Prospects of Large Deployable Reflector Antennas for a New

advertisement

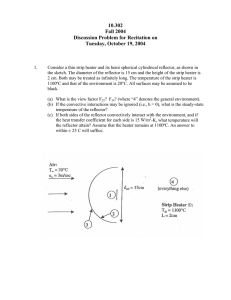

Prospects of Large Deployable Reflector Antennas for a New Generation of Geostationary Doppler Weather Radar Satellites Eastwood Im1, Mark Thomson2, and Houfei Fang3 Jet Propulsion Laboratory, California Institute of Technology, Pasadena, CA 91109 James C. Pearson 4 and James Moore5 ManTech SRS Technologies, Huntsville, AL 35806 and John K. Lin 6 ILC Dover LP, Frederica, DE 19946 A novel mission concept, namely NEXRAD in Space, has been developed for detailed monitoring of hurricanes, cyclones, and severe storms from a geostationary orbit. This mission concept requires a space deployable 35-m diameter reflector that operates at 35GHz with a surface figure accuracy requirement of 0.21 mm RMS. This reflector is well beyond the current state-of-the-art. To implement this mission concept, several potential technologies associated with large, lightweight, spaceborne reflectors have been investigated by this study. These spaceborne reflector technologies include mesh reflector technology, inflatable membrane reflector technology and Shape Memory Polymer reflector technology. Nomenclature Td Tg Tr Ts = = = = deformation temperature glass transition temperature recovery temperature storage temperature I. Introduction U nder NASA’s Earth Science Technology Program, a novel mission concept has been developed for detailed monitoring of hurricanes, cyclones, and severe storms from a geostationary orbit1,2. This mission concept is named as “NEXRAD in Space (NIS)”. NIS is designed to operate in the geostationary orbit at an altitude of 36,000 km. It would provide Ka-band (35 GHz) radar and line-of-sight Doppler velocity profiles over a circular Earth region of approximately 5200 km in diameter with a 12-km horizontal resolution, and a minimum detectable signal of 5 dBZ. The NIS radar achieves its superb sampling capabilities by use of a 35-m diameter in-space deployable spherical reflector. The antenna has two transmit-receive array feeds that create a three-dimensional image of both reflectivity and Doppler velocity inside and surrounding the storm systems approximately every 60 minutes. Both the reflector and the spacecraft will remain stationary as the feeds perform spiral scans to 4o to cover a 5200-km diameter circular area on the Earth’s surface. 1 Manager, Earth Science Instruments and Technology Office and Advanced Instruments Program Office, 4800 Oak Grove Drive/MS300-243, Member AIAA. 2 Principal Engineer, Mechanical Systems Division, 4800 Oak Grove Drive / MS299-100, Senior Member AIAA. 3 Senior Engineer, Mechanical Systems Division, 4800 Oak Grove Drive / MS299-100, Senior Member AIAA. 4 Aerospace Engineer, Aerospace Technologies Directorate, 500 Discovery Drive, Member AIAA. 5 Vice President and Director, Aerospace Technologies Directorate, 500 Discovery Drive, Member AIAA 6 Lead Design Engineer, Engineering, One Moonwalker Road / MS22, Senior Member AIAA. 1 American Institute of Aeronautics and Astronautics The mission concept requires a space deployable 35-m diameter reflector that operates at 35-GHz with a surface figure error of 0.21 mm RMS. This reflector technology, however, is well beyond the current state-of-the-art. In order to implement NIS, several potential technologies associated with large, lightweight, spaceborne reflectors are being investigated. These spaceborne reflector technologies, which include mesh reflector technology, inflatable membrane reflector technology and Shape Memory Polymer (SMP) reflector technology, will be discussed in the following sections. II. Mesh Reflectors Mesh reflectors are the only types of deployable antenna reflectors that have successfully flown in space as parts of an instrument or other satellite system. More than twenty two mesh reflectors have or will be flown by 2009 for USA commercial and/or science missions. The largest current mesh reflector aperture is 17 meters and will be increased to 22 meters with the launch of the MSV telecommunications satellite by 2009. Figure 1. The 9.1-m mesh reflector for NASA ATS-6 mission Figure 2. 