US

Caddy

TA34 AC/DC

Instruction manual

0460 227 187 US 110503

Valid from program version 1.20

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1

3

Useful information about the welding equipment

The power source is equipped with the function True AC rating (GTAW). . . . . . . . . . .

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

4

2 GTAW WELDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

1.2

2.1

2.2

2.3

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbol and Function explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hidden GTAW functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

6

12

3 SMAW WELDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

3.1

3.2

3.3

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbol and Function explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hidden SMAW functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

14

15

4 WELDING DATA MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 FAULT CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

16

5.1

5.2

List of fault codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault code descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

17

6 ORDERING SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ORDERING NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

20

Rights reserved to alter specifications without notice.

TOCa

-2-

US

1

INTRODUCTION

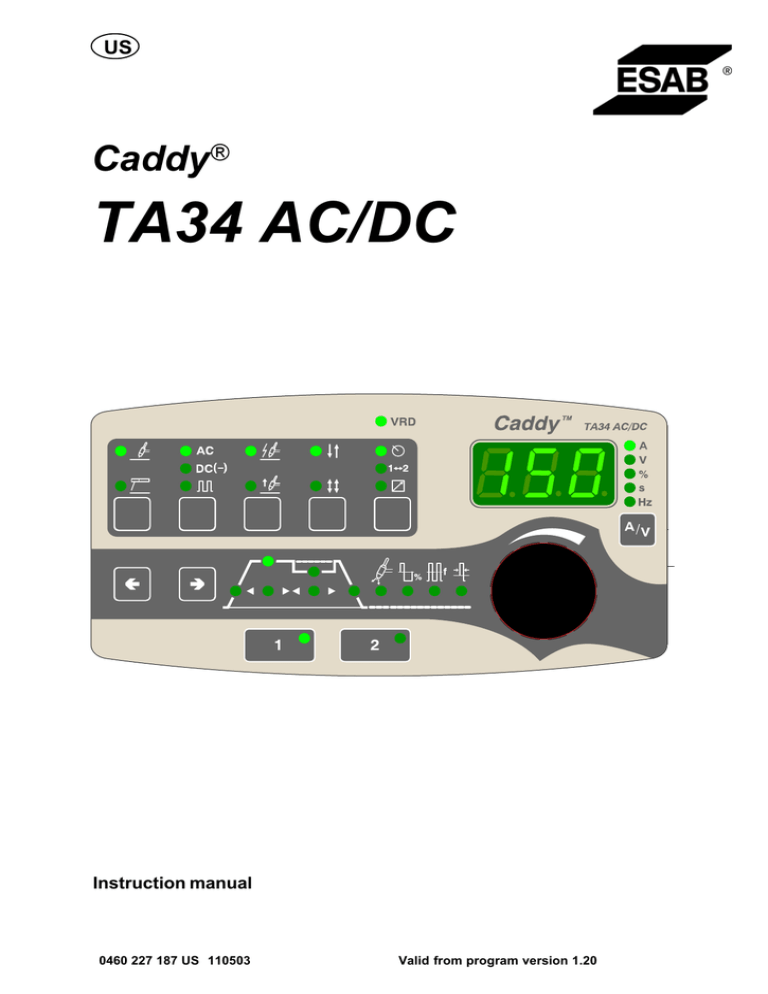

The manual describes the use of TA34 AC/DC control panel.

For general information about operation see instruction manual for the power source.

When mains power is supplied the unit runs a self diagnosis of the

LEDs and the display, the program version is displayed and in this

example the program version is 0.18.

NOTE! Differences in the panel function may occur, depending on which product is

installed.

Instruction manuals in other languages can be downloaded from the website,

www.esab.com.

1.1

Useful information about the welding equipment

The power source is equipped with the function True AC rating (GTAW).

“True AC rating” means the average current can be maintained in the event of

variations in inductance and resistance in the welding circuit. This is the result of

active process control, which compensates for the inductance present in the

welding circuit.

The process is optimised so that the energy in the arc will correspond to the set

welding current selected for AC (alternating current). Process optimisation normally

leads to welding being possible at a lower set current value (than with previous

power sources) thanks to reduced losses in the welding circuit.

