Now! - Edmund Optics

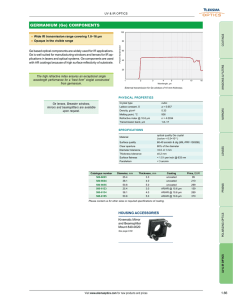

advertisement

launch & Production DEVELOPMENT & ProTOTYPING pages 12-13 pages 6-11 quality & support page 14 DEsign & Proof-of-concept pages 3-5 Concept & Planning page 2 Contact us for a Stock or Custom Quote Today! USA: +1-856-547-3488 ASIA: +65 6273 6644 EUROPE:+44 (0) 1904 788600 JAPAN:+81-3-3944-6210 www.edmundoptics.com/manufacturing CONCEPT & PLANNING Your project is unique – how can we best help you? At Edmund Optics® (EO), we specialize in creating cost effective solutions that meet our customer’s specifications and timelines. Our goal is for each of your projects to be as successful as possible, and for you to have the very best experience along the way – from initial technical and application support all the way through to product delivery, product quality, and beyond. At the concept and planning stage, our multi-disciplined engineers are ready to provide confidential, application engineering support. Whether you need help selecting from the world’s largest inventory of off-the-shelf components or you need assistance discussing custom components for your project’s requirements, we complement your design team with a unique combination of optical and imaging design expertise, manufacturing know-how, and proficiency across a multitude of diverse applications. From industry-leading customer service to real-world technical support, Edmund Optics® is dedicated to serving your needs and making your next project a success – Discuss your project needs with us today! Contact us today for confidential, application engineering support! • 24-Hour Live Technical Support, Sunday 8PM - Friday 8PM ET • Phone, Email, and Online Chat Contact Methods – Get Support Your Way! • Dedicated Global Technical Support Team • Quick NDA and CDA Process 24-HOUR TECHNICAL PHONE SUPPORT 800.363.1992 or 856.547.3488 Sunday, 8 PM – Friday, 8PM ET DATASHEETS • 2D & 3D Drawings, Zemax Files & More! • Spec Sheets • Filter & Lens Curves • Full Datasheets Available for all TECHSPEC® Imaging Lenses VIDEO RESOURCES • Engineering Tutorials • EO Imaging Lab • Corporate Videos • Product Overviews & More! Leverage the wealth of technical content on our website! • Over 45,000 Documents and Drawings for Download • 2D & 3D Drawings, Specification Sheets, Prescription Files, Coating Curves, and More! • Videos, Tech Tools, Application Notes, Articles, and More! EO TECH TOOLS • Laser Spot Size Calculator • Focal Length Calculator • Koehler Illumination & More! APPLICATION NOTES • Application Examples • Calculation Examples • Graphical Illustrations & More! For more TECHNICAL RESOURCES, visit www.edmundoptics.com/resources 2 design & Proof-of-concept Looking for design assistance? Many times, our customers have needs so specialized that they require design support. To meet these needs, Edmund Optics® offers a variety of design services. We excel at optical design services for imaging and non-imaging optical components, optomechanical system design, and optical assembly. In many cases, our dedicated design engineers can create ideal solutions for your optical challenges by integrating products from our broad off-the-shelf inventory. When use of stock components is not possible, EO engineers can often modify existing products or generate custom designs, using our extensive manufacturing resources to create products that meet unique customer needs. Whichever the case, we’ve found that approaching the design and proof-of-concept stage with an eye towards manufacturability at the onset yields the fastest, most affordable, and most effective results. EO engineers are prepared to take your project all the way from design to prototype to volume production. Expert Design Engineering Resources! • Global Staff of Optical and Mechanical Designers • Broad Design Expertise – From UV to Visible to NIR, SWIR, MWIR, and LWIR • Emphasis on Designing for Manufacturability – from Prototype to Volume Production • Excel at Imaging, Projection, and Visual Systems • Experienced in Challenging Envelope and Environment Requirements • Well Versed in Complex Optical Analysis, Including Stray Light Analysis • Proficient with Multitude of Design Tools: Zemax OpticStudio, Code V®, FRED™, SolidWorks, MATLAB® Did you know? EO has over 150 engineers on staff, located at each of our global sales offices and manufacturing facilities, as well as our two dedicated design service locations in Tucson, Arizona and Shenzhen, China. For more design assistance, visit www.edmundoptics.com/design 3 design & Proof-of-concept With flexible design and proof-of-concept solutions, EO can support wherever your project needs take you. Stock Modify Stock Custom From our website you can