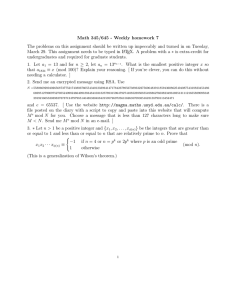

Modeling and Control of Power Electronics Based DC Networks

Modeling and Control of Power Electronics Based DC

Networks

Dissertation

Presented in Partial Fulfillment of the Requirements for the Degree

Doctor of Philosophy in the Graduate School of The Ohio State

University

By

Luis Herrera,

Graduate Program in Electrical and Computer Engineering

The Ohio State University

2015

Dissertation Committee:

Dr. Jin Wang, Advisor

Dr. Longya Xu

Dr. Mahesh S. Illindala

c Copyright by

Luis Herrera

2015

Abstract

The introduction of power electronic converters provides flexibility in the transformation of electrical energy such as ac-dc and dc-ac. For this reason, dc networks are becoming more popular in applications such as electric aircraft, navy ships, long distance power transmissions, and future microgrids in outer space. These systems are typically composed of multiple sources (ac or dc) and multiple loads (ac or dc) interconnected together through power electronics. In this work, modeling methods aimed at efficient real time simulation, stability analysis, and controller design for dc networks are presented.

Real time simulation is a fundamental tool used in industry to test hardware and/or software without the need of the actual system. For example, Hardware-inthe-Loop (HIL) techniques are commonly used to test a control unit for a vehicle, power converter, etc. The increase in switching frequency of the power electronics

(due to new devices such as SiC/GaN), decreases the time step needed to simulate these systems. For this reason, FPGAs are being commonly used for real time simulation. Nevertheless, the low level programming required introduces challenges in the modeling and implementation. Methods and algorithms are proposed to efficiently model the power devices including ‘on’ characteristics. In addition, a discussion of machine simulation including saturation and its implementation in FPGA are discussed.

ii

The use of power electronics to deliver power to loads (e.g. motors, dc electronic loads, etc.) introduces a negative impedance effect as seen by the network. This effect can potentially cause instability problems in the system. These types of loads are commonly referred in literature as Constant Power Loads (CPLs). To study the stability of dc networks with CPLs, a method is proposed based on Linear Matrix

Inequalities (LMIs) and Semidefinite Programming (SDP). The advantage of the proposed method relies on the use of static feedback without the need of knowing the load power and/or its derivatives.

Lastly, the modeling, simulation, and control of High Voltage DC Networks is presented. In these systems, Modular Multilevel Converters (MMCs) are typically used as an interface between the ac and dc networks. These types of converters can utilize hundreds to thousands of switches. Therefore, the simulation, offline and real time, is a main challenge. In addition, the circulating current through each arm affects the power losses in the power devices and causes larger current and voltage stress on the passive components. In this case, a controller is proposed to eliminate this oscillation and a platform for efficient simulation of MMCs is developed. Real time simulation and HIL validation of the controller are presented.

iii

To

God, my family, and all the inspiring mentors iv

Acknowledgments

My deepest gratitude goes to my PhD advisor, Dr. Jin Wang for all of his support, guidance, and encouragement over my studies. He has allowed me to pursue topics in different areas while at the same time helped me to develop creative and critical thinking. I would not have completed this dissertation without his support.

I would also like to thank Dr. Mahesh S. Illindala and Dr. Longya Xu for serving in all of my exam committees during my PhD studies. Their advice, comments, and support throughout my studies have given me invaluable insight into different details of my research. They are both experts in their respective area and I value their advice sincerely.

I am deeply grateful for the many wonderful and inspiring mentors I have had throughout my education. I very thankful to Mr. Frank Leach, for helping me to begin thinking “outside the box.” Dr. Somsak Sukittanon, who has always been a constant help. Without all of his advice and support I would not have continued on to graduate school. I would also like to thank Dr. Andrea Serrani. His passion for mathematics and control coupled with his amazing lectures have truly shaped my research direction and interests. Lastly, I am indebted to Dr. Wei Zhang, who has given me advice in my research projects and continued to fuel my interest in control through his classes.

v

I would also like thank my parents, Fabio Herrera and Amparo Duque, and my brother, Oswaldo Herrera, for all of their support and teachings throughout all of my life. Through many ups and downs, they have always been there for me with their love and support. I would like to thank my parents in law, Enhui Yao and

Yunxia Niu, for all of their support during my PhD. I want to thank my wife, Xiu

Yao, whom I love deeply. She has patiently helped me through many hard times with her unconditional love. Her faith in me has given me confidence whenever I am confronted with difficult situations. Lastly, I want to thank God for all of His blessings and carrying me throughout all of these years.

vi

Vita

May 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B.S. Engineering,

University of Tennessee at Martin

December 2014 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M.S. Electrical Engineering,

The Ohio State University

Sept 2010 to present . . . . . . . . . . . . . . . . . . . . . . . . Ph.D. student,

The Ohio State University

Publications

Research Publications

L. Herrera, and J. Wang, “Stability analysis and controller design of dc microgrids with constant power loads,” in Proceedings of 2015 IEEE Applied Power Electronics

Conference and Exposition (APEC) , Charlotte, NC, Mar. 15-19, 2015.

L. Herrera, X. Yao, and J. Wang, “Modeling and circulating current control of MMC,” in Proceedings of 2015 IEEE Applied Power Electronics Conference and Exposition

(APEC) , Charlotte, NC, Mar. 15-19, 2015.

X. Yao, L. Herrera, and J. Wang, “Impact evaluation of series dc arc faults in dc microgrids,” in Proceedings of 2015 IEEE Applied Power Electronics Conference and

Exposition (APEC) , Charlotte, NC, Mar. 15-19, 2015.

L. Herrera, C. Li, X. Yao, and J. Wang, “FPGA based detailed real-time simulation of power converters and electric machines for EV HIL applications,” IEEE Trans.

On Industry Applications , vol. 51, no. 2, pp. 1702-1712, Mar./Apr. 2015.

C. Li, L. Herrera, J. Jia, L. Fu, Y. Huang, A. Isurin, A. Cook, and J. Wang, “Design and implementation of bidirectional isolated cuk converter for low voltage and high current automotive dc source applications,” IEEE Trans. On Vehicular Technology , vol. 63, no. 6, pp. 2567-2577, Jul. 2014.

vii

X. Yao, L. Herrera, S. Ji, K. Zou, and J. Wang, “Characteristic study and timedomain discrete-wavelet transform based hybrid detection of series dc arc faults,”

IEEE Trans. on Power Electronics , vol. 29, no. 6, pp. 3103-3115, Jun. 2014.

L. Herrera, E. Inoa, F. Guo, J. Wang, and H. Tang, “Small-signal modeling and networked control of a PHEV charging facility,” IEEE Trans. on Industry Applications , vol. 50, no. 2, pp. 1121-1130, Mar. 2014.

F. Guo, L. Herrera, R. Murawski, E. Inoa, C. Wang, P. Beauchamp, E. Ekici, and J.

Wang, “Comprehensive real-time simulations of the smart grid,” IEEE Trans. on

Industry Applications , vol. 49, no. 2, pp. 899-908, Mar./Apr. 2013.

X. Yao, L. Herrera, and J. Wang, “Modulation and control of MMC based multiterminal HVDC,” in Proceedings of 2014 IEEE Energy Conversion Congress and

Exposition (ECCE) , Pittsburgh, PA, Sept. 14-18, 2014.

Fields of Study

Major Field: Electrical and Computer Engineering viii

Table of Contents

Page

Abstract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Dedication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

Acknowledgments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Vita . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Previous Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modeling and Real Time Simulation of Power Converters . .

Stability Analysis of Converter Based DC Networks . . . . .

High Voltage DC Networks . . . . . . . . . . . . . . . . . .

Organization and Contributions . . . . . . . . . . . . . . . . . . . .

1

2

4

1

2

7

8

Modeling and Simulation of Power Electronic Systems

. . . . . . . . . .

10

Review of Modeling Methods for Power Electronic Systems . . . . .

10

State Space Methods . . . . . . . . . . . . . . . . . . . . . .

10

Modified Nodal Analysis . . . . . . . . . . . . . . . . . . . .

