Integrated Power Electronics Using a Ferrite Based Low

Integrated Power Electronics Using a Ferrite-Based

Low-Temperature Co-Fired Ceramic Materials System

Abstract

This paper discusses a new approach to making hybrid power electronic circuits by combining a low-temperature

(850°C to 950°C) co-fired ceramic (LTCC) substrate, planar

LTCC ferrite transformers/inductors and integrated passive components into a multilayer monolithic package using a ferrite-based LTCC material system. A ferrite tape functions as the base material for this LTCC system. The material system includes physically and chemically compatible dielectric paste, dielectric tape and conductor materials which can be co-fired with the base ferrite LTCC tape to create sintered devices with excellent magnetic coupling, high permeability (~400), high resistivity (> 10 12 Ω ·cm) and good saturation (~0.3 T). The co-fired ferrite and dielectric materials can be used as a substrate for attaching or housing semiconductor components and other discrete devices that are part of the power electronics system. Furthermore, the ability to co-fire the ferrite with dielectric and conductor materials allows for the incorporation of embedded passives in the multilayer structure to create hybrid power electronic circuits.

Overall this thick film material set offers a unique approach to making hybrid power electronics and could potentially allow a size reduction for many commercial dc-dc converter and other power electronic circuits.

Introduction

Alex Roesler, Josh Schare and Chad Hettler

Sandia National Laboratories

Albuquerque, NM

Dave Abel, George Slama and Daryl Schofield

NASCENTechnology

Watertown, SD

Magnetic components, namely inductors and transformers, are necessary for most commercial power electronic circuits such as point-of-load (PoL) converters. Often the magnetic components represent some of the largest and most expensive parts in these circuits. With the continual push to shrink the size and cost of commercial electronic devices, numerous research efforts over the past decade have focused on new materials and manufacturing techniques to help address these limitations. Examples range from low profile magnetic cores with conventional wire wound technology; to integrating planar transformers and embedded passives into the substrate of a printed circuit board (PCB) [1]-[6]; to thick-film inductors and transformers using screen-printed ferrite pastes

[7] and [8] or LTCC ferrite tape [9]-[29]; to using microfabrication and thin film techniques to incorporate inductors and transformers directly on silicon alongside integrated circuits (ICs) for integrated dc-dc converters [30]-

[35]. Most of these approaches look to increase power

The present work involves a new system-in-package approach for power electronic applications that combines an

LTCC substrate, planar LTCC ferrite transformers/inductors and integrated passive components into a multilayer monolithic package using a ferrite-based LTCC material system. A ferrite tape functions as the base material for this

LTCC system. The material system includes physically and chemically compatible co-fired ferrite, dielectric and conductor materials that can be prepared in paste or tape format. This material system correspondingly allows for the ferrite magnetic component(s) to be integrated directly with dielectric substrate materials in a multilayer structure. To date there has been limited research on LTCC materials systems that allow integration of both dielectric tape and ferrite tape within a single co-fired monolithic composite

[19]-[21],[23][28][29]. The ability to co-fire both dielectric and ferrite tape can provide performance advantages for hybrid or system-in-package power electronics. For example, the use of LTCC ferrite tape as a substrate for mounting discrete components can lead to performance degradation due to the high parasitic inductance created by locating traces on top of a ferromagnetic material [15]. In [15] this was addressed by incorporating magnetic shields between the buried magnetic component and the external circuitry, which required a discrete LTCC dielectric substrate that was fired separately from the LTCC ferrite structure that contained the embedded magnetic component. A co-firable dielectric tape allows direct integration of metal shields between buried ferrite layers and the external surfaces of the co-fired composite structure. In addition, a dielectric paste and/or tape that can be co-fired with the LTCC ferrite can allow both magnetic and capacitive devices to be embedded within the substrate. Finally, co-firable ferrite and dielectric materials can also be combined to create sintered ferrite devices with excellent magnetic coupling and high resistivity (> 10 12

Ω •cm) [9]-[12].

