electrical contractor

AURORA HALOGEN ACCENT HOUSING 6

GENNA WALL WASH SQUARE TRIM

INSTALLATION INSTRUCTIONS

Fixtures must be installed by a qualified electrician (check with local and national codes for proper installation).

To prevent electrical shock , disconnect electrical supply before installation or servicing.

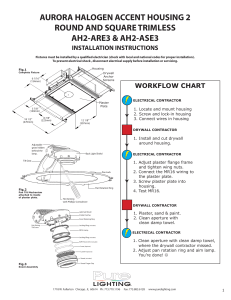

Fig.1

Complete Fixture

4 5/8”

(117mm)

4 3/4”

(120mm)

15 3/4”

(400mm)

7 1/8”

(180mm)

Fig.2

Genna Wall Wash Trim Assembly

9 1/4”

(235 mm)

4 Mounting

Hanger Bars

Perforated Strip

5 Plaster Plate

WORKFLOW CHART

ELECTRICAL CONTRACTOR

1. Locate and mount housing

2. Screw and lock-in housing

3. Connect wires in housing

DRYWALL CONTRACTOR

1. Install and cut drywall

around housing

ELECTRICAL CONTRACTOR

1. Adjust plaster flange frame

and tighten wing nuts.

2. Connect the lamp wiring to

the plaster plate.

3. Screw plaster plate into

housing.

4. Test lamp.

DRYWALL CONTRACTOR

1. Plaster, sand & paint.

2. Clean aperture with

clean damp towel.

ELECTRICAL CONTRACTOR

1. Clean aperture with clean damp towel,

where the drywall contractor missed.

2. Attach safety cable on trim and insert

trim into plaster plate and you’re done!

1

2

ELECTRICAL CONTRACTOR

1

Use these dimensions when locating center point of aperture during installation.

Align fixture using laser or chalk line.

4 5/8 "

(117mm)

4

5/8

"

(117mm)

4 3/4 "

(120mm)

11

7/8

"

(302 mm)

7 1/8 "

(180mm)

NOTE: APERTURE

IS CENTERED WITH

CURVES IN HOUSING.

Alignment

Notch

Hangers bars must align and remain flush with joist.

2

9 1/4 "

(235mm)

Alignment

Notch

Drywall

anchor screens may be removed, if the joists are less than 11 1/2” apart.

NOTE: APERTURE

IS CENTERED WITH

CURVES IN HOUSING.

(NOT CENTER OF HOUSING)

MUST BE

FLUSH WITH

JOIST.

ELECTRICAL CONTRACTOR

3

After fixture is positioned, tighten all (6) screws on hangers bars.

REMODEL NOTE: CUT

DRYWALL TO MIDDLE

OF JOIST.

4

After installation, pull on the fixture to ensure there is no movements.

3

ELECTRICAL CONTRACTOR

5

LINE INPUT 120V - 240V

INSIDE AURORA JUNCTION BOX

(NOT TO SCALE)

- Neutral

+ Dimmable Switchleg

*NOTE*

Leave 12” of wire in the junction box for future maintenance through

the fixture aperture.

TO NEXT FIXTURE

Pull on wire nuts to make sure the

connection is tight.

THERMAL

PROTECTOR

MAGNETIC LOW

VOLTAGE DIMMER

TEST HOUSING TO VERIFY

PROPER HOOK UP AND

FUNCTION. IF NECESSARY,

REPAIR ELECTRICAL

CONNECTIONS AT THIS POINT.

INSIDE AURORA

FIXTURE

120V 75W MAGNETIC

TRANSFORMER

MR16 LAMP

4

WIRING DIAGRAM

FOR USE WITH PURE LIGHTING AURORA NON-RGB FIXTURES

DRYWALL CONTRACTOR

6

Drywall contractor must install drywall and cut 12" (305mm) X 9 1/2" (235mm) hole with rotary cutting tool around fixture or pre-cut hole in drywall prior to installation.

El contatista debe instaler el techo falso y cortar una apertura de 12" (305) X 9 1/2" (235mm) en el mismo previo a la instalacion.

ELECTRICAL CONTRACTOR

7

Electrician must anchor drywall to drywall anchor screens. Insert screws through drywall into anchor screens on fixture.