17

Proposed Electrical/Thermal Modeling . . . . . . . . . . . . . . . .

21

Electrical Model . . . . . . . . . . . . . . . . . . . . . . . .

21

Thermal Model . . . . . . . . . . . . . . . . . . . . . . . . .

25

Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

Modeling of Electric Machines . . . . . . . . . . . . . . . . . . . . .

29 ix

Saturation Modeling . . . . . . . . . . . . . . . . . . . . . .

31

Computational Algorithm . . . . . . . . . . . . . . . . . . .

34

Electro-Thermal Algorithm Validation . . . . . . . . . . . . . . . .

37

Hardware Description . . . . . . . . . . . . . . . . . . . . .

38

Model Description . . . . . . . . . . . . . . . . . . . . . . .

38

Experimental and Real Time Results . . . . . . . . . . . . .

41

Real Time Simulation of an EV Drive

. . . . . . . . . . . . . . . .

42

Model and Saturation Characteristics

. . . . . . . . . . . .

44

Real Time Results . . . . . . . . . . . . . . . . . . . . . . .

45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

Stability Analysis of DC Networks

. . . . . . . . . . . . . . . . . . . . .

48

Examples of CPLs . . . . . . . . . . . . . . . . . . . . . . . . . . .

48

Stability Analysis of DC Networks . . . . . . . . . . . . . . . . . .

50

Problem Formulation . . . . . . . . . . . . . . . . . . . . . .

50

Region of Attraction Review for 1 CPL

. . . . . . . . . . .

52

Proposed SDP Technique . . . . . . . . . . . . . . . . . . . . . . .

55

Single CPL . . . . . . . . . . . . . . . . . . . . . . . . . . .

55

Multiple CPLs . . . . . . . . . . . . . . . . . . . . . . . . .

58

Controller Design . . . . . . . . . . . . . . . . . . . . . . . . . . . .

64

Feedback Design . . . . . . . . . . . . . . . . . . . . . . . .

64

Case Study . . . . . . . . . . . . . . . . . . . . . . . . . . .

68

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

. . . . . . . . . . . . . . . . . . . . . . . . .

71

. . . . . . . . . . . . . . . . . . . .

71

. . . . . . . . . . . . . . . . . . . . . .

71

Controller Design . . . . . . . . . . . . . . . . . . . . . . . .

74

Efficient Modeling of MMC . . . . . . . . . . . . . . . . . . . . . .

80

Equivalent Circuit - Thevenin Method . . . . . . . . . . . .

81

. . . . . . . . . . . . . . . . . . . . . . .

83

Hardware-in-the-Loop Controller Validation . . . . . . . . . . . . .

86

Platform Design . . . . . . . . . . . . . . . . . . . . . . . .

86

HIL Example . . . . . . . . . . . . . . . . . . . . . . . . . .

88

Real Time Simulation of MMC Based HVDC . . . . . . . . . . . .

90

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

95

Conclusion and Future Work . . . . . . . . . . . . . . . . . . . . . . . . .

98

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

98 x

Future Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

101

Appendices

109

LMI Methods in Stability Analysis . . . . . . . . . . . . . . . . . . . . .

109

A.1 Mathematical Preliminaries . . . . . . . . . . . . . . . . . . . . . .

109

A.2 Algorithms for Computing Region of Attraction . . . . . . . . . . .

111

HIL Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

114

B.1 Gain Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . .

114

B.2 DSP Implementation . . . . . . . . . . . . . . . . . . . . . . . . . .

116 xi

List of Tables

Table Page

Summary of explicit integration methods. . . . . . . . . . . . . . . . .

14

Summary of implicit integration methods.

. . . . . . . . . . . . . . .

15

Norton equivalent elements for MNA. . . . . . . . . . . . . . . . . . .

19

Simulation parameters for circuit and proposed model validation.

. .

23

Power converter electrical parameters. . . . . . . . . . . . . . . . . . .

39

Thermal parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Real time EV drive simulation parameters. . . . . . . . . . . . . . . .

45

Circuit parameters and initial conditions for Fig. 3.2. . . . . . . . . .

52

Parameters for dc microgrid with Q = 2 CPLs. . . . . . . . . . . . . .

61

Parameters for simulation of three phase MMC. . . . . . . . . . . . .

79

Single phase MMC for HIL validation of controller. . . . . . . . . . .

88

HVDC case study simulation parameters (offline). . . . . . . . . . . .

93 xii

List of Figures

Figure Page

Detailed dc microgrid of more electric aircraft, navy ships, etc. . . . .

4

Boost converter with discontinuous mode.

. . . . . . . . . . . . . . .

15

Hybrid automaton for a discontinuous boost converter. . . . . . . . .

16

Results showing the different modes for a boost converter.

. . . . . .

16

Representation of capacitor and inductors by a Norton equivalent circuit. 18

Discretization and MNA formulation for boost converter. . . . . . . .

19

Equivalent methods for modeling power switches. . . . . . . . . . . .

22

Inductor and output current comparison. . . . . . . . . . . . . . . . .

24

Thermal model for an IGBT and diode inside the same module. . . .

25

Parallel modeling of electrical and thermal systems. . . . . . . . . . .

27

2.10 Flowchart of the algorithm to compute the power losses.

. . . . . . .

29

2.11 Simulation Results Showing Output of the Power Loss Computation

. . . . . . . . . . . . . . . . . . . . . . .

30

2.12 Typical saturation characteristics for an induction machine. . . . . . .

33

2.13 High level diagram for FPGA implementation of machine model. . . .

35

− 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36 xiii

2.15 Boost converter for real time electro-thermal simulation.

. . . . . . .

37

2.16 Experimental setup for electro-thermal model verification.

. . . . . .

39

2.17 Electro-thermal RT Power Loss Validation.

. . . . . . . . . . . . . .

40

41

42

2.20 Real time results showing the junction temperature of the power devices. 43

2.21 EV traction drive real time HIL example . . . . . . . . . . . . . . . .

43

2.22 HIL results of an EV drive system. . . . . . . . . . . . . . . . . . . .

44

2.23 Saturation characteristics of the machine in Table 2.7. . . . . . . . . .

45

46

Example of regulated loads/CPLs. . . . . . . . . . . . . . . . . . . . .

49

Simplification of a source and power converter load as a CPL. . . . .

50

51

53

Illustration on computing bound α using (3.18) for one CPL. . . . . .

56

Simplified version of the dc microgrid shown in Fig. 1.1 with Q CPLs.

58

64 xiv

65

Robust controller using energy storage to increase robustness margin.

66

3.10 Detailed control diagram for Q = 2 CPLs. . . . . . . . . . . . . . . .

69

3.11 Results of the closed loop system to a short circuit fault in the dc link at t = 0 .

70

MMC single phase structure. . . . . . . . . . . . . . . . . . . . . . . .

72

Equivalent MMC circuit including disturbance.

. . . . . . . . . . . .

74

Equivalent model for circulating current control. . . . . . . . . . . . .

76

Reduced order observer circulating current suppression. . . . . . . . .

79

Implementation of reduced order observer with N = 100 SMs/arm.

The controller is turned on at t = 1 .

1 s. . . . . . . . . . . . . . . . . .

80

Submodule simplification for MMC based on [28]. . . . . . . . . . . .

81

Proposed submodule simplification for real time simulation. . . . . . .

83

Simulation results and comparison of the methods discussed in Section

4.2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

86

87

88

4.11 HIL Validation of controller and efficient modeling methods. . . . . .

89

4.12 HIL results for a single phase MMC with parameters in Table 4.2.

Note: the controller is turned on at t = t

. . . . . . . . . . . . . . . .

91

4.13 HVDC case study based on the Lower Churchill project [10] .

. . . .

92 xv

4.14 Output controller in dq frame for Soldier’s Pond Station. Salisbury

93

4.15 Case study I: Salisbury increments its power from 400 MW to 800 MW. 94

4.16 Case study II: Salisbury reverses its power flow to − 400 MW.

. . . .

95

4.17 Real time simulation results of HVDC systems.

Pond whereas R stands for Salisbury. . . . . . . . . . . . . . . . . . .

