Automotive_Electrical_and_Electronic_Systems_I

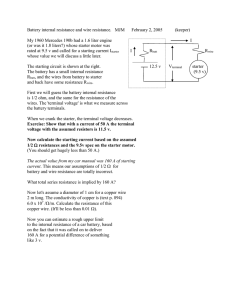

advertisement

Automotive Electrical and Electronic Systems I Safety Unit: 1 Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): Students will: 1. Demonstrate personal and environmental safety practices associated with clothing, eye protection, hand tools, power equipment, and proper ventilation related to automotive electrical and electronic system operation and maintenance. Students will: 1. Describe the safe use of all tools and equipment used in automotive electrical and electronics repair work. 2. Demonstrate the safe use of all tools and equipment used in automotive electrical and electronics repair work. Can the student work safely in the automotive service environment? Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Suggested Materials, Equipment and Technology Resources Content Knowledge 1. 2. 3. 4. 5. 6. 7. MSDS OSHA Regulations Shop specific rules and procedures Hand Tool Safety Power tool safety Stationary tool and equipment safety Safety procedures Brainstorming/Discussion Case Studies/ Scenarios Collaborative Learning Cooperative learning Demonstration Guest Speaker Note Taking PBL (Problem based Learning) Work Sheets 1. MSDS Sheets 1. OSHA Regulations 2. NATEF Task Sheets Unit Assessment: Unit/Course CTSO Activity: Unit/Course Culminating Product: 1. 2. 3. 4. 5. 6. Industry-based written tests Industry-based Performance tasks Oral Presentations Demonstrations Teacher Observations Checklists 1. Give oral presentation on assigned lesson topic. 2. Begin SkillsUSA Leadership Development Programs. 3. Establish documentation for portfolio organization. 4. Begin review of SkillsUSA Contest projects to help design lab activities. 1. Accomplishment of industry based written and performance testing 2. Accomplishment of appropriate NATEF performance standards regarding safety Course/Program Credential(s): Other: Credential Certificate Postsecondary Degree University Degree Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I. Automotive Electrical and Electronic Systems I Unit: 2-5 Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): General Electrical System Diagnosis Student will: 2. Diagnose electrical and electronic system problems. 3. Identify electrical and electronic systems concerns. • Determining necessary action for electrical and electronic systems concerns 4. Research vehicle and service information, including vehicle service history, technical service bulletins, and interpretation of vehicle and major component identification numbers. 5. Create a work order for general electrical system concerns. Students will: 1. Complete work order to include customer information, vehicle identifying information, customer concern, related service history, cause and correction. 2. Identify and interpret electrical/electronic system concern; determine necessary action. 3. Research applicable vehicle and service information, such as electrical/electronic system operation, vehicle service history, service precautions, and technical service bulletins. 4. Locate and interpret vehicle and major component identification numbers (VIN, vehicle certification labels, and calibration decals). 5. Diagnose electrical/electronic integrity of series, parallel and series-parallel circuits using principals of electricity Ohm’s Law). 6. Use wiring diagrams during diagnosis of electrical circuit problems. 7. Demonstrate the proper use of a digital multi meter [DMM] during diagnosis of electrical circuit problems. 8. Check electrical circuits with a test light; determine necessary action. 9. Measure source voltage and perform voltage drop tests in electrical/electronic circuits using a volt meter; determine necessary action. 10. Measure current flow in electrical/electronic circuits using ammeter; determine necessary action. 11. Check continuity and measure resistance in electrical/electronic circuits and components using an ohmmeter; determine necessary action. 12. Check electrical circuits using fused jumper wires; determine necessary action. 13. Locate shorts, grounds, opens, and resistance problems in electrical/electronic circuits; determine necessary action. 14. Measure and diagnose the cause(s) of excessive key-off battery drain (parasitic draw); determine necessary action. 15. Inspect and test fusible links, circuit breakers, and fuses; determine necessary action. 16. Inspect and test switches, connectors, relays, solenoid solid state devices, and wires of electrical/electronic circuits; perform necessary action. 17. Remove and replace terminal end from connector. 18. Repair connectors and terminal ends. 19. Repair wiring harness (including CAN/BUS systems). 20. Perform solder repair of electrical wiring. 21. Identify location of hybrid vehicle high voltage circuit disconnect( service plug) location and safety procedures. Essential Question(s): Will the student be able to correctly and effectively diagnose general electrical system problems? Content Knowledge 1. Complete work order. A. demonstrate knowledge of work order creation by either paper work order or computer based program. B. document customer complaint or reason for visit to point where technician will have enough information to get started. C. Review related history for customer / vehicle. D. Present cause and correction on work order for customer. 