K-PH-CL-SFS-KT20 Application Design S-020801

advertisement

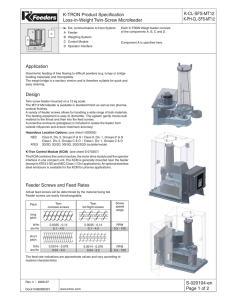

Coperion K-Tron Product Specification Twin-Screw Compact Pharma Feeder A D C B Ext. communication to host system AFeeder B Weighing system C Control Module D Operator interface K-PH-CL-SFS-KT20 Each COPERION K-TRON weigh feeder consists of the components A, B, C and D. Component A is specified here. Application Gravimetric feeding of free flowing to very poorly flowing powders (e.g. lumpy, moist or bridge building materials), especially in pharma applications. Design Twin-screw feeder with interchangeable feeding tools mounted on a weigh bridge. All parts in contact with the bulk material being fed are stainless steel. Feeding equipment is easy to dismantle. The horizontal agitator gently moves bulk material to the large throat and into the discharge screws. The scale housing is completely enclosed. Controller: (see separate data sheets) The SmartConnex® control system allows individual or multi-component control. Each feeder has its own control module. Connection between feeders, operator interface and smart I/O is via an industrial network. A variety of protocols is available for connection to the plant’s host system. Hazardous Location Options: (see sheet I-000002) NEC Class II, Div. 2, Groups F & G / Class II, Div. 1, Groups F & G Class I, Div. 2, Groups C & D / Class I, Div. 1, Groups C & D ATEX 3D/3D, 3D/2D (outside/inside) Feeder Screws and Feed Rates Actual feeder screws will be determined by the material being fed. Speed range (rpm) and the type of gear are determined by the feed rate. Feeder screws are easily interchangeable. Pitch Twin concave screws Twin auger screws Speed range coarse dm3/h 0.4 - 28 ft3/h 0.01 - 1.0 dm3/h 0.4 - 31 ft3/h 0.01 - 1.1 RPM 1.9 -139 fine dm3/h ft3/h 0.14 - 10 .004 - 0.3 RPM dm3/h ft3/h 0.15- 11 .004 - 0.4 1.9 -139 Max. feed rates are based on a max. motor speed of 2000 RPM and min. motor speed of 20 RPM. The feed rate indications are approximate values. The gravimetric feed rate can be calculated with the bulk density. Rev. 2013-09 www.ktron.com Doc # 0290027301 S-020801-en Page 1 of 2 Coperion K-Tron Product Specification Twin-Screw Compact Pharma Feeder Configuration Description K-PH-CL-SFS-KT20 Alternatives Remarks Weight kg (lb) Coverplastic stainless Hopper 12 dm3 (0.42 ft3) 36 (79.4) 95 W, 180V IP55, NEMA 12 Motor drive Horiz. Pressure Vertical Outlet (std) compensation Weigh bridge (gross capacity) Materials: Material contact parts and scale: Seals: Paint: IP65, NEMA 4 30 kg (66 lb) Weighing Range: Gross scale capacity (30 kg) less feeder weight. stainless steel DIN 1.4404 / 1.4435 (AISI 316L) PTFE and Silicone Light grey RAL 7035 Dimensions mm (in) Temperature-Limits: Ambient: 0 to 40.5 °C / 32 to 105 °F Material: -20 to 55 °C / -4 to 130 °F Options shown with vertical outlet 1 Housing for motor & gearbox 2 Wall mounting fixture 3 Air purge nozzles 4 Vertical discharge Ø 254 (10) Ø 220 (8.7) 365 (14.4) Ø 50 (2) 21.5 (0.85) Ø 52 (2.05) Clamp DIN DN50 38 (1.5) 419 (16.5) 55 (2.2) 357.5 (14.1) Safety screen 50 (2) 145.5 (5.7) 260.5 (10.3) 230 (9.1) 93.5 (3.7) 139.5 (5.5) 410 (16.1) 191 (7.5) 330.5 (13) 17 (0.67) Horizontal outlet Caution: these measurements are for general reference only. Please consult dimensional drawing for exact measurements www.ktron.com All addresses: / Alle Adressen: / Toutes les adresses: I-000001 Copyright by K-Tron Technologies, Inc. Covered by patents in USA and other countries. Specifications subject to change without notice. Rev. 2013-09 S-020801-en Page 2 of 2