601416 *Recommended for OptiMo system 125 Eugene O’Neill Drive, New London, CT 06320 800-934-5432 • 860-445-3800 (corp) • 860-405-2922 (fax) www.ortronics.com OptiMo Rev. 1 06/04