K-CL-SFS-MT12 K-PH-CL-SFS-MT12 K-TRON Product

advertisement

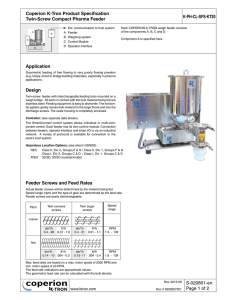

K-TRON Product Specification Loss-in-Weight Twin-Screw Microfeeder A D C B A B C D Ext. communication to Host System Feeder Weighing System Control Module Operator Interface K-CL-SFS-MT12 K-PH-CL-SFS-MT12 Each K-TRON Weigh feeder consists of the components A, B, C and D. Component A is specified here. Application Gravimetric feeding of free flowing to difficult powders (e.g. lumpy or bridge building materials) and micropellets. The weigh bridge is a sanitary version and is therefore suitable for quick and easy cleaning. Design Twin screw feeder mounted on a 12 kg scale. The MT12 Microfeeder is available in standard finish as well as two pharmaceutical finishes. A variety of feeder screws allows for handling a wide range of bulk materials. The feeding equipment is easy to dismantle. The agitator gently moves bulk material to the throat and then into the feed screws. A protective enclosure (plexiglass) is included to isolate the feeder from outside influences and ensure maximum accuracy. Hazardous Location Options: (see sheet I-000002) NEC ATEX Class II, Div. 2, Groups F & G / Class II, Div. 1, Groups F & G Class I, Div. 2, Groups C & D / Class I, Div. 1, Groups C & D 3D/3D, 3D/2D, 3G/3G, 2GD/2GD (outside/inside) K-Tron Control Module (KCM) (see sheet S-070207) The KCM combines the control module, the motor drive module and the operator interface in one compact unit. The KCM is generally mounted near the feeder (except in ATEX 2 GD and NEC Class 1 / Div I applications). An optional stainless steel enclosure is available for the KCM for pharma applications. Feeder Screws and Feed Rates Actual feed screws will be determined by the material being fed. Feeder screws are easily interchangeable. Pitch Twin concave screws Twin full flight screws Screw speed range 0.0035 - 0.14 0.1 - 4.0 0.0035 - 0.14 0.1 - 4.0 RPM 0.5 - 100 0.0014 - 0.078 0.04 - 2.2 0.0014 - 0.078 0.04 - 2.2 RPM 0.5 - 100 long pitch ft3/hr dm3/hr short pitch ft3/hr dm3/hr The feed rate indications are approximate values and vary according to material characteristics. Rev. 4 / 2006-07 Doc# 0490006301 www.ktron.com S-020104-en Page 1 of 2 K-CL-SFS-MT12 K-PH-CL-SFS-MT12 K-TRON Product Specification Loss-in-Weight Twin-Screw Microfeeder Configuration Description Alternatives Remarks Cover Weight kg (lb) Standard (plexiglass) 0.25 (0.55) Hopper 1 dm3 (0.04 ft3) 0.93 (2.05) 2 dm3 (0.07 ft3) 1.58 (3.48) Stepper (standard) Motor drive IP55, NEMA 12 Servo Stepper 5.48 (12.1) ATEX 2GD, Class 1 / Div I Servo 8.45 (18.6) Feeding unit MT12 12 kg Scale 26.4 lb 1.92 (4.2) IP65, NEMA 4 (gross capacity) Materials: Product contact parts: Stainless steel DIN 1.4435/1.4404 (AISI 316L), DIN 1.4571 (AISI 316Ti), DIN 1.4581 (standard version only) Seals: Alloy 60, Silicone (food grade), PTFE (food grade) Weighing Range: Gross scale capacity 12 kg less feeder weight. Temperature-Limits: Operating temp.: Material temp.: 5 to 45°C (41 to 113°F) 5 to 45°C (41 to 113°F) Dimensions mm [in] 363 (14.3) 28 (1.1) 692 (27.2) 150 (5.9) 619 (23.6) 600 (23.6) 287 (11.3) 99 ( 3.9) 77 (3.0) 430 (16.9) 597 (23.5) Caution: these measurements are for general reference only. Please consult dimensional drawing for exact measurements K-TRON AMERICA / Pitman, NJ 08071 USA / Tel: (856) 589-0500 / e-mail: ka@ktron.com K-TRON (Switzerland) Ltd / CH-5702 Niederlenz / Tel: +41 62 885 71 71 / e-mail: ks@ktron.com All addresses on sheet: / Alle Adressen auf Blatt: / Toutes les adresses sur fiche: I-000001 Copyright by K-TRON. Covered by patents in USA and other countries. Specifications subject to change without notice. Rev. 4 S-020104-en Page 2 of 2