July 2014

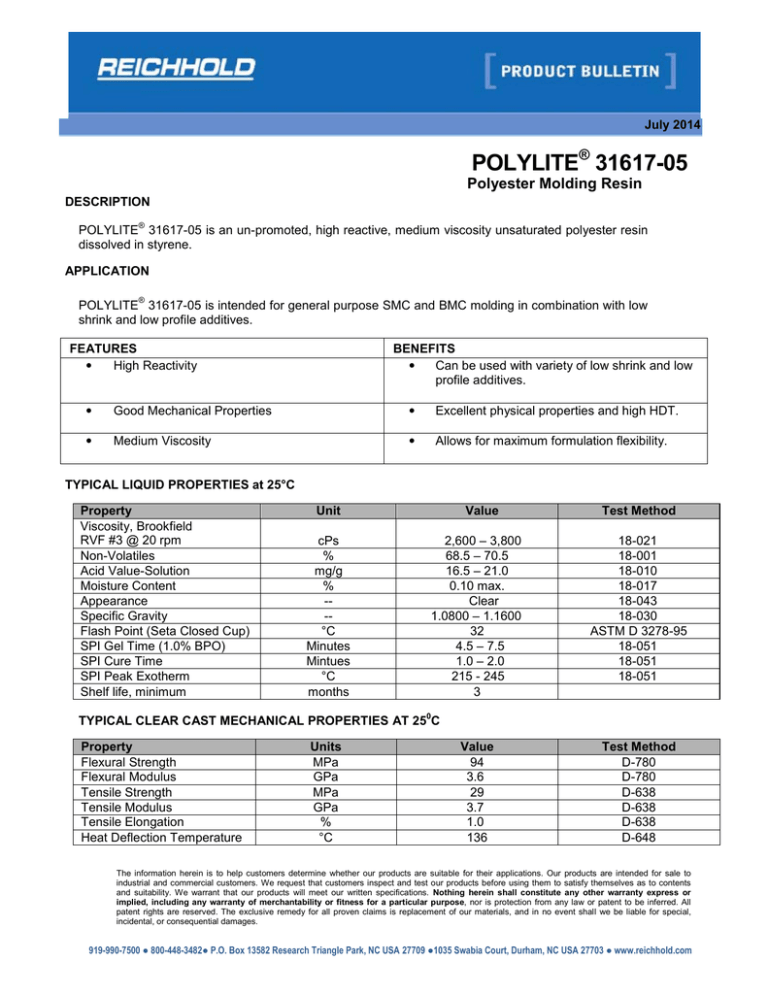

POLYLITE® 31617-05

Polyester Molding Resin

DESCRIPTION

®

POLYLITE 31617-05 is an un-promoted, high reactive, medium viscosity unsaturated polyester resin

dissolved in styrene.

APPLICATION

®

POLYLITE 31617-05 is intended for general purpose SMC and BMC molding in combination with low

shrink and low profile additives.

FEATURES

•

High Reactivity

BENEFITS

Can be used with variety of low shrink and low

•

profile additives.

•

Good Mechanical Properties

•

Excellent physical properties and high HDT.

•

Medium Viscosity

•

Allows for maximum formulation flexibility.

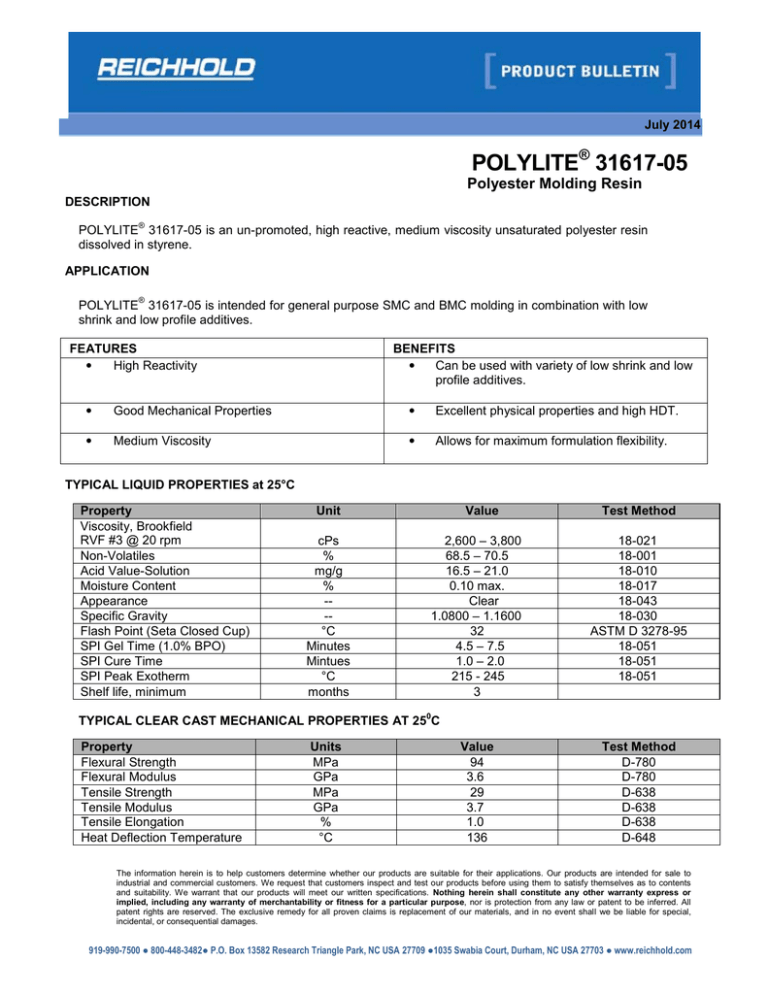

TYPICAL LIQUID PROPERTIES at 25°C

Property

Viscosity, Brookfield

RVF #3 @ 20 rpm

Non-Volatiles

Acid Value-Solution

Moisture Content

Appearance

Specific Gravity

Flash Point (Seta Closed Cup)

SPI Gel Time (1.0% BPO)

SPI Cure Time

SPI Peak Exotherm

Shelf life, minimum

Unit

cPs

%

mg/g

%

--°C

Minutes

Mintues

°C

months

Value

2,600 – 3,800

68.5 – 70.5

16.5 – 21.0

0.10 max.

