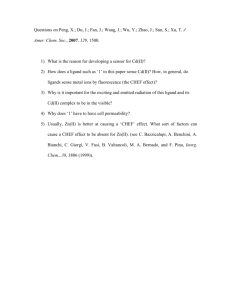

High-Throughput Catalysis

advertisement

1 High-Throughput Catalysis MacMillan Group Meeting Oct. 22, 2008 Jay Conrad 2 Enantioslective Catalysis and the Chemical Industry ■ Bulk chemical prcesses already make use of "Green" homogeneous catalysis e.g. hydroformylation - carbonylation - oxidation ■ In fine chemicals have been slow to adopt new technologies e.g. pharmaceuticals - agrochemicals - dyestuffs - flavours - fragrences H.U. Blaser Chem. Commun. 2003, 293. 3 Enantioselective Catalysis and Fine Chemicals ■ Difficulties impletmenting catalytic technologies Problems with homogeneous catalysis: loading - leaching - cost - TIME "Cannot spend years to develop a reaction that may not make it to production." - H.U. Blaser (Solvias) Really need to develope enantioselective catalysis - Chiral drugs onthe market in 1992 58%, 2006 75%. However developement time is especially problematic for enantioselective catalysis. ■ Fine Chemical Research and developement clock is ticking on patents Time for enantioselective catalysis? H. U. Blaser Appl. Catal. 2001, 221, 119. 4 High-Throughput Catalysis ! Why it takes so long, consider all the moving parts of a catalytic reaction: metal (amine) counterion (co-cat) ligand ancillary ligand metal / ligand ratio prep method substrate/cat ratio reactant solvent temperature pressure concentration substrate/reactant ratio rate of addition pH additives - acids, bases, salts 10 trials for each variable = 1017 combinations From lead discovery to an optimized prcoess can be very time intensive J. de Vries Eur. J. Org. Chem. 2003, 799. 5 The Trial and Error Component to Developing Chemsitry ! Nobel prize winner acknowledges role luck/trial and error "Since acheiving about 95% ee only involves energy differences of about 2 kcal, which is no more than the barrier encountered in a simple rotatation of ethane, it is unlikely that before the fact one can predict what kind of ligand structures will be effective." - W. S. Knowles Acc. Chem. Res. 1983, 16, 106. ! In 25 years we still face the same challenges in the design of chemical reactions "Success in developing new and highly enantioselective catalysts depends upon design, experience, intuition, trial and error and/or serendipity." - M. Reetz Angew. Chem. Int. Ed. Eng. 2008, 47, 2556. ! To attack these problems researchers have adopted high-throughput methods 6 High-Throughput Catalysis ■ Traditional optimization - Serial 1 Reaction One shot at the target - reload precise and accurate but slow turnaround ■ High-Throughput - Parallel Many Reactions lower precisions and accuracy but many more chances of hitting the target 7 High-Throughput Catalysis ! What is high-throughput catalysis? evaluation of large numbers of experiments reaction optimization combinatorial approaches to reaction design Reviews: M. Reetz Angew. Chem. Int. Ed. Eng. 2001, 40, 284. A. F. Volpe Jr. Appl. Catal. A 2001, 221, 23. S. Brase Synthesis, 2001, 1431. K. Ding Chem. Eur. J. 2004, 10, 2872. R. Paciello Chem. Rev. 2006, 106, 2912. M. Reetz Angew. Chem. Int. Ed. Eng. 2008, 47, 2556. catalyst or ligand discovery 8 High-Throughput Catalysis ■ Requirements for HT catalysis Hardware: Robots, parallel reactors Fast analysis Libraries of ligands / catalyst Software for data handling ■ Typical workflow for HT catalysis 9 Important Early Examples ! C-H Activation CO2(L-Men) CO2(L-Men) CO2(L-Men) N2 