2. Knowledge of common electrical system problems; poor ground loose connections, weak battery, failed diode etc. 3. Ability to use technical data base to research necessary testing and repair procedures 4. Knowledge of locations for important identifying numbers (VIN, calibration etc.) 5. Knowledge and understanding of parallel, series and parallel circuits and how to test them 6. Knowledge of how to use wiring diagrams, symbols and annotations Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) 1. Brainstorming/Discussion 2. Case Studies/ Scenarios 3. Collaborative Learning 4. Cooperative learning 5. Demonstration 6. Experiments 7. Field Trips 8. Five Plus one (5+1) 9. Games 10. Group investigation 11. Guest Speaker 12. Guided Practice 13. Instructional Technology 14. Laboratory/ Shop Exercise 15. Lecture, Lecture/Demonstration 16. Note Taking 17. PBL (Problem based Learning) 18. Ten plus two (10+2) 19. Work Based Learning 20. Work Sheets Suggested Materials, Equipment and Technology Resources 21. Laboratory Shop Equipment 22. Tools, Supplies adequate for class numbers 23. PPE in sufficient quantity for class numbers 24. PowerPoint presentations 25. Handouts 26. Textbook, online and print 27. Modules 28. Online Technical Reference (AllData, Mitchell) Computers, laptop and desktop 29. LCD Projectors 30. DVOM. 31. DSO 32. Oscilloscope 7. Demonstrated ability to accurately use DMM and other electrical test equipment 8. Appropriate use of 12v test light 9. Ability to set up and run voltage drop test using DMM 10. Ability to set up and run ammeter testing 11. Use of DMM to test continuity in circuits 12. Knowledge of circuit operation 13. Understanding of ground fault and power side testing of electrical circuits test same with jumper wires and other 14. Use of industry approved methods of determining excessive and parasitic drain 15. Knowledge of how and when fusible links are to be used 16. Knowledge of different types of switches, connectors etc including ability to test 17. Knowledge of proper wire stripping, insulating methods fro replacement of emergency terminal; ends 18. Knowledge of wire sizes terminal types for connecting wires of same and/or different sizes 19. Appropriate repair of can bus wires 20. Knowledge of how to prepare wire , use of solder gun 21. Use of technical reference material to locate hybrid disconnect 33. Unit Assessment: Student will take written tests, demonstrate knowledge of system operation, and successfully complete applied skills performance tasks (hand on). Unit/Course CTSO Activity: Skills USA activity appropriate to tasks being taught Continue SkillsUSA Leadership Development Programs. Unit/Course Culminating Product: Student will demonstrate knowledge of system being taught; provide accurate diagnosis of system and industry standard repairs. Removing repairing and replacing components of a vehicle located in the laboratory Accomplishment of appropriate NATEF performance standards Course/Program Credential(s): X Credential Other: Certificate Postsecondary Degree University Degree Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I. Automotive Electrical and Electronic Systems I Battery Diagnosis and Service Unit: 6 Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): Students will: 6. Demonstrate battery state-of-charge tests, including inspecting and cleaning battery cables, connectors, clamps, and hold downs. Students will: 1. Perform battery state-of-charge test: determine necessary action. 2. Perform battery capacity (or conductance test); confirm proper battery capacity for vehicle application; determine necessary action. 3. Maintain or restore electronic memory functions. 4. Inspect, clean, fill, and replace battery. 5. Perform slow/fast battery charge. 6. Inspect and clean battery cables, connectors, clamps, and hold downs; repair or replace as needed. 7. Start a vehicle using jumper cables and a battery or auxiliary power supply. 8. Indentify high voltage circuits of electric or hybrid electric vehicle and related safety precautions. 9. Identify electronic modules, security systems and/or radios that require re-initialization or code entry following battery disconnect. 10. Identify hybrid vehicle auxiliary (12v) battery service, repair and test procedures. Why are strong electronic knowledge and skills so important in automotive technology today? Content Knowledge 1. Selection of appropriate equipment to test batteries and knowledge of battery construction to know when a battery has failed 2. As above using appropriate test equipment, compare battery to rating for car using technical Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Brainstorming/Discussion Case Studies/ Scenarios Collaborative Learning Cooperative learning Demonstration Experiments Five Plus one (5+1) Suggested Materials, Equipment and Technology Resources Laboratory Shop Equipment Tools, Supplies adequate for class numbers PPE in sufficient quantity for class numbers PowerPoint presentations Handouts Textbook, online and print Modules Online Technical Reference (AllData, reference material 3. Use of memory battery or similar device, to hold functions normally deleted with battery disconnect 4. Knowledge of chemical reactions caused by some cleaning agents, battery safety policies and procedures (remove negative cable 1st etc.) 5. Set up and select appropriate charging functions to properly charge battery. 6. Understand capabilities of corrosive materials as well as their invasive properties. 7. Knowledge of how to properly hook up cables or jump box to start disabled vehicle 8. Understanding of extremely high voltage nature of hybrid, location of isolation switches 9. Locate and program modules that require same when battery power is disconnected. 