For the best possible oxide break-up and a long tungsten electrode life for AC TIG,

we recommend a negative AC balance (-70%), which is also the basic setting on

delivery. It is possible to reduce the weld pool penetration for AC GTAW by

reducing the heat exchange by lowering the AC balance. The minimum AC balance

value is -50%, see tables 1-3 on page 9 for recommended current ranges. This

primarily facilitates welding of weaker/thinner material dimensions.

Measured value in the display for arc voltage V, and welding current A, is arithmetic

average value = rectified average value.

-3bi18d1aa

© ESAB AB2007

US

1.2

Control panel

Knob for setting data (current, voltage, percentage, seconds, or frequency)

Display

Choice of welding method GTAW

or SMAW

Pushbutton for selection of GTAW-welding with:

S

S

S

Alternating current AC

Direct current DC Direct current DC - with pulsing

Pushbutton for selection of SMAW-welding with:

S

S

S

Alternating current AC

Direct current DC Direct current DC +

Choice of HF start

or LiftArct

Choice of 2-stroke

or 4-stroke

Setting from panel

, program change with torch trigger switch

or

connecting remote control unit

-4bi18d1aa

© ESAB AB2007

US

Display of VRD function (reduced open-circuit voltage) is active or inactive.

(NOTE! This function works for power sources where it is implemented.)

Indication of which parameter is shown in the display (current, voltage,

percentage, seconds or frequency)

Choice of current indication (A) or voltage indication (V) during welding, in the

display

Indication of selected setting parameter, see page 7. The right-hand button is

also used for hidden functions

Buttons for weld data memory settings. See page 16.

2

GTAW WELDING

2.1

Settings

GTAW without pulsing AC/DC and GTAW with pulsing DC

Function

Setting range

In steps of:

Default value

HF or LiftArct

-

LiftArct

2 stroke or 4 stroke

-

2 stroke

0-5s

0.1 s

0.5 s

Slope up-time

0 - 10 s

0.1 s

0.0 s

Slope down time

0 - 10 s

0.1 s

1.0 s

Gas post flow time

0 - 25 s

0.1 s

10.0 s

Current

4 A - max 3)

1A

60 A

Active panel

OFF or ON

-

ON

Changing trigger data

OFF or ON

-

OFF

Remote control unit

OFF or ON

-

OFF

0-99%

-

30%

-

-

-

HF / LiftArc t

2/4-stroke

1)

1)

Gas pre flow time

Min current

2)

2)

VRD

1)

2)

3)

These functions cannot be changed while welding is in progress.

These functions are hidden TIG functions, see description in point 2.3.

The setting range is dependent on the power source used.

GTAW with AC

Function

Setting range

In steps of:

Default value

Balance setting

50 - 98 %*

1%

50 %

Frequency setting

10 - 152 Hz

1 - 3 Hz

65 Hz

Electrode preheating

automatic

manual

80 - 120 ms

15 - 100 ms

1

1

-

*) Depending on frequency setting.

-5bi18d1aa

© ESAB AB2007

US

GTAW with pulsing DC

Function

Setting range

3)

In steps of:

Default value

1A

60 A

1.0 s

Pulse current

4 A - max

Pulse time

0.01 - 2.5 s

0.01 s

0.001 - 0.250 s

0.001 s

Micro pulse 2)

Background current

4 A - max

Background time

Micro pulse 2)

2)

3)

3)

1A

20 A

0.01 - 2.5 s

0.01 s

1.0 s

0.001 - 0.250 s

0,001 s

These functions are hidden TIG functions, see description in point 2.3.

The setting range is dependent on the power source used.

2.2

Symbol and Function explanations

GTAW welding

GTAW welding melts the metal of the workpiece, using an arc struck from a tungsten

electrode, which does not melt itself. The weld pool and the electrode are protected

by shielding gas.

Alternating current

The advantage of an alternating current is good oxide break-up capacity when

welding light metals (aluminium, magnesium and their alloys).

The advantages of alternating current are reduced risk of magnetic arc blow and

good oxide break-up capacity when welding aluminium.

