Speed Increaser

advertisement

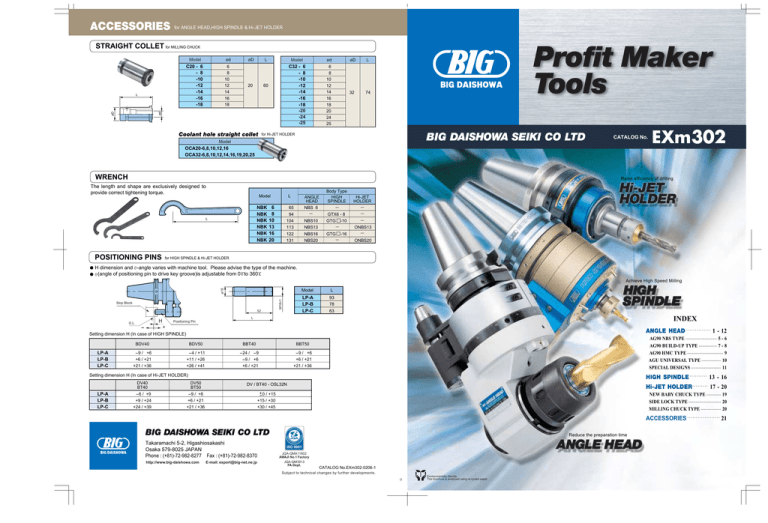

for ANGLE HEAD,HIGH SPINDLE & Hi-JET HOLDER STRAIGHT COLLET for MILLING CHUCK ød 6 8 10 12 14 16 18 øD L 20 60 ød øD L Model C20 - 6 - 8 -10 -12 -14 -16 -18 Model ød C32 - 6 - 8 -10 -12 -14 -16 -18 -20 -24 -25 6 8 10 12 14 16 18 20 24 25 øD L 32 74 for Hi-JET HOLDER CATALOG No. Model OCA20-6,8,10,12,16 OCA32-6,8,10,12,14,16,19,20,25 WRENCH Raise efficiency of drilling The length and shape are exclusively designed to provide correct tightening torque. Model NBK NBK NBK NBK NBK NBK L POSITIONING PINS 6 8 10 13 16 20 L ANGLE HEAD 65 NBS 6 Body Type HIGH SPINDLE Hi-JET HOLDER GTX6 - 8 94 104 NBS10 113 NBS13 122 NBS16 131 NBS20 GTG -10 GTG -16 ONBS13 ONBS20 for HIGH SPINDLE & Hi-JET HOLDER H dimension and -angle varies with machine tool. Please advise the type of the machine. (angle of positioning pin to drive key groove)is adjustable from 0° to 360°. Model L LP-A LP-B LP-C 93 M18X1 ø18 Achieve High Speed Milling Stop Block 52 63 INDEX L H G.L. 78 Positioning Pin + - ·············· Setting dimension H (In case of HIGH SPINDLE) BDV50 BBT40 BBT50 -9 / +6 -4 / +11 -24 / -9 -9 / +6 +6 / +21 +11 / +26 -9 / +6 +6 / +21 +21 / +36 +26 / +41 +6 / +21 +21 / +36 BDV40 LP-A LP-B LP-C Setting dimension H (In case of Hi-JET HOLDER) DV50 BT50 DV / BT40 - OSL32N -6 / +9 -9 / +6 + -0 / +15 +9 / +24 +6 / +21 +15 / +30 +24 / +39 +21 / +36 +30 / +45 ·········· 13 - 16 ········· 17 - 20 NEW BABY CHUCK TYPE · · · · · · · · · · · · 19 SIDE LOCK TYPE · · · · · · · · · · · · · · · · · · · · · · · · · · · 20 MILLING CHUCK TYPE · · · · · · · · · · · · · · · · · 20 ACCESSORIES · · · · · · · · · · · · · · · · · · · 21 MAN G A Takaramachi 5-2, Higashiosakashi Osaka 579-8025 JAPAN Phone : (+81)-72-982-8277 Fax : (+81)-72-982-8370 http://www.big-daishowa.com E-mail: export@big-net.ne.jp ER TIFIE D Reduce the preparation time EM C ST LP-A LP-B LP-C DV40 BT40 1 - 12 AG90 NBS TYPE · · · · · · · · · · · · · · · · · · · · · · · · · · 5 - 6 AG90 BUILD-UP TYPE · · · · · · · · · · · · · · · 7 - 8 AG90 HMC TYPE · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 9 AGU UNIVERSAL TYPE · · · · · · · · · · · · · · · · 10 SPECIAL DESIGNS · · · · · · · · · · · · · · · · · · · · · · · · · 11 EM Y ENT S ISO 9001 JQA-QMA11602 AWAJI No.1 Factory JQA-QM3913 FA Dept. CATALOG No.EXm302-0206-1 Subject to technical changes by further developments. O Environmentally friendly This brochure is produced using re-cycled paper. . PAT WIDE RANGE OF COMPACT AND RIGID HEADS, FROM MILLING CHUCK TYPES TO UNIVERSAL TYPES, SUITABLE FOR ALL KINDS OF MACHINING APPLICATIONS. P11 NBS TYPE P5 ~6 BUILD-UP TYPE HMC TYPE P7 ~8 UNIVERSAL TYPE P9 P10 BUILD-UP TYPE / HMC TYPE Compact design assures rigidity Overhang is minimized for added rigidity and strength. As a result, the projection length with cutting tool is shorter, which reduces the overall load on the Angle Head and thus improves the unit's cutting capabilities. Further, the minimized overhang helps eliminate interference with the ATC (automatic tool changer) and connecting storage pockets in the tool magazine. High Rigidity S-Type, which has a steel housing and a stronger locating pin assembly, is also available. ATC may not be utilized for some machining centers. Innovative sealing method The advanced non-contact sealing method prevents coolant and particle contamination better than any other sealing method. Innovative Seals Unique coolant jacket MAX. 1MPa Cutter head adjustable 360° Jacket allows coolant coming through stop block to be efficiently directed to the tool cutting edge while simultaneously cooling the Angle Head. Reference faces are provided on both sides of all heads for easier setting of cutter directions. BIG-PLUS is standard on all BT & DV Taper versions PAT. Simultaneous taper and flange contact between machine spindle and toolholder provides improved rigidity and ATC repeatability. Interchangeability with conventional spindles ensures suitability for your existing machines. Patented; Japan, USA, Canada, Germany, UK, France, Italy, Taiwan, and South Korea SPINDLE SYSTEM DUAL PAT. CONTACT eliminate multiple set-ups combine vertical, horizontal and angular operations on one machine one original set-up saves time, speeds production and guarantees accuracy 1 SUPERIOR QUALITY COMPONENTS Superior quality components For smooth and powerful operations and to minimize noise and vibration, all Angle Heads are equipped with hardened and ground chrome-nickel steel spiral bevel gears, super precision hardened and ground spindles, and high precision angular contact ball bearings. Clearance CONVENTIONAL SPINDLE SYSTEM DUAL FIT BIG-PLUS SPINDLE SYSTEM PAT. CONTACT 2 P5~6 BDV40 (BBT40) MAX.6,000 min-1 6 ø0. BDV50 (BBT50) 6 BDV50-AG90/AGH35-230 BBT50-AG90/AGH35-230 MAX.3,000 min-1 (QUICK CHANGE ADAPTERS) 45 275 245 215 240 (230) 210 (200) BDV50-AG90/NBS 6-275 BBT50-AG90/NBS 6-275 BDV50 (BBT50) ø32 230 BDV50-AG90/HMC32-230 BBT50-AG90/HMC32-230 240 (230) 210 (200) P9 10 215 ø10 -ø 29 33 MAX.3,000 min-1 45 5 ø1. 