4.9-meter S-/Ku-Band dual antennas for TDRS Mesh reflector technology has very significant flight heritage, Fig. 1 is the picture of the Wrap-Rib Mesh Reflector for ATS-6 that is developed by Lockheed3. The diameter of the reflector is 9.1 m and the RF frequency is S-band. The ATS-6 was launched on May 30, 1974. Figure 2 shows the Radial Rib Reflector developed by Harris4 for NASA Tracking & Data Relay Satellite (TDRS). Twelve TDRS Ku/S-Band antennas have been deployed in orbit with successful operations since 19835. Figure 3 shows the picture of the Folding Radial Rib Mesh Reflector developed by Harris, first flown on the ACES spacecraft in 2000 for the Garuda mobile communications system. Meanwhile, the European and Japanese space agencies have also developed and flown different types of Figure 3. ACES Garuda 12-meter L-Band mesh reflectors. reflectors A mesh shaping network that is typical of radially ribbed reflectors is shown in Fig. 4. It comprises various front & rears cords that control the position of the antenna mesh within the aperture. The cords are tensioned and positioned by a plurality of drop and edge ties, which thusly govern the deployed surface shape of the mesh. It is by adjustment of these cords that the required reflector surface figure is achieved. Of all the current mesh reflector technologies the current state-of-the-art for demonstrated on-orbit stability and surface accuracy is Northrop Grumman Space Technology’s AstroMesh reflector. Figure 5 gives a schematic view of the AstroMesh. 2 American Institute of Aeronautics and Astronautics The primary components of an EDGE TIE AstroMesh reflector6 are a flat deployable FRONT CORD perimeter truss, front and rear nets, tension ties, and mesh. The front and rear nets are composed of high stiffness, near-zero CTE NOTE: MESH NOT SHOWN FOR CLARITY composite web elements that form two backto-back geodesic domes. One of the domes is shaped to approximate the required parabolic surface metric with triangular facets. The webs are tensioned to high stress levels by even application of normal loads from the REAR CORDS tension ties. These high stress levels allow DROP TIES the front net to maintain very high stability Figure 1. Typical radial-rib mesh shaping network and precision despite parasitic mesh loads. The structural behavior of the nets is such that near zero mechanical pillowing of the mesh is experienced, so that far fewer drop ties are required than by the typical radial rib reflector. The flat truss is relatively deep and is composed of near-zero-CTE carbon fiber composite. This deep truss is very stiff and highly thermally stable. Five AstroMesh reflectors have been deployed on commercial spacecraft since 2000. Two are on Thuraya spacecraft (see Fig. 6) which were launched in October 2000 and June 2003. Both Thuraya spacecraft have 12.25-meter aperture reflectors. The MBSat spacecraft (see Fig. 6) was launched Figure 5. Schematic view of the AstroMesh reflector in March 2004 with a 12-m AstroMesh reflector on board. Two 9-meter AstroMesh reflectors are on Inmarsat 4 (see Fig. 6) spacecraft which were launched in April 2005 and October 2005. The antenna mesh that comprises the reflective surface of all current deployable mesh reflectors is evenly stretched across the aperture. Mesh is typically made of extremely fine gold-plated molybdenum wire that is Tricot knitted thus making it highly elastic, which allows it to yield to the structural definition provided by the reflector structures. Noteworthy advantages of using mesh include its ability to be arbitrarily packaged in an extremely small volume without introducing any permanent plastic deformations, its extremely low areal mass, high stability and longevity in a space environment. With minor development effort mesh will be capable of excellent RF reflectivity and cross-pol performance to at least the 35 GHz band required by the NEXRAD instrument. Figure 6. Thuraya spacecraft, MBSat spacecraft and Inmarsat 4 spacecraft The deployable reflector structures that support mesh, however, will require significant development to be able to support the required surface accuracy of 0.21 mm. The best mesh reflector surface accuracy that has been demonstrated thus far, in terms of the ratio of aperture diameter (D) to surface accuracy (δRMS) is in the vicinity of D/δRMS = 20,000 to 30,000. Extrapolation from the theoretical study given in reference 7 leads us to conjecture that the maximum possible value of D/δRMS for a passively maintained reflector structure is well below D/δRMS = 100,000. 