Co-Fired Ferrite and Dielectric Material Properties

The co-firable material set used in this study includes three different LTCC ferrite tapes based on NiCuZn compositions, a dielectric tape, two dielectric pastes, a buried silver conductor paste, a via-fill silver conductor paste, and an external silver solderable conductor paste. References [22] and [29] provide a good overview of the materials issues and inductor/transformer into the substrate, and in many cases look to decrease overall circuit size by also embedding passives within the substrate. reducing the ferrite sintering temperature through the use of sintering aids and fluxes. The three different ferrite tapes provide different magnetic properties after firing. All three

978-1-4244-6411-1/10/$26.00 ©2010 IEEE 720 2010 Electronic Components and Technology Conference

ferrite tapes are compatible with the co-firable dielectric paste and tape materials. To characterize the magnetic properties, toroidal cores were fabricated from each tape, wound with magnet wire, and characterized using a Wayne Kerr 3260B

Precision Magnetics Analyzer (for inductance measurements), and a Tektronics TDS420A Digital Oscilloscope with

TCP202 Current Probe (for BH loop measurements). Note that external wire, and not co-fired silver, was used to provide the magnetizing current for these tests. Magnetic properties were determined based on the as-fired toroidal core dimensions, similar to the method described in [16]. When fired with a peak firing temperature of approximately 900 °C the three ferrite tapes possess a permeability of 60, 200 and

400, and are correspondingly referred to as 60 μ tape, 200 μ tape and 400 μ tape, respectively. The 60 μ tape possesses a

Curie temperature > 350 °C; the 200 μ and 400 μ tapes possess a Curie temperature > 125 °C. A B-H hysteresis loop obtained for a toroid fabricated from the 400 μ ferrite LTCC tape is provided in Figure 1. The ferrite tape possesses a saturation magnetization slightly above 300 mT. Unless noted otherwise, all magnetic devices discussed in this paper were fabricated utilizing the 400 μ tape.

400

300

200

100

0

-1400 -1200 -1000 -800 -600 -400 -200

-100

0 200 400 600 800 1000 1200 1400 most embedded capacitor needs since fired thicknesses are limited to approximately 10 µm for screen printed paste.

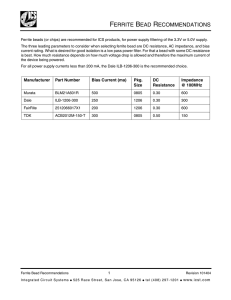

Table 1 summarizes the permittivity of the dielectric and ferrite materials. All measurements were taken at room temperature, 1 MHz, using an HP4192A impedance analyzer.

Table 1: Dielectric permittivity of the co-firable ferrite and dielectric materials.

Material Description

3203Y 400 μ Ferrite Tape

3204Y 200 μ Ferrite Tape

3205Y 60 μ Ferrite Tape

3206Y Dielectric Tape

3207Y Dielectric Paste #1

3208Y Dielectric Paste #2

ε r

@ 1 MHz

18.6

19.1

15.4

18.3

5.9

43

Most applications require good dielectric performance over a range of frequency and temperature. Figure 2 through

Figure 4 summarize these performance properties. Figure 2 provides change in capacitance versus frequency up to 50

MHz, normalized to the 1 MHz readings summarized in Table

1. The dissipation factor as a function of frequency (up to 50

MHz) is plotted in Figure 3. Finally, Figure 4 shows change in capacitance versus temperature normalized to 100 kHz room temperature measurements. As evident in these figures, reasonable dielectric performance is offered by these materials. For example, dielectric paste #2 offers a capacitance density of 3.8 nF/cm 2 (assuming a fired thickness of 10 µm), low dissipation from 10 kHz to 10 MHz, and very stable capacitance over -55 °C to 85 °C.

Δ Capacitance vs.

Frequency

-200 100.0

-300

80.0

60.0

-400

Magnetizing Force (A/m)

Figure 1 : B-H loop measured on a toroid fabricated from the

LTCC ferrite tape possessing a fired permeability of 400.