find free information, shop our catalog of over 27,600 products, view in stock status of our items or request a free Edmund Optics® print catalog. With our 96% same day order fulfillment rate, you can rest assured that the items you need will be in stock and ready to ship same day. Plus, the majority of our optical components are specifically designed for efficient volume manufacture and integration, saving you time and money. Leveraging the world’s largest inventory of optical components, we can make modifications to any of our stock optical components in just 2-3 weeks. Modification services include customizing the size, shape, and edges of stock optics, improving the surface figure or accuracy of the optical surface, coating, mounting, kitting, inspecting, sorting, and more! Can’t find what you need in our selection of standard products? Need an optic built to your specifications? We can make it for you! Our expert design and manufacturing engineers are ready to develop a custom solution to both meet your needs and exceed your expectations. • Over 27,600 Unique Optical Components • Available to Ship Same Day • No Hassle 30 Day Evaluation Period and Return Policy • Detailed Specifications, Drawings, and Prescriptions Online • Published Initial Price Breaks with Additional Volume Pricing Available Upon Request • Build-to-Print Manufacturing • Global Manufacturing Facilities • Leverage EO’s Extensive Stock Inventory as Your “Semi-Finished” Starting Point • ITAR Registered and Compliant • Competitive Volume Pricing • Fast 2 - 3 Week Turnaround • Precision Optical Components - Spherical & Aspheric Lenses - Mirrors -Windows -Filters - Prisms - Cube and Plate Beamsplitters • Impressive Array of Modification Services - Dimensional Changes - Surface Treatments - Coatings - Mounting - Kitting and Specialized Packaging - Sorting and Inspection - Customer Specified Testing • Precision Multi-Element Assemblies • State-of-the-Art Metrology from Interferometry to Spectroscopy to MTF • Environmental Testing Capabilities Build-to-print process 1 2 Customer Print or Specification Sheet 3 Certified & Traceable Raw Materials 4 Optical Fabrication Application of Optical Coatings 5 Bonding & Assembly 6 Final Inspection, Documentation, & Packaging For more detailed manufacturing capabilities, visit www.edmundoptics.com/manufacturing 4 design & Proof-of-concept 5 Tips for Designing with Off-the-Shelf Optics Using off-the-shelf optics in your next design project comes with many advantages. If budget or time restrictions eliminate the possibility of utilizing custom optics in your application, stock optics are readily available and easily implemented to fit your design requirements. Here are some quick tips to help make designing with off-the-shelf optics easy! 1 SIMPLIFY Start on paper with a paraxial design and break it into subsystems of finite and infinite conjugate optical groups. Determine the focal lengths you want for each group before trying to optimize in a code such as Zemax, Code V®, or another ray tracing software of your choice. Once you have the focal lengths required, you can start using paraxial equations to help choose the off-the-shelf lenses that provide the required focal lengths. Your preferred ray tracing code should have a selection of off-the-shelf lenses built into it (Figure 1) that you can use to model the selected lenses and optimize your spacing. If not, the lenses can typically be input into the software with the information provided by the supplier. All EO TECHSPEC® components are available in most design codes and Zemax files are available on our website at www.edmundoptics.com/zemax 2 GO MONOCHROMATIC If at all possible, use a monochromatic source such as an LED or Laser or use an optical filter to make your system monochromatic. Using a monochromatic or narrow band light will greatly reduce the complexity of the design. As a rough guideline, reducing the source waveband to less than 50nm will generally make using singlets possible in your design. Chromatic aberrations cause difficulty when composing a design, so your options will be simplified if a broadband light source is not required. 3 UTILIZE OFF-THE-SHELF subsystems By using off-the-shelf components such as achromatic doublets, microscope objectives, machine vision lenses, multi-element relays, or other subsystems, you can often achieve your application’s exact correction requirements for factors such as color, field angles, and large apertures. In many cases, these subsystems can even be modeled in your code if the prescriptions are provided by the supplier (Figure 2). Even if the prescription is not available, a paraxial surface can be used to approximate the subsystem. 