3 American Institute of Aeronautics and Astronautics Because the NIS Goal for D/δRMS = 170,000 the mesh reflector that successfully supports this mission must offer in-flight adjustment of the surface figure. Whether this control is fully active with short update periods or more quasi-static in nature has yet to be determined. Nonetheless, an appropriate reflector surface metrology system with feedback and control of the mesh surface shaping structure will be required7. To achieve surface figure control to 0.21 mm RMS during the orbit the contour of mesh can be controlled by changing the lengths of the tie elements, whether it is the drop ties of a radial rib reflector or the tension ties of the perimeter truss. With advancements in miniature actuator technologies potentially appropriate linear actuators for this application are readily available. Figure 7 shows a miniature actuator8 that could be Figure 7. Piezoelectric linear micro-actuator used to change the length of a tie assembly for surface shape control. This and other similar approaches are being considered by the NIS project for application to mesh reflectors. III. Inflatable Membrane Reflector As with terrestrial radio frequency (RF) communications, future RF communications for space are trending towards large aperture and high frequency antennas. Transporting these large aperture antennas into space and then operating them creates a need for a low packaging factor (stowed volume / deployed volume) and a low areal density (aperture mass / aperture area) while also demonstrating the sub-millimeter surface shape accuracy that is required for Ka-band. While conventional antenna design technologies have advanced and are now capable of larger apertures and higher frequencies, they still possess some implicit properties that may limit the areal density and packaging factors. Furthermore, achieving and maintaining precision shape following deployment represents another new set of challenges for conventional designs. Hence, there is a need to continue development of other enabling technologies, such as inflatable thin film antennas, that may offer better solutions to these issues. During the last two decades, SRS has partnered JPL, NASA, Air Force, and large defense contractors to develop inflatable thin film concentrators. Initially these concentrators were designed to concentrate sunlight as a heat source for solar thermal propulsion systems. Later, these same designs were modified to concentrate sunlight for inspace solar power generation. More recently, and more prominently, these designs have been modified to function as transmit / receive antennas with both in-space and terrestrial applications. SRS has fabricated and tested on-axis and off-axis parabolic geometries with apertures up to 10m. Lightweight inflatable structures were developed to support these antennas including inflatable tori, that support the periphery, and inflatable radomes, that encapsulate the antenna while supporting the periphery. A. Design / Fabrication Approach A typical inflatable antenna consists of two thin films, a reflector and a canopy, that are joined around the edges. The relatively thin (<1-mil) polymer films are cast on a precisely shaped mandrel and then thermally cured and released. The reflector film is typically metalized with a vapor deposited silver or aluminum coating, nominally very thin. The membranes are then joined using a leak tight bonding technique. Following fabrication, the antenna is integrated with an inflatable torus or radome via compliant features that minimize loading changes associated with thermal excursions. Figure 8 shows a typical inflated antenna design. The antenna and torus structures are precisely inflated to approximately achieve the desired membrane stress and structural stiffness. Then, the boundary tension is adjusted to achieve the best shape. While the reflector film and canopy film are cast as one piece polymer thin films with a parabolic shape, achieving high surface accuracy after inflation deployment and in the space thermal environment is more challenging. Inflation pressure and film stress introduce shape errors, especially slope error near the edges (characteristic Hencky (W Error)). Thermal loads cause less systematic shape errors. The thermal induced shape errors can be significant and may drive the need for active control of the inflatable antenna. 