A Cover Story:

Reinforcement

Supports and Ties

Placing reinforcing steel properly

is critical to concrete durability

By Susan C. McCraven

W

hat do the words slab bolsters, high chairs, wire

reels, dobies, continuous

runners, sand plates, rod

buster, and sore backs mean to

you? If you are thinking reinforcing

steel placement, you are correct.

Workers who place re-inforcing steel,

commonly called rod busters or

ironworkers, have one of the most

physically demanding jobs in the

industry.

“We have to ask why we need reinforcing bar supports in the first

place,” insists Dave Wilkes, president

of Meadow Burke Products, Tampa,

Fla. “In order to produce a quality

product, a minimum concrete cover

over the re-steel must be maintained.

Ties and supports are our insurance

for establishing the specified cover

necessary to protect the steel from

corrosion.”

Rebar suppor ts and tie wires

Reinforcing bar supports are

made of steel wire, precast concrete,

or plastic. There are four classes of

bar supports based on the degree of

protection provided against corrosion. The Concrete Reinforcing Steel

Institute (CRSI) lists typical types

and sizes of supports and industry

placing practices for these reinforcement accessories:

Class 1: Plastic-protected wire bar

supports provide maximum protection

against corrosion for severe exposure

or where grinding or sandblasting of

the surface is necessary.

Class 1A: Epoxy-coated, vinylcoated, or plastic-coated wire bar supports for moderate to maximum exposure where no grinding or sandblasting

is required. Class 1A generally is used

for epoxy-coated reinforcing bars.

Class 2: Stainless steel protected

wire bar supports that serve in conditions of moderate exposure and light

grinding or sandblasting.

Class 3: Bright basic wire bar supports, which provide no protection

against rusting, and are used where

they will not come in contact with the

exposed concrete surface or where surface blemishes can be tolerated.

While all-plastic supports are not

subject to rusting, they must be designed so that they do not crack

under loading or when used in cold

weather. Because of the difference in

thermal properties (plastic expands

and contracts due to temperature

changes much more than do concrete

and steel, which share a similar coefficient of thermal expansion), plastic supports should be perforated

over 25% of the gross plane area.

The perforations compensate for

thermal property differences.