Drywall Anchor Screen

Insert

Dry wall S cre ws Here

Drywall Anchor Screw

5

ELECTRICAL CONTRACTOR

8 Loosen (4) wing nuts and adjust plaster flange frame to be flush with drywall. All 4 corners MUST be exactly even with drywall. Plaster flange frame adjust to accommodate 1/2" (13mm) to 1 1/4" (32mm) ceiling thickness.

Lo n se w

In gn ut s to adjust pla ste r fl an e g m e

Plaster Flange

Frame

9 Use a straight edge or level and move plaster flange frame up or down to be exactly even with drywall.

6

Ceiling

10 Use a straight edge or level and move plaster flange frame up or down to be exactly even with drywall. n w

In g nu ts t o adjust pla ste r fl an g e g

TI e m

LEVEL

PLASTER

FLANGE FRAME AND

TIGHTEN WING NUTS OR

PLASTER SEAMS WILL CRACK !

ELECTRICAL CONTRACTOR

11 Pull lamp socket wire through heat shield door opposite of the junction box.

12 Loosely attach plaster plate using all (4) screws. After all (4) screws are started, go back and tighten the screws securely.

13 Use level to verify that plaster plate is flush and even with the drywall.

DRYWALL CONTRACTOR

Compatible only with traditional, level 5 surface finishing, not self-leveling, PVA primer systems.

14 Plaster (Yeso)

Apply a 1/16" layer of Durabond® 45 compound around all four sides. Make sure provided paint shields is in place.

DO NOT USE TAPE.

DO NOT USE PVA PRIMER SYSTEMS.

Aplicar una capa delgada de Durabond® alrededor de los cuatro lados. Asegurese que el protector de pintura este puesto.

15 Sand (Lijar)

Sand and plaster again, until smooth finish is achieved.

Lijar y aplicar yeso otra vez hasta que la supercie estes completamente lisa.

8

16 Paint (Pintar)

Paint over the paint shield. Remove paint shield 20 to 60 minutes after painting.

Pintar sobre el protector de pintura. Remover el protector de pintura 20-60 minutos despues de pintar.

17 It is optional to paint trim to match ceiling, apply 3 light coats with paint brush only. Use painters tape to mask off edges and beveled side of the trim.

Si usted va a pintar el marco para combinar con el techo, aplique tres capas ligeras de pintura con rollo o spray. Use cinta de pintores para proteger los bordes y el lado del borde biselado.

PAINT THIS SURFACE ONLY

Solamente pinta esta superficie

DO NOT PAINT

THESE SURFACES

No pinte estas superficies

DRYWALL CONTRACTOR

18

Remove paint shield from aperture

20-60 minutes after painting.

Remueva el protector de pintura de la apertura de 20 a 60 minutos despues de pintar.

19

Remove any excess paint that is on the plaster plate aperture. The trim will not fit correctly if any excess paint remains around aperture. Wipe inside of aperture with clean damp towel.

Remueva cualquier exceso de pintura que este en la apertura. El marco no quedara bien colocado si existe cualquier exceso de pinrura alrededor de la apertura. Limpie adentro de la apertura con una toalla limpia y humeda.

ELECTRICAL CONTRACTOR

20

Pull socket wire through aperture, attach lamp to socket wire.

21

MR16 LAMPING

ORIENTATION

LAMP

HID RING

GLASS SHIELD

TRIM

CMH LAMPING

ORIENTATION

NOTE: When installing lamp use drawing to properly install all the parts.

Insert lamp into the trim, and secure using the lamp springs.

9

ELECTRICAL CONTRACTOR

22

Using the provided Allen wrench attach trim to safety cable.

23 Insert trim into plaster plate, tilt trim and insert back edge.

24 Once the back edge of the trim is in place push trim straight up, verify that the trim snaps in properly and fits flush with the ceiling.

ELECTRICAL CONTRACTOR

25 Verify trim position and test complete fixture once trim and lamp are installed.

WALL

Tilt lamp up and insert fingers though slot in Genna Trim

Apply pressure and tilt forward to remove

Genna trim.

1718 W.

Fullerton Chicago , IL 60614 Ph: 773.770.1196 Fax: 773.883.6128 www.purelighting.com