4 American Institute of Aeronautics and Astronautics However, recent improvements in low coefficient of thermal expansion space ratable polymers can potential reduce the magnitude of thermal distortions9. B. Recent Inflatable Thin Film Antenna Technology NASA and SRS Technologies have successfully collaborated on research and development of lightweight thin-film antennas. To date, on-axis, off-set, and Cassegrain antennas, from 0.3m to 4m in aperture, have been designed, fabricated, and radio frequency (RF) characterized via range testing10. The designs address requirements for space based systems as well as inflatable terrestrial radome antennas. Fixed, deployable, and adaptive test structures are being developed to support the thin film antennas during testing and future operations. RF characterizations of off-set and on-axis antennas have been performed in the NASA GRC Far Field and Near Field facilities at frequencies from Xband to Ka-band. Thus far, frequencies through Ku-band have indicated excellent antenna performance. Ka-band test results indicate that improved antenna surface shape accuracy (sub-millimeter values) is required for efficient operation. Thus, shape optimization, tooling technology, fabrication processes, and active shape control techniques are being Figure 8. 4mx6m Off-Axis Inflatable Antenna considered to enable Ka-band operations. All of this successful lightweight inflatable thin-film antenna research and development has the potential to enhance current RF communications capabilities and enable many future RF requirements that need efficiently packaged deployable antennas with large apertures. Figure 9 shows RF characterization data from the 4mx6m testing. This data demonstrates the X-band antenna performance while showing the need for shape improvement to extend performance to Ka-band. Figure 9. 8.4 GHz Data for 4m x6m Test Article (676 Measure Efficiency) C. Recent Adaptive Antenna Work There are a number of technical challenges for large inflatable thin film antennas. The primary challenge is shape errors reduction to enable Ka-band and other higher frequency applications. The shape errors are the result of inflation pressure (membrane effects including Hencky W-error, oil can, other boundary errors) and thermal distortions. Key technologies being developed to address the challenges include: 1) improved membrane materials, 2) active control and 3) improved tooling and manufacturing processes. 5 American Institute of Aeronautics and Astronautics A membrane with an initially parabolic shape assumes a characteristic error when subject to inflation loads. This error, known as Hencky or W error, can be corrected with passive means. One possible solution is tailored membrane thickness or reflective coating stress distribution. This has been demonstrated for optics on meter class structures. SRS has demonstrated this with a membrane optic as shown in Fig. 1011. Another possible solution is initial shape optimization, which has been demonstrated for large scale apertures for correction of classic Hencky Error and other static boundary errors. Figure 11 shows a model of an on-axis thin film with the W error. hC (R ) = h0 + h2 ( kR ) 2 + h4 ( kR ) 4 + h6 ( kR ) 6 10 Inch Test Article with Variable Coating Figure 10. Nonlinear coating Prescription for Parabolic Shape developed by Mike Wilkes (AFRL) Variable Coating Thickness to Correct W Error Initial tooling mandrel shape optimization is another way to correct errors. SRS has both modeled and demonstrated this technique. Figure 12 shows that optimizing mandrel shape significantly improves reflector shape while advanced high temperature tooling enables fabrication of optimized membrane apertures12. Thermally induced shape aberrations are also significant. Resulting shape errors can be large (for example, 13.9 mm for a 25 meter polyimide antenna in geosynchronous orbit)13. Static shape optimization alone is not an option for inflatable antenna made from the current generation of space rated polymer materials under most operational scenarios. Possible solutions include low or zero CTE membrane materials and / or active shape control. As shown in Fig. 13, reduced CTE materials can help enable very large ultra-light deployable apertures for high band width communications, space science, earth science, and other applications. Figure 11. Model of 23 Meter Thin Film Antenna with Characteristic Shape Error Shape Error Along Major Axis 0. 300 0. 250 0. 200 Initially Parabolic 0. 