EQ Credit - U.S. Green Building Council

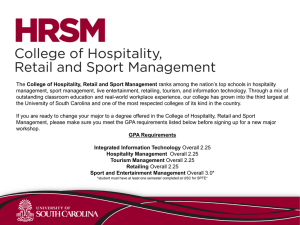

advertisement