97

A.1 T-S Fuzzy formulation . . . . . . . . . . . . . . . . . . . . . . . . . .

111 xvi

Chapter 1: Introduction

1.1

Motivation

Significant advances have been achieved in the electrification of the world over the past centuries. One of these, the induction motor in the late 1800s, became a

catalyst for the widespread adoption of an ac electric grid [56]. One of the reasons

for this adoption is the ability to transmit ac power over long distances as opposed to dc; it was impossible to increase the dc voltage levels at the time. Without the help of power electronics, as a discipline/technology, it seemed inevitable that ac systems dominated.

Nowadays, power electronics provide significant flexibility in the manipulation and/or design of ac and dc systems. Devices such as transistors, thyristors, IGBTs, and MOSFETs allow for the seamless conversion of ac to dc and vice-versa with efficiencies as high as 99%. For this reason, hybrid dc/ac systems are becoming more and more attractive. These new types of mixed power networks are being not only applied to the electric grid, but in “small” isolated microgrids for mission specific applications. Some examples include: Plug-in Hybrid Electric Vehicle (PHEV) charging stations, electric car power systems, more electric aircraft, electric navy ships, etc.

1

Recently, the development of new technologies for power devices, namely SiC and GaN, provides several advantages over Si based devices. Some of these include: higher operating temperature, faster switching frequency, etc. As the switching speed of these devices increases, simulation models must become more and more detailed and lower time steps are needed to accurately capture their dynamics. In addition, the bandwidth of the controllers for the devices can also increase. Therefore, modeling/simulation is an important topic nowadays as well as the stability analysis and controller design of power electronics systems. These topics are necessary and fundamental for the safe operation and adoption of these systems.

1.2

Previous Work

1.2.1

Modeling and Real Time Simulation of Power Converters

In order to help in the introduction and adoption of SiC and GaN to the current market, Real Time (RT) simulation plays a fundamental role in the design and testing of these converters/machines drives. Due to the increase in the switching frequency, the time step of the real time model should be much smaller than the converter’s switching time step, i.e.

T s

T sw

. Currently, typical CPU based real time simulation can only achieve a minimum time step of T s

≥ 10 µ s caused by the large bus latencies in a CPU. In order to decrease this time step as much as possi-

ble, Graphical Processing Units (GPU) provide a viable alternative [33]. Although

GPUs have good parallel processing capabilities, they inherit the same drawbacks as

CPUs. Field Programmable Gate Arrays (FPGAs) have excellent parallel processing capabilities and small bus latencies which make them ideal for fast RT simulation.

Its main disadvantage is the low level programming required.

2

In literature, several papers have studied different methods and approaches for modeling power devices/power systems in FPGA. Two well-known methods include

state space modeling, and Modified Nodal Analysis (MNA) [45, 64]. Moreover, a

state machine to model the characteristics of IGBTs and MOSFETs was discussed in

[63]. In [55], the authors studied the modeling of power converters and ac machines in

FPGA for real time simulation. However, the power converter models were developed using MNA and the ac machines were modeled without saturation. Furthermore, most

literature have implemented these models using fixed point operations [63, 55, 49],

while only a few have presented models using single, double, and/or custom floating

Another important factor in power converter modeling and simulation is their thermal behavior. It is required to maintain these devices within allowable operating temperature. For this reason, modeling of the thermal characteristics of power converters are important during the design and troubleshooting stages. Recent papers have dis-

cussed offline electrical and thermal modeling of power converters [19, 29, 36, 46, 59].

In [19], a thermal model of an IGBT is used in order to compute the junction tem-

perature of the devices based on the calculated power losses. In [29], an algorithm

for offline simulations of the electrical and thermal components of power converters

is studied. Lastly, [59] presented a real time implementation of a thermal model

incorporated to an actual controlled full bridge for temperature monitoring.

In EV drives, typical machines for traction drive include permanent magnet syn-

chronous machine (PMSM), induction machines (IM), and reluctance drives [3, 22].

One of the most important factors which influences the dynamic and steady state response of a machine is saturation. Although this topic has been studied extensively

3

for offline simulations [12, 17], it is considerably new in its implementation for FPGA

real time simulation.

1.2.2

Stability Analysis of Converter Based DC Networks

The recent advancement of power electronics presents a wide range of opportunities in the design of microgrids. These dc networks are composed of multiple generation units and ac/dc loads interconnected together through filters and power

converters. A typical structure of these systems is shown in Fig. 1.1 [21, 53, 54].

Figure 1.1: Detailed dc microgrid of more electric aircraft, navy ships, etc.

The controllers of each source or loads in the dc network are designed to track either a voltage, current, or power reference. Due to the advances in power electronics and digital control, these power converters track the desired signal and reject any disturbances with very high accuracy. However, the high bandwidth of the loads introduce a negative impedance effect as seen from the network’s perspective. This

4

effect is very commonly seen in tightly regulated loads such as inverter motor drive

systems [21, 35], electronic loads, and power supplies [14]. Therefore, typical studies

represent these loads as Constant Power Loads (CPL) [5, 37]. The study of CPLs in dc

power networks is fundamental to automotive [21, 35, 54], marine systems [15, 44, 66],

and aircraft applications [50, 51, 70].

The stability analysis of CPLs has encompassed ac systems as well [4]. During

the early stages, priority was given to the small signal behavior of these systems.

Techniques based on linearization [5] and impedance based criteria [24, 72, 13, 77, 42]

have been largely utilized. However, it is still desired to obtain a better technique for the stability analysis during large signal excursions.

An application of global stability analysis is for filter design. The design of the

filters shown in Fig. 1.1 is typically carried out locally. For example, the EMI filter

may be designed based only on its frequency response. However, these filters, as well as the CPLs, will greatly impact the stability and robustness of the dc microgrids.

As an example, a smaller capacitor connected to a CPL will decrease the stability

margin for the system but a bigger capacitor will increase cost and size [53]. It is

therefore important to study how these parameters impact the global behavior of the system. One way to accomplish this goal is to compute a Region of Attraction (ROA) for an operating point. Different methods of computing an estimation on the ROA have been presented in literature:

1. Mixed Lyapunov functions [5]

2. Takagi-Sugeno (T-S) Fuzzy model [53, 54]

5

4. Reverse trajectory tracking [2]

Among these, the methods based on Mixed Lyapunov functions and Genetic algorithms were shown to be highly conservative while the reverse trajectory tracking method is a graphical approach that is difficult to use in a high dimensional system.

Lastly, the T-S Fuzzy model approach shows good results but its computational complexity grows exponentially with respect to the number of CPLs in the microgrid.

Therefore, it is important to design efficient algorithms to compute the region of attraction considering the overall complexity.

While computing a ROA can be useful for the design of the passive components of the dc microgrid, it is also important to consider the possibility of increasing the

robustness of the system. For example, [14] considers the use of passive damping

filters to stabilize the dc network with CPLs. However, this method will increase the overall cost and size of the system. A different approach is to use control strategies to mitigate the effects of the CPLs with the use of energy storage or the dc source. One

control method considers sliding mode and feedback linearization techniques [21, 71].

However, one drawback is the need to use derivatives which in the presence of noise

may not cancel completely the non-linearity [8]. In [50], a control Lyapunov function

is used to generate a feedback law to stabilize the system. The main drawback of this approach is the need to inject a stabilizing current (modifying the load behavior) at all the CPLs. Therefore, this is still an important problem where different approaches can be of great value.

6

1.2.3

High Voltage DC Networks

The electricity consumption has been increasing rapidly all over the world. The possibility of expanding the ac transmission capacity is either limited by the availability of land or by the huge costs from long distance bulk power transmission. As an alternative, High Voltage dc Transmission (HVDC) is becoming a popular solution.

For transmission distances longer than 700 km, the investment cost of HVDC becomes

lower than HVAC [57]. Moreover, HVDC cables do not have the capacitance problem

of AC cables which makes it possible for long distance underwater transmission [11].