150 Shape Optimized Design (Biased mandrel) 0. 100 0. 050 0. 000 80. 000 60.000 40.000 20.000 0.000 -20.000 -40. 000 -0.050 Film Thickness - .001” Pressure - .022” H2O High Tension Case Figure 12. Shape Correction via Tool Optimization 6 American Institute of Aeronautics and Astronautics -60. 000 -80. 000 Adaptive control strategies and/or advanced signal processing is another way to control errors in thin film antennas. Under a technology development program SRS and Northrop Grumman performed a 5m feasibility demo and successfully demonstrated a method for using electrostatic forces to control the shape of a lightweight deployable membrane aperture14. A high voltage power supply and control system, large dynamic range shape control, and statically stable electrostatic control. An example of shape correction for pressure and -150Co temperature change is shown in Fig. 14. Active controls can provide additional flexibility and reduce risks associated with modeling errors and environmental unknowns. It offers potential for morphing antenna technology to optimize aperture for different functions. Adaptive antenna concepts can meet the density (<2kg/m2), power (<200 Watts ), and size (>20m diameter) characteristics desired for future Ka and higher band systems. Key technologies for adaptive control includes: 1) integration of reflector with light weight deployable reaction structures for electrostatic control or 2) development of in plane surface actuation technology using piezoelectric patches or other surface strain approaches, and 2) improved materials with low CTE and low modulus, and more durable RF coatings or RF reflective polymers. Shape error of 5-meter CP1 reflector caused by partial shading (i.e. thermal) Figure 13. Reduced CTE materials required to enable very large ultra-light deployable apertures for high band width communications, Space Science, Earth Science, and other applications Low CTE Data D. Current Work Under a current effort an actively controlled inflatable reflector is being designed to demonstrate this technology for future applications such as the NIS antenna. This work includes advanced material studies, the design and fabrication of an inflation control system, manufacturing of the inflatable antenna, and integration with a test support ring. The test article will use piezoelectric surface actuators to demonstrate the ability to achieve Ka band accuracy under dynamic thermal loads. Uncorrected 3.42 RMS Error mm Figure 14. Corrected .0052mm RMS Error Modeled Results for 29 Channel Electrostatic Control Current activities are also focusing on improving materials for future inflatable antenna applications. Materials under development by SRS Technologies include metal filled polymers that are RF reflective. This material could improve the thin film antenna manufacturing process by eliminating the need for coating the polymer film with an RF reflective material. Although effective, the coating process is expensive, time consuming, error prone, and presents particular challenges for large apertures (generally >2m) due to handling fixtures and facility limitations. 7 American Institute of Aeronautics and Astronautics The metal filled RF polymer will simplify the manufacturing process and provide an effective RF reflective coating. These RF reflective polymers are also incorporating new polymer formulations that significantly reduce the coefficient of thermal expansion of the material. Silver filled polyimides have been fabricated that perform comparably with vacuum deposited aluminum coated materials. As requirements for antenna size and accuracy continue to increase new technologies must be developed to meet these requirements. Inflatable antenna technology offers the maximum packaging efficiency and a simple reliable deployment method. The inflatable technology offers a solution to aperture requirements >25 m where other antenna technologies begin to be limited by launch vehicle volume and mass restrictions. IV. Shape Memory Polymer Reflector Rigidizable materials in general are materials that are initially flexible to enable system packing and deployment, and become rigid when exposed to an external stimulus15. Although many types of rigidization mechanisms exist, this section will deal with thermally activated Shape Memory Polymer (SMP) composite materials and structures for antenna reflector applications. The effect of shape memory can be