catalyst N O O N O DDQ oxidation N O O O Previous best: Cu(OTf)2 - BOX 64% yield 2.3:1 dr "M" CO2(L-Men) CO2(L-Men) BOX: M M H N H Me O N O O N O O Me Ph O Sulikowski J. Org. Chem. 1995, 60, 2326. Review: Davies Nature 2008, 451, 417. N Ph 10 Important Early Examples ! Evaluation of ligands, solvent and metals for C-H Activation Me Me O O N O Ph N Ph Ph O N Ph N Ph Ph N N Ligands H O N N H iPr iPr AgSbF6 Sc(OTf)3 Cu(OTf)2 OH N O N N tBu H tBu tBu HO tBu H [Rh(nbd)]BPh4 Metals THF MeCN CHCl3 MePh Solvents AuCl(SMe2) La(OTf)3 Yb(OTf)3 = 96 experiments Burgess Angew. Chem. Int. Ed. Engl. 1996, 35, 220 11 Important Early Examples ! New catalysts identified CO2(L-Men) CO2(L-Men) CO2(L-Men) N2 catalyst N O O N O DDQ oxidation N O O Previous best: Cu(OTf)2 CH2Cl2 64% yield 2.3:1 dr Me O N Ph 61% yield 4.4:1 dr Me O Me O N Ph 75% yield Me O N Ph AgSbF6 THF Cu(OTf)2 THF Me Me O N O N Ph 3.5:1 dr Ph - The same ligand was found to give better dr - Silver at the time was rarely used - First silver catalyzed C-H insertion N Ph O 12 Important Early Examples ! Notable features and comments from the Burgess paper First use of microtiter 96 well plate for catalyst developement - long used in biology Advantages of high-throughput catalysis outlined: - highly efficient method for catalyst evaluation - parallel format encourages the trial of a wider range of conditions - increases chemists ability to be creative - the potential for rapid optimization of industrial processes is outlined - one reaction per well is the only efficient way to evaluate catalyst 13 Chiral Catalysts for the Strecker Reaction ! Jacobsen - parallel synthetic ligand libraries O catalyst N TBSCN F3C N H CN TFA ! Modifed Schiff bases were prepared in a combinatorial fashion on a solid support R R O N R M Linker1 amino acid Linker2 O R N N M R Solid support tridentate Schiff base complex E. N. Jacobsen J. Am. Chem. Soc. 1996, 118, 8983. E. N. Jacobsen J. Am. Chem. Soc. 1998, 120, 4901. O R 14 Chiral Catalysts for the Strecker Reaction ■ The initial catalyst screen the ligand itself is better than the metal complexes! 15 Chiral Catalysts for the Strecker Reaction ■ Optimization of the urea and thiourea catalysts Ph R H N O N H S R R N H N Ph tBu H N O HO S N H N H N HO X OMe tBu tBu 80% ee ■ a new class of catalysts discovered ■ many new applications ■ major advance in H-bonding catalysis ■ showcase of combinatorial catalyst design 16 Polyolefin Catalyst Discovery ! Polyolefin production is a 100 billion-dollar industry catalyst R n R polyolefin myriad applications !-olefin feedstock chemical ! Mechanism: Polymer growth by alkene 1,2-insertion with chain migration P M M P M P 17 Polyolefin Catalyst Discovery ! Highly active single-site catalysts been developed for over 50 years 1957 - Ziegler/Natta catalysts 1980 - Kaminsky 1963 - Nobel Prize TiCl4 or Cl Ti O Al Me Cl MAO additive increases activty + AlEt3 1986 - Jordan no activator 1985 - Britzinger ansa metallocenes Me Zr THF Cl B(C6F5)4 highly active can now do polypropylene Ti Cl syndiotactic polymers L. Cavallo, F. Piemontesi Chem. Rev. 2000,100, 1253. G. Fink, R. Muelhaupt, H. H. Brintzinger Ziegler Catalysts, Springer, Berlin, 1995. 