10. Use technical reference material to locate service batter on hybrid vehicles. 11. Series, parallel, series-parallel circuits 12. Wiring diagrams 13. Multimeter 14. Test light 15. Voltage 16. Current flow 17. Continuity and resistance 18. Fused jumper wires 19. Shorts, grounds, opens, and resistance 20. Key-off battery drain 21. Fusible links Games Group investigation Guest Speaker Guided Practice Instructional Technology Laboratory/ Shop Exercise Lecture, Lecture/Demonstration Note Taking PBL (Problem based Learning) Work Based Learning Work Sheets Mitchell) Computers, laptop and desktop LCD Projectors 22. Switches, connectors, relays, solid state devices, and wires 23. Wiring harnesses and connectors 24. Solder repair 25. Systems concerns 26. Vehicle and service information 27. Vehicle and major component identification numbers 28. State of charge 29. Battery capacity 30. Electronic memory functions 31. Inspect, clean, fill, and replace 32. Battery charge 33. Battery cables, connectors, clamps, and hold-downs 34. Jumper cables and power supplies Unit Assessment: Student will take written tests, demonstrate knowledge of system operation, successfully complete applied skills performance tasks (hand on) Unit/Course CTSO Activity: SkillsUSA activity appropriate to tasks being taught. Unit/Course Culminating Product: Student will demonstrate knowledge of system being taught; provide accurate diagnosis of system and industry standard repairs. Removing repairing and replacing components of a vehicle located in the laboratory Accomplishment of appropriate NATEF performance standards Course/Program Credential(s): X Credential Other: Certificate Postsecondary Degree University Degree Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I. Automotive Electrical and Electronic Systems I Unit: 7 Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): Starting System Diagnosis and Repair Students will: • 7. Explain starting system operations and repair. • Performing test procedures for starting systems Students will: 1. Diagnose and repair starting system malfunctions. 2. Perform starter current draw tests; determine necessary action. 3. Perform starter circuit voltage drop tests; determine necessary action. 4. Inspect and test starter relays and solenoids; determine necessary action. 5. Remove and install starter in a vehicle. 6. Inspect and test switches, connectors, and wires of starter control circuits; perform necessary action. • Differentiate between electrical and engine mechanical problems that cause a slow-crank or no-crank condition. 8. List the equipment needed to perform a starter current draw test. • Explaining the process of performing starter current draw tests • Identifying proper course of action based on the test results 9. List the equipment needed to perform a starter circuit drop test. • Explaining the process of performing starter circuit drop tests • Identifying proper course of action based on the test results 10. List the equipment needed to test starter relays and solenoids. • Explaining the process of inspecting and testing starter relays and solenoids • Identifying proper course of action based on the test results • List tools need to remove and install a starter in a vehicle 11. Explain the process in removing and installing a starter in a vehicle. 12. Identify switches, connectors, and wires of starter control circuits. 13. Identify the location of switches, connectors, and wires of starter control circuits. 14. Identify equipment used to test switches, connectors, and wires of starter control circuits. 15. Identify inspection and test criteria for switches, connectors, and wires of starter control circuits. • Explain the process of inspecting and testing switches, connectors and wires of starter control circuits. 17. Define slow-crank. 18. Define no-crank condition. Essential Question(s): Do starting systems impact other automotive systems? Content Knowledge Current draw Current drop Circuit voltage drop Relays and solenoids Switches, connectors, and wires Starters and starter controls Electrical and engine mechanical problems Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Brainstorming/Discussion Case Studies/ Scenarios Collaborative Learning Cooperative learning Demonstration Experiments Five Plus one (5+1) Games Group investigation Guest Speaker Guided Practice Instructional Technology Laboratory/ Shop Exercise Lecture, Lecture/Demonstration Note Taking PBL (Problem based Learning) Work Based Learning Work Sheets Suggested Materials, Equipment and Technology Resources Laboratory Shop Equipment Tools, Supplies adequate for class numbers PPE in sufficient quantity for class numbers PowerPoint presentations Handouts Textbook, online and print Modules Online Technical Reference (AllData, Mitchell) Computers, laptop and desktop LCD Projectors Unit Assessment: Student will take written tests, demonstrate knowledge of system operation, and successfully complete applied skills performance tasks (hands on). Unit/Course CTSO Activity: Continue SkillsUSA Professional Development Program. SkillsUSA activity appropriate to tasks being taught Unit/Course Culminating Product: Student will demonstrate knowledge of system being taught; provide accurate diagnosis of system and industry standard repairs. Removing repairing and replacing components of a vehicle located in the laboratory Accomplishment of appropriate NATEF performance standards Course/Program Credential(s): X Credential Certificate Postsecondary Degree University Degree Other: Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I. Automotive Electrical and Electronic Systems I Unit: 8 Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): Charging Systems Diagnosis and Repair Students will: 8. Explain starting system operations and repair. • Explain charging system component operations and repair. Students will: 1. Diagnose and repair charging system malfunctions 2. Perform charging system output test: determine necessary action 3. Diagnose charging system for the cause of undercharge, no-charge 4. Inspect and test starter relays and solenoids; determine necessary action. 