Traditional HVDC systems usually consisted of thyristor based stations with three level converters, point-to-point or back-to-back topologies, connected to strong ac systems. In the 1980s, the concept of Multiterminal HVDC (MTDC) has emerged

and has been studied intensively [43, 58]. MTDC was proven to be feasible in theory,

but in practice only three terminals were realized. Commutation failure was expected when the ac system experience transients such as voltage flicking, which then lead

to the complete shut off of that terminal [73]. A Voltage Source Converter (VSC)

based MTDC does not rely on the ac system voltage to accomplish commutation, and therefore can operate at reduced power mode at such situations. This feature is very helpful in connecting remote renewable energy sources or isolated island systems.

For MTDC applications, Modular Multilevel Converters (MMC) offer several advantages over a typical three phase inverter. For example, higher number of voltage levels help to decrease the ac harmonic content and avoid the need of passive filters.

In addition, each switch has a voltage stress of V sw

= V dc

/N , where N is the total number of sub-modules per arm, making its implementation for HVDC applications more feasible.

7

However, without additional modulation strategy or control for a MMC, an os-

cillation occurs in the circulating current of each phase [74]. This oscillation causes

additional stress on each switch and does not contribute to the active power transfer between the dc and ac side. For this reason, several methods have been proposed in recent years to eliminate this oscillation. Among these, there are controllers based

on abc/dq proportional integral (PI) control [74], proportional-resonant (PR) control

[80, 75], repetitive control [82], and energy based controllers [1, 6]. A problem with

PI, PR, or repetitive controllers is choosing the gains to avoid instability. Tuning these controllers is generally accomplished through transfer function and bode plot analysis. Nevertheless, even if the system appears stable through bode plot, a high

gain might diminish the performance and cause instability [82, 75]. This is unwanted

for a larger scale system such as MTDC which requires the controller to be stable under all possible operation situations including contingencies.

1.3

Organization and Contributions

This dissertation makes several contributions aiding in the implementation of dc microgrids with a case study in HVDC systems.

In Chapter 2, a review of numerical integration techniques and their use in the

modeling and simulation of power electronics based systems is presented. In addition, a change in the formulation of the Thevenin equivalent is proposed in order to include the on characteristics of a power device. With this formulation an electrical/thermal algorithm is proposed and implemented in FPGA for real time simulation. Lastly, a numerical algorithm for the simulation of saturation in an induction machine is discussed and the FPGA based simulation of a motor drive is presented. These two

8

types of loads are very common in dc networks and can behave as CPLs discussed in the following chapter.

In Chapter 3, an introduction to the problem of negative impedance is presented

based on a simplified case with one CPL. A method is proposed to compute the region of attraction of the dc network with multiple CPLs based on a Semidefinite

Programming formulation. Considering the use of energy storage, a robust controller design is then introduced. The goal of this controller is to expand the region of attraction by a desired amount while minimizing the battery effort. Simulation results are presented for a case study with two CPLs. The analysis conducted in this chapter has applications in many types of dc networks ranging from low to high voltage.

In Chapter 4, an introduction to HVDC is discussed. Beginning with MMCs,

a re-formulation of the dynamic equation of the circulating current is proposed. A controller based on an internal model of the disturbance is presented and a practical implementation is shown with a Hardware in the Loop (HIL) validation. Lastly, a platform is presented to simulate MMCs with a realistic number of SMs per arm in a HVDC case with both offline and real time simulation.

Lastly, in Chapter 5, a summary of the dissertation and future work which arises

from it are discussed.

9

Chapter 2: Modeling and Simulation of Power Electronic

Systems

In this chapter a review of different methods are introduced to model and simulate power converters and electric machines. A proposed method to efficiently compute the on characteristics of power devices is presented with applications in electrical/thermal modeling of power converters. In addition, the efficient computation of saturation in an induction machine is presented along with an example for an electric drive system.

The modeling techniques presented in this chapter will be used in the remainder of this dissertation.

2.1

Review of Modeling Methods for Power Electronic Systems

2.1.1

State Space Methods

The modeling of power electronics systems falls in the category of hybrid dynam-

ical systems [27]. In this dissertation, a switching dynamic system is considered to

be of the form:

˙ = f q

( t, x, u ) , x (0) = x

0

(2.1) where x ∈

R n , u ∈

R m , t ∈

R ≥ 0

, and q ∈ Q . The set of “modes” Q represents all the feasible vector fields and it is assumed to be finite. For a typical power converter

10

with N > 1 switches, the set Q = 1 , 2 , ..., 2 N , i.e. there are a total of 2 N different combinations of the switches. For power switches, the modes can be a function of the states and time: q = Φ( t, x, σ ) .

(2.2) where σ is the discrete (e.g. ideal switches) inputs. For example, whether an ideal switch is on/off may only be a function of a discrete external input, whereas a diode depends on the states of the systems. In order to obtain a numerical solution for

(2.1), different types of integration techniques are reviewed.

Explicit Integration

For simplicity, assume that we have an autonomous system of the form:

˙ ( t ) = f ( t, x ) , x (0) = x

0

(2.3) and x ∈

R and t ∈

R ≥ 0

. In general, we would like to approximate the solution or trajectory of the system to a certain time step T s

Z

T s dx =

0

Z

T s

0 f ( τ, x ( τ )) dτ (2.4) which simplifies to: x ( T s

) = x (0) +

Z

T s f ( τ, x ( τ )) dτ.

0

(2.5)

Explicit integration approximates the integral term using only the previous state.

One of the most common methods is Forward Euler (FE), where the integral is approximated as:

Z

T s f ( τ, x ( τ )) dτ ≈ T s f (0 , x (0)) .

0

(2.6)

11

Using this method, the numerical solution at time T s is: x ( T s

) ≈ x (0) + T s f (0 , x (0)) .

(2.7)

The local error for FE can be obtained using Taylor’s theorem: x ( T s

) = x x (0) T s

+ ¨ ( ξ )

T

2 s

2

(2.8) where ˙ (0) = f (0 , x (0)) and some ξ ∈ (0 , T s

). This implies that

|| x ( T s

) − ( x (0) + T s f (0 , x (0))) || =

T s

2

|| ¨ ( ξ ) || .

2

(2.9)

The local error is then commonly denoted as O ( T 2 s

) since it is proportional to T 2 s

.

Obtaining an estimate at x ( T s

) then allows us to repeat this procedure to obtain another estimate at time t

2

= 2 T s

. In general: x k +1

= x k

+ T s f ( t k

, x k

) , k = 0 , 1 , ...

(2.10)

Another condition of interests is the global error.

Assuming x ( t ) are the actual values of x at time t , ˜ ( t ) are the Forward Euler approximations, and the following conditions:

∂f ( t, x ( t ))

∂x

≤ L, || ¨ ( t ) || ≤ M, (2.11) for an arbitrary t

, then the global error is defined as [23]:

|| x ( t ) − ˜ ( t ) || ≤

T s

M

2 L e

L ( t − 0)

− 1 .

(2.12)

From (2.12), the global error for Forward Euler is

O ( T s

) which can be a major drawback of using this method. Lastly, the stability of the continuous system does not

12

implies stability of the discrete approximation. For example, assume that we have a one dimensional linear system of the form:

˙ ( t ) = λx, x (0) = x

0

.

(2.13) and λ is real. The exact solution in this case is x ( t ) = e λt x (0). Thus, if λ < 0 this system will decay to 0 as t → ∞ . Applying Forward Euler we obtain: x k +1

= x k

+ T s

λx k

= (1 + T s

λ ) x k

(2.14) which implies: x n

= (1 + T s

λ ) n x

0 for n = 1 , 2 , 3 , ...

(2.15)

We can see (2.15) as a sequence of numbers

{ x n

} which converges to zero as well if

| 1 + λT s

| < 1 ⇒ T s

2

<

| λ | assuming λ < 0 .

(2.16)

In other words, using Forward Euler, the time step must be sufficiently small in order to guarantee the numerical approximation of an asymptotically stable system converges to 0.

A summary of a few explicit integration methods and their errors is shown in

Tab. 2.1. It should be noted that in order to decrease the local and global error the

computations increase as well.

Implicit Integration

Implicit integration methods not only use past approximations of x ( t ), but may use the present values as well. A common example is the Backward Euler (BE)

method. Using (2.3), the approximation of the solution at time

t = T s by BE is given

13

Table 2.1: Summary of explicit integration methods.