Direct current

A higher current produces a wider weld pool, with better penetration into the workpiece.

Pulsed current

Pulsing is used for improved control of the weld pool and the solidification process.

The pulse frequency is set so slow that the weld pool has time to solidify at least

partially between each pulse. In order to set pulsing, four parameters are required:

pulse current, pulse time, background current and background time.

-6bi18d1aa

© ESAB AB2007

US

Parameter settings

1. Slope up

2. Welding current

3. Pulse time

4. Background current

5. Background time

6. Slope down

7. Gas post flow time

8. Balance

9. Frequency

10. Electrode preheating

Slope up

The slope up function means that, when the GTAW arc strikes, the current rises

slowly to the set value. This provides `gentler' heating of the electrode, and gives the

welder a chance to position the electrode properly before the set welding current is

reached.

Pulse current

The higher of the two current values in the event of pulsed current.

Current

Background

time

Pulse current

Background

current

Pulse time

Time

GTAW welding with pulsing.

Pulse time

The time the pulse current is on during a pulse period.

Background current

The lower of the two current values in the event of pulsed current.

Background time

Time for background current which, along with the time for pulse current, gives the

pulse period.

Slope down

TIG welding uses “slope down”, by which the current falls 'slowly' over a controlled

time, to avoid craters and/or cracks. when a weld is finished.

-7bi18d1aa

© ESAB AB2007

US

Slope down

GTAW welding uses “slope down”, by which the current falls 'slowly' over a

controlled time, to avoid craters and/or cracks. when a weld is finished.

Gas post-flow

This controls the time during which shielding gas flows after the arc is extinguished.

Balance

Setting the balance between the positive (+) electrode and negative (-) electrode

half period during alternating current welding (AC).

Lower balance value produces more heat on the electrode and better oxide

break-up on the workpiece.

Higher balance value produces more heat to the workpiece and better penetration.

Frequency

Lower frequency (alternating current) transfers more heat to the workpiece and

produces a wider weld pool.

Higher frequency produces a narrower arc with higher arc force (narrower weld

pool).

HF

The HF function strikes the arc by means of a spark from the electrode to the

workpiece as the electrode is brought closer to the workpiece.

Automatic preheating of electrode with AC

The preheating function is designed to provide a stable arc and a safe start in a

balanced manner. The electrode preheating time is controlled by a preprogrammed

time in relation to the set welding current. It is possible to set (finetune) the automatic

preheating when on the outer area of the electrode's current range, see

recommended current range below.

The setting range for preheating is 80 - 120 ms, where 100 ms is equal to the basic

value (value on delivery).

-8bi18d1aa

© ESAB AB2007

US

Current ranges for electrode WP (pure tungsten)

Welding current A

Max A AC - 50% Balance

Max A AC - 70% Balance

Electrode diameter (mm)

Table 1 – Recommended current ranges for electrode selection WP = Green

Colour coding and classification names as per ISO 6848:2004

Current ranges for electrode WC20 (WCe2)

Welding current A

Max A AC - 50% Balance

Max A AC - 70% Balance

Electrode diameter (mm)

Table 2 – Recommended current ranges for electrode selection WC20 = Grey

Colour coding and classification names as per ISO 6848:2004

-9bi18d1aa

© ESAB AB2007

US

Current ranges for electrode WLa 15/Gold Plus

(70% AC Balance)

Welding current A

l max A AC

Electrode diameter (mm)

Table 3 – Recommended current ranges for electrode selection WLa15 = Gold

Colour coding and classification names as per ISO 6848:2004

Deactivation of automatic preheating of electrode

In hidden GTAW functions (see point 2.3) automatic preheating can be deactivated

for a manual setting from 15 - 100 ms for adjustment in specific instances. When

switching from an automatic to a manual setting, the previous autogenerated value

for preheating is used and a preferred value is selected using the knob.

LiftArct

The LiftArct function strikes the arc when the electrode is brought into contact with

the workpiece and then lifted away from it.

Striking the arc with the LiftArc functiont. Step 1: the electrode is touched on to the workpiece.

Step 2: the trigger switch is pressed, and a low current starts to flow. Step 3: the welder lifts the

electrode from the workpiece: the arc strikes, and the current rises automatically to the set value.