Chairs and supports are available

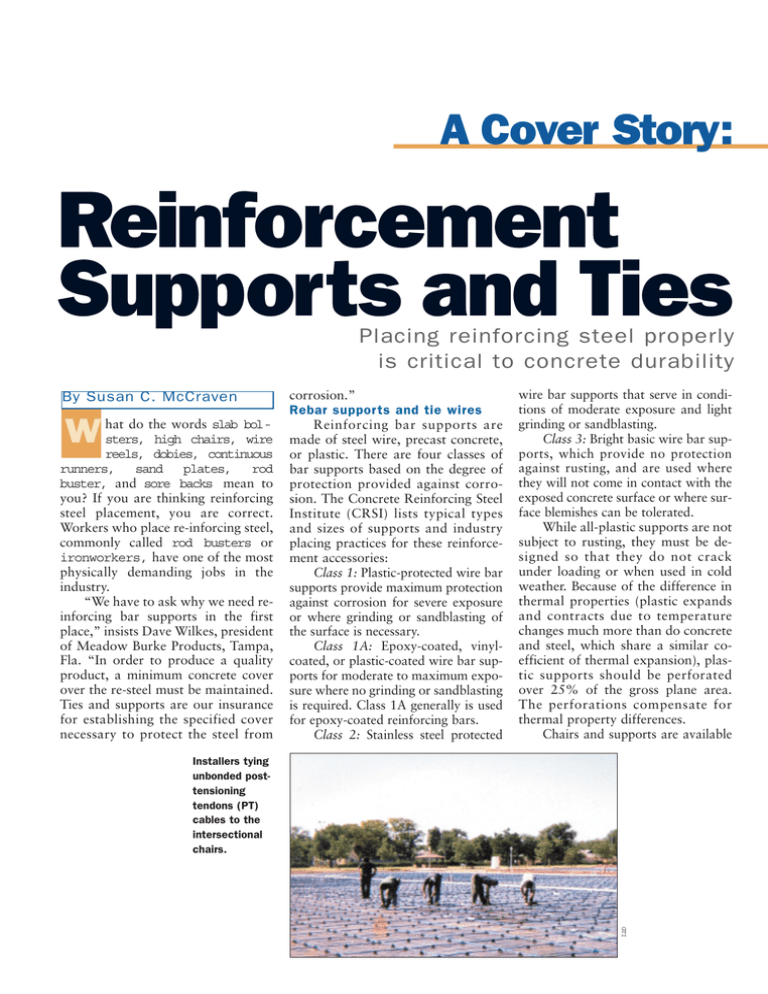

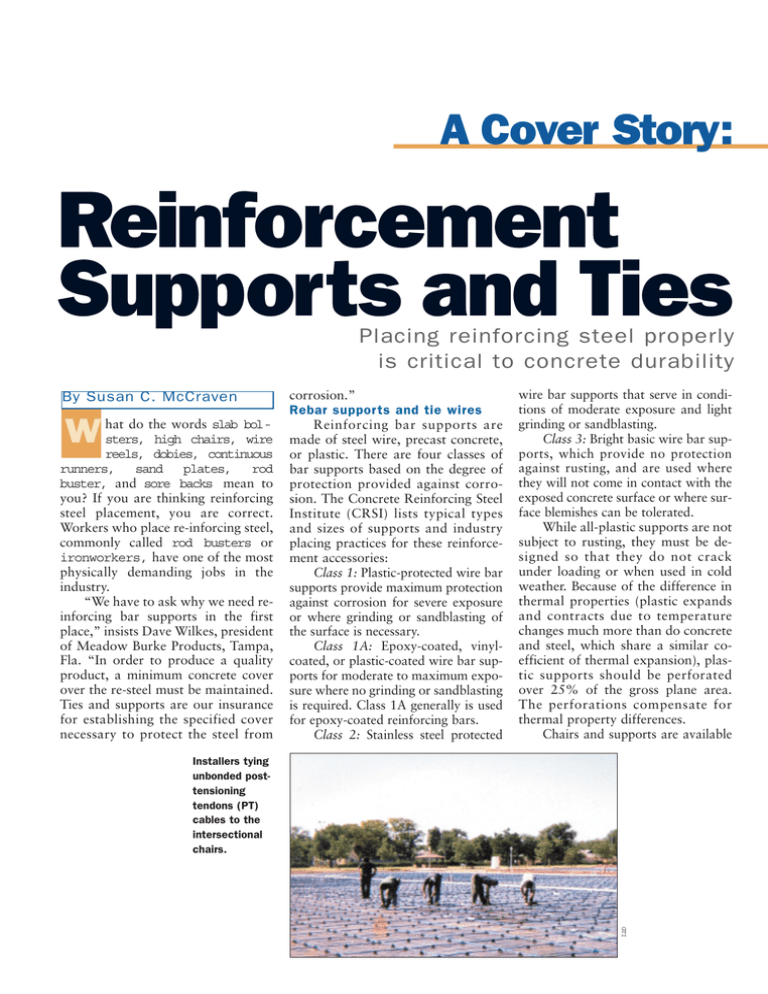

Installers tying

unbonded posttensioning

tendons (PT)

cables to the

intersectional

chairs.

GTI

G O PA ENTERPRISES

This “TiChair” device

locks rebar and posttensioning cable into

position directly at

the intersection, eliminating all wire tying.

The lightweight nylon

is noncorrosive, has

rounded edges for

safety, and is colorcoded for size.

Tie types vary according to

the situation.

Det. A is a snap or single tie;

Det. B is a wrap and snap tie;

Det. C is a saddle or “U” tie;

Det. D is a wrap and saddle

tie; and Det. E is a figureeight tie.