18 Polyolefin Catalyst Discovery ! Catalysts aggressively patented - need new structures for industrial processes New ligand designs: N Me N Ti Me2Si R P Cl N M Cl N Me P tBu Constrained geometry (Dow) Me Ti N Me R Phosphoramides (Nova) McConville New Metals: R Ar R N CH3 Pd R N sol Ar 1995 - Brookhart R Me N tBu Al N Me-B(C6F5)4 R 1997 - Jordan N Me Al O MeB(C6F5)4 1999 - Gibson 19 Polyolefin Catalyst Discovery ■ Can a new catalyst for α-olefin polymerization be rapidly discovered and optimized? Target: linear low-density polyethylene by ethlyene/octene copolymerization catalyst ? hex hex LLDPE Workplan: Dow Chemicals / Symyx: V. Murphy J. Am. Chem. Soc. 2003, 125, 4306. 20 Polyolefin Catalyst Discovery ■ A library of 24 ligands is used to make a series of novle catalysts L M(CH2Ph)4 XH L M(CH2Ph)4 - PhCH3 X M = Zr, Hf 21 Polyolefin Catalyst Discovery ■ Primary discovery workflow ■ Zr results known ligands for Zr polymerization TMS H N N H N N New ligand NH O 22 Polyolefin Catalyst Discovery ■ Hf results - a new, highly active polyolefin catalyst 23 Polyolefin Catalyst Discovery ! 2nd Screen - Focused library of ligands with Hf Change condtions to commercially relevant copolymerization conditons - higher temperature 130 °C - larger scale (15 mL) high pressure batch reactors Me Me NH O Me Me original hit New ligand library: R1 NH O R2 R1 NH O R2 96 amino - ether type ligands R1 NH O R2 24 Polyolefin Catalyst Discovery ■ 2nd Screen - Focused library of ligands with Hf Hf(CH2Ph)4 ligand hex 100 psi 250 uL AliBu3 [Me2PhNH][B(C6F5)4] hex 25 Polyolefin Catalyst Discovery ! Final results - one gallon batch reactor catalyst hex 450 psi 250 g AliBu3 [Me2PhNH][B(C6F5)4] hex 130 °C isoparafin solvent Dow Production Catalyst Me2Si Ti N O Me Me Optimized Catalyst Initial Lead Me Mes O CH2Ph N Hf CH2Ph N Hf CH2Ph CH2Ph tBu CH2Ph CH2Ph activity (g polymer/umol cat) 52.30 7.56 13.76 Mw 59 500 97 000 181 000 2.0 3.0 2.8 0.912 0.910 0.917 Mw/Mn density (g/mL) 26 Polyolefin Catalyst Discovery ! What about polymer tacticity? catalyst Me Me Me ! Added value high performance plastics Ph Ph Ph Ph Ph Ph Ph atactic syndiotactic brittle low melting 50 c / lb (styrofoam cups) Dow - Questra tough crystaline high melting $3 / lb Ph 27 Polyolefin Catalyst Discovery ! Catalyst controls polymer microstructure Ph C2 Zr Me Ph M Me H M Ph Me M Ph Me Ph Zr Me Me enantiotopic Britzinger 1985, Chem Rev Ph isotactic homotopic C1 Me M Ph H Me M Ph Me M Ph Me Ph Ph syndiotactic 28 Polyolefin Catalyst Discovery ■ Isotactic catalyst developement over the last 30 years ■ Current state of the art Me Me Me Si Zr Me 29 Polyolefin Catalyst Discovery ■ Isotactic catalyst developement - 39 ligand screen dramatically influences performances Hf(NMe2)4 R1 R3 + AlMe3 / [Ph3C][B(C6F5)4] NH N R2 Me 75 °C toluene V. Murphy, J. C. Stevens, V. Busico Angew. Int. Ed. Engl. 2006, 45, 3278. Me Me polypropylene 30 Polyolefin Catalyst Discovery ■ NMR provides a qualitative measure of isotacticity for a polymer remarkably regular - very few polymer irregularities 31 Polyolefin Catalyst Discovery ! Two new catalysts identified Me2N Hf(NMe2)4 NH NMe2 Hf 10 AlMe3 N N N - 2 NHMe2 Me Me Me also: Hf -2 Al2Me5(NMe2) Me Hf N N N N ! Mechanistic model: metallocene mimic Me Me Hf isotactic polypropylene P Hf Me 32 Polyolefin Catalyst Discovery ! Hold on, how do you get isotactic polymer from a C1 symmetric ligand ? C1-symmetric the ligand should give rise to enantiotopic binding sites N Hf N Me Me Hf P Me Me enantiotopic Me syndiotactic ! The twisting of the ligand makes the coordination sites pseudo-homotopic Me Hf P Hf P Me C1 ligand with diasterotopic