- 10 bi18d1aa

© ESAB AB2007

US

2 stroke

Gas pre-flow

Slope

up

Slope down

Gas post-flow

Functions when using 2 stroke control of the welding torch.

In the 2 stroke control mode, pressing the GTAW torch trigger switch (1) starts gas

pre-flow (if used) and strikes the arc. The current rises to the set value (as controlled

by the slope up function, if in operation). Releasing the trigger switch (2) reduces the

current (or starts slope down if in operation) and extinguishes the arc. Gas post-flow

follows if it is in operation.

4 stroke

Gas pre-flow

Slope

up

Slope down

Gas post-flow

Functions when using 4 stroke control of the welding torch.

In the 4 stroke control mode, pressing the trigger switch (1) starts gas pre-flow (if

used). At the end of the gas pre-flow time, the current rises to the pilot current (a few

ampere), and the arc is struck. Releasing the trigger switch (2) increases the current

to the set value (with slope up, if in use). When the trigger switch is pressed in (3)

the current returns to the set pilot current (with ”slope down” if in use).

When the trigger switch is released again (4) the arc is extinguished and any gas

post flow occurs.

Active panel

Settings are made from the control panel.

Changing trigger data

This function permits changing between different welding data memories by a double

press on the trigger of the welding gun.

Only applies for GTAW welding.

- 11 bi18d1aa

© ESAB AB2007

US

Remote control unit

Settings are made from the remote control unit.

The remote control unit must be connected to the remote control unit socket on the

machine before activation. When the remote control unit is activated the panel is

inactive.

VRD (Voltage Reducing Device)

The VRD function ensures that the open-circuit voltage does not exceed 35 V when

welding is not being carried out. This is indicated by a lit VRD LED.

The VRD function is blocked when the system senses that welding has started.

If the VRD function is activated and the open-circuit voltage exceeds the 35 V limit,

this is indicated by an error message (16) appearing in the display and welding

cannot be started whilst the error message is displayed.

2.3

Hidden GTAW functions

There are hidden functions in the control panel.

To access the functions, press

for 5 seconds. The display shows a letter and

a value. Select function by pressing the right arrow. The knob is used to change the

value of the selected function.

To exit hidden functions, press

for 5 seconds.

Function

Settings

A = gas pre-flow

0-5s

l = min current

0 - 99%

L = automatic start pulse/electrode preheating

P = start pulse

0 = OFF; 1 = ON

value on delivery 70A at

setting 60A

b = micro pulse (only in DC)

0 = OFF; 1 = ON

Gas pre-flow

This controls the time during which shielding gas flows before the arc is struck.

- 12 bi18d1aa

© ESAB AB2007

US

Min current

Used to set the minimum current for the remote control T1 Foot CAN.

If the max current is 100 A and the min current is to be 50 A, set the concealed

function min current to 50%.

If the max current is 100 A and the min current is to be 90 A, set the min current to 90%.

This function also applies when setting background current with pulsed GTAW.

Electrode preheating

In the function automatic start pulse/electrode preheating (L), electrode preheating is

only activated in AC. This function is used to achieve a stable arc rapidly, and

preheating extends the service life of the electrode.

Start pulse

NOTE! To activate manual start pulse (P), the function (L) must first be deactivated

in the hidden function, select (0 = OFF).

Start pulse produces a safe, controlled start and is balanced and adapted to the

electrode diameter and set welding current.

Micro pulse

In order to select micro pulse, the machine must be in the pulsed current function

.

The value for pulse time and background current is normally 0.01 – 2.50 seconds. By

using the micro pulse, the time can go down to 0.001 seconds. When the micro pulse

function is active, times that are shorter than 0.25 seconds are shown in the display

without decimal points.

3

SMAW WELDING

3.1

Settings

Function

Setting range

In steps of:

Default value

Current

16 - max. A 3)

1A

100 A

0 - 99

1

0

0 - 99

1

5

0=OFF or 1=ON

-

OFF

1=OFF or 0=ON

-

ON

Active panel

OFF or ON

-

ON

Remote control unit

OFF or ON

-

OFF

0-99%

-

30%

-

-

-

Hotstart

2)

Arc force

2)

Drop welding

2)

Weld regulator ArcPlust

Min current

VRD

2)

3)

2)

2)

These functions are hidden TIG functions, see description in point 2.3.

