Presentation

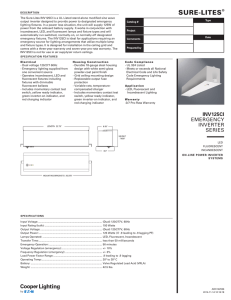

advertisement

A company of the WALDMANN GROUP The shift to LED in Industrial Task Lighting Prepared for WALDMANN USA February 1st 2011 © Herbert Waldmann GmbH & Co. KG Topics The move to LED – Why is it happening? What are the barriers to change? What is the time frame for change? Who are the customers making and not making the change now? LED compared to halogen, incandescent and fluorescent LED as a task light source Q&A 2 The move to LED – Why is it happening? LED is a much better source for task lighting Maintenance free operation reduces costs Much less heat than halogen/incandescent Low voltage operation is much safer Small, slim package fits in tight spaces Easily controllable through the use of optics Works best in directional light applications Variety of beam distributions Low impact/load on machine power supply Impervious to shock or vibration 3 What are the barriers to change? Currently, a very limited installed base of products in the marketplace Still only a few products on the market, able to withstand industrial use and conditions on a daily basis Initial product costs are higher compared to older technologies Costly to develop for Industrial applications, must be = or > IP65 Often MRO purchase is a product identical to light needing replacement Not yet a viable replacement for very high lumen output requirements 4 What is the time frame for change? Within 5-8 years, incandescent lamps will be obsolete and halogen will be in a very steep decline. Essentially all incandescent extinct within 10 years Fluorescent and HID will continue to be used but in lower quantities and primarily for low-cost ambient applications that are easy to re-lamp Within 5 years, all major machine manufacturers will have switched over to LED for lighting the interior of their machines and equipment Within 5 years, generally all new task lights will use LED, not fluorescent 5 Which customers are making the change now? Customers tend to be larger, Fortune 500 type companies looking to systematically upgrade facilities and equipment These companies typically have “Green” initiatives for removing inefficient light sources with the goal of reducing energy consumption and carbon emissions Sophisticated manufacturing such as aircraft, automotive, electronics, semiconductors, medical, defense OEM’s looking to reduce heat, size and footprint of lighting equipment within their machines Machine rebuilders looking to upgrade 6 Which customers will be more resistant to change? Mid-size and smaller operations who’s primary concerns involve initial product acquisition costs Customers whose applications require less sophisticated lighting equipment and do not require waterproof, vibration or impact protection Customers choosing to replace lighting equipment on an “as-needed” basis with identical products to those being replaced Customers burned by inferior quality LED equipment which often burn out faster than traditional products replaced 7 LED – Advantages and disadvantages Cost advantages Low energy consumption Low heat emission Long lifetime of the light source No maintenance costs Low disposal costs Cost disadvantages Efficiency still must be improved (Price / Lumen) High development costs for the LED PCBs Higher initial product cost LED – Advantages and disadvantages Technical design advantages Small in size (fit in conventional lights) Modern designs with slim housings Possibility of individual light shapes thanks to different LED arrangements Vibrant color using different color LED’s, i.e. red, blue, green Instant ON/OFF functionality Ability to develop precise optics Technical design disadvantages Color differences are often visible, in spite of identical binnings LED – Advantages and disadvantages Technical advantages Shock and vibration resistant Instant on/off operation, no warm up Precise light orientation (beam angle) without additional reflector thanks to the integral LED optics No UV / IR radiation No bulb socket required Safety through protective low voltage Good color rendering properties (RGB) Technical disadvantages Poor color rendering properties (about Ra 85) with white LEDs Color temperature & color rendering depend on the temperature and age of the LED LED vs. Fluorescent vs. Halogen LED Best suited for task lighting Lower power consumption Very little heat output Extremely long life (50,000+ hours) Fluorescent Best suited for area (ambient) lighting Low power consumption Moderate heat output Long life (up to 30,000 hours) Halogen (Incandescent) Can be task or ambient High power consumption High heat output Moderate/Low life (<5,000 hours) 11 LED’s as a Task Light Source Sweet spot for LED Lighting Excellent at penetrating through liquids and coolants Low heat in the direction of beam minimizes baking on of coolants Power supply can be integrated into machine switch Instant on/off with no impact on lamp life Multiple beam angles available for precise focus and positioning Operates at a very high frequency 12 Why Waldmann?? Products are “Professional Grade” and designed specifically for heavy daily use in harsh, demanding Industrial applications Lower cost alternatives tend to have poor quality components and limited performance and control Lower quality products fail in these environments for two primary reasons: Excessive heat build-up Liquid intrusion Similar grade differences as in tools 13 Why Waldmann?? Our products are much safer to use than lower quality products Elimination of pinch points Concealed springs that will not corrode and break Mounting and adjustment hardware is much more robust and much less prone to failure Hardware or adjustment failure can compromise employee safety Lower quality components add to worker fatigue and eye strain Our warranty and service is superior to our competitors 14 Summary…Why LED?? LED is taking over the Industrial Task Lighting space, the benefits overwhelming, incandescent sources will soon be obsolete New product development will almost exclusively focus on LED or a combination of LED and fluorescent Large, environmentally concerned organizations are the early adopters of LED technology OEM’s are moving to LED in new machines and away from fluorescent Green solutions are becoming essential in new construction 15 A company of the WALDMANN GROUP THANK YOU VERY MUCH FOR YOUR TIME. Any Questions © Herbert Waldmann GmbH & Co. KG