29 33 BDV50-AG90/NBS 6-245 BBT50-AG90/NBS 6-245 275 BDV40-AG90/NBS 6-240 BBT40-AG90/NBS 6-230 17 29 33 BDV50-AG90/NBS 6-215 BBT50-AG90/NBS 6-215 17 29 33 245 BDV40-AG90/NBS 6-210 BBT40-AG90/NBS 6-200 17 29 33 BDV :180 (BBT:170) 65 43 45 BDV40-AG90/NBS 10-240 BBT40-AG90/NBS 10-230 5ø2. BDV50-AG90/NBS 10-245 BBT50-AG90/NBS 10-245 P10 BDV40 (BBT40) BDV40-AG90/NBS 13-240 BBT40-AG90/NBS 13-230 ø2. 5- BDV50-AG90/NBS 13-275 BBT50-AG90/NBS 13-275 BDV40-AGU/NBS13-280 BBT40-AGU/NBS13-270 MAX.6,000 min-1 65 ø20 BDV50 (BBT50) BDV40-AG90/NBS 20S-175S BBT40-AG90/NBS 20S-165S MAX.3,000 min-1 Automatic tool change may not be utilized for some machining centers. 5- ø20 65 BDV50-AG90/NBS 20-230 BBT50-AG90/NBS 20-230 MAX.3,000 min-1 200 230 62 35 33 BDV:175 (BBT:165) ø2. 65 0° ~9 0° BDV50-AG90/NBS 13-245 BBT50-AG90/NBS 13-245 52 28 45 ø20 62 BDV:180 (BBT:170) 275 245 52 BDV50-AGU/NBS20-315 BBT50-AGU/NBS20-315 0° ~9 0° 52 28 45 BDV40-AG90/NBS 13-210 BBT40-AG90/NBS 13-200 ø13 28 BDV50-AG90/NBS 13-215 BBT50-AG90/NBS 13-215 28 52 5- 100 210 (200) BDV:180 (BBT:170) 45 ø2. 240 (230) 52 45 28 52 BDV40-AG90/NBS 13-180 BBT40-AG90/NBS 13-170 3 (SPINDLE ANGLE : 0° - 90 °) ø13 45 5- 45 ø13 45 ø2. 43 BDV50-AG90/NBS 10-275 BBT50-AG90/NBS 10-275 28 5- 45 215 ø2. 43 25 BDV40-AG90/NBS 10-210 BBT40-AG90/NBS 10-200 45 BDV50-AG90/NBS 10-215 BBT50-AG90/NBS 10-215 25 45 25 43 43 25 45 BDV40-AG90/NBS 10-180 BBT40-AG90/NBS 10-170 25 43 25 100 MAX.4,000 min-1 115 5- (Except for #50-AG90/NBS20-230) 100 BDV40-AG90/NBS 6-180 BBT40-AG90/NBS 6-170 ø1. -ø MAX.6,000 min-1 17 29 33 25 17 -ø 17 25 BDV50 (BBT50) (Except for NBS20 models) BDV:180 (BBT:170) ø0. P7~8 230 (SPINDLE ANGLE : 90 °) 65 Automatic tool change may not be utilized for some machining centers. 4 SPINDLE SYSTEM (SPINDLE ANGLE : 90 °) DUAL PAT. CONTACT It is the outstanding rigidity and accuracy of the NEW BABY CHUCK, used for holding the cutting tool, that produces high precision with less runout. Available in various sizes to meet specific production requirements. 40 TAPER 50 TAPER K L L2 øE ø97 G ød K L L1 Min. access bore øF L2 ø125 G øE ø97 Q S=110 5 Pin Compression R18 M Fixed Length H R21 M Model Description BDV40 - AG90 G ød P P Q S=65 G Min. access bore øF L1 6 Collar Compression / NBS 6 - 180 3 Pin Compression Fixed Length H New Baby Chuck Type AG90° Series Shank No. The rotation of the cutting tool is in reverse direction of the machine spindle.(Speed Ratio 1:1) The rotation of the cutting tool is in reverse direction of the machine spindle.(Speed Ratio 1:1) Shank BDV BBT Model BDV40-AG90/NBS 6 -180 -210 -240 -AG90/NBS10 -180 -210 -240 -AG90/NBS13 -180 -210 -240 -AG90/NBS20S -175S BBT40-AG90/NBS 6 -170 -200 -230 -AG90/NBS10 -170 -200 -230 -AG90/NBS13 -170 -200 -230 -AG90/NBS20S -165S ød øE G K 0.25 - 6 20 21 17 1.5 - 10 30 30 25 2.5 - 13 35 31 28 2.5 - 20 46 35 33 0.25 - 6 20 21 17 1.5 - 10 30 30 25 2.5 - 13 35 31 28 2.5 - 20 46 35 33 L 180 210 240 180 210 240 180 210 240 175 170 200 230 170 200 230 170 200 230 165 L1 125 125 125 122 115 115 115 112 1. The standard Fixed Length H is 8mm. Other lengths are available upon request. 2. The angles of positioning pin to drive key groove and direction of cutting edge are adjustable from 0° to 360°. 3. BIG-PLUS tools can be used in machining centers with conventional spindles. 5 L2 M 55 85 115 55 85 115 55 85 115 53 55 85 115 55 85 115 55 85 115 53 77 107 137 77 107 137 77 107 137 72 77 107 137 77 107 137 77 107 137 72 Collet Max. min-1 29 67 NBC 6 6,000 45 43 91 NBC10 6,000 52 45 101 NBC13 6,000 65 62 132 NBC20 3,000 33 29 67 NBC 6 6,000 45 43 91 NBC10 6,000 52 45 101 NBC13 6,000 65 62 132 NBC20 3,000 P Q 33 øF Weight (kg) 5.1 5.3 5.5 5.5 5.9 6.2 5.6 6.0 6.3 8.0 5.1 5.3 5.5 5.5 5.9 6.2 5.6 6.0 6.3 8.0 Shank BDV BBT Model BDV50-AG90/NBS 6-215 -245 -275 -AG90/NBS10-215 -245 -275 -AG90/NBS13-215 -245 -275 -AG90/NBS20-230 BBT50-AG90/NBS 6-215 -245 -275 -AG90/NBS10-215 -245 -275 -AG90/NBS13-215 -245 -275 -AG90/NBS20-230 ød øE G K 0.25 - 6 20 21 17 1.5 - 10 30 30 25 2.5 - 13 35 31 28 2.5 - 20 46 35 35 0.25 - 6 20 21 17 1.5 - 10 30 30 25 2.5 - 13 35 31 28 2.5 - 20 46 35 35 L 215 245 275 215 245 275 215 245 275 230 215 245 275 215 245 275 215 245 275 230 L1 160 160 160 160 160 160 160 160 L2 M 55 85 115 55 85 115 55 85 115 70 55 85 115 55 85 115 55 85 115 70 82 112 142 82 112 142 82 112 142 97 82 112 142 82 112 142 82 112 142 97 Collet Max. min-1 29 67 NBC 6 6,000 45 43 91 NBC10 6,000 52 45 101 NBC13 6,000 65 62 132 NBC20 3,000 33 29 67 NBC 6 6,000 45 43 91 NBC10 6,000 52 45 101 NBC13 6,000 65 62 132 NBC20 3,000 P Q 33 øF Weight (kg) 12.6 12.8 13.0 13.0 13.4 13.7 13.1 13.5 13.8 14.2 12.6 12.8 13.0 13.0 13.4 13.7 13.1 13.5 13.8 14.2 For NEW BABY COLLET P22 1. The standard Fixed Length H is 6mm. Other lengths are available upon request. 