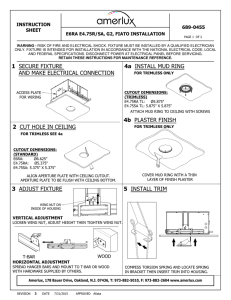

Instruction Sheet – LED | Drywall or Hard Surface

advertisement

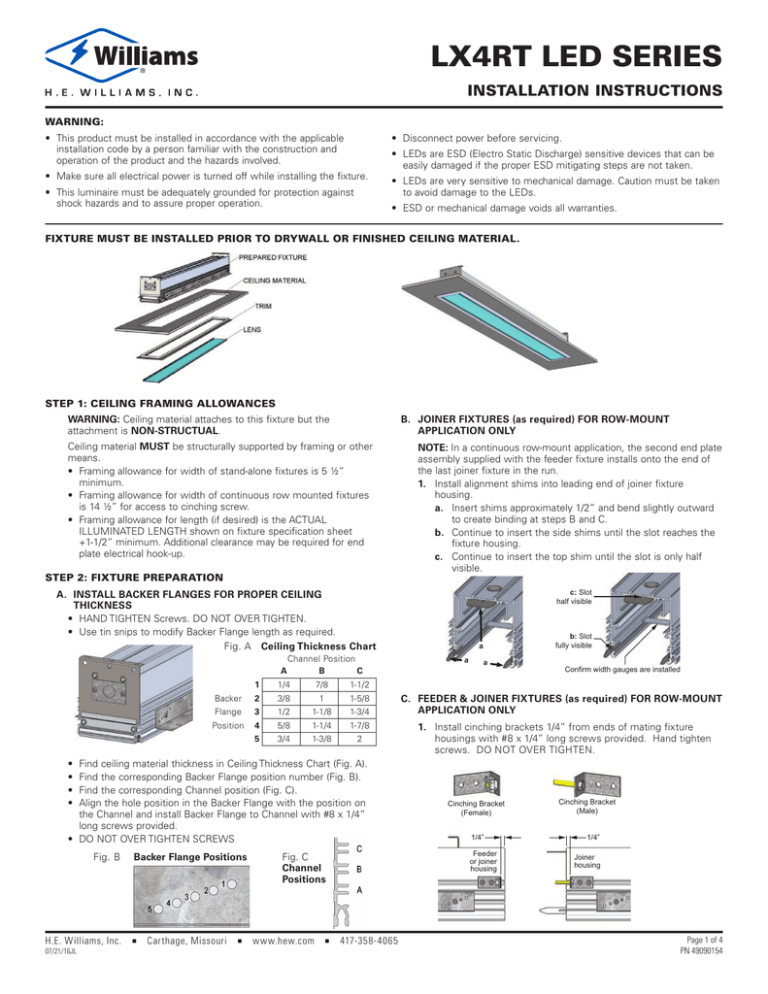

LX4RT LED SERIES INSTALLATION INSTRUCTIONS WARNING: • T his product must be installed in accordance with the applicable installation code by a person familiar with the construction and operation of the product and the hazards involved. • Disconnect power before servicing. • Make sure all electrical power is turned off while installing the fixture. • LEDs are very sensitive to mechanical damage. Caution must be taken to avoid damage to the LEDs. • T his luminaire must be adequately grounded for protection against shock hazards and to assure proper operation. • LEDs are ESD (Electro Static Discharge) sensitive devices that can be easily damaged if the proper ESD mitigating steps are not taken. • ESD or mechanical damage voids all warranties. FIXTURE MUST BE INSTALLED PRIOR TO DRYWALL OR FINISHED CEILING MATERIAL. STEP 1: CEILING FRAMING ALLOWANCES WARNING: Ceiling material attaches to this fixture but the attachment is NON-STRUCTUAL. B. JOINER FIXTURES (as required) FOR ROW-MOUNT APPLICATION ONLY Ceiling material MUST be structurally supported by framing or other means. • Framing allowance for width of stand-alone fixtures is 5 ½” minimum. • Framing allowance for width of continuous row mounted fixtures is 14 ½” for access to cinching screw. • Framing allowance for length (if desired) is the ACTUAL ILLUMINATED LENGTH shown on fixture specification sheet +1-1/2” minimum. Additional clearance may be required for end plate electrical hook-up. STEP 2: FIXTURE PREPARATION NOTE: In a continuous row-mount application, the second end plate assembly supplied with the feeder fixture installs onto the end of the last joiner fixture in the run. 1. Install alignment shims into leading end of joiner fixture housing. a. Insert shims approximately 1/2” and bend slightly outward to create binding at steps B and C. b. Continue to insert the side shims until the slot reaches the fixture housing. c. Continue to insert the top shim until the slot is only half visible. c: Slot half visible A. INSTALL BACKER FLANGES FOR PROPER CEILING THICKNESS • HAND TIGHTEN Screws. DO NOT OVER TIGHTEN. • Use tin snips to modify Backer Flange length as required. Fig. A Ceiling Thickness Chart A Channel Position B C 1 1/4 7/8 1-1/2 Backer 2 3/8 1 1-5/8 Flange 3 1/2 1-1/8 1-3/4 Position 4 5/8 1-1/4 1-7/8 5 3/4 1-3/8 2 • • • • Find ceiling material thickness in Ceiling Thickness Chart (Fig. A). Find the corresponding Backer Flange position number (Fig. B). Find the corresponding Channel position (Fig. C). Align the hole position in the Backer Flange with the position on the Channel and install Backer Flange to Channel with #8 x 1/4” long screws provided. • DO NOT OVER TIGHTEN SCREWS Fig. B H.E. Williams, Inc. 07/21/16JL Backer Flange Positions Carthage, Missouri a a 417-358-4065 b: Slot fully visible Confirm width gauges are installed C. FEEDER & JOINER FIXTURES (as required) FOR ROW-MOUNT APPLICATION ONLY 1. Install cinching brackets 1/4” from ends of mating fixture housings with #8 x 1/4” long screws provided. Hand tighten screws. DO NOT OVER TIGHTEN. Cinching Bracket (Female) 1/4” Feeder or joiner housing Fig. C Channel Positions w w w.hew.com a Cinching Bracket (Male) 1/4” Joiner housing Page 1 of 4 PN 49090154 LX4RT SERIES INSTALLATION INSTRUCTIONS STEP 3: FIXTURE MOUNTING C. CONTINUE FIXTURE INSTALLATION A. INSTALL FIRST FIXTURE (Stand-Alone fixture or FEEDER fixture in row-mount application) 1. Set width gauges at equal distances to maintain channel width during ceiling material installation. 