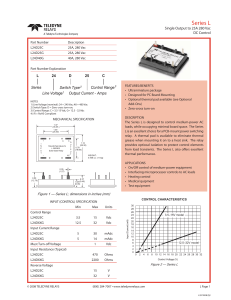

12 - TE Connectivity

advertisement