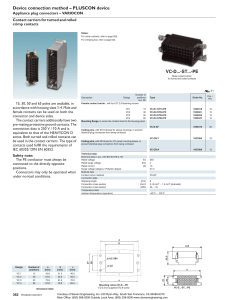

DL Series ZIF connectors

advertisement