collect

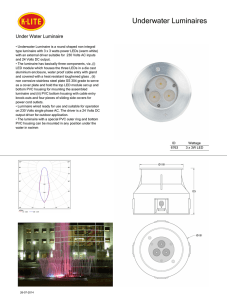

advertisement