2. The angles of positioning pin to drive key groove and direction of cutting edge are adjustable from 0° to 360°. 3. BIG-PLUS tools can be used in machining centers with conventional spindles. For NEW BABY COLLET P22 For STOP BLOCK P21 S=80 type are available upon request. For STOP BLOCK P21 6 PAT. SPINDLE SYSTEM (SPINDLE ANGLE : 90 °) DUAL CONTACT Spindle head is equipped with short taper for quick changing of various adapters. STANDARD TYPE BUILD-UP TYPE AG35 øF= Minimum bore size that an AG35 adapter can fit into, excluding the cutting tool. 45 230 10 65 45 ø125 45 Min. Access Bore øF Designed for greater rigidity by having the face of the spindle bore in line with the center of the machine spindle. Also helps minimize interference problems with ATC and storage problems within magazine. ADAPTER SERIES Gage Line for AG35 Adapters 100 S=110 0 ø38.1 NEW BABY CHUCK 2 L R21 6 Collar Compression Fixed Length H ød øC Draw Bar 10 3 Pin Compression 97 MAX.3,000 min-1 Model ød L øC øF AG35-NBS10 -NBS13 -NBS16 -NBS20 1.5 - 10 2.5 - 13 2.5 - 16 2.5 - 20 47 30 35 42 46 162 168 54 Weight (kg) 0.6 0.7 0.8 0.9 170 For NEW BABY COLLET P22 35 - BDV BBT BDV50-AG90/AGH35-230 BBT50-AG90/AGH35-230 Weight(kg) 15.0 15.0 1. The cutter rotates in the same direction of the machine spindle. 2. The standard Fixed Length H is 6mm. Other lengths are available upon request. 3. The angles of positioning pin to drive key groove and direction of cutting edge are adjustable from 0° to 360°. 4. BIG-PLUS tools can be used in machining centers with conventional spindles. 230 Build Up Type AG90° Series L NEW HI-POWER MILLING CHUCK ød / AGH Model øC Model Description BDV50 - AG90 Shank For STOP BLOCK P21 Shank No. Model ød L øC øF Weight (kg) AG35-HMC20 20 60 52 178 1.5 C-Spanner(FK52-55) must be ordered separately. For STRAIGHT COLLET THE BACK COVER PAGE L HIGH RIGIDITY TYPE H F1 Compression Provided with a steel housing and reinforced locating pin assembly for applications where increased rigidity is required to perform various types of heavier machining. F2 Tension (forward) AUTO TAPPER TYPE B (Automatic depth control) F3 Tension (reverse) Model 10 65 45 ø125 d øC 45 230 Tap Collet BZ12, BZ20 0 ø38.1 AG35-ATB12E -ATB20E 45 Gage Line for AG35 Adapters d øC L For AUTO TAPPER TYPE B F3 øF 4 5 d d - Weight (kg) 1.0 1.7 øD M4 - 12 P1/8 M8 - 20 P1/8 - 3/8 BZ20- d 2 F2 Model BZ12- d øD 100 F1 5 M4 - M12 80 40.5 72 0.5 M8 - M20 115 57.5 102.5 6.5 TAP COLLET TYPE BZ S=110 H 19 31 R 21 10 6 Collar Compression 3 Pin Compression Fixed Length H Draw Bar L H SHELL MILL ARBOR 97 / AGH 35 - 230 Build Up Type AG90° Series 7 BDV BDV50-AG90/AGH35-230S BBT50-AG90/AGH35-230S BBT S High Rigidity Type Shank No. Model øD L H øF Weight (kg) AG35-FMC27-20 27 20 20 - 0.7 Weight(kg) 16.3 16.3 1. The cutter rotates in the same direction of the machine spindle. 2. The standard Fixed Length H is 6mm. Other lengths are available upon request. 3. The angles of positioning pin to drive key groove and direction of cutting edge are adjustable from 0° to 360°. 4. BIG-PLUS tools can be used in machining centers with conventional spindles. S=80 type are available upon request. For STOP BLOCK P21 L MORSE TAPER ADAPTER MT. No. øC BDV50 - AG90 Shank ød Model Description Model øD MAX.3,000 min-1 Model ød MT.No. L øC øF Weight (kg) AG35-MT1 -MT2 12.065 17.78 1 2 50 60 24 32 164 180 0.6 0.7 8 SPINDLE SYSTEM (SPINDLE ANGLE : 90 °) DUAL PAT. DUAL Suitable for all cutting angles. In addition to the cutter head being adjustable a full 360°, the spindle also becomes easily and precisely adjustable from L L1 L2 0° to 90° by 1° increments. F øE ø97(#40) ø125(#50) 45 230 C2 STANDARD TYPE Designed for greater rigidity by having the face of the spindle bore in line with the center of the machine spindle. Also helps minimize interference problems with ATC and storage problems within magazine. CONTACT C1 Greater versatility is obtainable with Milling Chuck capacity of ø32mm by utilizing Straight Reduction Collets and other accessories. PAT. SPINDLE SYSTEM (SPINDLE ANGLE : 0° to 90°) CONTACT 45 S 45 ø32 ød ø80 øD 65 100 S=110 Min.Access Bore ø175 ø125 M 6 Collar Compression(#50 Only) 5(#40), 3(#50) Pin Compression Fixed Length H Shank R 21 Model ød øE øD BDV40-AGU/NBS13-280 BDV50-AGU/NBS20-315 BBT40-AGU/NBS13-270 BBT50-AGU/NBS20-315 2.5 - 13 2.5 - 20 2.5 - 13 2.5 - 20 35 46 35 46 115 140 115 140 C1 C2 L L1 L2 M F S Collet 97 125 97 125 280 315 270 315 180 200 170 200 100 115 100 115 124 125 124 125 102 118 102 118 65 110 65 110 NBC13 NBC20 NBC13 NBC20 97 6 Collar Compression BDV 3 Pin Compression Fixed Length H BBT MAX.3,000 min-1 Model Description BDV50 - AG90 / HMC 32 - 230 Chucking size New Hi-power Milling chuck Type AG90° Series Shank No. Shank Model Weight(kg) BDV BBT BDV50-AG90/HMC32-230 BBT50-AG90/HMC32-230 51 65 51 65 1. The standard fixed length H 40Taper=8mm , 50Taper=6mm. Other lengths are available upon request. 