Method Procedure

Forward Euler x k +1

= x k

+ T s f ( t k

, x k

)

Midpoint Method x k +1

= x k

+ T s f t k

+

T s

2

, x k

+

T s

2 f ( k, x k

)

Heun’s Method w = 3 f t k

+

2 T s

3

, x k

+

2 T s

3 f ( t k

, x k

) x k +1

= x k

+

T s

4

[ f ( t k

, x k

) + w ]

Runge Kutta 4 w

1

= T s f ( t k

, x k

) w

2

= T s f t k

+

T s

2

, x k

+

1

2 w

1 w

3

= T s f t k

+

T s

2

, x k

+

1

2 w

2 w

4

= T s f ( t k

+ T s

, x k

+ w

3

) x k +1

= x k

+

1

6

( w

1

+ w

2

+ w

3

+ w

4

)

Loc. Error Glob. Error

O ( T 2 s

)

O ( T 3 s

)

O ( T

O ( T s

2 s

)

)

O

O

(

(

T

T

3 s

5 s

)

)

O ( T

O ( T

2 s

4 s

)

) by: x ( T s

) ≈ x (0) + T s f ( T s

, x ( T s

)) .

This sequence converges to 0 if:

1

| 1 − T s

λ |

< 1 ⇒ | 1 − T s

λ | ≥ 1 .

14

(2.17)

The main challenge in solving (2.17) is that the term

f ( T s

, x ( T s

)) is not known. To obtain ˜ ( T s

) for nonlinear systems, an iteration technique such as Newton-Raphson can be employed.

Considering the same linear system as (2.14) and employing BE we obtain:

x k +1

= (1 − T s

λ )

− 1 x k for k = 0 , 1 , ...

(2.18) or x n

= (1 − T s

λ )

− 1 · n x

0

.

(2.19)

(2.20)

Table 2.2: Summary of implicit integration methods.

Method Procedure

Backward Euler x k +1

= x k

+ T s f ( t k +1 k, x k +1

)

Trapezoidal x k +1

= x k

+

T s

2

( f ( t k

, x k

) + f ( t k +1

, x k +1

))

Midpoint Method x k +1

= x k

+ T s f ( t k

+

T s

2

,

1

2

( x k

+ x k +1

))

Loc. Error Glob. Error

O ( T 2 s

)

O ( T 3 s

)

O ( T 3 s

)

O ( T s

O ( T 2 s

O ( T 2 s

)

)

)

This implies that if λ < 0 (asymp. Stability), then the BE numerical approximation also decays as k → ∞ ! This property of the BE method is known as A-stability. A summary of implicit integration methods and its local and global errors is shown in

Boost Converter Example

A hybrid dynamical system can be constructed for a discontinuous boost converter. In this circuit the inductor current is not allowed to be negative due the diode.

The circuit is shown in Fig. 2.1. Let

x

1

, i l

, x

2

, v c

, u

1

, v dc

> 0 be the inductor

Figure 2.1: Boost converter with discontinuous mode.

15

Figure 2.2: Hybrid automaton for a discontinuous boost converter.

Figure 2.3: Results showing the different modes for a boost converter.

current, the capacitor voltage, and the input voltage respectively. Then the hybrid system can be described by the following:

16

• Q = { 1 , 2 , 3 } (set of modes)

• X =

R

2 (state space)

• The vector fields are: f

1

( x, u ) =

1

1 u

− l rc

1 x

2

, (switch on) f

2

( x, u ) =

− 1 l

1 c x x

1

2

−

+

1 rc

1 l u x

2

1

, (switch off-cont. current)

f

3

( x, u ) =

0

− 1 rc x

2

(switch off-disc. current)

The discrete input, σ = s is the switching signal of the IGBT. The transitions from

system was implemented using Forward Euler integration as described in the previous subsections.

2.1.2

Modified Nodal Analysis

Modified Nodal Analysis (MNA) is a very popular method for simulating power

electronics/systems. Nodal analysis was first introduced by H. W. Dommel [18] to

describe a method of finding the time response of electromagnetic transients in arbitrary networks. Other important contributions to the development of MNA were

presented by C. Ho [31] and more recently by J. Mahseredjian [52].

The MNA represents dynamic elements of circuits by a Norton equivalent as shown

Y x

, and current source (also known as history term), j x

, for an inductor/capacitor depends on the type of integration method used. For

17

(a) Inductor and capacitor elements.

(b) Norton equivalent.

Figure 2.4: Representation of capacitor and inductors by a Norton equivalent circuit.

example, beginning with the dynamic equation for an inductor: v l

= L di dt l and using BE

(2.21) i l

( t ) =

T s v l

( t ) + i l

( t − T s

)

L it is possible to see that

Y l

,

T s

L and j l

( t − T s

) , − i l

( t − T s

) .

(2.22)

(2.23)

A summary of the admittances and history terms for inductor/capacitors using BE

and Trapezoidal integrations is shown in Table 2.3.

Using this Norton representation for inductors/capacitors, the numerical integration (using implicit methods) for a certain circuit becomes the solution of a linear system of the form:

Ax k +1

= u k for k = 0 , 1 , ...

(2.24) where the vector x ∈

R n + m contains the voltages at each node ( n nodes) in a circuit as well as certain branch currents (defined by m voltage sources) and u contains the

18

(a) Actual circuit model.

(b) Discretized boost converter model.

Figure 2.5: Discretization and MNA formulation for boost converter.

history and input terms. For linear circuits containing only independent sources, the matrix A is of the following form:

A =

Y B

B T 0

(2.25) where Y ∈

R n × n is the admittance matrix and B ∈

R n × m is a matrix of 1s and 0s depending on the connection of independent voltage sources.

Example for Boost Converter

Consider a typical boost converter as shown in Fig. 2.5a. This passive components

are first replaced by the Norton equivalent form and the switches are modeled by a

Table 2.3: Norton equivalent elements for MNA.

Element Y x

(BE)

L

C

T

L

C

T s s j x

(BE)

− i l

( t − T s

)

C

T s v c

( t − T s

)

Y x

(Trap.)

T

2

2

T s

L

C s j x

(Trap.)

− i l

( t − T s

) +

T s

2 L v l

( t − T s

) i c

( t − T s

) +

2 C v c

( t − T s

)

T s

19

varying resistance (large off resistance/small on resistance). The equivalent network

Using the MNA, we can solve this system as follows:

Y

L

− Y

L

0

0

0

1

− Y

L

Y

L

+ Y rL

− Y rL

0

0

0

j

L

− j

L

0

0

j

C

V dc

0

− Y rL

Y rL

+ Y s 1

+ Y s 2

− Y s 2

0

0

0 0 1

v

1

−

0

Y s 2

0

0

0

0

Y

R

+ Y s 2

+ Y rC

− Y rC

0

− Y rC

Y rC

+ Y

C

0

v

v

3

2

v

4

v

5

0 0 0 i dc

=

(2.26) or in more compact form:

A q x k +1

= u k

.

(2.27)

Notice that the matrix A is time-varying, due to the representation of the switches as a small on resistance/large off resistance. To solve for x it is typically necessary to compute the inverse of A q such that x k +1

= A

− 1 q u k

. However, since A is commonly sparse, an LU decomposition for A is preferred in practice whenever it is not feasible to store all possible A

− 1 (e.g. when the number of switches is very large). Using this

LU decomposition, the solution becomes:

L q

U q x k +1

= u k

⇒ L q y k +1

= u k

U q x k +1

= y k +1

(2.28)

That is, we can solve two sets of linear equations by using forward and backward

20

2.2

Proposed Electrical/Thermal Modeling

This section presents a method to efficiently compute the on characteristics of the switching devices. Based on this approach, an electro-thermal algorithm for parallel modeling of power converters is proposed.

2.2.1

Electrical Model

The method introduced by Pejovic [64] represents a switch as a resistor and current

source in parallel as shown in Fig. 2.6a. By letting the resistor be a constant value,

the current source is changed as follows:

J

N

=

( i k

− G

N v k if s k +1

= 1 if s k +1

= 0

.

(2.29)

Studying the equivalent equations of the circuit in Fig. 2.6a, we can see that the

switch is represented as a small inductor when on and a small capacitor when off.