CONCRETE REINFORCING STEEL INSTITUTE

Rebar tying

machines are uniquely designed to

replace the manual

process of tying

rebar. They can save

time and money

while eliminating the

backbreaking nature

of tying rebar.

U-TIER

Rod busters have

to bend constantly

on the job to

install reinforcement and ties. This

work on Highway

401 in Ajax,

Ontario, is physically demanding.

in various heights (usually 1⁄4 inch) to

support specific reinforcing bar size,

and prices vary for each category and

material. Supports also are used to

support post tensioning cables in the

dropped position. In general, plastic

accessories are less expensive than

metal supports, and prices will vary

depending upon the quantity, region,

and supplier. For example, the price

for 100 Class 3, bright basic wire 2inch-high chair with plate is $125. For

100 2-inch-high plastic high chairs

with base the price is about $20.

To meet the specification for

concrete cover, it is not enough to

simply place the bars on supports.

Reinforcing steel must be secured to

prevent displacement during construction activities and concrete

placement. Although equipment can

vary from region to region in the

country, tie wire is usually available

in 3- to 4-pound coils. Wires are

placed in a wire holder or a reel is

suspended from the rod buster’s belt

for accessibility. The wire is typically 161⁄2 - or 16-gauge black, soft, annealed wire.

More heavily reinforced structures require 15- or 14-gauge wire to

hold the proper position of the rebar.

A variety of tie types (ties are basically wire twists for connecting intersecting bars), from snap or single ties

to saddle ties, is used in the concrete

reinforcing industry. The CRSI book

Placing Reinforcing Bars illustrates the types of ties and describes

the circumstances where each is commonly used (see figure).

Standard practice

CRSI writes the rules for acceptable standard practice in the reinforcing steel industry. CRSI’s

Manual of Standard Practice, or

MSP-1, is referenced by the ACI 318

Building Code Requirements. CRSI’s

Placing Reinforcing Bars is the

rod buster’s indispensable handbook.

CRSI publications provide drawings showing the proper placement

of supports and ties, but structural

drawings usually indicate only the

specified concrete cover. The reinforcing steel subcontractor is

responsible for proper installation of

supports and ties. As an example, the

table on page 43 is typical of what

Typical reinforcing steel cover specification

Reinforcing steel shall have protection as follows:

Use

Beam and column bars and

tied shear wall boundary zones

Slab bars

Wall bars: interior faces

exposed to earth or weather

Cover

11⁄2" (to stirrup or ties)

1"

3

⁄4"

11⁄2" (#5 and smaller)

2" (#6 and larger)

3"

Footing bars

Concrete wall reinforcing (unless otherwise noted):

Wall Thickness

6"

8"

10"

Horizontal Bars

#4 @ 16" o.c.

#4 @ 12" o.c.

#4 @ 18" o.c.

Vertical Bars

#4 @ 16" o.c.

#4 @ 16" o.c.

#4 @ 18" o.c.

12"

#4 @ 16" o.c.

#4 @ 16" o.c.

the reinforcing steel installation contractor would get in a specification

for reinforced concrete construction.

Industry rules for proper installation of reinforcing steel are found

in CRSI’s MSP. Here are some things

to remember:

1. Epoxy-coated reinforcing bars

and supports must be coated entirely

with a dielectric material, such as

epoxy or plastic.

2. Bar supports are not intended

as support for construction equipment such as concrete pumps or buggies.

3. Spacing of bar supports depends

upon the size and placing of the reinforcing bar being supported. For example, for a one-way solid slab, with #5

temperature-shrinkage bars, high chairs

are used at 4 feet on center; for #4 bars,

high chairs would be placed 3 feet on

center to prevent sagging.

4. Highway bridgework may

require more stringent specifications

for supports and ties depending upon

the transportation authority that has

jurisdiction. (See comments under

“New technology and trends.”)

5. Concrete cover tolerance cannot exceed minus one-third of the

minimum cover required on the project drawings or specifications.

