Technical Specifications

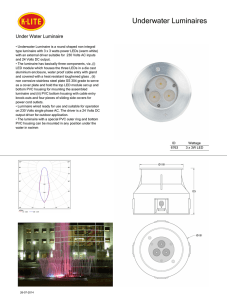

advertisement

L100 My White Recessed DIVISION 26 00 00 SECTION 26 51 00 ELECTRICAL INTERIOR LIGHTING Part 1 1.01 General Summary A. Section Includes: 1. Interior LED Luminaire, LEDs and drivers. 1.02 References A. Tested to IESNA LM-79-08 and LM-80 Testing Standards at 25°C ambient temperature B. Union Made Affiliated with IBEW Local 363 C. NRTL Listed for Damp Location 1.03 Definitions A. CCT – Correlated Color Temperature B. CRI – Color Rendering Index C. CLL – Constant Lumen Level Curve D. UL – Underwriters Laboratory E. NRTL – Nationally Recognized Testing Laboratories F. LED – Light Emitting Diode G. RoHS – Restriction of Hazardous Substances Directive H. CSA – Canadian Standards Association I. L70 – Reported Life of LED lumen maintenance (L, in hrs.) 70% lumen maintenance J. ASTM – American Society for Testing and Materials K. IBEW – International Brotherhood of Electrical Workers L. IESNA – Illuminating Engineering Society of North America M. LM-80 – IESNA approved method of measuring Lumen Depreciation of LED Light Sources N. LM-79-08 – Approved Method for the Electrical and Photometric Measurements of Solid-Sate Lighting Products or LEDs O. PFC – Power Factor Correction P. PCI – Powder Coating Institute 1.04 Performance Requirements A. All lighting products as herein after specified shall be a standard product of the manufacturer, and shall consist of components that will be readily available for future replacement for period of (5) years. B. Provide all lighting fixtures as shown complete with all hardware necessary to install fixtures. C. Luminaire shall be free of light leaks. D. Luminaire suitable for use in maximum ambient temperatures of 35°C (95°F). Minimum ambient operating temperature of -20°C (-4°F) for standard DALI (DMD) and DMX-512 (DMX) dimming drivers. E. LED package shall be designed around the lumen maintenance of 95% at 25,000 hours and 88% at 60,000 hours (CLL). F. Calculated L70 of 168,000 hours and Reported L70 greater than 60,000 (CLL) at 55ºC. G. All wiring shall be adequate for LEDs, Driver and Voltage requirements. H. It shall be the responsibility of the fixture manufacturer to ensure a timely completion of their portion of the project in accordance with the project schedule. I. If the fixture manufacturer is lacking any information necessary to complete the tasks in the agreed upon time frame, it is the fixture manufacturer’s responsibility to notify the owner and request additional information. 1.05 Submittals Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 1 of 5 | 03/31/2016 Rev 0.1 L100 My White Recessed 1.06 Quality Assurance A. Manufacturer Qualifications: 1. Minimum 30 years’ experience in the manufacture of exterior luminaires. 2. All fixtures and electrical components shall be new, of good quality, and be approved by and bear a NRTL Label (e.g. CSA, UL). 1.07 Delivery, Storage, and Handling A. Store products in manufacturer's unopened packaging until ready for installation. B. Store components off the ground in a dry covered area, protected from adverse weather conditions. 1.08 Warranty A. Manufacturer shall provide a limited five (5) year warranty on luminaire and workmanship, as well as a five (5) year limited warranty on LED light engine and driver when installed and operated according to the manufacturer’s instructions. Any luminaire or workmanship found defective during the warranty period would be either repaired or replaced by the manufacturer. Luminaire shall be suitable for ambient temperatures of 35°C (95°F). Part 2 2.01 Products Manufacturer A. Manufacturer Contact: Selux Corporation 5 Lumen Lane, P.O. Box 1060 Highland, NY 12528 phone: (845) 834-1400 fax: (845) 834-1401 toll free: (800) 735-8927 email: seluxus@selux.com website: www.selux.us/en.html B. Substitutions: Not permitted. 