Options for co-fired dielectric materials include screen printable dielectric pastes and a cast dielectric tape, all of which possess shrinkage and shrinkage rates that are well matched to the LTCC ferrite tapes. (Note that the ability to co-fire the dielectric tape has only been demonstrated with the

400 μ ferrite tape.) Besides being useful as substrate materials for mounting external circuit components, the co-firable dielectric materials can also be used to embed capacitors within the multilayer structure. The NiCuZn ferrite materials can also be used as a dielectric material for embedded capacitors when their lower insulation resistance does not preclude their use. Note that the 400µ tape possesses a resistivity of 3.58 x 10 12 Ω ·cm at room temperature, and the dielectric tapes possesses a resistivity of 5.2 x 10 14 Ω ·cm at room temperature. The dielectric tape possesses a dielectric breakdown strength approximately double that of the ferrite tapes, although breakdown strengths for the fired ferrite materials exceed 5V/µm which is more than adequate for

40.0

20.0

0.0

‐ 20.0

‐ 40.0

‐ 60.0

‐ 80.0

3203Y

3204Y

3205Y

3206Y

3207Y

3208Y

‐ 100.0

10,000 100,000 1,000,000 10,000,000 100,000,000

Hz

Figure 2 : Change in capacitance versus frequency for the dielectric and ferrite materials. The measurements are normalized to the 1 MHz readings in Table 1.

Design of Magnetic Components with High Coupling

As mentioned previously, the ferrite and dielectric materials can be combined to create sintered inductive devices with good magnetic coupling. The process used to construct transformers with good turn coupling is outlined chronologically in Figures 5a through 5f.

721 2010 Electronic Components and Technology Conference

10

9

8

7

6

5

4

3

2

1

3203Y

3204Y

3205Y

3206Y

3207Y

3208Y and extremely poor transformer performance. Figure 6 provides an illustration from a finite element method magnetics (FEMM) finite element model [36] that shows the flux distribution in an LTCC transformer without the low permeability layers. (The figure shows a 2-D axisymmetric cross-section for one half of the transformer.) Note that the design possesses an interleaved winding structure (primary sandwiched between secondary windings) and an 8:1 turns ratio. The image clearly shows the poor flux linkage with the secondary, with a large portion of the flux traveling through the regions of the transformer that contain the secondary windings. Figure 7 provides FEMM output for the same transformer in Figure 6, with the low-permeability layers applied over the windings. The structure possesses noticeably improved coupling. The inclusion of the low-permeability layer over each winding layer creates a higher reluctance magnetic path through the winding regions. The flux therefore prefers the low-reluctance core path, thereby leading to a considerable improvement in the coupling.

0

10,000 100,000 1,000,000 10,000,000 100,000,000

Hz

Figure 3 : Dissipation versus frequency for the dielectric and ferrite materials listed in Table 1. a) b) c)

Δ Capacitance vs.

Temperature

10.0

0.0

‐ 10.0

‐ 20.0

50.0

40.0

30.0

20.0

d) e) f)

3203Y

3204Y

3205Y

3206Y

3207Y

3208Y

‐ 30.0

‐ 40.0

‐ 50.0

‐ 60 ‐ 40 ‐ 20 0 20 40 60 80

° C

Figure 4 : Change in capacitance over temperature for the cofirable dielectric and ferrite materials. The measurements are taken at 100 kHz and normalized to the 20 °C readings.

First, interlayer connections are made using vias which are punched into the ferrite tape and filled using stencils (Fig. 5a).

Conductive windings are then screen printed and dried, with line widths down to 3 mils achievable. Next, low permeability material is applied over the coils to direct flux and improve coupling. The sheets are then aligned and stacked together. High pressure pressing, or laminating, melds all the layers into a solid mass. The matrix of transformers is then singulated into individual pieces. Next, they are fired in a furnace following a precise and carefully controlled temperature profile with peak temperatures in excess of 850

°C. The firing process burns off the organic binders and plasticizers, and then sinters the layers and printings into a solid monolithic structure, physically bonding the particles together.

FEM modeling can illustrate the effects of the low permeability dielectric on the transformer performance.

Without the low-permeability dielectric, upon firing the coils become completely embedded in ferrite with uniform permeability throughout. This results in very poor coupling

Figure 5 : Processing steps for building LTCC ferrite devices with good magnetic coupling.