The value of the capacitance/inductance depends on the type of integration method

used. In [64], Backward Euler was the recommended method due to its decreased

in transient oscillation as opposed to Trapezoidal integration. Using BE, the capacitance/inductance values are:

L = T s

R, C =

T s

R

(2.30)

From (2.30), the following relations can be obtained:

L ∝ R and C ∝ 1 /R . Therefore, there is always a trade-off when choosing R , a smaller R implies a small inductance

but larger capacitance. For small time steps (ns range) it is typically chosen as 1 [64].

Deriving the nodal equations for a complete converter, the system is of the form:

Ax k +1

= u k

⇒ x k +1

= A

− 1 u k

21

(2.31)

(a) (b)

Figure 2.6: Equivalent methods for modeling power switches.

where A, A

− 1 matrices are constant. The current sources for each switch J

N are a component of the input vector u k

.

This method is equivalent to using a ‘Thevenin’ representation shown in Fig. 2.6b

[78]. In this case, the voltage source is represented as:

E

TH k +1

=

(

− R

TH i k v k if s k +1

= 1 if s k +1

= 0

.

(2.32)

Analyzing the on behavior of the Thevenin representation, the equivalent voltage is:

V eq k +1

= E

TH k +1

+ R

TH i k +1

= − R

TH i k

+ R

TH i k +1

(2.33)

We can see that when i k

= i k +1

(i.e.

i is in steady state) V eq

= 0. The on characteristics of a power device are governed by its on resistance r on and forward voltage v f

. In order to include these characteristics into (2.33) as an input to the

system, we can let the new voltage source E

TH be:

E

TH k +1

= − R

TH i k

+ r on i k

+ v f k

(2.34) where it is clear the on steady state is V eq

= r on i + v f

. This proposed representation

22

is particularly useful in the case where r on and v f are a function of the current and device junction temperature. Since they are input to the system, the A

− 1 matrix is still constant. The on parameters, r on

( i, T j

) and v f

( i, T j

), are nonlinear terms and need to be re-computed after every time step. Using conventional MNA, the matrix

A

in (2.31) would have to be re-computed as well as its inverse or

LU matrices at each time step.

Compared to a (hybrid) state space approach, the nonlinear parameters r on and v f also imply the need to recompute the system and input matrices in x k +1

= A j

( x, u ) x k

+ B j

( x, u ) u k for j = 1 , ... , 2 N and N switches during each time step.

To validate the previous method, a circuit simulation using Matlab SimPower

Systems was performed with the parameters shown in Table 2.4. Using SimPower

Systems, the on resistance and forward voltage were incorporated into the switch and diode respectively. The results of this simulation were then compared with the

Table 2.4: Simulation parameters for circuit and proposed model validation.

L r on

T s

1 mH

10 mΩ

1 µ s

V f

F sw r load

1 V

1000 Hz

2 Ω

C

V dc

1 mF

10 V

23

Figure 2.7: Inductor and output current comparison.

proposed method by using (2.35):

R

L

+ r l

E

E

0 i

TH d

TH

J cap

1 0

i

L

− R i

TH

0

0

R

− i

TH

R d

TH

1

1

1 0 − ( G c

0

− 1

+

1 r load

)

i d v sw

v out

=

V in

− E thL

(2.35) where R

L

=

L

T s

, G c

=

C

T s

, J cap

= − G c

V n out

, and E thL

= − R

L i

L k

. Lastly, the voltage input for the IGBT is given by:

E i

TH k +1

=

(

− R i

TH

( i

L k

− i v sw k d k

) + V ce k if s i k +1 if s i k +1

= 1

= 0

(2.36)

24

and for the diode:

E d

TH k +1

=

(

− R d

TH

( i d k

) + V f k v sw k

− v out k if s d k +1 if s d k +1

= 1

= 0

The diode’s on state is decided by:

.

s d k +1

= s d k

( i d k

≥ 0) + ¯ d k

(( v sw k

− v out k

) > V f k

)

(2.37)

(2.38)

Fig. 2.7 shows a comparison between these two results where the green curve repre-

sents the results if r on and v f were to be ignored.

2.2.2

Thermal Model

The thermal behavior of a switch from its junction temperature to the case is typically specified in the data sheet. Since the junction temperature is given by

T j-c

= Z th, j-c

P loss

, (2.39) there exists an analogy between this equation and a regular circuit representation where P loss

↔ I in and T j-c

↔ V j-c

. For this reason, the junction to case impedance

Figure 2.8: Thermal model for an IGBT and diode inside the same module.

25

Z th, j-c

, the case to fin Z th, c-f

, and the fin to ambient Z th, f-a are specified as RC networks.

The complete thermal model for an IGBT and diode inside the same module or

case is presented in Fig. 2.8. Notice that this system can be represented as

˙ ( t ) = A th x ( t ) + B th u ( t ) y ( t ) = C th x ( t ) + D th v ( t ) (2.40) where the matrices A th

, B th

, C th

, and D th are

A th

B th

= Diag

=

1

C i

1

.

..

C

1 i

N

0

.

..

0

1

C c-f

1

C f-a

− 1

, ...,

τ i

1

0

−

τ i

N

1

,

−

τ d

1

1

, ...,

−

τ d

N

1

.

..

0

1

C d

1

.

..

1

C d

N

1

C c-f

1

C f-a

1 · · · 1 0 · · · 0 1 1

,

− 1

R c-f

C c-f

,

R f-a

C f-a

−

1

1

C th

=

0 · · · 0 1 · · · 1 1 1

0 · · · 0 0 · · · 0 1 1

, D th

0 · · · 0 0 · · · 0 0 1

=

1

1

1

(2.41) where τ

α q

= R

α q

C

α q for q ∈ { 1 , ..., N } and α ∈ { i, d } .

The states x = T i

C 1

... T i

CN

T d

C 1

... T d

CN

T

C c-f

T

C f-a

>

, u = P d

P i

>

, v = T a

, and y = T j i T j d T

C

T f

>

. The total power losses for the IGBT and diode, P i and P d respectively, are computed based on the conduction and switching losses of each device. The conduction losses will be taken into account using the approach discussed in the previous subsection. Therefore, for an actual IGBT (superscript i ) and diode

26

(superscript d )

P

α cond

= i

α v f

α

( i

α

, T j

α

) , where α ∈ { i, d } .

(2.42)

These conduction losses are included in the electrical model and the forward voltage will be modified depending on i and T j through each device. To take into account the switching losses in the electrical model will require detailed knowledge of the device.

For example, the leakage inductances of the device affect the transient response at different levels. Since a highly elaborate model of the device increases complexity and overall time step, the switching losses will be calculated using the device datasheets

[29]. The switching energy is usually given for an IGBT as follows:

E i sw

= E i sw − on

+ E i sw − off and the total switching losses can then be computed as:

P i sw

= E i sw

F sw

2.2.3

Algorithm

(2.43)

(2.44)

Motivated by the results presented in the previous subsections, an electro-thermal

algorithm is shown in Figs. 2.9 and 2.10. Note that in Fig. 2.9, an external PWM

Figure 2.9: Parallel modeling of electrical and thermal systems.

27

signal is fed to the power loss block. This signal represents the total time for which the power losses are averaged. Thus if T s-epwm

= T sw

, the program is averaging the power losses over one complete switching cycle. However, if T s-epwm

< T sw then the power losses are updated more frequently and the total losses will have a ripple based on the on current through the device.

The flowchart representing the power loss computation algorithm is composed of three main parts:

1. Switching loss counter C α sw − on

, C α sw-off

.

2. On current addition i α tot

.

3. Forward voltage and power loss computation.

The superscript α = 1 , ..., N implies that each parameter needs to be computed for N switches in a circuit. Although the algorithm is averaging the power losses for a period of T e-pwm

, it runs at the same time step as the electrical circuit model T s

.

For the same boost converter shown previously, this algorithm is applied to compute the power losses and thermal model. The simulation results are shown in Fig.

T e-pwm

= T sw which can be inferred from the power loss waveform.

Lastly, since the conduction losses are taken into account by updating the forward voltage and on resistance in the electrical model, the switching losses should be taken into account as well to achieve power balance.