1. Raise the fixture into position and secure using the suspension holes for wire tie or 1/4-20 rod. Suspension Holes for WIRE TIE or 1/4-20 ROD 1. Make electrical connections to fixture. 2. Install ceiling material within 3/8” from housing. 3. Fasten ceiling material to the backer flanges on the fixture. 2. Ensure proper fixture level by hanging the bottom of backer flange even with the ceiling material mounting structure. WARNING: Ceiling material attaches to this fixture but the attachment is NON-STRUCTUAL. Ceiling material MUST be structurally supported by framing or other means. END VIEW Backer Flange Backer Flange Ceiling Material Mounting Structure Ceiling Material Ceiling Material 3/8” maximum gap between ceiling material and fixture housing B. INSTALL JOINER FIXTURE(s) (as required) FOR ROWMOUNT APPLICATION ONLY 4. Remove width gauges from housings. 1. Hang far end of joiner fixture and raise the joining end into alignment with previous fixture. a. Cut gauge in half. b. Push gauge halves up. 2. Make electrical connections between fixtures 3. Mate joiner fixture to previous installed fixture and tighten cinching screw into cage nut in mating cinching bracket. Tighten until connection is firm. Cinching brackets should not touch. (5/16” Drive) 1/4” 1/4” c. Pull gauge halves out from fixture channel. Brackets may flex when tightened but should not touch 5/16” drive 4. Continue with remaining joiner fixtures as required until row is complete. Be sure to install the end plate assembly supplied with the feeder fixture onto the end of the final joiner fixture. Page 2 of 4 PN 49090154 H.E . W illiams, In c. C ar t hage, Mis s our i w w w.he w.c om 417- 3 5 8 - 4 0 6 5 LX4RT SERIES INSTALLATION INSTRUCTIONS TRIM SERIES (LX4RTR FLANGED TRIM VERSION) STEP 4: INSTALL GALVANIZED FIXTURE COVER 1. For row-mount application, cut the double mitered side trim, supplied with feeder fixture, in the middle between clips that are approximately 4” apart. Install one half of the trim into the fixture at the start of the row and the other half of the trim into the fixture at the end of the row. Position tight against the double mitered end trim already installed. A. For FLANGED TRIM installation, install galvanized fixture cover supplied with fixture to protect from over spRay during ceiling finish work. Tape over finger holes after installation. Length varies by application 2ft max between clips 4” approx. Cut on centerline 3/4” approx. (both ends) DBL miter - side trim 2. Install 8ft side trims between the previous trims installed. Cut the last 8ft side trim to fit square with the half piece of mitered side trim at the end. DO NOT RECUT THE MITERED ENDS. 1. Align side flanges on fixture cover with end plate. End Plate Half piece of mitered side trim (both ends) Side Flange Cut to length as required STEP 8: INSTALL LENSES SIDE VIEW Align 8ft side trim A. Insert one side of lens into one side of fixture housing. 