The setting range is dependent on the power source used.

- 13 bi18d1aa

© ESAB AB2007

US

3.2

Symbol and Function explanations

SMAW welding

SMAW welding may also be referred to as welding with coated electrodes. Striking the

arc melts the electrode, and its coating forms protective slag.

During SMAW welding, it is possible to weld with reversed polarity without reconnection

of welding cables on the power source.

Select SMAW welding

and then press

S

AC, for alternating current

S

DC (-) for direct current with negative polarity on the electrode

S

Non LED is on, for direct current with positive polarity on the electrode

Active panel

Settings are made from the control panel.

Remote control unit

Settings are made from the remote control unit.

The remote control unit must be connected to the remote control unit socket on the

machine before activation. When the remote control unit is activated the panel is

inactive.

VRD (Voltage Reducing Device)

The VRD function ensures that the open-circuit voltage does not exceed 35 V when

welding is not being carried out. This is indicated by a lit VRD LED.

The VRD function is blocked when the system senses that welding has started.

If the VRD function is activated and the open-circuit voltage exceeds the 35 V limit,

this is indicated by an error message (16) appearing in the display and welding

cannot be started whilst the error message is displayed.

- 14 bi18d1aa

© ESAB AB2007

US

3.3

Hidden SMAW functions

There are hidden functions in the control panel.

To access the functions, press

for 5 seconds. The display shows a letter and

a value. Select function by pressing the right arrow. The knob is used to change the

value of the selected function.

To exit hidden functions, press

for 5 seconds.

Function

Settings

C = Arc Force

0 - 99

d = drop welding

0 = OFF; 1 = ON

F = regulator type ArcPlust

0 = OFF; 1 = ON

H = Hotstart

0 - 99

I = min current

0 - 99%

Arc force

The arc force is important in determining how the current changes in response to a

change in the arc length. A lower value gives a calmer arc with less spatter.

Drop welding

Drop welding can be used when welding with stainless electrodes. The function

involves alternately striking and extinguishing the arc in order to achieve better

control of the supply of heat. The electrode needs only to be raised slightly to

extinguish the arc.

Welding regulator ArcPlus™

A welding regulator is a type of control that produces a more intense, more

concentrated and calmer arc. It recovers more quickly after a spot short-circuit,

which reduces the risk of the electrode becoming stuck.

S

ArcPlust (0) is recommended for a basic electrode

S

ArcPlustll (1) is recommended for a rutile and cellulose electrode

Hot start

Hot start increases the weld current for an adjustable time at the start of welding,

thus reducing the risk of poor fusion at the beginning of the joint.

Min current

Used to set the minimum current for the remote control unit T1 Foot CAN.

If the max current is 100 A and the min current is to be 50 A, set the hidden function

min current to 50%.

If the max current is 100 A and the min current is to be 90 A, set the min current to 90%.

- 15 bi18d1aa

© ESAB AB2007

US

4

WELDING DATA MEMORY

Two different welding data programs can be stored in the control panel memory.

Press button

or

for 5 seconds to store the welding data in the

memory. The welding data is stored when the green indicator lamp starts to flash.

To switch between the different welding data memories press button

or

.

The welding data memory has a back-up battery so that the settings remain even if

the machine has been switched off.

5

FAULT CODES

The fault code is used to indicate that a fault has occurred in the equipment. It is

indicated in the display by an E followed by a fault code number.

A unit number is displayed to indicate which unit has generated the fault.

Fault code numbers and unit numbers are shown alternately.

If several faults have been detected only the code for the last occurring fault is

displayed. Press any function button or turn the knob to remove the fault indication

from the display.

NOTE! If the remote control is activated, deactivate the remote control by pressing

to remove the fault indication.