triggered by a stimulus other than temperature such as light or chemicals and these are classified as photo responsive and chemical responsive shape memory respectively. By definition, thermally activated shape memory polymers are polymers that can be predetermined to regain their original cured shape after being packed or deformed above their glass transition temperature by applying an external thermal influence. The SMP polymers differ from the traditional thermoplastic polymers in their ability to restore to their original shape by mere application of heat. To date, SMP have been demonstrated to recover more than 99% of their original shape in most applications if they are not under the influence of an external mechanical load. The thermo-mechanical response of a thermally activated SMP can be characterized by four critical temperatures16. The glass transition temperature, Tg, is the transition point for thermo mechanical deformation and recovery. Polymers possessing a glass transition temperature exhibit rubbery characteristics above Tg and exhibit a glassy state below Tg. The deformation temperature, Td, is the temperature at which the polymer can be deformed into a temporary shape. Td can be above or below Tg, but for folding or packing purpose it is not recommended to tightly fold SMP below Tg. The folding temperature for this class of SMP is typically 20°C above Tg. The storage temperature, Ts, is lower than Tg and denotes the temperature at which the polymer is stable in the packed or deployed state over long period of time. Finally, the recovery temperature, Tr, is the temperature at which the original shape is recovered. The manufacturing methods for SMP composite structures are similar to the traditional thermoset composites. The desired final shape of the SMP composite structure is set during its initial cure cycle at an elevated temperature. Once the SMP material is completely cured, it can be reheated to a minimum of 20oC above the Tg where it becomes flexible and can be tightly folded. The flexibility of the SMP composite at the folding temperature depends on the properties of both the resin and the fiber. After the material is folded, it can be constrained in that position and then cooled to approximately 15oC below Tg or Ts at which point the SMP composite can be unconstrained and will remain frozen in the folded position until it is heated again. When the SMP is heated to the recovery temperature after being folded, the SMP material will naturally begin to return to its initial cured shape based on the shape memory recovery force of the composite. In actual applications, although the composite has a higher shape memory recovery force than the shape memory polymer resin alone, inflation gas is often required to augment the structure’s return to its originally cured shape. Recently test has been conducted on this SMP composite material and results can be found in several published papers17,18. Shape memory polymers have been widely used in the commercial and medical fields with well known performance heritage. Some examples of biomedical applications are artificial muscles, catheters, wire mesh stents and other human interface devices. However, to date, shape memory polymers have only seen limited applications in space systems, but a number of applications are under development. These applications include structural components such as composite tube structures, reflector dish structures, and hinges. Several systems under developed are for very large truss or boom structures. In structural applications where large system payload mass is part of the deploying structure the limited recovery force available from the SMP is not sufficient to deploy the system. Therefore, some form of force augmentation is required to deploy the system. One option is to use inflation pressure inside the SMP structure to assist with the deployment. For precision structures where the fibers must be properly strained to remove all packing deformities, the use of inflation deployment offers the benefit of accuracy. 