4 CONSIDER MOUNTING OPTIONS Whether prototyping or trying to save the time and expense associated with purchasing custom housings, consider off-the-shelf mounting options. For example, the TECHSPEC® Optical Cage System allows you to easily assemble your optical components and provide plenty of freedom for making spacing adjustments. Most off-the-shelf cage systems allow for mounting common optical component sizes, as well as ways for mounting microscope objectives, C-mount camera lenses, and other subcomponents. 5 USE COMPONENTS where they work Off-the-shelf lenses such as Plano-Convex (PCX), Plano-Concave (PCV), Double-Convex (DCX), Double-Concave (DCV), and Achromats are optimized for small fields and small apertures. These components work best when integrated into systems that do not have very steep ray angles. For example, when designing a high magnification relay, use a complex multi-element subsystem for the high numerical aperture side of the relay and an achromat for the low numerical aperture side. For instance, a 15X system (Figure 3) consisting of a 20X infinite conjugate objective on the object side and a 150mm focal length achromatic lens on the image side, will provide a very well-corrected system. Figure 2: Prescription of EO Micro Video Lens (#58-204) Figure 1: Lens Catalog from Zemax Figure 3: Use Off-the-Shelf Components to Quickly Assemble a 15X Microscope For more optics application notes, visit www.edmundoptics.com/appnotes 5 development & Prototyping When developing a product, being able to quickly and easily iterate your prototypes is critical. Edmund Optics® makes prototyping easy by simplifying and expediting the pathway to production. For stock solutions, we ship same-day from our globally renowned world’s largest inventory of optical components. Beyond our immediately available 27,600 stock optics, quick “modified stock” customizations are available in just 2-3 weeks. Finally, if we can’t find a solution offthe-shelf, our engineers can develop a custom solution to meet your unique needs. From design to prototype to volume production – we’ll recommend the best solution to create the optics you need while maintaining the desired budget. ONE STOCK OPTIC = INFINITE POSSIBILITIES Custom Coating Non-Standard Geometry Mounting Did you know? Aspherized Surface Through-Hole Diameter Reduction Combine multiple modification services on the same optical component, such as resizing and coating, to reduce overall lead time and cost. Modification Services Offered Diameter Reduction Truncation Linear Cut to Size Edge Blackening Core Drilling & Through-Hole Engraving Serialization Coating Sorting or Inspection Sphere to Asphere Lenses Mirrors Windows Filters Polarizers Beamsplitters Prisms 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 What can we make for you? Learn more at www.edmundoptics.com/modify 6 3 3 3 3 3 development & Prototyping quick modifications to component dimensions Diameter Reduction Need an optic of a specific size? We can quickly and easily reduce the outer diameter of our off-the-shelf optics to meet your exact requirement. Before (Stock) After (Modified) Before (Stock) After (Modified) Before (Stock) After (Modified) Application Examples • Exact/precision fit an optic to your lens barrel • Match filter diameters to your unique system Typical Specifications Starting Part Size Minimum Finished Diameter Diameter Tolerance Clear Aperture 6 - 400mm 3.0mm ± 0.1mm 80% Beam Deviation Bevel Angle Tolerance Edge Chips Surface Quality 3 - 5 arcmin 45° ±15° ≤0.50mm 80-50 Truncation For design applications requiring a unique shape, a truncated lens, window, or mirror may be the best option. A truncation occurs when one or more straight cuts are applied to a round optic. Application Examples • Remove excess material in weight-sensitive applications • Custom mounting and fixturing Typical Specifications Starting Part Size 5 - 300mm Minimum Finished Part Size 3.0mm Maximum Thickness30mm Truncation Width Tolerance ±0.1mm Beam Deviation Bevel Angle Tolerance Edge Chips Surface Quality 3 - 5 arcmin 45° ±15° ≤0.50mm 80-50 Linear Cut to Size Need a custom sized or shaped optic? We can cut any optic to meet your needs. For thin, flat optics, we offer an economical and easily repeatable scribe and break process. For thicker optics, our expert team may use precision saw cuts to create the desired geometry. A linear cut to size is not limited to only flat optics; the process can also be applied to optics with curved surfaces. For instance, a PCX lens can be modified from having a circular diameter to having a square outer edge. Application Examples • Remove excess material in weight-sensitive applications • Custom mounting and fixturing • Custom viewing windows