The power is:

P in

= P out

+ P cond

+ P sw

.

(2.45)

28

Figure 2.10: Flowchart of the algorithm to compute the power losses.

Thus [29] explains the addition of a current source in parallel to the input voltage of

the converter. This current will have a value as:

I sw

=

P sw

V in

(2.46)

and power balance (2.45) can be achieved. The RT implementation and validation of

the results presented will be shown in Section 2.4.

2.3

Modeling of Electric Machines

The development of dynamic models for electric machines has been studied for the past several decades. These models can be categorized by the choice of coordinate

29

Figure 2.11: Simulation Results Showing Output of the Power Loss Computation

Algorithm with T s-epwm

= T sw

.

systems upon which is studied and the choice of state variables (e.g. flux linkage or current). The phase domain model uses three phase coordinates, abc , to represent the state variables. The second uses a combination of phase and quadrature axis variables, for example stator quantities are modeled in phase domain and rotor variables are modeled in dq domain. This method is known as Voltage Behind Reactance. The last method uses dq

coordinates to represent all the variables [76].

For RT implementation, the dq model offers several advantages such as static inductance parameters and a lower order system. For this reason, it is one of the most commonly used machine models. For an induction motor, its dynamics in dq frame are given by: v sr dq

= pλ sr dq

+ Ω λ sr dq

+ R i sr dq

(2.47)

30

where p := d dt

, Ω , R ∈

R

4 × 4 , v sr dq

, λ sr dq

, i sr dq

∈

R

4 . The matrices Ω , R are as follows:

0 − ω 0

Ω =

ω 0

0 0

0

0

0 0 ( ω − ω r

)

R = Diag ( r s

, r s

, ¯ r

, ¯

∗ r

)

0

0

− ( ω − ω r

)

0

(2.48) where ω is the angular speed of the reference frame ( ω = 0 for stationary frame) and ω r is the rotor angular speed. In addition, these matrices assume the vectors

λ sr dq

, i sr dq

, and v sr dq are of the form x sr dq

= x s d

, x s q

, ¯ r d

, ¯ r q

> where x = λ, i, or v .

One of the most influential elements which affect the machine dynamic response

is core saturation. However, the model in (2.47) does not consider saturation in the

mutual inductance. Although several studies of modeling electric machines in FPGA

have been presented in literature, e.g. see [63, 55, 61], very few have modeled these

with saturation characteristics. For this reason, we briefly review what has been done to account to model saturation in FPGA and present implementation of these characteristics using a mathematical derivation.

2.3.1

Saturation Modeling

Saturation of an inductor occurs when its core can no longer store magnetic energy.

For example, a typical B-H curve gives a good representation of saturation as the magnetic field strength ( H ) increases and the flux density ( B ) remains constant. The main effect of saturation in an ac machine occurs in its mutual inductance L m

. The leakage inductances of the stator and rotor remain in air for a significant part of their path and thus saturation does not often occur.

31

FEA Methods

Recent studies focuses on using Finite Element Analysis (FEA) to simulate sat-

uration for a three phase machine, particularly PMSM [32, 20]. The machine is

designed using a FEA software such as JMAG [34] and the saturation characteris-

tics are stored in look-up tables. For FPGA implementation, these tables are then a function of different currents i d

, i q and rotor position θ r

. These tables need to be quite dense and/or include interpolation techniques in order to avoid any large jump discontinuities. This can then be major drawback causing incorrect transient behavior.

Mathematical Method

Typical saturation characteristics for an induction machine is shown in Fig. 2.12.

We assume that the magnetizing flux and current are complex quantities described

in polar coordinates as follows [12]:

λ m

( | λ m

| , µ ) = | λ m

| e jµ i m

( | i m

| , µ ) = | i m

| e jµ

(2.49)

(2.50)

Since there is a one to one relationship between | λ m

| and | i m

| : d | λ m

| dt

= d | λ m

| d | i m

| d | i m

| dt

= L y d | i m

| dt

(2.51) where L y

:= d | λ m

| d | i m

| is defined as the ‘dynamic inductance.’

The following two equations are derived from the derivative with respect to time of λ m

i m

(2.50), and separating it into its real and imaginary parts (denoted

32

Figure 2.12: Typical saturation characteristics for an induction machine.

by subscripts d and q respectively): dλ md dt dλ mq dt

= L dd di md dt

= L qd di md dt

+ L dq di mq dt

+ L qq di mq dt

The new inductance parameters are:

(2.52)

L dd

:= L y cos

2

( µ ) + L m sin

2

( µ )

L qq

:= L m cos

2

( µ ) + L y sin

2

( µ )

L dq

= L qd

:=

L y

− L m

2 sin(2 µ ) .

(2.53) where L m

= | λ m

| / | i m

| (note that it is not constant) and µ = tan

− 1

( i mq

/i md

). The terms L dd and L qq correspond to saturation in their own axis, whereas the terms

L dq

= L qd are cross saturation terms. It is also clear to see that during the linear region

(unsaturated) L y

≡ L m and these equations are identical to the classical unsaturated model of a three phase induction machine.

33

By incorporating (2.52) into (2.47), we can redefine the equations for an induction

machine in a stationary reference frame as: v sr dq

= R i sr dq

+ ΩL r i sr dq

+ L p i sr dq

(2.54)

The matrices L ( | λ m

| , µ ) and L r

( | λ m

| ) vary based on the saturation parameters and are defined as follows:

L =

L ls

+ L dd

L

L

L dq dd dq

L ls

L

+

L

L dq dq qq

L qq

0 0 0

L r

=

0 0 0

0 L m

− L m

0 − ( L lr

0

+ L m

)

L lr

L

L

+ dd dq

L dq

L dd

L dq

L

L qq dq

L lr

+ L qq

0

( L lr

0

+ L m

)

0

(2.55)

Thus (2.54) constitutes the new

dq model of a three phase induction machine including saturation. The same idea is followed to derived saturated models for other types of machines.

2.3.2

Computational Algorithm

The saturation model presented in the previous subsection only requires knowledge

of the saturation curve, such as the one in Fig. 2.12. Therefore, this curve can be

represented as:

| λ m

| ( | i m

| ) =

(

L m

| i m

| for | i m

| < | i mc

| f

˜

( | i m

| ) | i m

| for | i m

| ≥ | i mc

|

(2.56)

L m is the slope of the linear region, and ˜ ( | i m

| ) | i m

| is a (interpolated) function describing the nonlinear saturated region. In order to make sure there is a smooth transition between the unsaturated to saturated region or vice versa, it is required

34

Figure 2.13: High level diagram for FPGA implementation of machine model.

that the function | λ m

| ( | i m

| ) ∈ C 1 , i.e. continuous and with continuous first derivative.

This will ensure that at the point | i mc

| , L m

( | i mc

| ) = L y

( | i mc

| ).

For the FPGA implementation, (2.54) should be transformed into state space form

as: di sr dq dt

= L

− 1

( − R − ΩL r

) i sr dq

+ L

− 1 v sr dq

.

(2.57)

This model is then discretized using typical methods such as Implicit Backward Euler,

Trapezoidal, Runge Kutta, etc. The choice of method depends on the system to be studied. Since the time step used in FPGA is in the ns range, Forward Euler’s method simplifies computation over other integration methods. The percent difference compared with Runge Kutta is < 1 % for a wide range of machine parameters. Thus: i k +1

= ( I + T s

A ) i k

+ T s

B v k

(2.58) for A = L

− 1 ( − R − ΩL r

) and B = L

− 1 .

However, several challenges arise from (2.58): the matrices are time varying, non-

linear, and L

− 1 need to be computed at every time step. A general procedure for

35

the computation of the induction machine system with saturation is shown in Fig.

2.13. There are different options to compute

L

− 1 at every time step. Since it is a symmetrical matrix, a Cholesky decomposition could be used. However, we can see that although this matrix is a function of µ and | I m

| , it is found that the det ( L ) is independent of µ : det ( L ) = d

1

( L m

+ L y

) + d

2

L m

L y

+ d

3

(2.59)

Figure 2.14: Computation of L

− 1 .

where d

1

, d

2

, d

3 are constants defined as d

1

:= L

2 ls

L lr

+ L ls

L

2 lr d

2

:= L

2 ls

+ L

2 lr

+ L ls

L lr d

3

:= L

2 ls

L

2 lr

.

