OIL & GAS PRODUCTION

Refinery Outgassing Bottleneck Resolved

Via Proper Control Valve Sizing & Selection

RESULTS:

Improved valve design avoids 15-month periodic repair & replacement.

Improved reliability and increased throughput.

Return-On-Investment: less than 24 hours.

APPLICATION

Hot, low-pressure, flash drum level control in Gas-Oil Hydro

Treater (GOHT) producing light cycle gas oil (LCGO) in

combined duty shared with distillate hydrotreater (DHT).

CUSTOMER

Large refinery processor.

CHALLENGE

Customer was experiencing that, over time, its gas-oil

hydrotreater capacity had grown to the point where two

components of the high-pressure separator let-down service

would occasionally be flagged as unit constraints.

Refinery operations are such that the gas-oil hydrotreater

and distillate hydrotreater share the duty of Light Cycle Gas

Oil production (LCGO). During unit shutdown, the GOHT

was unable to handle LCGO production on it’s own, making

it a further constraint. The two units became the bottleneck

to achieving maximum LCGO production during a distillate

hydrotreater turnaround.

Further, corrective repair work to these two valves was

required every 15 months. This was due to valve and trim

washout and excessive vibration causing packing problems

and premature yoke failures. Improper valve sizing created

choked flow conditions which resulted in unit constraints

during normal and temporary feed slate conditions.

(Continued on back side.)

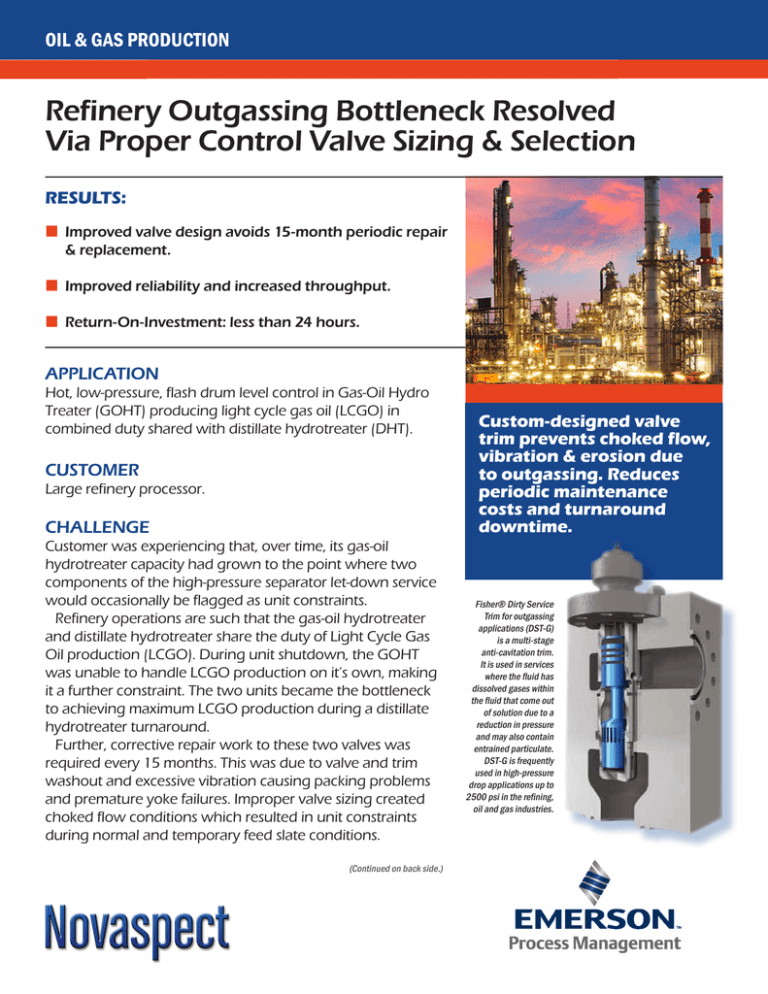

Custom-designed valve

trim prevents choked flow,

vibration & erosion due

to outgassing. Reduces

periodic maintenance

costs and turnaround

downtime.

Fisher® Dirty Service

Trim for outgassing

applications (DST-G)

is a multi-stage

anti-cavitation trim.

It is used in services

where the fluid has

dissolved gases within

the fluid that come out

of solution due to a

reduction in pressure

and may also contain

entrained particulate.

DST-G is frequently

used in high-pressure

drop applications up to

2500 psi in the refining,

oil and gas industries.

OIL & GAS PRODUCTION

Diagram of typical gas oil

hydrotreater process (at right);

cross section drawing (below

right) of the Fisher 3”x3” Type

HPAS with 2-Stage DST-G,

custom-designed for specific

customer refinery application.

(Continued from front side.)

SOLUTION

Novaspect and Fisher® collaborated with customer process

engineers to understand the complete set of process conditions

that were creating the outgassing conditions in both normal and

temporary feed slate conditions. The Novaspect-Fisher experts

used a “bracket” sizing technique to understand the valve flow

coefficient (Cv) requirements that could result from different

outgassing phenomena.

The resulting solution was a customized Fisher 3”x3” Type HPAS

valve with 2-Stage DST-G outgassing trim designed specifically for

this application. Its valve body was designed to meet customer

piping and material specs with a contoured and expanded outlet

to prevent “choked flow” and other problems such as vibration

and erosion due to outgassing. The resulting trim was suitably

customized to meet the Cv requirements of the customer.

ECONOMIC ANALYSIS

The project Return On Investment (ROI) was recorded at less than

24 hours, calculated during a temporary feed slate opportunity.

After installing the Novaspect solution, these valves have not failed

since (96 months) versus every 15 months before.

Emerson Process Management provided by Novaspect offers an

array of control system support services designed to help achieve

business objectives, reduce or contain operating and service

costs, and keep control systems running at peak performance. It

is a partnership that understands your business and can help you

operate your plant safely, reliably and more efficiently.

To learn more about how we can solve your challenging

process application, contact Novaspect today.

Novaspect Inc.

1124 Tower Road | Schaumburg, IL 60173

PH: 847.956.8020 | FX: 847.885.8200

Contact Us: www.novaspect.com

Rev. 04.14.15

© 2015 Novaspect Inc. All rights reserved. The Fisher trademark is owned by the

Emerson Process Management business unit of Emerson Electric Co.; Emerson

Process Management, Emerson, and the Emerson logo are trademarks and

service marks of Emerson Electric Co.; Novaspect and the Novaspect logo are

trademarks of Novaspect Inc., a Local Business Partner of Emerson.