Typical Specifications Starting Part Size 5 - 300mm Minimum Finished Part Size 3.0mm Maximum Thickness 30mm Truncation Width Tolerance Bevel Angle Tolerance Edge Chips Surface Quality ± 0.1mm 45° ±15° ≤0.50mm 80-50 7 development & Prototyping quick modifications to component dimensions Before (Stock) After (Modified) Edge Blackening Is stray light interfering with your system’s performance? Stray light is energy outside of the clear aperture of an optical system that scatters off of the edges of an optical or mechanical component and reaches the sensor in the form of noise. Because stray light contributes noise rather than signal, stray light is a common limiting factor in overall performance of multi-element systems. To minimize stray light, we can edge blacken an optic using an RoHS compliant, solvent-resistant ink and improve overall light throughput. Typical Specifications Starting Part Size Diameter Increase Clear Aperture Before (Stock) 3 - 250mm +0.1mm added (nominal) unchanged After (Modified) Application Examples • Improving image quality in imaging systems • Maximizing light throughput in optical systems CORE Drilling & Through-Hole Need to make dimensional adjustments to a filter? We can use a core drill to separate the filter substrate from the mount, while retaining optical performance in the filter’s central aperture. Before (Stock) After (Modified) In certain specialty applications, a through-hole in an optic may be required. We can drill through-holes to help simplify the optic mounting process or to enable compatibility with specific application requirements. Application Examples • Creating a custom diameter for a filter • Filter mount removal • Custom mounting holes • Combining laser beams Typical Specifications Starting Part Size Minimum Finished Diameter Diameter Tolerances Clear Aperture Before (Stock) 6.5 - 50mm 3.0mm ± 0.5mm or better 80% After (Modified) Contact us for a list of standard core drills available with no additional tooling charges. Engraving & Serialization Need a specific marking, engraving, or serialization to help monitor and track prototype assemblies throughout the development process, brand components, or ease identification? We can help. If you have traceability concerns, we can engrave or serialize parts according to your requirements. Application Examples • Apply a logo to the anodized aluminum barrel of an assembly • Two, nearly identical, lenses being dropped into a lens tube? Engrave the edge with letters or numbers to indicate assembly order • Create component position indicators along the surface of a breadboard • Add a fiducial mark to a set of polarizers to indicate the direction of linear polarization What can we make for you? Learn more at www.edmundoptics.com/modify 8 development & Prototyping Add a coating to any uncoated stock part • Standard Anti-Reflection and High Reflection Coatings Can be Applied to Uncoated Substrates Such as Lenses, Windows, or Prism Faces • Broadband or Laser-Line Designs Available Covering UV, Visible, and Infrared Wavelengths • Additional Coating Types Such as Transparent-Conductive Indium-Tin Oxide (ITO) or High Laser Damage Threshold Coatings Also Available Standard Coating Options standard broadband anti-reflection coatings Coating Description λ/4 MgF2 @ 550nm UV-AR [250 - 425nm] UV-VIS [250 - 700nm] VIS-EXT [350 - 700nm] VIS-NIR [400 - 1000nm] VIS 0° [425 - 675nm] VIS 45° [425 - 675nm] YAG-BBAR [500 - 1100nm] NIR I [600 - 1050nm] NIR II [750 - 1550nm] Telecom-NIR [1200 - 1600nm] 5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0 400 Coating Description 3 J/cm2 @ 355nm, 10ns UV Enhanced Aluminum 3 J/cm2 @ 355nm, 10ns 5 J/cm2 @ 532nm, 10ns — 500 600 700 Wavelength (nm) 1000 1200 Wavelength (nm) Ravg >85% 400 - 700nm 0.3 J/cm2 @ 1064nm, 10ns Enhanced Aluminum 5 J/cm2 @ 532nm, 10ns — Ravg >95% 400 - 650nm 0.2 J/cm2 @ 532nm, 10ns Ravg >98% 500 - 800nm 0.5 J/cm2 @ 532nm, 10ns Ravg >98% 2 - 10µm 0.5 J/cm2 @ 1064nm, 10ns Protected Silver 7 J/cm2 @ 1064nm, 10ns 8 J/cm2 @ 1064nm, 10ns Ravg >94% 700 - 800nm Protected Gold 0.8 J/cm2 @ 1064nm, 10ns Ravg >97% 800 nm - 2µm — — Learn more at www.edmundoptics.com/modify 800 900 1000 1100 NIR I (600 - 1050nm) NIR II (750 - 1550nm) Telecom-NIR (1200 - 1600nm) SWIR (900 - 1700nm) YAG-BBAR (500 - 1100nm) 800 0.5 J/cm2 @ 355nm, 10ns 5 J/cm2 @ 532nm, 10ns Standard Near Infrared Anti-Reflection Coatings 600 Ravg >85% 250 - 700nm Protected Aluminum λ/4 MgF2 @ 550nm VISO° (425 - 675nm) UV-AR (250 - 400nm) UV-VIS (250 - 700nm) VIS-NIR (400 - 1000nm) VIS-EXT (350 - 700nm) 400 Typical Energy Density Limit 0.3 J/cm2 @ 532nm, 10ns Standard Visible Anti-Reflection Coatings 300 Specifications 100 98 96 94 92 90 88 86 84 82 80 0.2 Typical Reflectance