5.1

List of fault codes

U 0 = welding data unit

U 2 = power source

U 1 = cooling unit

U 4 = remote control unit

Fault code

Description

U 5 = AC-unit

U0

U1

U2

U4

x

U5

4

Power supply 5 V

x

6

High temperature

7

High temperature

8

Supply voltage 24V/15V

x

x

9

Supply voltage -11V

x

x

x

x

x

x

12

Communication error (warning)

x

14

Communication error (bus off)

x

15

Messages lost

x

16

High open-circuit voltage VRD

19

Memory error

20

High inductance in the welding circuit

x

x

x

x

x

x

- 16 bi18d1aa

© ESAB AB2007

US

Fault code

5.2

Fault

code

Description

U0

25

Lost contact with AC-unit

x

26

Program operating fault

x

29

No cooling water flow

x

41

Lost contact with the cooling unit

x

U1

U2

U4

U5

x

Fault code descriptions

Description

E4

5 V power supply low

U0

The power supply voltage is too low.

U5

The current welding process is stopped and starting is prevented.

E6

Action: Turn off the mains power supply to reset the unit. Send for a service technician if

the fault persists.

High temperature

U1

The thermal overload cut-out has tripped.

U2

The current welding process is stopped and cannot be restarted until the temperature has

fallen.

U5

Action: Check that the cooling air inlets or outlets are not blocked or clogged with dirt.

Check the duty cycle being used, to make sure that the equipment is not being overloaded.

E7

High temperature

U5

The thermal overload cut-out has tripped.

The current welding process is stopped and cannot be restarted until the temperature has

fallen.

Action: Check that the cooling air inlets or outlets are not blocked or clogged with dirt.

Check the duty cycle being used, to make sure that the equipment is not being overloaded.

E8

Faulty 24 V/15 V supply voltage

U1

The supply voltage is too high or too low.

U5

The current welding process is stopped and starting is prevented.

E9

Action: Turn off the mains power supply to reset the unit. Send for a service technician if

the fault persists.

Faulty 24 V/15 V supply voltage

U1

The supply voltage is too high or too low.

U5

The current welding process is stopped and starting is prevented.

E 12

Action: Turn off the mains power supply to reset the unit. Send for a service technician if

the fault persists.

Communication error (warning)

U0

Less serious interference on the CAN bus.

U1

Action: Check that there are no faulty units connected on the CAN bus. Check the cables.

Send for a service technician if the fault persists.

U4

U5

- 17 bi18d1aa

© ESAB AB2007

US

Fault

code

Description

E 14

Communication error (bus off)

U0

Serious interference on the CAN bus.

Action: Check that there are no faulty units connected on the CAN bus. Check the cables.

Send for a service technician if the fault persists.

E 15

Communication problems (lost message)

U0

The system's CAN bus has been overloaded.

E 16

Action: Send for a service technician if the fault persists.

High open-circuit voltage VRD

U2

Open circuit voltage has been too high.

Action: Turn off the mains power supply to reset the unit. Send for a service technician if

the fault persists.

E 19

Memory error

U0

Content of existing memory is incorrect. Basic data will be used.

Action: Turn off the mains power supply to reset the unit. Send for a service technician if

the fault persists.

E 20

High inductance in the welding circuit

U2

The power source cannot produce the desired current because the measured inductance

in the welding circuit is too high. The fault indication is reset if the inductance reading

receives a sufficiently low value at weld start. Resetting can also be achieved by turning off

the power.

Action: Use shorter welding cables and ensure that the cables are not coiled up. Place the

welding cable and connector cable next to each other. If possible, the inductance can be

reduced by welding with a shorter arc

E 25

Send for a service technician if the fault persists.

Lost contact with AC-unit

U0

The control panel has lost contact with the AC unit.

The current welding process stops.

Action: Send for a service technician if the fault persists.

E 26

Program operating fault

U0

Something has prevented the processor from performing its normal tasks in the program.

The program restarts automatically. The current welding process will be stopped. This fault

does not disable any functions.

E 29

Action: Send for a service technician if the fault persists.

No cooling water flow

U0

The flow monitor switch has tripped.

U1

The current welding process is stopped and starting is prevented.

Action: Check the cooling water circuit and the pump.