2. The angles of positioning pin to drive key groove and direction of cutting edge are adjustable from 0° to 360°. 3. The cutter rotates in the same direction of the machine spindle. 4. BIG-PLUS tools can be used in machining centers with conventional spindles. For NEW BABY COLLET P22 Max. Weight min-1 (kg) 6,000 4,000 6,000 4,000 9.7 20.0 9.7 20.0 For STOP BLOCK P21 16.8 16.8 1. The standard Fixed Length H is 6mm. Other lengths are available upon request. 2. The angles of positioning pin to drive key groove and direction of cutting edge are adjustable from 0° to 360°. 3. The cutter rotates in the same direction of the machine spindle. 4. BIG-PLUS tools can be used in machining centers with conventional spindles. For STOP BLOCK P21 For STRAIGHT COLLET THE BACK COVER PAGE EXCLUSIVE CLAMPING BOLTS AND NUTS PRECISE ANGLE ADJUSTMENT EASILY ADJUSTABLE SPINDLE ANGLE FROM 0° to 90°. HIGH RIGIDITY TYPE Provided with a steel housing and reinforced locating pin assembly for applications where increased rigidity is required to perform various types of heavier machining. Unique setting mechanism enables the spindle angle to be precisely set at 1° increments. 45 230 ø80 45 Easy and precise angle settings at 1° increments is achieved by the unique angle setting mechanism without utilizing any special tools or a test bar. 45 97 60° 50° ° 40 ° 30 ° 20 100 S=110 65 ø32 Min.Access Bore ø175 ø125 Specially selected materials and special design for clamping the head guarantees rigidity for even end milling applications. 10 ° 0° Loosen all Clamping Screws and then manually slide the Spindle Housing close to the target angle. Caution: Do not hold a cutting tool directly to avoid injury. R 21 6 Collar Compression 3 Pin Compression For example, when setting at 42°, align the arrow mark on the Spindle Housing with the 42° mark engraved on the head within ±1°. Tighten the Angle Setting Screw marked "2". Due to the concentricity of the round shaped Angle Setting Screw, the Spindle Housing is fixed at the exact target angle. Tighten all Clamping Screws and then loosen the Angle Setting Screw. Fixed Length H MAX.3,000 min-1 Model Description BDV50 - AG90 / HMC 32 - 230 S High Rigidity Type Chucking size New Hi-power Milling chuck Type AG90° Series Shank No. 9 Shank Model BDV BBT BDV50-AG90/HMC32-230S BBT50-AG90/HMC32-230S Adjustable AGU Universal Series expands Angle Head capabilities to accomplish various angular machining applications. Weight(kg) 18.1 18.1 1. The standard Fixed Length H is 6mm. Other lengths are available upon request. 2. The angles of positioning pin to drive key groove and direction of cutting edge are adjustable from 0° to 360°. 3. The cutter rotates in the same direction of the machine spindle. 4. BIG-PLUS tools can be used in machining centers with conventional spindles. Drilling or end milling on the angled surface. Corner rounding. Profiling. Machining draft angle of a mold. S=80 type are available upon request. For STRAIGHT COLLET THE BACK COVER PAGE For STOP BLOCK P21 10 AG90 SERIES S TYPE STANDARD BBT50-AG90/AGH35-230S (with AG35-FMC25.4) Workpiece : Carbon Steel S55C (JIS) / CK55 (DIN) Cutter : 80mm Shell Mill Cutting Depth : 2mm 2mm Cutting Width : 60mm Spindle Speed : 600 min-1 Cutting Speed : 150m/min. Cutting Feed : 360mm/min. Workpiece : Carbon Steel S55C (JIS) / CK55 (DIN) Cutter : 80mm Shell Mill Cutting Depth : 3mm 3mm Cutting Width : 60mm Spindle Speed : 600 min-1 Cutting Speed : 150m/min. Cutting Feed : 360mm/min. AG90 SERIES (HMC TYPE) for SMALL CUTTER for SMALL DRILL TWIN HEAD for SHELL MILL SPECIAL ANGLE for SLOT MILLING CUTTER EXTRA LONG S TYPE BBT50-AG90/HMC32-230 BBT50-AG90/HMC32-230S Workpiece : Carbon Steel S55C (JIS) / CK55 (DIN) Cutter : 20mm Endmill with 2-flute of H.S.S. 3mm Cutting Depth : 3mm Spindle Speed : 400 min-1 Cutting Speed : 25m/min. Cutting Feed : 72mm/min. Workpiece : Carbon Steel S55C (JIS) / CK55 (DIN) Cutter : 20mm Endmill with 2-flute of H.S.S. 4mm Cutting Depth : 4mm Spindle Speed : 400 min-1 Cutting Speed : 25m/min. Cutting Feed : 72mm/min. AG90 SERIES 20mm 5 1 STANDARD 40 (NBS TYPE) 10mm 115 degree NEW BABY COLLET / NBS13 180 degree NEW BABY COLLET / NBS20 FLANGE MOUNT Workpiece : Cast Iron FC25 (JIS) / GG25 (DIN) Cutter : 10mm Endmill with 2-flute of H.S.S. Cutting Depth : 10mm Spindle Speed : 1,000 min-1 Cutting Speed : 31m/min. Cutting Feed : 100mm/min. NEW BABY COLLET / NBS20 OIL FEEDER AGU SERIES (UNIVERSAL TYPE) BBT50-AGU/NBS20-315 Workpiece : S55C (JIS) / CK55 (DIN) Cutter : 20mm Endmill with 2-flute of H.S.S. Cutting Depth : 1mm Cutting Width : 40mm Spindle Speed : 400 min-1 Cutting Speed : 25m/min. Cutting Feed : 100mm/min. MILLING CHUCK / HMC25 SHELL MILL ARBOR / FMA38.1 NEW BABY COLLET / NBS20 10mm 456 BBT50-AG90/NBS10-275 35 degree NEW BABY COLLET / NBS20 60mm SPECIAL CUTTER HEAD BBT50-AG90/AGH35-230 (with AG35-FMC25.4) 60mm ULTRA SMALL HEAD (BUILD-UP TYPE) 20mm Our long experience and expertise enables us to design and manufacture special custom made Angle Heads for almost any customer application. 