2. Overlap ends of fixture covers. B. Push the corner of the opposite side of the lens into place. C. Continue pushing along the housing until the entire lens is installed. D. Cut final Row-Mount lens to length as required. To remove lens, pry out starting with the 4 inch wide end. STEP 5: TAPE OVER FINGER HOLES IN FIXTURE COVERS Tape over holes (painter’s tape) B C A Removal STEP 6: FINISH CEILING TREATMENT Including texture and paint as required. STEP 7: INSTALL FLANGED TRIM (AS REQUIRED FOR TRIM APPLICATION) LX4R90T CORNERS: FIXTURE LAYOUT A. Install and center double mitered end trim into ends of fixture. Corner fixture orientation follows the flow from the power entry end to the end of the run. LX4RT 5.7” end trim LX4R90T-JR Side trim JOINER RIGHT FEEDER LEFT POWER ENTRY H.E. Williams, Inc. Carthage, Missouri w w w.hew.com 417-358-4065 LX4R90T-FL LX4RT-4-J 4FT JOINER SAMPLE FIXTURE LAYOUT VIEWED FROM ABOVE CEILING PLANE LX4R90T-JR JOINER RIGHT JOINER LEFT LX4R90T-JL Page 3 PN 49090154 LX4RT SERIES INSTALLATION INSTRUCTIONS TRIMLESS SERIES (LX4RTL FLANGELESS TRIM VERSION) STEP 4: INSTALL FLANGELESS TRIM 3. Apply edge of mask to fixture housing inside of trim. A. Install and center double mitered end trim into ends of fixture. Factory cut end 5.9” end trim Side trim Mask 4. Remove adhesive liner from second edge of masking. 5. Apply second edge of mask to fixture housing. 1. For row-mount application, cut the double mitered side trim, supplied with the feeder fixture, in the middle between clips that are approximately 4” apart. Install one half of the trim into the fixture at the start of the row and the other half of the trim into the fixture at the end of the row. Position tight against the double mitered end trim already installed. Length varies by application 2ft max between clips 4” approx. Cut on centerline DBL miter - side trim 6. Continue masking fixture row. Overlap joints by 1”- 2” as shown above. 3/4” approx. (both ends) STEP 6: APPLY SEAM TREATMENT 2. Install 8ft side trims between the previous trims installed. Cut the last 8ft side trim to fit square with the half piece of mitered side trim at the end. DO NOT RECUT THE MITERED ENDS. Half piece of mitered side trim (both ends) 8ft side trim A. Tape and mud trim flange to ceiling material. Apply tape to cover half of trim. NOTE: USE A NON MOISTURE ABSORBENT TAPE, SUCH AS FIBERGLASS MESH TAPE, TO AVOID SEAM POPPING ON THE TRIM. Cut to length as required STEP 5: INSTALL FILM MASKING (SUPPLIED WITH FIXTURE) NOTE: Adhesive on masking film is not permanent and can be reapplied. A. Adjust length of mask by cutting mid-section only as required. Use factory cut ends to mask tight with ends of fixture. Tape over half of trim Tape and mud trim flange STEP 7: FINISH CEILING TREATMENT Including texture and paint as required. Factory cut end Cut from center as required STEP 8: INSTALL LENSES (See Page 3, Step 8) 1. Allow for 1”-2” overlap of masking when installed. 1”-2” overlap 2. Remove adhesive liner from one edge of masking. Page 4 of 4 PN 49090154 H.E . W illiams, In c. C ar t hage, Mis s our i w w w.he w.c om 417- 3 5 8 - 4 0 6 5