8 American Institute of Aeronautics and Astronautics SMP composite materials have recently been utilized for investigation on a number of development programs for space applications. Four such programs that can directly benefit the development of large deployable antenna reflector are discussed below. These programs include SMP booms and truss structures and SMP antenna reflectors. Figure 15. SMP composite truss application in deployed and packed configurations SMP cylindrical booms of various sizes (from 10 mm to 100 mm in diameter and 1-meter to 5-meter in length) have been extensively tested under NASA, DARPA and IRAD programs in the past few years at ILC Dover. The technical readiness levels of these booms are at 5 to 6 and they have also been assembled into truss structures for packing, deployment, structural, mechanical and thermal properties evaluations. The truss structure shown in Fig. 15 was fabricated from 1.5-m long, 45.7-mm diameter 2 ply IM7/SMP booms. This type of truss structures designed using SMP composites has demonstrated deployed-to-packed length ratios of 100:1. Truss structures like this can be used to construct the back support structure (struts and perimeter trusses of various shape) for large lightweight space based antenna reflectors. Figure 16. JHU/APL Hybrid Inflatable Antenna 2-Meter SMP Composite Reflector SMP composite materials have also been used to manufacture deployable parabolic reflector dishes. The use of this technology is currently planned for JHU/APL’s Hybrid Inflatable Antenna19 and JPL’s Advanced Precipitation Radar Antenna Singly Curved Parabolic Antenna Reflector20. For the Hybrid Inflatable Antenna, a 2-m diameter SMP composite reflector was recently fabricated and assembled into a toroidal support structure to demonstrate feasibility of the technology (Fig. 16). For this application, both the reflector dish and the support torus are envisioned to be fabricated from the SMP composite. To date, packing and deployment trials have not been demonstrated on the 2-m reflector, but two 0.5-m reflectors were fabricated from a carbon/SMP composite to demonstrate a potential folding scheme (Fig. 17). 9 American Institute of Aeronautics and Astronautics The same carbon/SMP composite has also been used to fabricate the Singly curved parabolic antenna models for feasibility study. These antenna models are 1/10th scale of the actual application with a length and width of approximately 0.5-m. After cure, a vapor deposited aluminum (VDA) polyimide film was bonded to the inner surface of the antenna to increase its reflectivity. For packing and deployment demonstration, the reflector was heated in an oven to above glass transition temperature for packing (in this case it was rolled, see Fig. 18). After the antenna was packed it was taken out of the Figure 17. 0.5-meter SMP Composite Reflector oven and allowed to cool in the rolled up shape. Then it was placed back in the oven for deployment by the material’s shape memory return function only. This shape memory return feasibility test was qualitatively successful and further work is continuing in this area to work on the details of scaling this technology up to larger size antennas and quantitatively measure the shape memory recovery response of the composite. SMP material technology can be further developed for ultra lightweight reflector by applying innovative composite fibers in both weave construction and material with the SMP polymers. Ultra lightweight SMP reflectors can be supported by SMP trusses to construct large reflectors in space. Figure 18. 0.5-m SMP Composite Singly Curved Parabolic Reflector Deployed and Packed Configurations V. Conclusions In order to implement the NIS mission concept, several potential technologies associated with large, lightweight, spaceborne reflectors have been investigated and discussed by this paper. These spaceborne reflector technologies include mesh reflector technology, inflatable membrane reflector technology and Shape Memory Polymer reflector technology. Mesh reflector technology has a very rich flight heritage and is very promising to be developed for the NIS application. Inflatable antenna technology offers the maximum packaging efficiency and a simple reliable deployment method. The inflatable technology offers a solution to very large apertures where other deployable reflector technologies begin to be limited by launch vehicle volume and mass restrictions. SMP material is a new type of material which has very unique and desirable characteristics. It is being developed rapidly and also has the potential for the NIS reflector application. Another major issue associated to the NIS 35-m reflector is how to maintain the 0.21-mm RMS surface contour precision requirement. It is concluded by previous studies that active surface shape control for the 35-m deployable reflector is necessary and several studies have been initiated21,22. Acknowledgments Authors would like to express the appreciations to Ubaldo Quijano and Gregory Davis of JPL for their help and support. The work described was performed at Jet Propulsion Laboratory, California Institute of Technology, ManTech SRS Technologies, and ILC Dover LP under a contract with the National Aeronautics and Space Administration. 