1mm 40mm 30° NEW BABY COLLET / NBS13 HSK SHANK All new applications are subject to review by engineering in order to confirm the Angle Head will operate with in its capacity. 11 12 Speed Increaser . PAT min-1 Obtain optimum cutting tool performance HIGH SPEED MACHINING INCREASES PRODUCTIVITY WITH GREATER ACCURACY AND SUPERIOR FINISH High efficiency cutting tools have been developed for advanced high speed machining. HIGH SPINDLE maximizes performance of these cutting tools by increasing the spindle speeds up to higher required levels. Reduce load to machine spindle Reinforced gear driving system The planetary gears, which have been constantly up-graded since the development of our first "High Spindle" back in 1970, achieves smooth operation with minimal heat generation and high torque transmission. Continuous use at high revolutions results in shorter life span of the machine spindle due to excessive load to its motor and bearings. HIGH SPINDLE reduces this load and greatly extends the life of the expensive machine spindle. BIG-PLUS is standard on all BT & DV Taper versions PAT. Simultaneous taper and flange contact between machine spindle and toolholder provides improved rigidity and ATC repeatability. Interchangeability with conventional spindles ensures suitability for your existing machines. High precision collet chuck system Clearance 1 m at nose [NEW BABY CHUCK] 1µm CONVENTIONAL FIT BIG-PLUS SPINDLE SYSTEM 3µm ød 4xd The BIG New Baby Collet is world renowned for its unmatched accuracy and precision. It offers concentricity close to sub-micron. Max. Runout Collet Class At nose At 4 d AA 1µm 3µm Runout at spindle nose in High Spindle guaranteed to be within 5µm. Runout at 4 times d guaranteed to be within 10µm. Patented; Japan, USA, Canada, Germany, UK, France, Italy, Taiwan, and South Korea SPINDLE SYSTEM DUAL High Spindle improves drilling and end-milling performance on existing machines by multiplying the spindle speed 4,5, or 6 times. 13 PAT. CONTACT Rigidity increased 1.7 times Larger diameter body and spindle with double angular contact bearings and reinforced locating pin assembly greatly increases rigidity. Higher durability (Advanced sealing method) The advanced non-contact sealing method provides improved protection against coolant and particle contamination than any other seals. Multi-directional coolant supply Universal Coolant Nozzles are capable of being adjusted to suit the length of cutting tool. Thus, the maximum coolant delivery to the cutting edge is assured. Note: HIGH SPINDLE can be operated without coolant running through the housing. L mm 20kgf Pinpoint coolant jet for shorter cutting tools Deflection Model BBT40-GTG5-10-140-65 BBT50-GTG6-10-158-80 BBT50-GTG4-16-177-80 L Deflection Rigidity 200 220 240 36µm 25µm 11µm 58% less 78% less 93% less Comparison against previous model. A 1/8 pipe tap thread is provided in the High Spindle so that various types of customer supplied coolantjet nozzles can be utilized which will provide pinpoint delivery to the cutting edge of short tools (BDV/BBT taper models only). 14 For Machining Centers For Machining Centers Higher spindle speeds are available without excessive load on the machine spindle. PAT. SPINDLE SYSTEM DUAL MAX CONTACT Special design for Dai & mold. Long nose design for interference. Long tool life with Grease nipple. PAT. SPINDLE SYSTEM DUAL MAX -1 0min -1 0min 0 20,0 CONTACT 0 24,0 200 54.5 K1 0.01 K1 ø100 L ø25 ø44 ød 4D 0.01 S L1 4D øD2 ød øD1 COOLANT Speed Ratio : 5.67 Model Description S Model Description BDV40 - GTG 5 - 10 - 155 BDV50 - GTX COOLANT Speed Ratio Shank No. BDV Shank No. K1 S Speed Ratio Max. min-1 Weight (kg) 30 80 58 65 4.67 20,000 5.0 20 30 100 63 80 5.67 20,000 9.0 25.5 42 110 63 80 3.80 15,000 10.8 ød L L1 øD1 BDV40-GTG5-10-155 1.5 - 10 155 20 BDV50-GTG6-10-163 1.5 - 10 163 -GTG4-16-182 2.5 - 16 182 - 204 8 MODEL BBT50-GTX6-8-200 CUTTER WORKPIECE MATERIAL Boll nose endmill R3/2flutes Prehardened steel HRC40 REVOLUTION 20,000min-1 Type øD2 Model - Speed Ratio ø18 Type Shank 6 BBT40-GTG5-10-140-65 BBT40-GTG5-10-140 1.5 - 10 140 20 30 80 43 65 4.67 20,000 4.8 BBT50-GTG5-10-158-80 BBT50-GTG6-10-158 1.5 - 10 158 20 30 100 58 80 5.67 20,000 8.8 BBT50-GTG4-16-177-80 -GTG4-16-177 2.5 - 16 177 25.5 42 110 58 80 3.80 15,000 10.6 Shank ød Model L K1 BDV BDV50-GTX6-8-204 0.5 - 8 204 62 80 9.5 BBT BBT50-GTX6-8-200 0.5 - 8 200 58 80 9.3 3,600mm/min FEED RATE Weight (kg) S Good surface RESULT 1. Clamping nut and wrench are included. 2. Collet must be ordered separately. 3. Please be aware of the risk of fire when using oil-based coolant. DIN standard shank w/o BIG-PLUS are available upon request. BBT 1. 