36

(2.60)

It can be seen from (2.59) that det(

L ) = 0 ∀ t . Thus, the matrix L is always non-

singular. Taking advantage of (2.59), the matrix inverse is then computed by calcu-

lating the determinant and the adjoint matrix in parallel , i.e.

L

− 1 = L

∗

/ det ( L ). The

procedure is outlined in Fig. 2.14.

(a) Electro-thermal boost converter.

(b) Equivalent circuit in MNA and Thevenin equivalent.

Figure 2.15: Boost converter for real time electro-thermal simulation.

2.4

Electro-Thermal Algorithm Validation

In order to demonstrate the electro-thermal algorithm discussed in Section 2.2, a

model of a boost converter is built in a real time simulator as shown in Fig. 2.15.

37

2.4.1

Hardware Description

Real Time Platform

An Opal RT based platform is used in order to simulate the described electro-

thermal model in real time [60]. This platform utlilizes a Xilinx Virtex 6 FPGA in

order to model the system. The analog to digital converter (ADC) has a time rate of 2 .

5 µ s, the digital to analog converter (DAC) 1 µ s, and the digital input/output

(DIO) has a refresh rate of 0 .

2 µ s.

Power Electronics Platform

The boost converter is built based on a Powerex PS22A78-E IPM [65].

To accurately measure the power losses, a Yokogawa WT3000 power meter was used

[79]. The dc power supply is a Magna Power TS1500-16.5. The controller is a TI

TMS320F28335 and is used to send the gating signals to the converter. The experi-

mental setup is shown in Fig. 2.16.

2.4.2

Model Description

The main difference between the boost converter in Fig. 2.15a and the one in

Section 2.2 is the introduction of the current source

i sw

The equations for this circuit are similar to (2.35).

The values of the inductor, capacitor, thermal model, etc. Are shown in Tables

2.5 and 2.6. These values are based on the actual power converter parameters. In

order to compute the forward voltages for the IGBT and diode, a surface fit was used

38

based on the device datasheet v f i

T j i

, i on i

= 0 .

8433 + i i on

0 .

02905 + 5 .

818e

− 5

T j i v d f

T j d

, i d on

= 1 .

023 + i d on

0 .

03469 − 5 .

896e

− 5

T j d

(2.61)

Figure 2.16: Experimental setup for electro-thermal model verification.

Table 2.5: Power converter electrical parameters.

L r l

R [40 330] Ω F sw

T s

13 mH

200 ns P in

0.463 Ω C

10800 Hz V in

[600 4500] W d

1.1 mF

[200 325] V

[30 40] %

The same procedure is applied to the switching energy of the IGBT E i sw

. Lastly, the diode switching losses due to its reverse recovery current are assumed to be

39

Table 2.6: Thermal parameters.

R

1

C

1

R

2

C

2

IGBT 0.1568

0.0409

0.3814

0.2474

R

3

0.2318

Diode 0.2546

0.02519

0.6191

0.1524

R c-f

C c-f

R f-a

0.245

0.1405

0.175

0.3763

C f-a

T a

1333 [20 23 .

6] o C

C

3

3.7644

2.3189

Figure 2.17: Electro-thermal RT Power Loss Validation.

constant at P d sw

= 3 W.

The time steps of the boost converter, the power loss algorithm, and the thermal model are T s

= 200 ns.

40

2.4.3

Experimental and Real Time Results

Fig. 2.17 presents a comparison of the RT calculated power losses at different

input current against the actual power converter power losses. We can see that the algorithm closely matches the experimental values.

To test the validity of the electrical circuit, we perform a change in the input voltage from 300 V to 325 V. A comparison of the experimental and real time results

are shown in Fig. 2.18. It can be seen that the real time model follows well the

experimental results.

(a) Experimental resuls (b) Real Time results

Figure 2.18: Comparison of the experimental and real time results by a change in voltage input.

The next step involves validation of the thermal model. The input voltage is changed from V in

= 200 V (1.03 kW) to V in

= 325 V (2.73 kW). In this case, the losses in the IGBT and diode will contribute to rise in the heatsink temperature.

Validating this rise in temperature will also give an indication of the calculation of

41

the IGBT and diode power losses. The results of the experimental and real time

waveforms are shown in Fig. 2.19.

Lastly, in Fig. 2.20, a duty cycle step change is introduced to the system to show

the estimated junction temperatures of the IGBT and diode in real time.

Figure 2.19: Comparison of a change in power to validate algorithm and thermal model.

2.5

Real Time Simulation of an EV Drive

An FPGA model of a three phase induction machine with saturation is modeled

using procedure outlined in Section 2.3. The complete setup is shown in Fig. 2.21.

In order to control the EV drive, an external Wanda 3U target machine running a

Linux operating system is used [60].

42

Figure 2.20: Real time results showing the junction temperature of the power devices.

Figure 2.21: EV traction drive real time HIL example

43

2.5.1

Model and Saturation Characteristics

| i mc

| =

1 .

25 A, the inductances L m

( | i mc

| ) = L y

( | i mc

| ).

(a) System response to step input.

(b) HIL Closed loop speed control

Figure 2.22: HIL results of an EV drive system.

44

2.5.2

Real Time Results

The achieved time step of the EV drive without saturation is T unsat s

= 200 ns and with saturation is T sat s

= 650 ns. The results of the system are shown in Fig. 2.22.

One of the advantages of a fast simulation time step, is the possibility of running

the model at higher switching frequencies. In Fig. 2.22a, the inverter is switching at

F sw

= 24 kHz. In here, rated voltage is applied to the machine without closed loop control.

In Fig. 2.22b, vector control is used to regulate the machine speed and

(a) Mutual Flux (b) Dynamic and static Ind.

Figure 2.23: Saturation characteristics of the machine in Table 2.7.

Table 2.7: Real time EV drive simulation parameters.

R s

L ls

V dc

T unsat s

1 .

97 Ω

200 ns

R r

10 .

23 mH L lr

800 V F sw

T s sat

2 .

82 Ω

8 mH

J

[2 24] kHz P m

650 ns T s-cpu

0 .

11 kgm 2

0 .

598 mH

2

25 µ s

45

Figure 2.24: Results for the machine with input voltage fundamental frequency of f = 30 Hz.

flux. The details of the control can be found in [7]. The impact of the saturation

in the magnetizing flux to the controller is part of future study. The saturation of

the motor is illustrated in Fig. 2.24. It is possible to see that the starting electro-

mechanical torque for the saturated conditions has a lower magnitude than the one for the saturated one. Furthermore, the torque frequency and phase are not affected

by the saturation validating previous results in saturation modeling [12, 38, 17, 39].

2.6

Conclusion

A platform for modeling detailed power converters and electric machines geared towards EV applications was developed. A switch representation including the on

parameters was proposed in Section 2.2. Using this switch representation, an algo-

rithm for electro-thermal modeling of power converters was presented. In addition, this model was validated using a Powerex PS22A78-E IPM.

46

Furthermore, a mathematical derivation was presented to model the saturation and cross-saturation effects in an induction machine. An algorithm to compute L

− 1 was presented to decrease the simulation time step. Lastly, an example was presented to show a comparison of saturated and unsaturated machine conditions. Using the previously discussed methods, a case study of an EV drive using an induction machine was modeled in FPGA at T s sat

= 650 ns and T unsat s

= 200 ns. A comparison of the saturated and unsaturated model was presented showing the importance of modeling saturation.

47

Chapter 3: Stability Analysis of DC Networks

In this chapter, the negative impedance/Constant Power Load (CPL) behavior of power electronics based loads dc networks will be studied in detail. Several examples will be discussed at the beginning of this chapter to illustrate the types of conditions/loads that will behave as CPL. A method based on Semidefinite Programming

(SDP) is then proposed to compute the region of attraction of systems with multiple

CPLs. Lastly, a controller design based on a similar SDP is proposed to increase the robustness of dc networks.

3.1

Examples of CPLs

The study of CPLs has encompassed both ac and dc systems [4]. These types of