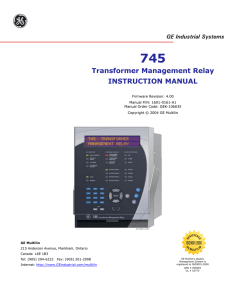

735/737 Feeder Protection Relay

advertisement

GE Consumer & Industrial TRIP STATUS TIME 51 COMMUNICATION 1 2 3 4 5 6 7 8 INST 50 A C 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% +1 +2 +4 +8 +16 ADDRESS 1200 PHASE PICKUP CURRENT BAUD 2400 B 9600 SERVICE REQUIRED 19200 RELAY IN SERVICE 735/737 Feeder Protection Relay TEST (% OF CT) GROUND PICKUP G CLEAR Release Notes PHASE PICKUP (% OF CT) INSTANTANEOUS (x CT) 6 4 10 12 E IN Y MEL EXT RE 1 16 HI LO HI RS LO E TI ME 2 VE FI NIT 8 9 INV ER S 7 5 LO H I 6 3 MODERATELY 5 14 130 40 HI 8 90 200 LO SE INVER 0 OFF 10 0 22 OFF DE 0 TIME MULTIPLIER MAL INVERSE NOR E HI 20 CURVE SHAPE LO 30 120 11 150 16 60 70 0 180 80 50 RY VE 0 14 4 10 OFF 20 GROUND PICKUP (% OF CT) 7 6 9 8 10 FI E LO RS HI Y MEL EXT RE VE DE LO E TI ME IN 2 1 10 GE Publication Number: GER-4070 12 16 HI 4 INV ER S 6 5 LO H I 5 14 MODERATELY HI 3 HI NIT 8 130 40 LO SE INVER 30 120 90 200 E LO 150 16 60 70 0 180 80 50 INSTANTANEOUS (x CT) MAL INVERSE NOR RY VE 0 14 20 0 10 0 11 0 OFF 22 OFF TIME MULTIPLIER CURVE SHAPE 4 OFF 20 Copyright © 2005 GE Multilin 737 Feeder Protection Relay 803649A2.CDR Overview Summary • Affected products: 735/737 Feeder Protection Relay • Date of release: November 18, 2005 • Firmware revision: 1.56 • Hardware revision: D Release summary This release note describes the 735/737 Feeder Protection Relay harsh environment option release. GE Multilin technical support GE Multilin contact information and call center for product support is shown below: GE Multilin 215 Anderson Avenue Markham, Ontario Canada L6E 1B3 Telephone: 905-294-6222 or 1-800-547-8629 (North America), +34 94 485 88 00 (Europe) Fax: 905-201-2098 (North America), +34 94 485 88 45 (Europe) E-mail: multilin.tech@ge.com Home Page: http://www.GEmultilin.com GE Multilin 1 Release details 735/737 harsh environment option release notes Release details Modified features Hardware: added Harsh Environment option This release includes the addition of the Harsh Environment coating option. This option is for use in sulfur-rich environments such as petroleum and chemical plants, oil refineries, paper and pulp recycling plants, sewer and wastewater plants, and steel mills. The atmosphere produced by various chemical technologies in such facilities causes a serious corrosion problem for many metals used in electrical apparatus. Humidity and temperature variation contributes to the corrosion process leading to electronic equipment failures. The Harsh Environment coating option: • protects electronic equipment from corrosive gases • reduces machines and processes down time • minimizes equipment maintenance and repair cost The order code has been changed to introduce the harsh environment option “-H”. Table 1: 735/737order codes 735/ – 6 – 6 – 6 – 6 – 6 737 – 6 – 6 – 6 – 6 – 6 735 | | | | | Basic Unit 737 | | | | | 1 | | | | Phase CT Secondary 5 | | | | 1 | | | Ground CT Secondary 5 | | | LO | | Control Power HI | | 485 | Options 422 | DEMO | Harsh environment H 2 Standard 735 relay with 50/51, 50G/51G protection 737 relay (same as 735 with 8 additional output relays) 1 A phase CT secondaries 5 A phase CT secondaries 1 A ground CT secondaries 5 A ground CT secondaries 20 to 60 V DC; 20 to 48 V AC at 50/60 Hz 90 to 300 V DC; 70 to 265 V AC at 50/60 Hz RS485 2-wire communications (standard) RS422 4-wire communications (optional) 735 demo/test case Harsh environment option GE Multilin