1 pce. of maximum size collet is included as standard accessory. (GTG5,6=NBC10-10AA,GTG4=NBC16-16AA) 2. (angle of locating pin to drive key groove) is adjustable to any degree from 0˚ to 360˚. 3. Special Air Purge oil mist lubrication style is available upon request for machining graphite, ceramic, tungsten and other composite materials. 4. Please be aware of the risk of fire when using an oil based coolant. 5. BIG-PLUS tools can be used in machining centers with conventional spindles. For NEW BABY COLLET P22 DIN standard shank w/o BIG-PLUS are available upon request. For POSITIONING PINS THE BACK COVER PAGE 1.3 0.6 For STOP BLOCK P21 For Conventional Machines Higher spindle speeds increase the productivity on Conventional Machines. BBT50-GTG4-16-177 Solid carbide drill ø2 Solid carbide endmill ø16 WORKPIECE MATERIAL Duralumin(A-2017) S55C / CK55 Duralumin(A-2017) Duralumin(A-2017) REVOLUTION 20,000min-1 16,000min-1 20,000min-1 15,000min-1 FEED RATE 3,000mm/min 3,500mm/min 2,000mm/min 1,000mm/min High metal removal rate 35cm3/min Extended tool life 1,200 holes by 1 drill Surface roughness Ry max 2µm High metal removal rate 90cm3/min 4D -1 00min 15,0 Model Description NT50U - GTG 155 4 - 16 - 150 Speed Ratio ø2 ST Type ST32-GTG4-16-155 3 1 Results will vary depending on workpiece, cutting tool, machine model, and other conditions. The rigidity and concentricity are often affected by the projection-length of a cutting tool. It is recommended to keep the projection as short as possible. 15 0.1 Model NT50U(M)-GTG4-16-150 ST32-GTG4-16-155 Shank ød 50 taper 32 cylindrical 2.5 - 16 2.5 - 16 1. 1 pce. of maximum size collet is included as standard accessory. (NBC16-16AA) 2. Please be aware of the risk of fire when using an oil based coolant. Weight (kg) 9.3 7.2 For NEW BABY COLLET P22 ød Max. min-1 15,000 15,000 ø42 ø32 Speed Ratio 3.80 3.80 80 20 10 4D 150 10 10 ST.No. Gear Shank No. 0.01 25.5 ø110 RESULT MAX 150 CUTTER NT.50 U=UNCI-8 (M=M24 P3) ø42 BBT50-GTG6-10-158 Solid carbide endmill ø6 / 2 flutes ø110 BBT50-GTG6-10-158 Solid carbide endmill ø8 / 2 flutes 0.01 25.5 ød BBT40-GTG5-10-140 150 80 MODEL NT Type NT50U(M)-GTG4-16-150 16 Coolant Feed . PAT Non-contact seal design eliminates wear damage to body. ENSURING COOLANT DELIVERY TO CUTTING EDGE REQUIRED FOR HIGH SPEED CUTTING. for water-soluble coolant only ds up to ds up -1 dle in 00 m 10,040 Tapers Spin High Speed Available spee spee to -1 dle in 0m 8,0050 Tapers Spin With the Hi-Jet Holder, coolant runs through a separate sealing section called the Merit Set. In the Merit Set, the sealing ring that stays stationary when the body rotates does not come in contact with the body. Only the sealing plate, which rotates with the body, has actual contact with the body. As a result, there is no friction from any seals which can cause body wear. The only wear will be to the Merit Set seals, which are easily replaceable parts. Coolant contamination and high speed operations are no longer limiting factors to the service life of the Coolant Feed Holders. Competitor Design To meet the increasing demand for high-speed operations due to use of carbide cutters, Hi-Jet Coolant Feed Holder models are available that run at speeds up to 10,000 min-1 for 40 tapers and 8,000 min-1 for 50 tapers. Their compact design and 360° adjustability assures compatibility with automatic tool changers of machining centers. Bearing Wear Part Cutting particles in coolant, high speed operation and high pressure cause wear damage. Seal Suitable for small dia. cutters due to high speed and pressure. Coolant C Muorre de nt l Sp Small diameter cutters require high spindle speeds to maintain high 2MPa cutting speed and high coolant pressure due to their small dia. coolant Coolaunrte s holes. The BIG Hi-Jet Pres Holder accepts even 0 smaller diameter shanks, providing high spindle speeds (Max. 10,000 min-1) and high coolant pressures (Max. 2MPa). Wear Part in 50 ta p Bearings in a separate housing from the coolant for extended life. co l s t le Seale d for er -1 fo nut Split Construction PAT. Ideal mechanical sealing construction enables use under high speed and high pressure cutting conditions, preventing the main body from wear damage. r coolan t-th r PAT. Easy maintenance by replacement of wear parts. Easily replaceable Merit Sets consist of Merit Plates, Merit Rings and O-Rings. Merit Plate Perfect sealing by utilizing coolant pressure! For high speed cutting. Prevents the ingress of particles to the collet and body. Special collets no longer necessary. 