binding sites behaves like a C2 symmetric - homotopic Me Me isotactic 33 Polyolefin Catalyst Discovery ! Comparison of new catalysts to highly developed industry standard metallocene Me Me Me Hf Hf Me Me N N Me Si Zr Me N N Me 6.9 bar propene, 10 equiv Al(iBu)2H, [Me2PhNH][B(C6F5)4], 90 °C Productivity TOF kg polymer / mmol cat / min 9.2 1.9 0.3 Mw [kDa] 95 300 710 Mw/Mn 2.0 2.1 3.2 Tm (°C) 142 127 141 > 300 desired > 150 desired 34 Polyolefin Catalyst Discovery ! In just 4 years a new catalyst for isotactic polypropylene production has been realized Me Me Hf N N Ph ! robust solution catalyst operating above 100 °C ! isotactic ! high Mw polypropylene ! Tm 150 °C ! now in produciton at Dow, trade name Versify 35 Industrial Scale Hydrogenation ! Each process uses different ligand reflecting substrate specificty and IP restrictions MeO CHO2H NHAc NHAc AcO OH 95% ee Monsanto 1 t/y L-dopa Parkinson drug 97% ee Takasago 300 t/y (citronellol - Vitamon E) CO2H 83% ee Enichem 15 t/y (aspartame sweetner) Me MeO P P PPh2 OMe Ph PPh2 99% ee Degussa-Huls 10 kg Me N N PPh2 PPh2 Ph2P Ph NBn Ph2P eniphos dipamp deguphos binap PCy2 O N O N Et NHtBu Me 97% ee Lonza > 200 kg pharmaceutical intermediate Fe PPh2 H josiphos H. U. Blaser Appl. Catal. A 2001, 221, 119. 36 Catalyst Design and the Hydrogenation Mechanism ■ Halpern discovered this behavior in asymmetric hydrogenation O Ph Me Ph2 P sol Rh MeO HN Me O Me P Ph2 -2 sol Me MeO2C Ph2 P Rh Me P Ph2 sol Me NH Ph Me O Me Ph2 MeO C 2 P Rh P Ph2 (chiraphos) Ph NH O Me diastereoisomers major isomer > 10:1 NMR and X-ray J. Halpern J. Am. Chem. Soc. 1980, 102, 5952. J. Halpern Science 1982, 217, 401. J. Halpern J. Am. Chem. Soc. 1987, 109, 1746. 37 Halpern Hydrogenation Mechanism Me Me MeO2C Ph2 P Rh NH Ph P Ph2 K Me Me O Me Ph2 MeO C 2 P Rh P Ph2 major kmaj NH + 1.4 kcal/mol O Me minor Oxidative addition of H2 (rate determining step) kmin = 580 kmaj H2 R H Ph P NH Rh Ph P !!G = 3.7 kcal/mol kmin H Ph R H NH Rh Me P O H H2 O P Me 1,2 insertion R H P NH Rh Ph P Ph R H NH Rh P Me P O O Me reductive elimination O MeO Bn minor O dechelation H N Me O H N MeO Bn Me O major 96% ee, > 50:1 38 Catalyst Design and the Curtin Hammett Principle K k1 C A major minor k2 B D TS2 G TS1 !G1 !!G !G2 A !G C B D The design of a suitable (enantioselective) catalyst becomes diffiuclt as the exact reaction pathway can depend on more reactive transient intermediates (A) ! The reaction outcome depends on !!G ! The equilibrium constant between the intermediates does not impact the reaction outcome ! Energies involved are 2-3 kcal/mol, current DFT has an error of about 1-5 kcal/mol ! While ligands can be cleverly designed, optimization is ultimately empirical 39 Hydrogenation at Merck and High-Throughput Optimizaiton ■ Parallel pressure reactors enabled the evaluation of many ligands C. S. Shultz, S. W. Krska Acc. Chem. Res. 2007, 40, 1320 40 Hydrogenation at Merck and High-Throughput Optimizaiton ! Conditions and ligand otimization in cooperation with Solvias led to a commercial process tBu P tBu Me 0.32 mol % Fe PPh2 CF3 CF3 F N N NH2 F F O N F 0.15 mol % [Rh(cod)Cl]2 50 °C, 150 psi H2 N N NH2 F MeOH, 18 h N O F sitagliptin (DPP-4 inhibitor) Treatment for type II diabetes FDA approved in October 2006 Just 6 months to reach 100 kg scale 20 MT has been produced to date C. S. Shultz, S. W. Krska Acc. Chem. Res. 2007, 40, 1320 >95%, 95% ee 41 Monodentate Phosphoramidites as Ligands for Hydrogenation ■ 3 groups independently reported enantioselcetive catalysis mediated by phosphoramidites O O O P OR O P NR M. Reetz Angew. Chem. Int. Ed. Engl. 2000, 112, 4047. P. G. Pringle Chem. Commun. 