6. Placing reinforcement onto

layers of fresh concrete or adjusting

the position of bars or welded wire

Location

@ CL of wall

@ CL of wall

cover distance

from each face

cover distance

from each face

fabric during concrete placement

should not be permitted. (The illadvised practice in slab construction

of placing reinforcement on the subgrade and pulling it up during concrete placement is called “hooking.”)

7. Spacers for vertical concrete

(wall construction) have traditionally

been optional. Side form spacers

include wire bar supports, doubleheaded nails, precast concrete blocks

(dobies), and proprietary all-plastic

shapes.

8. The ironworker foreman and

the inspector should check structural

drawings for bar placements, hooks,

and required concrete cover, and discuss any questions with the engineer.

9. Incorrect reinforcing steel placement practice could lead to serious concrete structural failure. For example,

lowering the top bars or raising the bottom bars by 1⁄ 2 inch more than that specified in a 6-inch deep slab could reduce

its load carrying capacity by 20%.

10. It is not necessary to tie bars at

every intersection. Tying adds nothing

to the strength of the finished structure. The purpose of tying is to maintain the bars in proper position during

construction and maintain the required concrete cover; beyond that,

additional tying is unnecessary.

11. “Tack” welding, or field welding, of crossing bars should be avoided. All welding should conform to

ANSI/AWS D1.4, “Structural Welding

Code—Reinforcing Steel.”

12. The ironworker, ironworker

foreman, contractor, and inspector all

have the responsibility to see that the

reinforcing bars in concrete construction are placed properly.

The federal government regulates

safety on the jobsite. OSHA regulations

have been a blessing for worker safety

but often a curse for construction

schedules. Jeff Larson, field superintendent of Steel Engineers, Las Vegas, says,

“The OSHA regulations for hoisting flyover zones have been particularly problematic. In high-rise construction here in

Nevada and elsewhere, keeping all

workers out from under the crane hoisting flyover zone is very difficult to

enforce.” On the other hand, Bill

Livingston, president of Quality ReSteel, Brighton, Mich., remembers the

days of no OSHA regulations in the

early 1960s. “In particular, the OSHA

regulations for barrier rails around

openings in construction have been a

good change. We cover OSHA and

proper safety methods at our industry training programs held annually

in San Diego.” Livingston explains,

“There will always be pros and cons

when it comes to OSHA regulations,

but job safety must be a priority.”

New technology and trends

Probably the newest tool to hit the

rebar placing profession is the tie gun.

According to Gary Miledi, president of

U-Tier Co., Dallas, “Our product retails

for about $1985. In the past there were

problems with maintenance of the tying

gun. The machines have been completely

redesigned and re-engineered and are

now very durable. We will provide trial

equipment to installers who would like

to assess the newer models.” U-Tier

claims that the wire gun is less physically

demanding for the installer, wastes less

material (wire), provides correct twisting

mechanics, and saves time on the job.

Larson, however, disagrees with the

time savings claim, saying, “Our rod

busters typically go through 2 to 21⁄ 2

rolls of wire per day; with 300 feet of

wire on a roll, it’s hard to see how the

gun can beat our production.” U-Tier

would counter that much of the reel wire

is wasted in material that is cut off.

Plastics are growing as the material

of choice for bar supports. Joe Harrison,

structural engineer and vice president

for marketing of General Technologies

Inc. (GTI), Stafford, Texas, says, “Plastics rapidly are becoming the bar support of choice. I would estimate that

about 50% of the bar supports used in

our area are plastic.” With over 20 years

of experience in the re-steel accessory

business, Harrison comments on what

he sees as the major trends: “We are

seeing greater acceptance of plastic or

composite bar supports across the country. Twenty years ago bar supports were

predominantly metal. As a result of corrosion problems and staining of concrete, plastic protected metal bar supports were developed. Ultimately, plastic

bar supports were developed as an alternate to a thin, plastic coating over metal.