E 41

Lost contact with the cooling unit

U0

The welding data unit has lost contact with the cooling unit. The welding process stops.

Action: Check the wiring. If the fault persists, send for a service technician.

- 18 bi18d1aa

© ESAB AB2007

US

6

ORDERING SPARE PARTS

When ordering replacement parts, order by part number and part name, as

illustrated on the figure. Always provide the series or serial number on the unit on

which the parts will be used. The serial number is stamped on the rating plate.

- 19 bi18d1aa

© ESAB AB2007

TA34 AC/DC

Ordering number

Ordering no.

0460 250 880

0460 227 170

0460 227 171

0460 227 172

0460 227 173

0460 227 174

0460 227 175

0460 227 176

0460 227 177

0460 227 178

0460 227 179

0460 227 180

0460 227 181

0460 227 182

0460 227 183

0460 227 184

0460 227 185

0460 227 186

0460 227 187

0460 227 189

0460 227 190

0460 227 191

0460 227 192

0460 227 193

Denomination

Control panel Caddyt TA34 AC/DC

Instruction manual SE

Instruction manual DK

Instruction manual NO

Instruction manual FI

Instruction manual GB

Instruction manual DE

Instruction manual FR

Instruction manual NL

Instruction manual ES

Instruction manual IT

Instruction manual PT

Instruction manual GR

Instruction manual PL

Instruction manual HU

Instruction manual CZ

Instruction manual SK

Instruction manual RU

Instruction manual US

Instruction manual EE

Instruction manual LV

Instruction manual SL

Instruction manual LT

Instruction manual CN

Instruction manuals and the spare parts list are available on the Internet at www.esab.com

- 20 bi18o

© ESAB AB2007

NOTES

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

- 21 notes

NOTES

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

- 22 notes

NOTES

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

.............................................................................................................................................................

- 23 notes

ESAB Welding & Cutting Products, Florence, SC Welding Equipment

COMMUNICATION GUIDE - CUSTOMER SERVICES

A

B

C

CUSTOMER SERVICE QUESTIONS:

Telephone: (800) 362-7080 / Fax: (800) 634-7548

Order Entry Product Availability

Pricing

Order Information

ENGINEERING SERVICE:

Telephone: (834) 664-4416 / Fax: (800) 446-5693

Warranty Returns

Authorized Repair Stations

Hours: 7.30 AM to 5:00 PM EST

Welding Equipment Troubleshooting

TECHNICAL SERVICE:

Telephone: (800) ESAB-123 / Fax: (843) 664-4452

Part Numbers

Technical Applications

Specifications

Hours: 8.00 AM to 7:00 PM EST

Returns

Hours: 8.00 AM to 5:00 PM EST

Equipment Recommendations

D

LITERATURE REQUESTS:

Telephone: (843) 664-5562 / Fax: (843) 664-5548

E

WELDING EQUIPMENT REPAIRS:

Telephone: (843) 664-4487 / Fax: (843) 664-5557

Repair Estimates

Repair Status

Hours: 7.30 AM to 3:30 PM EST

WELDING EQUIPMENT TRAINING:

Telephone: (843) 664-4428 / Fax: (843) 679-5864

Training School Information and Registrations

Hours: 7.30 AM to 4:00 PM EST

F

Hours: 7.30 AM to 4:00 PM EST

G

WELDING PROCESS ASSISTANCE:

Telephone: (800) ESAB-123

Hours: 7.30 AM to 4:00 PM EST

H

TECHNICAL ASST. CONSUMABLES:

Telephone: (800) 933-7070

Hours: 7.30 AM to 5:00 PM EST

IF YOU DO NOT KNOW WHOM TO CALL

Telephone: (800) ESAB-123

Fax: (843) 664-4452

Hours: 7:30 AM to 5:00 PM EST

or

visit us on the web at http://www.esabna.com

The ESAB web site offers:

Comprehensive Product Information

Material Safety Data Sheets

Warranty Registration

Instruction Literature Download Library

Distributor Locator

Global Company Information

Press Releases

Customer Feedback & Support

ESAB Welding & Cutting Products

110503

PO BOX 100545, Florence SC 29501-0545

- 24 backp3us