Curve for Metallic Mirror Coatings UV-NIR Range Reflectance (%) 5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0 200 Metallic Mirror Coatings Typical Energy Density Limit 10 J/cm2 @ 532nm, 10ns 1400 1600 100 98 96 94 92 90 88 86 84 82 80 1.5 0.3 0.4 0.5 1800 0.6 0.7 0.8 0.9 Wavelength (μm) 1.0 1.1 1.2 1.3 1.4 1.5 Typical Reflectance Curve for Metallic Mirror Coatings NIR-IR Range Reflectance (%) Reflection (%) Reflection (%) SWIR [900 - 1700nm] Specifications Ravg ≤1.75% 400 - 700nm (N-BK7) Rabs ≤1.0% 250 - 425nm Ravg ≤0.75% 250 - 425nm Ravg ≤0.5% 370 - 420nm Rabs ≤1.0% 350 - 450­nm Ravg ≤1.5% 250 - 700nm Ravg <0.5% 350-700nm Rabs ≤0.25% @ 880nm Ravg ≤1.25% 400 - 870nm Ravg ≤1.25% 890 - 1000nm Ravg ≤0.4% 425 - 675nm Ravg ≤0.75% 425 - 675nm Rabs <0.25% 532nm Rabs <0.25% 1064nm Ravg <1.0% 500 - 1100nm Ravg ≤0.5% 600 - 1050nm Rabs <1.5% 750 - 800nm Rabs <1.0% 800 - 1550nm Ravg <0.7% 750 - 1550nm Rabs ≤0.25% 1295 - 1325nm Rabs ≤0.25% 1535 - 1565nm Ravg ≤0.25% 1200 - 1600nm Rabs ≤1.5% 900 - 1700nm Ravg ≤1.0% 900 - 1700nm UV Enhanced Aluminum (Ravg >85% 0.25 - 0.7µm) Enhanced Aluminum (Ravg >95% 0.45 - 0.65µm) Protected Silver (Ravg >98% 0.5 - 0.8µm, Ravg >98% 2 - 10µm) Protected Aluminum (Ravg >85% 0.4 - 0.7µm) Protected Gold (Ravg >97% 0.8 - 2µm, Ravg >94% 0.7 - 0.8µm) 2.5 3.5 4.5 5.5 6.5 7.5 8.5 Wavelength (μm) 9.5 10.5 11.5 12.5 13.5 Need a wavelength specific coating? contact us with your unique requirements and get started today! 9 development & Prototyping quick modifications to optical surfaces Before (Stock) After (Modified) PCX LENS ASPHERE PCX LENS TO ASPHERE CONVERSION Center Thickness Tolerance Beam Deviation Aspheric Vertex Radius Tolerance Aspheric Figure Error (P-V) Bevel Edge Chips Surface Quality Modified Aspheric Design 15 - 75mm ±0.1mm 3 - 5 arcmin ±0.3% 1µm 0.5mm max facewidth at 45º ±15º <0.5mm 80-50 <150µm departure from the catalog best fit sphere Sphere to Asphere A single aspheric lens can often outperform several spherical elements, particularly in fast optical systems (low f/#). Edmund Optics® is pleased to offer this service to convert our spherical singlets to customized aspheric lenses by modifying one of our over 150 different stock PCX lens designs. Whether you have an aspheric lens already designed or only a preliminary setup, our engineers will work with you to help specify the right asphere for your application. Application Examples • Reduce lead time and cost by modifying a stock PCX lens rather than submitting a fully custom request • Simplify imaging system prototyping by only producing the number of aspheres that you require Need an ASPHERE FAST? Learn more at www.edmundoptics.com/ quick-aspheres Kitting Need to purchase multiple components for your system? To make things easier for you, we can create a custom bill of materials so that you only have to purchase a single stock number rather than each individual part. The custom bill of materials also ensures that all products are delivered together. Application Examples • Lens assembly components • Fluorescence filter sets • Your project’s bill of materials Custom Packaging Have specific packaging requirements? We’re here to help! In particular, tray-style packaging reduces packaging waste, allows for easier dock-to-dock processing, and eliminates excess handling concerns. Our team can ensure that your products are packed and delivered based on your specific requirements. Application Examples • Barcode labeling • Add your company name, part number, or other identification • Custom containers Inspection Reports By request, our metrology team can provide inspection reports that document the exact performance of your optic. For more information on our metrology services, please visit the inspection section of www.edmundoptics.com/modify. CALL US to discuss your specific requirements! 800.363.1992 or 856.547.3488 10 development & Prototyping additional services Mounting Using a standard optical mount? Let us save you time and money by ensuring your optical element is properly mounted for quick and easy integration into your optical system. Choose from any of our 450 unique optical component mounts and we’ll secure either a stock or customized optic to meet your requirements. For example, select one of our S-, C- and T- mounts designed for 3 - 50mm diameter lenses. We’ll mount the lens for you and you’ll quickly receive a customized lens assembly. It’s that simple! Looking for more complex optical assemblies? Contact us today to discuss your custom assembly needs. Before (Stock) After (Modified) Application Examples • Safely secure components • Ease the integration of optical components into existing systems • Reduce optic handling to minimize risk of component damage