2000, 961. J. G. de Vries, B. Feringa J. Am. Chem. Soc. 2000, 122, 11539. phosphite phosphoramidite ■ In some cases monodentate ligands are faster and more selective than bidentate O NHAc HO Me Et B. L. Feringa, J. G. de Vries Acc. Chem. Res. 2007, 40, 1267. 42 Optimization of Hydrogenation by Combinatorial Ligand Libraries ■ In situ formation of ligands from phosphites and amines O P O Cl R2 H N NEt3 R1 R1 O P O NEt3·HCl N R2 ■ Instant catalyst libraries from combiinatorial ligand - metal constructs 43 Optimization of Hydrogenation by Combinatorial Ligand Libraries ■ Hydrogentation screening results - substrate specificity towards ligand R1 and R2 ■ For both substrates a highly efficient and selective ligand was found: >90%, >90% ee 44 Unexpected Results in Monodentate Phosphoramidate Mediated Catalysis ! Use of 2 equiv of one ligand results in moderate to high selectivity O MeO H2 O NHAc NHAc MeO Me O La O [RhLaLa]BF4 P tBu 92% ee O Lb O [RhLbLb]BF4 P OMe 77% ee ! Not the average of the two ligands' selectivities, MLaLb faster and more selective 2 MLaLb MLaLa + MLbLb [RhLaLb]BF4 M. Reetz Angew. Chem. Int. ed. Eng. 2003, 42, 790. 98% ee 45 Rate Acceleration of Mixed Ligand Systems ■ Hetero-combination of matched S,S ligands provides faster rates of hydrogenation O O O O M. Reetz Angew. Chem. Int. Ed. Engl. 2006, 45, 1412. P P CH3 tBu 1a 1b 46 Even More Unexpected: Achiral Ligands Amplify Selectivity ! Higher selectivities werefound by using mixtures of ligands O NHAc MeO O H2 NHAc MeO Me [RhLaLb]BF4 98% ee [RhLaLa]BF4 75% ee [RhLbLb]BF4 0% ee ! Not the average of the two ligands' selectivities, MLaLb faster and more selective 2 MLaLb MLaLa + MLbLb 1 16 La O O P OMe 1 Lb O O P OMe Achiral M. Reetz Angew. Chem. Int. ed. Eng. 2005, 44, 2959. 47 Achiral Ligand Adopts Matched Case ! Comparing Combinations of different chiral to achiral phosphites O [RhLL]BF4 NHAc MeO Me Case 1: Matched Case 2: Mis-matched O O O O P O tBu O P O tBu O P OMe 100% 98% ee P OMe 84% 40% ee 100% 98% ee Achiral Case 3: Fluxinal O O P tBu O O P mis-matched OMe O O P matched OMe 48 High-Throughput Developement of a Mixed Ligand Hydrogenation Process ! DSM Pharma makes AliskirenTM a renin inhibitor via a hydrogenation process MeO O CO2H MeO Me MeO hydrogenation MeO Me Me OH Me H Me N H2N MeO O O MeO Me CONH2 O Me Me AliskirenTM - Novartis Goals: Reduce cost and stay within time-to-market window J. de Vries Org. Proc. Res. Dev. 2007, 11, 585. CO2H Me Me 49 High-Throughput Developement of a Mixed Ligand Hydrogenation Process ■ Initial study: monophos and additives 2 O Me P O N Me monophos MeO O MeO CO2H Me Me [Rh(cod)2]BF4 additive H2 MeO O MeO CO2H Me Me 50 High-Throughput Developement of a Mixed Ligand Hydrogenation Process ! Instant ligand library optimization with PPh3 additive Me O R P Cl H O 96 amines N R Me Me O 2 R P O N R Me MeO O MeO MeO CO2H Me Me PPh3 H2 [Rh(cod)2]BF4 O MeO CO2H Me Me 51 High-Throughput Developement of a Mixed Ligand Hydrogenation Process ■ Instant ligand library optimization with PPh3 additive Me O O Me R P N R 52 High-Throughput Developement of a Mixed Ligand Hydrogenation Process ■ Instant ligand library optimization with PPh3 additive Me O O Me R P N