Figure 6 : Output from a FEMM model showing poor coupling for an LTCC transformer without low-permeability dielectric over the winding layers. A large portion of the flux traverses through the secondary windings. The primary current was set to 1A in the model.

Similar to the formation of the high-reluctance path through the windings regions, the low-permeability dielectric can also provide a method for incorporating a high-reluctance path through the core. This provides the same benefits as adding an air gap to a conventional wirewound flyback

722 2010 Electronic Components and Technology Conference

transformer; namely, it prolongs the onset of saturation and allows for increased energy storage. In the case of the LTCC transformer, the gaps are completely monolithic and embedded between the ferrite tape layers.

Figure 7 : Output from a FEMM model showing the improved coupling obtained when including a low-permeability dielectric layer on top of each winding print. The dielectric layers channel the flux to the center core area. The primary current was set to 1A in the model.

For more details on the design of transformers with good turn coupling, see [9]-[12].

Note that the same approach can be used to construct inductors with good turn coupling. Prior work has shown that coils embedded directly in LTCC ferrite possess little turn coupling and the resulting inductance hence scales with the length of the coil [8]. However, given the planar structure of an LTCC inductor and process limitations such as line spacing for the screen printed coils, highest inductance density may actually be achieved by maximizing the length of the coil, such as with a meander design [37].

Figure 8 : Schematic drawing of a transformer with simple double plate structures embedded in the multilayer structure.

Passive Integration

As mentioned previously, capacitors can readily be buried within a multilayer stackup constructed using the LTCC materials. Options for the capacitor material include both the ferrite and dielectric tapes since the NiCuZn ferrite tapes possess sufficiently high insulation resistance for some applications. Figure 8 shows a layout for simple double plate structures that were integrated within a transformer using the

200µ ferrite tape as the dielectric. The application possessed low capacitance requirements (picofarads) but needed high breakdown capability; therefore, two layers of the ferrite tape

(~ 100 µm fired thickness) served as the capacitor dielectric layer, which provided sufficient voltage standoff. Figure 9 contains a picture of a fabricated transformer that incorporates the buried capacitors. The capacitance at 4 MHz for the two structures measured 6.51 and 18.64 pF (2R1 and 6R1, respectively, from Figure 8). Note that design considerations for buried capacitors include the as-fired tolerance. Based on process limitations, the tolerance of an embedded capacitor is limited to ±30%. If more precise capacitor tolerance is required, a capacitor could have an external plate exposed as a

“trimming” feature.

Figure 9 : Fired LTCC ferrite transformer with buried capacitors, based on the designs shown in Figure 8.

Work was also conducted to integrate resistors with the

LTCC ferrite materials. This effort utilized commercial resistor pastes available from Heraeus. Attempts to co-fire

723 2010 Electronic Components and Technology Conference

ferrite with the commercial resistor pastes did not yield good resistors. The best results used 2 layers of screen printed dielectric (separately fired) to insulate the resistor paste from the ferrite substrate (this process requires 3 post firings). The post-fired resistors showed robustness to humidity, and additional overcoats can be used for increased environmental protection. When post fired onto an LTCC ferrite substrate, high value resistor designs must take into account the ferrite insulation resistance since the parallel resistance from the substrate can be comparable to the desired resistor value. The effect of temperature on the insulation resistance must also be considered. Figure 10 shows a plot of the insulation resistance versus temperature for two conductor traces with 3 layers of ferrite insulation between them. The resistance falls off to 100 M Ω at 80 °C, which corresponds to an 80X reduction for the 400µ ferrite tape. A sintering aid or flux used in the ferrite tape may be the source of this drop-off with temperature.

P1 C1 S1

C2

P2 S2

8000

7000

6000

5000

4000

3000

2000

Figure 11 : Post-fired high value resistor divider integrated on top of a multilayer LTCC ferrite flyback transformer.

Note that no attempts were made to co-fire or post-fire resistors with the dielectric tape to date. Using the dielectric tape should help mitigate the issues encountered when integrating high value resistors with buried magnetic components.