Customer success: Prototyping Solution Every application has unique requirements. A customer found that one of our stock lenses met the performance requirements for an ultra-high temperature application, but the lens needed to fit within a specialized mount. We quickly made the required dimensional modifications and delivered a product that fit into the production mounting solution. Using S-, c-, and T-mount components and the TECHSPEC® optical cage system Selecting the right mounting component is critical when trying to maximize the performance of an optical system. Edmund Optics® offers fixed, adjustable, and kinematic mounts for a range of optical components including lenses, filters, mirrors, and prisms. Our modular S-, C-, and T-mount components can easily integrate with TECHSPEC® Optical Cage System components for added functionality, such as for minimizing stray light or for incorporating light sources, cameras, or detectors. Figures 1 - 4 demonstrate a few examples of how to use C-mount components within cage system setups. Figure 1: An Imaging System out of C-mount Components Figure 2: 30mm Inner Diameter Cage Plate with a C-mount Lens Mount Figure 3: Folded Path Prototype Set-up with Cage Component Parts Figure 4: OEM Imaging Assembly Prototype with Cage System Components Our large selection of S-, C-, and T-mounting components and accessories are cross compatible for easy system integration and prototyping. Each mount utilizes a retainer ring to evenly distribute pressure on the secured optic’s circumference, removing unneeded strain and the risk of damage. Many of the mounts are designed to hold single or multi-element optics. Having issues with stray light? C-mount extension tubes are simple solutions for minimizing stray light and for improving system performance. Any C-mount tube or C-mount lens mount with an outer diameter of 30mm can be secured within a 30mm inner diameter cage plate. Designed for modularity and flexibility, optical cage systems are high precision alternatives to complex optical alignment systems. Constructed of rods and plates, cage systems allow the user to continuously modify the system’s design by adding additional components, such as optical mounts and angular brackets. Using TECHSPEC® Optical Cage System components, Figure 4 shows a working prototype of an imaging-based inspection system. Also shown is the final OEM production unit. So much more online at www.edmundoptics.com/cage-system 3D Models Instructional Videos Application Examples Integration Tips 11 launch & Production Edmund Optics® manufactures and supplies customers around the globe with millions of precision optical components and optical assemblies. Whether stock, modified stock, or custom, we have the expertise and resources necessary to manufacture optical products based on your project’s specific requirements. Our dedicated and skilled team members will ensure that you receive the optimal solution for your application, while our quality assurance teams guarantee the best final products. Additional Requirements? We’ve Got You Covered! • Highly Flexible Volume Order Servicing • Support Blanket Orders and Other Stocking Agreements • Well Versed in Configuration Control, Change Control, and Copy Exact! (CE!) Requirements • Seamless FAR, DFAR, Quality Assurance Provision (QAP), and Testing Requirement Flow-downs Did you know? • ITAR Registered and Compliant; DPAS Servicing and Support • Global Supply Chain Network with Global Warehousing – Quickly and Easily Supporting Your Projects Wherever You Prefer to Procure or Build Edmund Optics® manufactures over 2 million optical components and 135,000 optical assemblies every year at our global facilities. global design & manufacturing Arizona, USA Japan New Jersey, USA China Singapore Arizona, USA Tucson Design Center focused design and applications engineering with over 30 years of experience 12 New Jersey, USA Corporate Headquarters 120,000 sq. ft. (11,148 m2); 20,000 sq. ft. (1,858 m2) of dedicated manufacturing space. High precision fabrication, coating, assembly, and testing cells Singapore 77,000 sq. ft. (7,150 m ) of manufacturing space. Highly vertically integrated facility for volume production of spherical and aspheric lenses, prisms, and other coated and mounted optics 2 Shenzhen, China Akita, Japan 16,140 sq. ft. (1,500 m ) of manufacturing space. On-site design, assembly, and testing of high volume optomechanical and imaging assemblies 80,000 sq. ft. (7,432 m2) of manufacturing space. High precision spherical lenses, prisms, and other coated optics with over 50 years of experience 2 launch & Production Precision optical components Lenses Prisms • Plano Convex (PCX), • Right Angle, Penta, Double-Convex (DCX), Schmidt, Amici Roof, Meniscus, Cylinder, Corner Cube, Dove, Achromats and Aspheres Rhomboid, Wedge, and Specialty Windows Plate and Cube Beamsplitters • Optical Flats, Laser AR, • Standard, Polarizing, Broadband AR, Crystalline, Non-Polarizing, Dichroic, and Specialty Glasses and Beam Combining Mirrors Assemblies • Laser, Precision Flat, • Imaging Lenses, Eyepieces, Metal Substrate, Focusing, Objectives, Relay, and and Specialty Other Optomechanical Assemblies Filters • Bandpass Interference, Notch, Edge and Dichroic, and Neutral Density For more detailed manufacturing capabilities, tear out the back cover of this brochure. 