R 53 High-Throughput Developement of a Mixed Ligand Hydrogenation Process ! The final process Me O 2 O MeO O P N P CO2H Me Me MeO Me Me 80 bar H2 IPA/H2O (80/20) 0.02 mol % [Rh(cod)2]BF4 MeO O MeO CO2H Me Me 100 % 90% ee TON 5000 TOF 1800/h TON > 10,000 possible 50 g substrate 3 54 Catalyst Design by Self-Assembly ! Combinatorial method for the design of new bidentate ligands N N A N H N H O Piv N N N Do Piv H N O O N H H H N N Do M H O T Do N Do N Me modular ligands DNA Base pairs Ligands: self assembled catalyst O R Piv N H N P Ar Piv Ph N P N H H O P O R B. Breit J. Am. Chem. Soc. 2006, 128, 4188. N O R R O 55 Catalyst Design by Self-Assembly ! Highly enantioselective ligand system found for hydrogenation [Rh(COD)2]BF4 La / L b H2 O MeO O N H Me CH2Cl2 Me MeO O O N H Me TON 1000 99% ee 100% conv Best ligand combination: O Piv N N H H O N P O Rh P O O (Control reactions showed the heterocombination to be superior to homocombinations of either ligand) 56 Self-Assembled Supramolecular Catalysts ! 3-aminochromanes are found in many natural products NHMs O NC EtO2C O OH H N N OH MK-0499 SR 58611A ! Hydrogenation of enamides of this type is difficult H N Me H N Rh-L O Me O Ph O O P N O P S N PPh2 PPh2 O Ph J. Ferringa J. Org. Chem. 2005, 70, 943. 94% conv 34% ee J. Ferringa Org. Lett. 2004, 6, 1433. 40% conv 34% ee C. Bruneau Adv. Syn. Catal. 2003, 345, 230. 94% conv (Ru) 80% ee 57 Self-Assembled Supramolecular Catalysts ■ Self asembled catalyst designed to solve the difficult hydrogenation of enamide Ligand library generated by self assembly of a suoramolecular porphyrin structure - supraphos J. N. H. Reek Angew. Chem. Int. Ed. Engl. 2006, 45, 1223. Review: B. Breit Angew. Chem. Int. Ed. Engl. 2005, 44, 6816. 58 Self-Assembled Supramolecular Catalysts ■ Modular ligands increases the accessible structural diversity 59 Self-Assembled Supramolecular Catalysts H N Me O [Rh(cod)2]BF4 Supraphos H N Me O H2 L2 - L'1 100% conv, 94% ee O O Rh Ph2 P P N O N N Zn Ph Supraphos All control reactions led to eroded selectivity - Binap 60% ee Ph N N Ph 60 New Methods for High-Throughput Screening ■ Mass spectrometric evaluation of catalysts by microscopic reversibility Me O N microscopic retro DA O Bn N (S ) Bn Me N Me O Pr Me N H 375 m/z Si Me Me Pr HCl O 1 h 50 °C Me O N (R ) Bu pseudoenantiomers with different mass Bn N Me 389 m/z Me Re Bu changing Bu and Pr gives the same result Mass labelled catalyst A. Pfaltz Angew. Chem. Int. Ed. Engl. 2008, 47, 3360. 61 New Methods for High-Throughput Screening ■ Determining relative catalyst enantioselectivity from microscopic reverse DA O Pr (S ) O (R ) catalyst pool 1 h 50 °C Bu With any new and exciting experiments more questions are raised can yield be addressed - a funciton of ionization potential will this be a general method how many catalysts can be done at once? mass overlap does this method account for Halpern type systems? 62 Conclusions ! HT techniques have impacted several fields of chemistry and industry ! HT/combinatorial catalysis is not anti-intellectual ! The goal of performing greater numbers of experiments increase creativity and chances of success ! So far, HT in fine chemicals is typically 100's not 1000's - enantioselective quality over quantity ! Impressive discoveries have been made: H-bonding, Hf polymerization, non-linear effects ! HT has enabled enantioselective catalysis to be adopted in fine chemical production