There are still regions where metal bar

supports are the material of choice;

however, an increasing number of DOTs

are converting to plastic accessories.”

Plastic supports can equal or exceed

the strength of traditional concrete

dobies. GTI’s composite bar chair has

been shown to support loads exceeding

2000 pounds. Tilt-up and precast panels

typically use all-plastic supports.

Reinforced concrete project drawings are not simple to decipher, and specifications are getting even more specific.

According to Livingston, “Rebar drawings are not easy to read. We teach

apprentice rod busters how to interpret

drawings and install the steel correctly.”

Larson said there is a growing requirement for additional testing of supports:

“More often today, we find that dobies,

or concrete block supports, must be certified for compressive strength.” Livingston and Larson agree that installation

requirements for highway work are

much more stringent. Larson stated that,

“Nevada’s DOT requires that bars

placed more than 1 foot on center be

tied at every intersection, or 100%. Bar

spacing less than 1 foot on center

must be tied at 50%.” Michigan’s

DOT is also more stringent than

CRSI, notes Livingston: “MDOT

requires that all top steel be tied at

100%, or at every intersection, and that

all bottom steel be tied at 50%. And you

never can get the DOT engineers to tell

you why this is necessary.”

The toughest trade?

Everyone agreed that rod busting is

the toughest trade in construction today.

“Rod busters must carry hot reinforcing

bars on their shoulders in the summer

and freezing bars in the winter,” said

Livingston’s son, Kevin, who already has

typical rod-busting backaches even as a

young man. “Unlike other construction trades, there is no downtime for

the rod buster. Guys work straight

through without stopping except for

mandatory breaks, and they bend over

constantly to place and tie steel.”

“We usually work without the advantage of cranes to lift the bars, as is

the case for structural steel and ironworkers,” says Bill Livingston. Back

problems are endemic in this trade,

and shoulder burns from hoisting hot

steel bars are not uncommon.

The reinforcing steel installation

trade shares the serious shortage of

trained workers presently experienced

by the concrete construction industry as

a whole. “Finding and keeping skilled

rod busters is no easy task. In our efforts

to find and keep workers, our ironworker local has agreed to establish

higher incoming pay scales for apprentice rod busters if they agree to stay in the

trade for a minimum period,” said

Livingston. Given the opportunity,

most rod busters will move on to less

physically punishing construction trades.

Look for the “New Generation

of Reinforcing,” covering nonsteel reinforcement in the September issue of

CONCRETE CONSTRUCTION. ■

References

1. ACI 117, “Standard Specifications for

Tolerances for Concrete Construction

and Materials and Commentary,”

American Concrete Institute,

Farmington Hills, Mich.

2. ACI 318, “Building Code Requirements

for Structural Concrete,” American

Concrete Institute, Farmington Hills, Mich.

3. Manual of Standard Practice, MSP1, Concrete Reinforcing Steel Institute,

Schaumburg, Ill.

4. Placing Reinforcing Steel,

Concrete Reinforcing Steel Institute,

Schaumburg, Ill.

Suppliers of reinforcement supports

and ties

Aztec Concrete Accessories;

877-531-3344; fax: 909.355.8649;

www.azteconline.com

Clip-Con Re-Bar Fasteners & Supplies;

800-634-7301; fax: 408.436.9694;

www.clip-con.com

Empire Specialty Steel;

716-366-1000; fax: 716.366.0478;

www.empirespecialtysteel.com

General Technologies Inc.; 888-255-0440;

fax: 281.240.0990; www.gti-usa.net

Gopa Enterprises; 800-767-9926; fax:

408.436.9694

Mar-Mac Wire; 843-335-5000; fax:

843.335.5100; www.marmacwire.com

Meadow Burke Products;

813-248-1944; fax: 813.248.0703;

www.meadowburke.com

U-Tier Co, Ltd.; 214-358-3500; fax:

214.358.3630; www.u-tier.net

Publication #C01H041

Copyright © 2001 Hanley-Wood, LLC

All rights reserved