Clear

1.0800 – 1.1600

32

4.5 – 7.5

1.0 – 2.0

215 - 245

3

Test Method

18-021

18-001

18-010

18-017

18-043

18-030

ASTM D 3278-95

18-051

18-051

18-051

0

TYPICAL CLEAR CAST MECHANICAL PROPERTIES AT 25 C

Property

Flexural Strength

Flexural Modulus

Tensile Strength

Tensile Modulus

Tensile Elongation

Heat Deflection Temperature

Units

MPa

GPa

MPa

GPa

%

°C

Value

94

3.6

29

3.7

1.0

136

Test Method

D-780

D-780

D-638

D-638

D-638

D-648

The information herein is to help customers determine whether our products are suitable for their applications. Our products are intended for sale to

industrial and commercial customers. We request that customers inspect and test our products before using them to satisfy themselves as to contents

and suitability. We warrant that our products will meet our written specifications. Nothing herein shall constitute any other warranty express or

implied, including any warranty of merchantability or fitness for a particular purpose, nor is protection from any law or patent to be inferred. All

patent rights are reserved. The exclusive remedy for all proven claims is replacement of our materials, and in no event shall we be liable for special,

incidental, or consequential damages.

919-990-7500 ● 800-448-3482● P.O. Box 13582 Research Triangle Park, NC USA 27709 ●1035 Swabia Court, Durham, NC USA 27703 ● www.reichhold.com

STORAGE

To ensure maximum stability and maintain optimum resin properties, resins should be stored in the original closed container

at temperature below 24°C/75°F and away from heat ignition sources and sunlight. Resin should be warmed to at least

18°C/65°F prior to use in order to assure proper curing and handling. All storage areas and containers should conform to local

fire and building codes. Copper or copper containing alloys should be avoided as containers. Store separate from oxidizing

materials, peroxides and metal salts. Keep containers closed when not in use. Inventory levels should be kept to a reasonable

minimum with first-in, first-out stock rotation.

Additional information on handling and storing unsaturated polyesters is available in Reichhold’s application bulletin “Bulk

Storage and Handling of Unsaturated Polyester Resins.” For information on other Reichhold resins, additives or initiators,

contact your sales representative or authorized Reichhold distributor.

SHELF LIFE

Shelf life is 3 months from date of shipment. Minimum shelf life performance refers to product in the original, unopened

container.

STANDARD PACKAGE

This product is available in non-returnable 55-gallon metal drums 496 lb. or 42,000 – 44,000-lb. tank truck.

SAFETY

READ AND UNDERSTAND THE MATERIAL SAFETY DATA SHEET BEFORE WORKING WITH THIS PRODUCT

Obtain a copy of the material safety data sheet on this product or contact the Reichhold service center prior to use.

Material safety data sheets are available from your Reichhold sales representative. Such information should be requested

from suppliers of all products and understood prior to working with their materials.

DIRECTLY MIXING ANY ORGANIC PEROXIDE WITH A METAL SOAP, AMINE, OR OTHER POLYMERIZATION

ACCELERATOR OR PROMOTER WILL RESULT IN VIOLENT DECOMPOSTION. WHEN ADDING ORGANIC PEROXIDES

TO A RESIN SOLUTION, PROMPTLY AND THOROUGHLY MIX THE RESULTING PRODUCT. NEVER ADD ORGANIC

PEROXIDES TO A HOT DILUENT OR PROCESS. PREVENT CONTAMINATION WITH FOREIGN MATERIALS, INCLUDING

WITHOUT LIMITATION, ACCELERATORS (SUCH AS DIMETHYL, ANILINE, OTHER AMINES OR COBALT COMPOUNDS),

HEAVY-METAL OXIDES OR SALTS (PARTICULARLY THOSE OF COBALT, IRON AND COPPER), STRONG ACIDS AND

SANDING DUSTS. USE CLEAN CONTAINERS MADE OF GLASS, POLYPROPYLENE, TEFLON, POLYETHYLENE, OR

CERAMIC TO PREVENT CONTAMINATION OF ORGANIC PEROXIDES DURING ITS HANDLING.

TECHNICAL SUPPORT

Reichhold’s technical support staff has extensive practical experience with various composites resins, end use performance

and manufacturing techniques. Please do not hesitate to request our assistance through your Reichhold sales or technical

representative.

Copies of test methods used to determine reported properties are available through your Reichhold representative.

Each user must determine the suitability of this product to his/her particular mode of operation and intended end

use application. A Reichhold representative will be available to assist in the proper selection of all Reichhold

products available for commercial use.

Properties reported in this bulletin are typical of those obtained in controlled laboratory tests and may vary in actual production;

therefore, we require our customers to inspect and test our products before using them to satisfy themselves as to contents

and suitability. We warrant that our products will meet our written specifications. Nothing herein shall constitute any other

warranty express or implied, including any warranty of merchantability or fitness for a particular purpose, nor is

protection from any law or patent to be inferred.

®

POLYLITE is a registered trademark of Reichhold, Inc.

®

POLYLITE 31617-05

Page 2