1000

20 30 40 50 60 70

Temperature (Celsius)

80 90

Integrated Power Converter Example

0

Using the compatible LTCC materials allows fabrication of composite structures with integrated, embedded components to support miniaturization of power electronic circuits. The ability to co-fire the ferrite with both dielectric

Figure 10 : Insulation resistance versus temperature measured across two conductor traces separated by 3 layers of fired ferrite tape. Three different samples were measured. and conductor materials thus offers a unique approach to making hybrid or system-in-package power electronic modules and could potentially allow a size reduction for many commercial dc-dc converter and other power electronic

Figure 11 shows a picture of a resistor divider integrated onto an LTCC transformer. The picture highlights surface termination connections to the primary (P1, P2), secondary

(S1, S2) and resistor divider (C1, C2). The resistor divider circuits. Figure 12 shows an example dc-dc converter built using the flyback topology. A multilayer flyback transformer is embedded in the substrate, and the ferrite/dielectric composite includes a cavity for mounting a large surface provides feedback used to regulate the output voltage across the secondary for a flyback dc-dc converter. Note that C1 connects directly to S1, and C2 provides the feedback signal to the converter electronics. Because of the high resistance of mount (SMT) component on the backside as well as topside metallization for mounting the remaining SMT components.

Note that both the ferrite tapes and the dielectric tape provide good insulation resistance for surface mounting components this divider (> 100 M Ω ) the design required floating the C2 terminal. Otherwise, the combination of the ferrite substrate insulation resistance in parallel with the C1-C2 resistance would result in the divider ratio fluctuating over temperature and there are no issues with resistive bypass of SMT components through the substrate, such as described in [28].

When co-firing dielectric and ferrite materials, a residual strain caused by mismatch between the dielectric and ferrite

(recall Figure 10). The divider was also actively laser trimmed with the required regulation voltage applied across

C1 and S2, which compensated for any change in the divider resistance due to voltage (i.e., voltage coefficient of thermal expansion coefficients can result in quenching of the ferrite permeability due to magnetostriction [28]. The composite dielectric/ferrite devices characterized in the present work did not exhibit any apparent quenching of the resistance). Resistive divider ratios with tolerances as good as ±1% were achieved. Although not incorporated for the ferrite permeability due to residual strain. This could result from better matching of the ferrite and dielectric thermal divider shown in Figure 11, fully floating C1 using dielectric performance since it helped isolate the high resistance divider from the ferrite substrate insulation resistance. expansion, or from a lower magnetostriction effect for the paste provided significantly improved temperature NiCuZn compositions used in this study, or a combination of the two.

724 2010 Electronic Components and Technology Conference

Figure 12 : Integrated flyback dc-dc converter built using the ferrite-based LTCC materials system. A cavity is incorporated into the multilayer structure for accommodating the SMT component shown in the bottom of the figure.

Future Work

Although the developed LTCC ferrite materials offer good performance, other research suggests that significant material improvements may be possible. For example, work by

Murthy points to possible NiCuZn compositions that provide increased saturation magnetization (600 mT) and permeability

(600) and improved insulation resistance (> 10 14 Ω •cm) [24].

Since no additional sintering aids or fluxes were added to the

NiCuZn formulations characterized by Murthy, these compostions may also allow increased density of the magnetic phase when designed into an LTCC material system.

Improved temperature dependence of the ferrite insulation resistance should also be possible with slight material modifications to the existing tape system.

Summary

A new ferrite-based LTCC materials system allows cofiring of ferrite, dielectric and conductor materials to construct composite structures with embedded magnetic and capacitive components. The dielectric and ferrite materials possess good insulation properties and hence work well as a substrate material for attaching or housing semiconductor components and other discrete devices that are part of the power electronics system. Overall, this materials system can enable new system-in-package approaches for power electronic applications.

References

1. O'Reilly, S., Duffy, M., O'Donnell, T., et al., “New integrated planar magnetic cores for inductors and transformers fabricated in MCM-L technology,”

International Journal of Microcircuits and Electronic

Packaging , Vol. 23, No. 1 (2000), pp. 62-69.