17 Stationary Part Merit Ring Coolant 1 d in MAX. 2MPa to o l s 4 0 t a p ers a n 0m d 8,0 0 high pump pressure required Rotating Part Merit Plate gh for MAX. 10,000 min-1 for New Baby Chuck Type (ONBS) Coolant Sealed Nut min 00 0 , 0 1 high spindle speed required ou dle Spin ee p to ds u Spee Sp small dia. coolant holes e small dia. cutter dl to maintain high cutting speed Bearing 00 10,0in-1 m Merit Ring 18 SIDE LOCK TYPE NEW BABY CHUCK TYPE Suitable for small diameter drills, gun drills and end mills due to high precision New Baby Chuck. Suitable for popular straight shanks with flat. L L N - 165 øC2 øC1 ød S Hi-Jet type Max. Capacity Oil hole Side Lock Holder Baby Perfect Seal (optional) Hi-Jet type Max. Capacity Oil hole New Baby Chuck N - 150 øD øC1 Model Description DV40 - OSL 20 S Model Description DV40 - ONBS 13 øC2 ød øD L1 Shank No. Shank No. Shank Model ød øD 2.5 - 13 35 DV DV40-ONBS13N-165 -ONBS20N-165 DV50-ONBS13N-165 -ONBS20N-165 2.5 - 20 46 2.5 - 13 35 2.5 - 20 46 BT40-ONBS13N-165 -ONBS20N-165 BT50-ONBS13N-165 -ONBS20N-165 2.5 - 13 35 2.5 - 20 46 2.5 - 13 35 2.5 - 20 46 øC1 165 81.6 øC2 S 73 65 80 165 165 165 99.6 81.6 99.6 80 80 73 65 80 80 80 1. Collet, Adjusting Screw and Wrench are optional items. 2. Max. coolant pressure is 2MPa. 3. Clamping Nut is sold separately. Please order BABY PERFECT SEAL(BPS) for your application. Weight (kg) Collet NBC13 10,000 MES-40 4.0 NBC20 8,000 MES-50 4.3 NBC13 NBC20 7.3 MES-50 8,000 10,000 MES-40 4.0 NBC20 8,000 MES-50 4.3 NBC20 7.3 MES-50 8,000 For NEW BABY COLLET P22 7.5 For STOP BLOCK P21 Model 20 32 58 40 64 32 165 58 20 32 58 40 64 80 8,000 MES-50 6,000 MES-65 8,000 MES-50 81.6 80 99.6 98 6,000 MES-65 80 8,000 MES-50 65 4.4 5.7 7.0 7.4 7.9 8.0 4.3 4.4 5.7 7.0 7.4 80 99.6 165 4.3 80 150 48 25 MES-65 98 150 48 6,000 65 99.6 165 25 98 99.6 150 48 25 MES-50 80 Weight (kg) 98 6,000 7.9 MES-65 8.0 For STOP BLOCK P21 For POSITIONING PINS THE BACK COVER PAGE 4.6 35 4.9 4.2 Model NBC13- 3- 4 3- 4.5 4- 5 4- 5.5 5- 6 5- 6.5 6- 7 6- 7.5 7- 8 7- 8.5 8- 9 8- 9.5 9-10 9-10.5 10-11 10-11.5 11-12 11-12.5 12-13 12-13 BPS20-03035 -0304 -04045 -0405 -05055 -0506 -06065 -0607 -07075 -0708 -08085 -0809 -09095 -0910 -10105 -1011 -11115 -1112 -12125 -1213 -1314 -1415 -1516 -1617 -1718 -1819 -1920 Cutter Shank Dia. 3 - 3.5 3- 4 4 - 4.5 4- 5 5 - 5.5 5- 6 6 - 6.5 6- 7 7 - 7.5 7- 8 8 - 8.5 8- 9 9 - 9.5 9 - 10 10 - 10.5 10 - 11 11 - 11.5 11 - 12 12 - 12.5 12 - 13 13 - 14 14 - 15 15 - 16 16 - 17 17 - 18 18 - 19 19 - 20 øD L1 4.0 4.3 4.6 46 5.1 5.2 4.6 Collet Model NBC20- 3 - 4 3 - 4.5 4- 5 4 - 5.5 5- 6 5 - 6.5 6- 7 6 - 7.5 7- 8 7 - 8.5 8- 9 8 - 9.5 9 - 10 9 - 10.5 10 - 11 10 - 11.5 11 - 12 11 - 12.5 12 - 13 12 - 13.5 13 - 14.5 14 - 15.5 15 - 16.5 16 - 17.5 17 - 18.5 18 - 19.5 19 - 20 PS- 0304 0405 0506 0607 0708 Corresponding BPS Model BPS -03035, 0304 -04045, 0405 -05055, 0506 -06065, 0607 -07075, 0708 OSL REDUCTION COLLET H L1 L PS-0809 0910 1011 1112 1213 Corresponding BPS Model BPS -08085, 0809 -09095, 0910 -10105, 1011 -11115, 1112 -12125, 1213 Model PS-1314 1415 1516 1617 1718 1819 1920 Corresponding BPS Model BPS -1314 -1415 -1516 -1617 -1718 -1819 -1920 ød OSL25-16 -20 OSL32-20 -25 OSL40-25 -32 16 20 20 25 25 32 øD L L1 25 62 5.5 32 66 5.5 40 76 5.5 H 48 50 50 56 56 60 MILLING CHUCK TYPE Suitable for end mills with straight shanks due to superior gripping force. L Model Description DV40 - OMC 20 N - 170 Hi-Jet type Max. Capacity Oil hole Milling Chuck Shank No. Shank DV Model Model øD 4.3 Collet Model øC1 L1 Replacement of PS Ring is recommended when coolant leaks due to damage of the PS Ring. 19 165 58 8,000 81.6 S ød øD Spare seal for Baby Perfect Seal 1 package contains 5 pcs. (1 size). 20 32 2 pcs. of Merit Ring and 2 pcs. of Merit Plate øC2 øC2 BPS13-03035 -0304 -04045 -0405 -05055 -0506 -06065 -0607 -07075 -0708 -08085 -0809 -09095 -0910 -10105 -1011 -11115 -1112 -12125 -1213 Cutter Shank Dia. 3 - 3.5 3- 4 4 - 4.5 4- 5 5 - 5.5 5- 6 6 - 6.5 6- 7 7 - 7.5 7- 8 8 - 8.5 8- 9 9 - 9.5 9 - 10 10 - 10.5 10 - 11 11 - 11.5 11 - 12 12 - 12.5 12 - 13 Standard New Baby Collet PS RING BT40-OSL 20N-150 -OSL 25N-165 -OSL 32N-165 BT50-OSL 20N-150 -OSL 25N-165 -OSL 32N-165 -OSL 40N-165 150 48 25 Merit Set Max. min-1 øC1 S øD L1 20 L ONBS20 Model Baby perfect seal DV40-OSL 20N-150 -OSL 25N-165 -OSL 32N-165 DV50-OSL 20N-150 -OSL 25N-165 -OSL 32N-165 -OSL 40N-165 øD ød ONBS13 Main body size ød Please do not use with neat oil coolant. Using with neat oil coolant carries a risk of fire. Sealed collet nut for coolant-through tools (order separately) Tool shank dia. clamping range: ø3 - ø3.5mm Model 1. Max. coolant pressure is 2MPa. BABY PERFECT SEAL PAT. BPS 13 - 03035 BT For POSITIONING PINS THE BACK COVER PAGE Please do not use with neat oil coolant. Using with neat oil coolant carries a risk of fire. Model Description DV 7.5 NBC13 NBC13 Shank øD BT L Merit Set 2 pcs. of Merit Ring and 2 pcs. of Merit Plate Max. min-1 BT Merit Set Model ød øD L øC1 øC2 S Max. min-1 2 pcs. of Merit Ring and 2 pcs. of Merit Plate Weight (kg) DV40-OMC 20N-170 DV50-OMC 20N-165 -OMC 32N-180 BT40-OMC 20N-170 BT50-OMC 20N-165 OMC 32N-180 20 60 170 81.6 80 65 8,000 MES-50 4.8 20 60 165 8,000 MES-50 6.8 32 80 180 6,000 MES-65 8.5 20 60 170 8,000 MES-50 4.8 20 60 165 8,000 MES-50 6.8 32 80 180 6,000 MES-65 8.5 1. Max. coolant pressure is 2MPa. 2. Nut for