2.02 2.03 Materials (Select model(s) below): A. Housing is made from one continuous piece of 6063-T6 extruded aluminum profile up to 8 feet in length. B. Runs longer than 8 feet, to be joined with the M100 Joining System to ensure easy installation in the field and a uniform appearance. C. Continuous run configurations are available in 1 foot nominal steps, starting at 2 feet. Series A. (L10) 4” (101mm) high x 3 15/16” (100mm) wide form that will support multiple mounting options 1. L100 (M100 LED Recessed) a) 1/2" Spackle in mount (SF1) b) 5/8” Spackle in mount (SF2) c) After Sheetrock spackle in mount (SF3) d) 9/16” Slot Grid mount (SG) e) D’Coustic® Ceiling mount (DC) B. (L1R1/2) 4” (101mm) high x 4 13/16” (122mm) wide including flange [3 11/16” (94mm) wide w/o flange] form that will support multiple mounting options. 1. L1R1/2 (M1R1/2 LED Recessed) a) T-Bar length with suspension clips mount (TB) b) T-Bar length with 1/4-20 threaded stud mount (TBS) c) T-Bar length perimeter mount (PMT) d) Rotating Crossbar mount (RC) e) 1/4-20 Threaded stud mount (TS) Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 2 of 5 | 03/31/2016 Rev 0.1 L100 My White Recessed f) Perimeter mount (PM) 2.04 Light Engine A. High efficacy LED light engine equipped with brand-name LEDs. B. Direct Light Engine 1. 1A32 (*648lm/8.6W per foot) *Values calculated from a 4’ fixture @ 2700K using LW shielding & DMX driver. This photometry can be used for any CCT with CLL. 2.05 CCT 1. CCT shall be tunable from 2700K through 6500K, and is to maintain a minimum CRI of 80. 2.06 Shielding A. Shielding shall be extruded impact resistant acrylic snap-in and readily available. B. Shielding 1. LW (LED optimized white lens) 2.07 Mounting A. Multi-Mount options are to be made from high quality materials and shall have the ability to be incorporated into multiple types of ceiling systems. 1. SF1 (1/2” spackle flange, L10 housing series) a) Luminaire designed for installation before sheetrock is installed. b) Luminaire supplied with (2) 1/4”-20 x 1” threaded studs installed on the top of the housing to suspend the luminaire. c) Spackle flange located on all 4 sides for use in 1/2” sheetrock, allows drywall to be screwed to flange and then spackled in. d) 6’ Flex whip supplied on the top of the housing for feed connection. 2. SF2 (5/8” spackle flange, L10 housing series) a) Luminaire designed for installation before sheetrock is installed. b) Luminaire supplied with (2) 1/4”-20 x 1” threaded studs installed on the top of the housing to suspend the luminaire. c) Spackle flange located on all 4 sides for use in 5/8” sheetrock, allows drywall to be screwed to flange and then spackled in. d) 6’ Flex whip supplied on the top of the housing for feed connection. 3. SF3 (After sheetrock spackle in, L10 housing series) a) Luminaire designed for installation after sheetrock is installed. b) Luminaire is suspended through the supplied flange (blocking behind the sheetrock is required). c) Spackle flange located on all 4 sides allows spackle in installation. d) Box with 7/8” hole supplied on the top of the luminaire that allows feed connection. 4. SG (Slot grid, L10 housing series) a) Luminaire designed for use in 9/16” slot grid ceiling grid. b) Luminaire supplied with (2) brackets secured with 1/4"-20 x 1” threaded studs on the top of the housing allowing either threaded rod or suspension wire to be used to suspend the luminaire. c) d) 6’ Flex whip supplied on the top of the housing for feed connection. 5. DC (D’Coustic®, L10 housing series) a) Luminaire is designed for installation in panel ceiling with a thickness of 2”. b) Luminaire supplied with (2) 1/4”-20 x 1” threaded studs installed on the top of the housing to suspend the luminaire. c) A 1/2” wide flange is supplied on all 4 sides, located 2 1/4” up from the lens surface to block the view into the plenum. 1) Flange location can be moved to meet project needs, please consult factory. Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 3 of 5 | 03/31/2016 Rev 0.1 L100 My White Recessed d) 6’ Flex whip supplied on the top of the housing for feed connection. TB (T-Bar length with wire suspension clips, L10R1 housing series) a) Luminaire designed for use in either 9/16” or 15/16” T-Bar ceiling grid. b) Luminaire supplied with spring steel clips (field installed/adjustable) that snap onto the luminaire and allow the luminaire to be installed using suspension wire. c) 6’ Flex whip supplied on the top of the housing for feed connection. 7. TBS (T-Bar length with 1/4"-20 x 1” threaded stud, L10R1 housing series) a) Luminaire designed for use in either 9/16” or 15/16” T-Bar ceiling grid. b) Luminaire supplied with (2) 1/4"-20 x 1” threaded studs installed on the top of the housing to suspend the luminaire. c) 6’ Flex whip supplied on the top of the housing for feed connection. 8. PMT (Perimeter mount T-Bar Length, L10R1 housing series) a) Luminaire designed for use in either 9/16” or 15/16” T-Bar ceiling grid. b) Luminaire supplied with steel wall brackets with provisions for 1/4"-20 hardware (hardware to code by others). Luminaire suspends from the steel wall brackets by (2) supplied 1/4"-20 x 2” threaded studs on the top of the housing. c) Luminaire also supplied with aluminum wall/shadow angle to create a shadow line hiding any imperfections in the wall. Angle is supplied with provisions for #10 screws approximately every 2’ (hardware to code by others) d) 6’ Flex whip supplied on the top of the housing for feed connection. 9. RC (Rotating crossbar, L10R1 or L10R2 housing series) a) Luminaire designed for use in ceilings from 1/4” to 2” thick. b) Luminaire supplied with (2) adjustable rotating crossbars (adjustable for 1/4” to 2” thick ceilings). c) 6’ Flex whip supplied on the top of the housing for feed connection. 10. TS (1/4”-20 x 1” threaded stud, L10R1 or L10R2 housing series) a) Luminaire designed for use in accessible ceilings (not intended for T-Bar ceilings). b) Luminaire supplied with (2) 1/4"-20 x 1” threaded studs installed on the top of the housing to suspend the luminaire. c) 6’ Flex whip supplied on the top of the housing for feed connection. 11. PM (Perimeter mount, L10R1 or L10R2 housing series) a) Luminaire designed for use in a variety of ceiling/wall types (not intended for T-Bar ceilings). b) Luminaire supplied with steel wall brackets with provisions for 1/4"-20 hardware (hardware to code by others). Luminaire suspends from the steel wall brackets by (2) supplied 1/4"-20 x 2” threaded studs on the top of the housing. c) Luminaire also supplied with aluminum wall/shadow angle to create a shadow line hiding any imperfections in the wall. Angle is supplied with provisions for #10 screws approximately every 2’ (hardware to code by others) d) 6’ Flex whip supplied on the top of the housing for feed connection. 6. B. 2.08 Interior luminaire finish shall utilize a high quality Polyester Powder Coating 1. WH (White) 2. BK (Black) 3. SV (Silver) 4. SP (Specify Premium Color) a) All luminaires are to be finished in a Tiger Drylac certified facility and undergo a 5 stage intensive pretreatment process where product is thoroughly cleaned, phosphate and sealed. b) Powered coated products shall provide an excellent salt and humidity resistances as well as an ultra violet resistance for color retention. c) All products shall be tested in accordance with test specification for coatings from ASTM and PCL. Voltage A. All drivers Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 4 of 5 | 03/31/2016 Rev 0.1 L100 My White Recessed 1. 2. 3. 120 (120 Volts) 277 (277 Volts) UNV (Universal 120 thru 277, 50/60hz capable) 2.09 Drivers A. Standard eldoLED Dimming Drivers, Electronic Class 2, high efficiency (PFC>0.90). 1. DMD (Digital Addressable, DALI) 2. DMX (DMX-512 Dimming Driver) 2.10 Options A. Fixture Options 1. DL (Damp location) 2. FS (In-Line fuse) 3. SS (Separate switching) B. Emergency Options 1. EC (Emergency circuit) END OF SECTION Selux Corporation · 5 Lumen Lane · P.O. Box 1060 · Highland, NY 12528 · Tel.: (845) 834 1400 · Fax: (845) 834 1401 · Website: www.selux.us · Email: seluxus@selux.com Page 5 of 5 | 03/31/2016 Rev 0.1