2. Ludwig, M., Duffy, M., O'Donnell, T., et al., “PCB integrated inductors for low power DC/DC converter,”

IEEE Transactions on Power Electronics , Vol. 18, No. 4

(2003), pp. 937-945.

3. Zhang, Y.E., Sanders, S.R., “In-board magnetics processes,” Proc 30 th Annual IEEE Power Electronics

Specialists Conference , Charleston, SC, June 1999, pp.

561-567.

4. Tang, S.C., Hui, S.Y.R., Chung, H.S.-H., “A low-profile power converter using printed-circuit board (PCB) power transformer with ferrite polymer composite,” IEEE

Transactions on Power Electronics , Vol. 16, No. 4

(2001), pp. 493-498.

5. Waffenschmidt, E., Ackermann, B., Ferreira, J.A.,

“Design method and material technologies for passives in printed circuit Board Embedded circuits,” IEEE

Transactions on Power Electronics , Vol. 20, No. 3

(2005), pp. 576-584.

6. Waffenschmidt, E., Ackermann, B., Wille, M., “Integrated ultra thin flexible inductors for low power converters,”

Proc 36th Annual IEEE Power Electronic Specialists

Conference , Recife, Brazil, June 2005, pp. 1528-1534.

7. Pernia, A.M., Prieto, M.J., Lopera, J.M., et al., “Thickfilm hybrid technology for low-output-voltage DC/DC converter,” IEEE Transactions on Industry Applications ,

Vol. 40, No. 1 (2004), pp. 86-93.

8. Prieto, M.J., Pernia, A.M., Lopera, J.M., et al., “Turncoupling in thick-film integrated magnetic components for power converters,” IEEE Transactions on Components and Packaging Technologies , Vol. 31, No. 4 (2008), pp.

837-848.

9. Abel, D.A., “Multi-layer transformer apparatus and method,” U.S. Patent 6 198 374, March 6, 2001.

10. Roesler, A.W., Schare, J.M., et. al., “Planar LTCC

Transformers for High-Voltage Flyback Converters”, to be published in IEEE Transactions on Components and

Packaging Technologies.

11. Wahlers, R.L., et. al., “Low-profile LTCC transformers,” in Proc. IMAPS 2002, pp. 76–80.

12. Slama, G., “Low-temperature cofired magnetic tape yields high benefits,” Power Electronics Technology , vol. 29, no.

1 (2003), pp. 30–34.

13. Hahn, R., Krumbholz, S., Reichl, H., “Low profile power inductors based on ferromagnetic LTCC technology,”

Proc 56th Electronic Components & Technology

Conference , San Diego, CA, June 2006, pp. 528-533.

14. Qingguang Yu, Hao Wang, Yinan Geng, et al., “Research of LTCC NiCuZn transformer prototype,” Proc 6 th World

Congress on Intelligent Control and Automation , Dalian,

China, June 2006, pp. 5272-5276.

15. Lim, M.H., Dong, J., van Wyk, J.D., et al., “Shielded

LTCC inductor as substrate for power converter,” Proc

725 2010 Electronic Components and Technology Conference

38th Annual IEEE Power Electronics Specialists

Conference , Orlando, FL, June 2007, pp. 1605-1611. http://www.eetimes.com/showArticle.jhtml?articleID=211

00064.

16. Lim, M.H.F., Zhenxian Liang, van Wyk, J.D., “Low profile integratable inductor fabricated based on LTCC technology for microprocessor power delivery applications,” IEEE Transactions on Components and

31. Ahn, C.H., Allen, M.G., “A planar micromachined spiral inductor for integrated magnetic microactuator applications,”

Microengineering

Journal of Micromechanics and

, Vol. 3, No. 2 (1993), pp. 37-44.

Packaging Technologies , Vol. 30, No. 1 (2007), pp. 170-

177.

17. Lim, M.H., van Wyk, J.D., Lee, F.C., et al., “A class of ceramic-based chip inductors for hybrid integration in power supplies,” IEEE Transactions on Power

Electronics , Vol. 23, No. 3 (2008), pp. 1556-1564.