Milling chuck type (OMC) needs to be removed when replacing a merit ring and a merit plate. Contact agent for this. 99.6 81.6 99.6 80 98 80 80 98 For STOP BLOCK P21 80 65 80 For POSITIONING PINS THE BACK COVER PAGE Please do not use with neat oil coolant. Using with neat oil coolant carries a risk of fire. 20 for ANGLE HEAD,HIGH SPINDLE & Hi-JET HOLDER STOP BLOCK NEW BABY COLLET Dimensional information of semi-finished stop blocks and instructions for additional machining New Baby Collet "AA" class guarantees ultra runout of 0.001mm at the nose. The dimensions and configuration of the stop block depend upon the model of the machining center. Therefore,the machine manufactuer should be referred to for advice. Semi-finished stop blocks are available,in order to ease the fitting to a machine. Please choose the appropriate stop block from the models shown below. For #40(S=65) #50(S=80) MODEL : SB-A/SB-B Model MODEL : SB-F 75 60 10 11 B M8 CAP BOLT 54 40 ø6 PIN 15 82 15 30 20 ød ø6 PIN 25 Runout of collet 30 19.6 45 10° 0 -15˚ 15 GAUGING 19.6 18 0 10°-15˚ GAUGING 18 4d 10 PT1/4 MAX. Runout (Micron) Colle Class At nose At end of test bar AA 1 3 15 10 20 SB-A=53 SB-B=43 9 ød 9 PT3/8 22 Maximum range 10 for milling øA 8 6 8.6 28 9 30° 11 45 13 28 10 NBC 6-0.5 AA -0.75AA -1 AA -1.25AA -1.5 AA -1.75AA -2 AA -2.25AA -2.5 AA -2.75AA -3 AA -3.175AA -3.25AA -3.5 AA -3.75AA -4 AA -4.25AA -4.5 AA -4.75AA -5 AA -5.25AA -5.5 AA -5.75AA -6 AA øA=9.5 Clamping Range ød 0.25 - 0.50 0.50 - 0.75 0.75 - 1.00 1.00 - 1.25 1.25 - 1.50 1.50 - 1.75 1.75 - 2.00 2.00 - 2.25 2.25 - 2.50 2.50 - 2.75 2.75 - 3.00 2.925 - 3.175 3.00 - 3.25 3.25 - 3.50 3.50 - 3.75 3.75 - 4.00 4.00 - 4.25 4.25 - 4.50 4.50 - 4.75 4.75 - 5.00 5.00 - 5.25 5.25 - 5.50 5.50 - 5.75 5.75 - 6.00 Model Description Max. capacity (mm) MODEL : SB-G/E NBS16 6 Model PIN 70 30 15 ø6 45 30° 30 28 110 PT1/8 10 25 0 10°-15˚ GAUGING 70 45 34 Maximum range for milling 11 ø10.5 6 15 27 10 22.7 ø7 ø6.8 1. Adjustment to the required height by milling the base. 2. Fix the stop block by inserting two dowel pins (ø6) Note : on the sketch indicates heat treatment (HRC45-50), all other surfaces can be milled. CAUTION The use of our stop block is strongly recommended. The units aredesigned to operate only if our original stop block is used and properlymounted to the machine. Failure to use our stop block could void anyor all warranties of the tool. 21 B=27 1. Collapsibility is 0.25 for NBC 6 and 0.5 for NBC 8 to NBC20. 2. For best performance, cutting tool shanks should be cylindrical without flats and be as long as the clamping section of the collet bore. NBS13 / ONBS13N Model NBC13- 3 AA - 3.175AA - 3.5 AA - 4 AA - 4.5 AA - 5 AA - 5.5 AA - 6 AA - 6.5 AA - 7 AA - 7.5 AA - 8 AA - 8.5 AA - 9 AA - 9.5 AA -10 AA -10.5 AA -11 AA -11.5 AA -12 AA -12.5 AA -13 AA øA=20.5 Clamping Range ød 2.5 - 3.0 2.925 - 3.175 3.0 - 3.5 3.5 - 4.0 4.0 - 4.5 4.5 - 5.0 5.0 - 5.5 5.5 - 6.0 6.0 - 6.5 6.5 - 7.0 7.0 - 7.5 7.5 - 8.0 8.0 - 8.5 8.5 - 9.0 9.0 - 9.5 9.5 - 10.0 10.0 - 10.5 10.5 - 11.0 11.0 - 11.5 11.5 - 12.0 12.0 - 12.5 12.5 - 13.0 B=31 NBS20 / ONBS20N Main body size New Baby Collet M6 CAP BOLT øA=16.5 Clamping Range ød 1.5 - 2.0 2.0 - 2.5 2.5 - 3.0 2.925 - 3.175 3.0 - 3.5 3.5 - 4.0 4.0 - 4.5 4.5 - 5.0 5.0 - 5.5 5.5 - 6.0 6.0 - 6.5 6.5 - 7.0 7.0 - 7.5 7.5 - 8.0 8.0 - 8.5 8.5 - 9.0 9.0 - 9.5 9.5 - 10.0 B=14 NBC 6 - 0.5 AA 90 75 65 Model NBC10- 2 AA - 2.5 AA - 3 AA - 3.175AA - 3.5 AA - 4 AA - 4.5 AA - 5 AA - 5.5 AA - 6 AA - 6.5 AA - 7 AA - 7.5 AA - 8 AA - 8.5 AA - 9 AA - 9.5 AA -10 AA Model 1. Adjustment to the required height by milling the base. 2. Fix the stop block by inserting two dowel pins (ø6) For #50(S=110) NBS10 NBS6 NBC16- 3 AA - 3.5AA - 4 AA - 4.5AA - 5 AA - 5.5AA - 6 AA - 6.5AA - 7 AA - 7.5AA - 8 AA - 8.5AA - 9 AA - 9.5AA -10 AA -10.5AA -11 AA -11.5AA -12 AA -12.5AA -13 AA -13.5AA -14 AA -14.5AA -15 AA -15.5AA -16 AA øA=25.5 B=35 Clamping Range ød 2.5 - 3.0 3.0 - 3.5 3.5 - 4.0 4.0 - 4.5 4.5 - 5.0 5.0 - 5.5 5.5 - 6.0 6.0 - 6.5 6.5 - 7.0 7.0 - 7.5 7.5 - 8.0 8.0 - 8.5 8.5 - 9.0 9.0 - 9.5 9.5 - 10.0 10.0 - 10.5 10.5 - 11.0 11.0 - 11.5 11.5 - 12.0 12.0 - 12.5 12.5 - 13.0 13.0 - 13.5 13.5 - 14.0 14.0 - 14.5 14.5 - 15.0 15.0 - 15.5 15.5 - 16.0 NBC20- 3 AA - 3.5AA - 4 AA - 4.5AA - 5 AA - 5.5AA - 6 AA - 6.5AA - 7 AA - 7.5AA - 8 AA - 8.5AA - 9 AA - 9.5AA -10 AA -10.5AA -11 AA -11.5AA -12 AA -12.5AA -13 AA -13.5AA -14 AA -14.5AA -15 AA -15.5AA -16 AA -16.5AA -17 AA -17.5AA -18 AA -18.5AA -19 AA -19.5AA -20 AA øA=28.5 Clamping Range ød 2.5 - 3.0 3.0 - 3.5 3.5 - 4.0 4.0 - 4.5 4.5 - 5.0 5.0 - 5.5 5.5 - 6.0 6.0 - 6.5 6.5 - 7.0 7.0 - 7.5 7.5 - 8.0 8.0 - 8.5 8.5 - 9.0 9.0 - 9.5 9.5 - 10.0 10.0 - 10.5 10.5 - 11.0 11.0 - 11.5 11.5 - 12.0 12.0 - 12.5 12.5 - 13.0 13.0 - 13.5 13.5 - 14.0 14.0 - 14.5 14.5 - 15.0 15.0 - 15.5 15.5 - 16.0 16.0 - 16.5 16.5 - 17.0 17.0 - 17.5 17.5 - 18.0 18.0 - 18.5 18.5 - 19.0 19.0 - 19.5 19.5 - 20.0 B=38 22