Chapter 7 Fire Resistant Materials and Construction

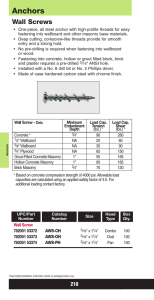

advertisement