5.0mm x 6.0mm SURFACE MOUNT LED LAMP Package

advertisement

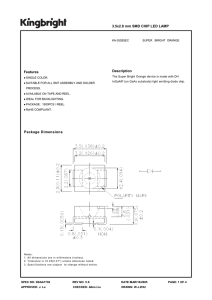

5.0mm x 6.0mm SURFACE MOUNT LED LAMP AT T E N T I O N OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC DISCHARGE SENSITIVE DEVICES Features lCHIPS CAN BE CONTROLLED SEPARATELY. l SUITABLE PROCESS. FOR ALL SMT ASSEMBLY AND SOLDER l AVAILABLE KAAF-5060PBESEEVGC BLUE / HYPER ORANGE /GREEN Description The Blue source color devices are made with InGaN on SiC Light Emitting Diode. The Hyper Orange source color devices are made with ON TAPE AND REEL. DH InGaAlP on GaAs substrate Light Emitting Diode. l PACKAGE: 500PCS / REEL. The Green source color devices are made with InGaN on SiC Light Emitting Diode. Static electricity and surge damage the LEDS. It is recommended to use a wrist band or anti-electrostatic glove when handling the LEDs. All devices, equipment and machinery must be electrically grounded Package Dimensions Notes: 1. All dimensions are in millimeters (inches). 2. Tolerance is ±0.25(0.01") unless otherwise noted. 3. Specifications are subject to change without notice. SPEC NO: DSAB9241 APPROVED : J. Lu REV NO: V.6 CHECKED : Allen Liu DATE: MAY/11/2003 DRAWN: F.Y.YUAN PAGE: 1 OF 6 Selection Guide Dic e P ar t N o . KAAF-5060PBESEEVGC Iv (m c d ) @ 30m A *50m A L en s Ty p e BLUE (InGaN) HYPER ORANGE(InGaAIP) GREEN (InGaN) Mi n . Ty p . *650 *1000 Un its Tes t C o n d i t i o n s nm I F =20mA nm I F =20mA nm I F =20mA pF VF=0V;f=1MHz V I F =20mA uA V R = 5V 110 WATER C LEAR Notes: 1. θ1/2 is the angle from optical centerline where the luminous intensity is 1/2 the optical centerline value. 2. * Luminous intensity with asterisk is measured at 50mA. V i ew i n g An g le 180 250 350 2θ1/2 100° Electrical / Optical Characteristics at TA=25°°C Sy m b o l P ar am et er D ev i c e λpeak Peak Wavelength λD D omi nate Wavelength ∆λ1/2 Spectral Li ne Half-wi dth C C apaci tance VF Forward Voltage IR Reverse C urrent Blue Hyper Orange Green Blue Hyper Orange Green Blue Hyper Orange Green Blue Hyper Orange Green Blue Hyper Orange Green All Ty p . Max . 465 630 520 470 621 525 25 20 38 110 25 45 3.7 2.0 4.0 4.3 2.5 4.5 10 Absolute Maximum Ratings at TA=25°°C P ar am et er Total Power di ssi pati on t [1] D C Forward C urrent Peak Forward C urrent [2] Reverse Voltage Operati ng/Storage Temperature B lu e 30 160 5 Notes: 1.Within 350mW at all chips are lightened. 2. 1/10 Duty Cycle, 0.1ms Pulse Width. SPEC NO: DSAB9241 APPROVED : J. Lu REV NO: V.6 CHECKED : Allen Liu H y p er Or an g e 350 50 30 195 5 Gr een 150 -40°C To +85°C 5 DATE: MAY/11/2003 DRAWN: F.Y.YUAN Un its mW mA mA V PAGE: 2 OF 6 KAAF-5060PBESEEVGC Blue SPEC NO: DSAB9241 APPROVED : J. Lu REV NO: V.6 CHECKED : Allen Liu DATE: MAY/11/2003 DRAWN: F.Y.YUAN PAGE: 3 OF 6 Hyper Orange SPEC NO: DSAB9241 APPROVED : J. Lu REV NO: V.6 CHECKED : Allen Liu DATE: MAY/11/2003 DRAWN: F.Y.YUAN PAGE: 4 OF 6 Green SPEC NO: DSAB9241 APPROVED : J. Lu REV NO: V.6 CHECKED : Allen Liu DATE: MAY/11/2003 DRAWN: F.Y.YUAN PAGE: 5 OF 6 KAAF-5060PBESEEVGC SMT Reflow Soldering Instruction Number of reflow process shall be less than 2 times and cooling process to normal temperature is required between first and second soldering process. Recommended Soldering Pattern (Units : mm) Tape Specifications (Units : mm) SPEC NO: DSAB9241 APPROVED : J. Lu REV NO: V.6 CHECKED : Allen Liu DATE: MAY/11/2003 DRAWN: F.Y.YUAN PAGE: 6 OF 6