5 INTERRELATED SURFACE terms for Specifying Lenses Surface Sag • The height (or depth) of a convex or concave lens surface is referred to as the sagitta, or simply sag, of that surface. • As the diameter of the lens increases, the sagitta increases; a change in diameter affects the sagitta more rapidly than a comparable change in surface power. • Sag Calculator: www.edmundoptics.com/sag Convex Surface Lens Diameter Sag Radius of Curvature Concave Surface Radius of Curvature Sag Lens Diameter Radius • A rotationally symmetric spherical lens surface is a section of a sphere and has a uniform radius of curvature across its surface. This radius is its theoretical or design shape. • In manufacturing, the radius of the component will differ slightly than its design shape, so a best-fit sphere to a surface or wavefront is obtained by comparing to a theoretical surface. • For testing purposes, the desired theoretical surface may be represented by a test plate, interferometric reference surface, or other measuring device of sufficient accuracy. Reference ISO 10110-5 for more detail. Power • Power or Radius Error is the deviation from the design shape of the surface. These differences are equal changes in the radius of curvature throughout the surface. • Test plates can be used to measure the sag difference between the theoretical surface radius and the part under test using interferometry. • Every fringe or change from light to dark ring is a sag difference of a ½ wavelength of the light used to see the interference. fringes = waves of power 2 Irregularity • Irregularity is the remaining form error when constant radius error (power) is removed from the measured surface. • This error can be expressed as peak-to-valley (PV). The maximum distance minus the minimum distance between the residual error of the best fit sphere and the surface or wavefront. Surface Flatness • A type of surface accuracy specification that measures the deviation of a flat surface such as that of a mirror, window, prism, or plano-lens. • This deviation can be measured using an optical flat. When the flat surface of the test optic is placed against the optical flat, fringes appear whose shape dictates the surface flatness of the optic under inspection. 13 quality & support Edmund Optics® has been a trusted source for quality optics, imaging, and optomechanical components for nearly 75 years. Every step of the way, EO is committed to ensuring product and procedural quality. Guided by ISO 9001 certification standards, Edmund Optics® employs a strict global quality program that is monitored by experienced staff and supported by the most innovative optical testing available. EO manufactured products undergo rigorous and thorough testing as part of the company’s quality program and in compliance with EO’s global quality procedures, as well as a host of ISO and mil-spec standards. We’re proud of our proven track record of tailored testing for optical assemblies customized to project requirements. Our inhouse optical assembly testing capabilities include: MTF, stray light, telecentricity, wavefront distortion, white light interferometry, mechanical profilometry, and much more. In-house environmental testing capabilities include: temperature, humidity, immersion, shock and vibration, and more. Additionally, Edmund Optics® has put proactive environmental management at the heart of our operations. EO has documented plans for improving resource efficiency and waste reduction through the Environmental Management System (EMS) ISO 14001. We hope our initiative will develop and sustain both supply and demand for greener goods, services and products, and reduce waste both in and outside of the company. Quality and Metrology capabilities Quality Standards #010433 QED ® ASI ™ Aspheric Stitching Interferometer • ISO 9001:2008 • ISO 14001 • ANSI / ASME Y14.5 • ISO 10110 • MIL-C-48497A • MIL-STD-810 • MIL-PRF-13830B • MIL-C-675C • Fully ITAR Compliant Factories Zygo ® NewView ™ Metrology • State-of-the-Art Optical Metrology • Automated Equipment for Optical Parameters such as Effective