COLOUR SELECTOR cover.ai

LOCKERS

WASHROOM PARTITIONS

Colour Selector Chart

• Twenty Two Standard Colours

• Four Stocked Colours (Overhead Braced Series)

• Anti-Graffiti Textured Finishes

• In addition to Hovik’s 22 standard decorative colours and 8 metallic finishes, formulated custom matches are also available.

***(Minimum 10 stall order)***

POWDER COAT FINISH TECHNICAL DATA

Powdercoating was developed in response to environmental problems associated with solvent-based coatings. Federal and state regulatory bodies will probably prohibit the use of solvent-based paints in the near future.

Test Characteristics of Powder Coated Finishes

Pencil Hardness ASTM D-3363 2H

Gloss (60 to 80) ASTM D-523 + -5 dependent on specific product

Salt Spray ASTM B-117 No corrosion creep more than 1/16

From after 1000 hours, resistance generally good to excellent.

Resistance to acids, alkalies, oils and most solvents.

Flexibility

Adhesion

ASTM D-522

Cross Hatch Test

Impact Resistance ATM D-2974

Past 1/8 inch

ASTM D-3359 Pass (Classification 5B)

Pass at a minimum of 100 inch

Direct and reverse

Care and Maintenance of Powder Coated Metal Compartments

Clean with a mild soap then wipe dry. A good quality automotive wax may be used to bring back luster. Compartments must receive proper ventilation so that excess humidity can escape and not be absorbed by the finish. Hovik will not accept responsibility for the product failure if the following agents are used for cleaning; abrasive powders or pads, water closet or ceramic tile cleaners, solutions containing more than 1% by volume of ammonia, acids or lye, and enzymes.

AGENT / DISTRIBUTOR www.hovikindustries.com

45225 Keith Wilson Road

Garrison Crossing

Chilliwack, BC V2R 5S1

PHONE: 604.858.2760

TOLL FREE: 1.888.684.6845

FAX: 604.858.2761

Manufacturers of Quality Metal

Compartments & Lockers

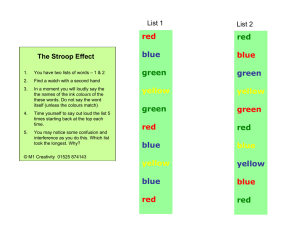

COLOUR SELECTOR for Powder Coated Finishes

Standard on Element and Enclave series, this type of paint finish is the latest in paint technology and is very durable.

It’s smooth, even, flawless finish is another example of Hovik’s commitment to quality. Our finish is environmentally friendly.

Hovik has 22 modern decorative colours including 4 premium anti-graffiti vein textured colours plus 8 metallic finishes.

NOTE: Specifying a low VOC coating such as Powdercoat is worth one point towards LEED certification.

ANTI GRAFFITI TEXTURES

(subject to slight upcharge) )

2001 SILVER VEIN

TEXTURE TEXTURE TEXTURE

METALLIC POWDER COATED FINISHES

(subject to slight upcharge)

TEXTURE

425 OLIVE

1220 1230 1680 1240

1334 1787 1085 1020

NOTE: Colour samples shown are for reference only and may not be exactly as shown.

FRAMES FOR LOCKERS = #650 BLACK

Custom colours and finishes are also available.

* Available in HOVIKHALT Anti-Graffiti Coating to offer maximum

vandalism protection using industry leading technology.

Manufacturers of Quality Metal

Compartments & Lockers

COLOUR SELECTOR for Powder Coated Finishes

Standard on Element and Enclave series, this type of paint finish is the latest in paint technology and is very durable.

It’s smooth, even, flawless finish is another example of Hovik’s commitment to quality. Our finish is environmentally friendly.

Hovik has 22 modern decorative colours including 4 premium anti-graffiti vein textured colours plus 8 metallic finishes.

NOTE: Specifying a low VOC coating such as Powdercoat is worth one point towards LEED certification.

ANTI GRAFFITI TEXTURES

(subject to slight upcharge) )

2001 SILVER VEIN

TEXTURE TEXTURE TEXTURE

METALLIC POWDER COATED FINISHES

(subject to slight upcharge)

TEXTURE

425 OLIVE

1220 1230 1680 1240

1334 1787 1085 1020

NOTE: Colour samples shown are for reference only and may not be exactly as shown.

FRAMES FOR LOCKERS = #650 BLACK

Custom colours and finishes are also available.

* Available in HOVIKHALT Anti-Graffiti Coating to offer maximum

vandalism protection using industry leading technology.

LOCKERS

WASHROOM PARTITIONS

Colour Selector Chart

• Twenty Two Standard Colours

• Four Stocked Colours (Overhead Braced Series)

• Anti-Graffiti Textured Finishes

• In addition to Hovik’s 22 standard decorative colours and 8 metallic finishes, formulated custom matches are also available.

***(Minimum 10 stall order)***

POWDER COAT FINISH TECHNICAL DATA

Powdercoating was developed in response to environmental problems associated with solvent-based coatings. Federal and state regulatory bodies will probably prohibit the use of solvent-based paints in the near future.

Test Characteristics of Powder Coated Finishes

Pencil Hardness ASTM D-3363 2H

Gloss (60 to 80) ASTM D-523 + -5 dependent on specific product

Salt Spray ASTM B-117 No corrosion creep more than 1/16

From after 1000 hours, resistance generally good to excellent.

Resistance to acids, alkalies, oils and most solvents.

Flexibility

Adhesion

ASTM D-522

Cross Hatch Test

Impact Resistance ATM D-2974

Past 1/8 inch

ASTM D-3359 Pass (Classification 5B)

Pass at a minimum of 100 inch

Direct and reverse

Care and Maintenance of Powder Coated Metal Compartments

Clean with a mild soap then wipe dry. A good quality automotive wax may be used to bring back luster. Compartments must receive proper ventilation so that excess humidity can escape and not be absorbed by the finish. Hovik will not accept responsibility for the product failure if the following agents are used for cleaning; abrasive powders or pads, water closet or ceramic tile cleaners, solutions containing more than 1% by volume of ammonia, acids or lye, and enzymes.

AGENT / DISTRIBUTOR www.hovikindustries.com

45225 Keith Wilson Road

Garrison Crossing

Chilliwack, BC V2R 5S1

PHONE: 604.858.2760

TOLL FREE: 1.888.684.6845

FAX: 604.858.2761