18. Ball, A., Lim, M., Gilham, D., et al., “System design of a

3D integrated non-isolated point of load converter,” Proc

23 rd Annual IEEE Applied Power Electronics Conference and Exposition , Austin, TX, February 2008, pp. 181-186.

32. Park, J. Y. Han, S.H., Allen, M.G., “Batch-fabricated microinductors with electroplated magnetically anisotropic and laminated alloy cores,” IEEE Transactions on Magnetics , Vol. 35, No. 5 (1999), pp. 4291-4300.

33. O'Donnell, T., Wang, N., Brunet, M., et al., “Thin film micro-transformers for future power conversion,” Proc

19 th Annual IEEE Applied Power Electronics Conference and Exposition , Anaheim, CA, February 2004, pp. 939-

944.

“Constrained sintering of dielectric and ferrite LTCC tape composites,” Journal of the European Ceramic Society

Vol. 25, No. 12 (2005), pp. 2061-2064.

,

34. Gardner, D.S., Schrom, G., Hazucha, P., et al., “Integrated on-chip inductors with magnetic films,” IEEE

Transactions on Magnetics , Vol. 43, No. 6 (2007), pp.

2615-2617.

20. Hee-Jun Kim, Young-Jin Kim, Jong-Ryoul Kim, “An integrated LTCC inductor embedding NiZn ferrite,”

Transactions on Magnetics

2840-2842.

IEEE

, Vol. 42, No. 10 (2006), pp.

35. Gardner, D.S., Schrom, G., Hazucha, P., et al., “Integrated on-chip inductors using magnetic material (invited),”

Journal of Applied Physics , Vol. 103, No. 7 (2008), pp.

07E927-1 - 07E927-6.

21. Haertling, C., Shapiro, A., et. al., “Low-temperaturecofired-ceramic (LTCC) tape structures including cofired ferromagnetic elements, drop-in components and multilayer transformer,” U.S. Patent 5 312 674 and U.S. Patent

5 532 667, July 2, 1996.

36. D. C. Meeker. (2006, Dec. 3). Finite Element Method

Magnetics, Version 4.0.1 [Online]. Available: http://femm.foster-miller.net

37. Kawabe, K. et al., “Planar Inductor,” on Magnetics

1806.

IEEE Transactions

, Vol. MAG-20, No. 5 (1984), pp. 1804-

22. Wahlers, R.L., et. al., “Materials system for low cost, non wire-wound, miniature, multilayer magnetic circuit components,” U.S. Patent 6 914 513, July 5, 2005.

23. Grader, G.S., et. al., “Method of making a multilayer monolithic magnet component,” U.S. Patent 5 349 743,

September 27, 1994.

24. Murthy, S.R., “Low temperature sintering of NiCuZn ferrite and its electrical, magnetic and elastic properties,”

Journal of Materials Science Letters , Vol. 21, No. 8

(2002), pp. 657-660.

25. Park, J. et. al., “Fabrication and magnetic properties of

LTCC NiZnCu ferrite thick films,” physica status solidi

(a) , Vol. 201, No. 8 (2004), pp. 1790-1793.

26. Hong, S.H. et. al., “Magnetic properties and sintering characteristics of NiZn(Ag, Cu) ferrite for LTCC applications,” Journal of Magnetism and Magnetic

Materials , Vol. 290–291, Part 2 (2005), pp. 1559-1562.

27. Matz, R. et. al., “Ceramic Multilayer Integration of Power

Electronic Inductors,” Ferroelectrics , Vol. 387, No. 1

(2009), pp. 77 - 84.

28. Matz, R. et. al., “Low temperature cofirable MnZn ferrite for power electronic applications,” Journal of

Electroceramics , Vol. 22, No. 1 (2009), pp. 209-15

29. Jao, J.-C. et. al., “Characterization of Inductor with Ni–

Zn–Cu Ferrite Embedded in B2O3–SiO2 Glass,”

Japanese Journal of Applied Physics , Vol. 46, No. 9A

(2007), pp. 5792 - 5796.

30. Ohr, Stephan, “Integrated Magnetics Shrinks DC-to-DC

Converter,” EE Times , May 25, 2004, online at