Focal Length (EFL), Distortion, Field Curvature, and Concentricity • Radiometrics: Straylight, Veiling Glare, etc. • Semi-Automated MTF Measurement Equipment • Environmental Testing Equipment such as Vibration, Humidity, and Immersion Zygo ® Interferometer Varian Spectrophotometer For manufacturing and metrology capabilities, visit www.edmundoptics.com/manufacturing 14 what can we make for you? phone & online chat 800.363.1992 or 856.547.3488 Monday - Friday, 8AM - 8PM ET Saturday, 10AM - 1PM ET sales@edmundoptics.com www.edmundoptics.com/contact 24-hour application SUPPORT 800.363.1992 or 856.547.3488 Sunday, 8PM - Friday, 8PM ET techsup@edmundoptics.com SHIPPING Orders received before 7:30PM ET Monday - Friday and 12:45PM ET Sat. can be shipped the same day within the US. * Please see our website for continental US rates and shipping options. * Same day shipping for orders shipping via FedEx must be received before 6:30PM ET Mon - Fri. online Look for the underlined volume message next to the price. Click on it for volume discounts. + Volume $350.00 – Volume $350.00 1 - 5 for $350.00 each 6 - 25 for $315.00 each 26 or more Request Quote ct ob e O Tear Along the Dotted Line VOLUME DISCOUNTS *T IN THE CATALOG 1-5 $350.00 $350.00 $350.00 $350.00 $350.00 6-25 $315.00 $315.00 $315.00 $315.00 $315.00 26+ Call Look for the quantity break pricing and green call out for OEM discounts. Contact a sales representative or engineer, visit www.edmundoptics.com/contact hi sc r2 01 4R ha rt rep ead ex res e nts Res earc h S u rv 90% of re spon ey, North American Res dents. 10% chose not to a ts den ion. pon st r th nswe is q ue #1 preferred supplier of optical components 8 years in a row. ® MANUFACTURING CAPABILITIES resource guide SPHERICAL Lenses spherical manufacturing capabilities Specifications Commercial Precision Diameter Range 4 - 200mm 4 - 200mm 4 - 200mm Diameter Tolerance +0/-0.1mm +0/-0.025mm +0/-0.01mm Center Thickness Tolerance Surface Sag Clear Aperture Radius • 6,200+ Stock Spherical Lenses Ready for Purchase • Available in Glass and Crystalline Materials with a Variety of Standard and Custom Coatings aspheric Lenses Power (P-V) 80% 90% 90% ±0.3% ±0.1% Fixed to testplate l/2 l/10 Centering (Beam Deviation) 3 arcmin 1 arcmin 0.5 arcmin Surface Quality (Scratch Dig) 80-50 40-20 10-5 <1.0mm <0.5mm <0.25mm High Precision Bevel (Face width @45 degrees) ASPHERIC manufacturing capabilities Specifications Commercial Precision Diameter 4 - 200mm 4 - 200mm 4 - 200mm Diameter Tolerance +0/-0.1mm +0/-0.03mm +0/-0.01mm 3µm 2µm 0.5µm Vertex Radius (Asphere) ±1% ±0.1% ±0.05% ±0.3% ±0.1% ±0.025% 3l 1.5l Irregularity (Spherical) (P-V) 1.0l l/4 l/2 l/10 Centering (Beam Deviation) 3 arcmin 1 arcmin 0.5 arcmin Center Thickness Tolerance ±0.10 ±0.05 ±0.01 Surface Quality (Scratch Dig) 80-50 40-20 10-5 <1.0mm <0.5mm <0.25mm High Precision Bevel (Face width @45 degrees) prism manufacturing capabilities Specifications Commercial Precision Dimensions 2 - 200mm 2 - 150mm 2 - 75mm Dimensional Tolerance +0/-0.1mm +0/-0.025mm +0/-0.01mm ±0.25mm ±0.1mm ±0.03mm 1.0l l/4 l/20 3 arcmin ±30 arcsec 45° & 90° ±0.5 arcsec Penta Prism Deviation 5 arcmin 3 arcmin 0.5 arcmin Bevel (Max Face width @45 degrees) ±0.2mm ±0.1mm ±0.05mm 80-50 40-20 10-5 Bonded Prism Assembly Beam Deviation 5 arcmin 3 arcmin 0.5 arcmin Bevel (Face width @45 degrees) <1.0mm <0.5mm <0.25mm Surface Quality (Scratch Dig) filter coating capabilities Dimensions (Diameter or Square) Substrates Spectral Ranges Edge Steepness (T50% to OD>4) Spectral Edge Tolerance Blocking Neutral Density Tolerance Center Wavelength (CWL) Bandwidth Transmission Reflection Polarization (S:P) Laser Damage Threshold Number of Layers Durability 2 - 1000mm All Glass Types 193nm - 14μm <0.5% <1% Deviation, <0.2% Special Cases >OD 7, Measured OD ±5% ±1nm 1nm - Broadband >95%, Typical 0.1 - 99.95% 10,000:1 Up to 20 J/cm2 @ 20ns Pulses 200+ MIL-STD-810: 10 Day, Humidity, MIL-C-48497A, Section 3.4.1 856.547.3488 | techsup@edmundoptics.com | www.edmundoptics.com/manufacturing Tear Along the Dotted Line Asphere Figure Error (P-V) Prism Physical Angle Tolerance • Durable, Hard Coated, Single Substrate • High Transmission, Deep Blocking, Steep Slopes • Custom Designs – UV; Visible; & Near, Mid-Wave, & Long-Wave IR ±0.01 ±0.01mm l/4 Irregularity (P-V) FILTERS & COATINGS ±0.05 ±0.025mm 1.5l V-Height • Custom Prisms in Any Geometry • Windows in All Optical Glass Types ±0.10 ±0.05mm 3l Radius (Spherical) Prisms & Flatwork High Precision 1.0l Irregularity (P-V) Power (Spherical) (P-V) • 550+ Stock Aspheric Lenses Ready for Purchase • Optical Glass, Plastic, Fused Silica, Germanium, Zinc Selenide, and Chalcogenide Substrates Try our Modify Stock Optics Service!