10 American Institute of Aeronautics and Astronautics References 1 Im, Eastwood, Durden, S. L., Rahmat-Samii, Y., Lou, M. Huang, J., “Conceptual Design of a Geostationary Radar for Monitoring Hurricanes,” Jet Propulsion Laboratory, California Institute of Technology, Pasadena. 2 H. Fang, E. Im, “Mechanical Technology Development on A 35-m Deployable Radar Antenna for Monitoring Hurricanes”, NASA ESTO B6P2, Earth Science Technology Conference 2006, Adelphi, Maryland, June 27-29, 2006 3 http://www.astronautix.com/craft/ats6.htm 4 http://www-pao.ksc.nasa.gov/kscpao/nasafact/tdrs.htm 5 Freeland, R. E., Helms, R. G., and Mikulas, M. M., “The Applicability of Past Innovative Concepts to the Technology for New Extremely Large Space Antenna/Telescope Structures,” Jet Propulsion Laboratory, California Institute of Technology (USA) 06ICES-224. 6 “The AstroMesh Deployable Reflector”, proceedings of International Mobile Satellite Conference 1997 (IMSC ’97), presented June 16-19, 1997, Jet Propulsion Laboratory, Pasadena, California. 7 Hedgepeth, J. M., “Accuracy Potentials for Large Space Antenna Reflectors with Passive Structure,” Journal of Spacecraft and Rockets, Vol. 19, No. 3, May-June 1982, pp. 211-217. 8 http://www.newscaletech.com/ 9 G. Poe, “Heteropolymeric Polyimide Polymer Compositions” PCT Pat. App. No. PCT/US06-29805. 10 James C. Pearson , Dr. Robert Romanofsky, “Thin Film Antenna Development and Optimization”, 14th AIAA/ASME/AHS Adaptive Structures Conference, Newport, Rhode Island, 1-2 May 2006. 11 J. Moore, B. Patrick, “Design and Testing of a One-Meter Membrane Mirror with Active Boundary Control”, Proceedings, SPIE International Symposium on Optics and Photonics, San Diego, CA, August 2005. 12 “Design Optimization of Thin Film Solar Concentrators Using Non-Linear Deflection Modeling”, presented at the 42nd AIAA/ASME Conference, AIAA 01-14122, 42nd Aerospace Science Meeting and Exhibit, Seattle, WA, April 2001. 13 S. Chodimella, J. Moore and J. Otto, H. Fang, “Design Evaluation of a Large Aperture Deployable Antenna”, AIAA-20061603 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, Rhode Island, May 1-4, 2006. 14 “Multi-Function, Adaptive, Large Aperture Sensor, Contractor Report, NRO-3-C-0047, 2003. 15 Cadogan, D.P. and Scarborough S. E., “Rigidizable Materials for Use in Gossamer Space Inflatable Structures,” AIAA2001-1417, 42nd AIAA/ASME/ ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference and Exhibit AIAA Gossamer Spacecraft Forum, Seattle, WA: April 16-19, 2001. 16 K.Gall, M.L Dunn, Y. Liu, G. Stephanic and D. Balzar. Applied Physics Letters, Vol.85 No 2, 2004. 17 Scarborough, S.E. and Cadogan, D.P., “Applications of Inflatable Rigidizable Structures,” SAMPE Symposium, Long Beach California, 2006. 18 Scarborough, S.E. and Cadogan, D.P., “Rigidzable Materials for Inflatable Space and Terrestrial Structures,” SAMPE Symposium, Long Beach California, 2005. 19 Willey, C, Bucolic, R, Skulney, W, Cadogan D.P., Lin, J.K., The Hybrid Inflatable Antenna (AIAA 2001-1258), 42nd AIAA/ASME/ASCE/AHS/ASC SDM Conference, 2001. 20 Lin, J.K, Sapna, G.H., Scarborough, S.E., Lopez, B.C., “Advanced Precipitation Radar Antenna Singly Curved Parabolic Antenna Reflector Development,” AIAA-2003-1651, 44th AIAA/ASME/ ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference and Exhibit AIAA Gossamer Spacecraft Forum, Norfolk, VA, April 7-10, 2003. 21 H. Fang, M. J. Pattom, K. W. Wang, E. Im, “Shape Control of Large Membrane Reflector with PVDT Actuation”, AIAA2007-1842, 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, Hawaii, April 23-26, 2007 22 H. DeSmidt, K. Wang, H. Fang, “Gore/Seam Cable Actuated Shape Control of Inflated Precision Gossamer Reflectors – Assessment Study”, AIAA-2006-1902, 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Newport, Rhode Island, May 1-4, 2006. 11 American Institute of Aeronautics and Astronautics