5. Remove and install starter in a vehicle. 6. Inspect and test switches, connectors, and wires of starter control circuits; perform necessary action. • Differentiate between electrical and engine mechanical problems that cause a slow-crank or no-crank condition. 8. List the equipment needed to perform a starter current draw test. • Explaining the process of performing starter current draw tests • Identifying proper course of action based on the test results 9. List the equipment needed to perform a starter circuit drop test. • Explaining the process of performing starter circuit drop tests • Identifying proper course of action based on the test results 10. List the equipment needed to test starter relays and solenoids. • Explaining the process of inspecting and testing starter relays and solenoids • Identifying proper course of action based on the test results • List tools need to remove and install a starter in a vehicle 11. Explain the process in removing and installing a starter in a vehicle. 12. Identify switches, connectors, and wires of starter control circuits. 13. Identify the location of switches, connectors, and wires of starter control circuits. 14. Identify equipment used to test switches, connectors, and wires of starter control circuits. 15. Identify inspection and test criteria for switches, connectors, and wires of starter control circuits. • Explain the process of inspecting and testing switches, connectors and wires of starter control circuits. 17. Define slow-crank. 18. Define no-crank condition. Essential Question(s): Do starting systems impact other automotive systems? Content Knowledge Current draw Current drop Circuit voltage drop Relays and solenoids Switches, connectors, and wires Starters and starter controls Electrical and engine mechanical problems Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Brainstorming/Discussion Case Studies/ Scenarios Collaborative Learning Cooperative learning Demonstration Experiments Five Plus one (5+1) Games Group investigation Guest Speaker Guided Practice Instructional Technology Laboratory/ Shop Exercise Lecture, Lecture/Demonstration Note Taking PBL (Problem based Learning) Work Based Learning Work Sheets Suggested Materials, Equipment and Technology Resources Laboratory Shop Equipment Tools, Supplies adequate for class numbers PPE in sufficient quantity for class numbers PowerPoint presentations Handouts Textbook, online and print Modules Online Technical Reference (AllData, Mitchell) Computers, laptop and desktop LCD Projectors Unit Assessment: Student will take written tests, demonstrate knowledge of system operation, and successfully complete applied skills performance tasks (hands on). Unit/Course CTSO Activity: Continue SkillsUSA Professional Development Program. SkillsUSA activity appropriate to tasks being taught Unit/Course Culminating Product: Student will demonstrate knowledge of system being taught; provide accurate diagnosis of system and industry standard repairs. Removing repairing and replacing components of a vehicle located in the laboratory Accomplishment of appropriate NATEF performance standards Course/Program Credential(s): X Credential Certificate Postsecondary Degree University Degree Other: Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I. Automotive Electrical and Electronic Systems I Lighting System Diagnosis and Repair Unit: 9 Content Standard(s) and Depth of Knowledge Level(s): Students will: 9. Analyze lighting systems to determine necessary repair. Students will: Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): 1. 2. 3. 4. 5. 6. 7. Diagnose and repair lighting system malfunctions. Diagnose the cause of brighter than normal, intermittent, dim, or no light operation; determine necessary action. Inspect, replace, and aim headlights and bulbs. Inspect and diagnose incorrect turn signal or hazard light operation; perform necessary action. Define brighter than normal, intermittent, dim, and no light operation. List possible causes of brighter than normal, intermittent, dim, and no light operation. Explain the process of diagnosing the cause of brighter than normal, intermittent, dim, or no light operation and determine necessary action. 8. Identify inspection criteria for headlights and bulbs. 9. Summarize the process of inspecting, replacing, and aiming headlights and bulbs. 10. Identify incorrect turn signal. 11. Identify inspection criteria for turn signals and head lights. 12. Explain the process of inspecting and diagnosing incorrect turn signal or hazard light operation. Can students diagnose and locate the cause of lighting malfunctions? Content Knowledge Light operation Light and lamp conditions Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Brainstorming/Discussion Suggested Materials, Equipment and Technology Resources Laboratory Shop Equipment Tools, Supplies adequate for class numbers Headlights and bulbs Turn signal and hazard light operation Case Studies/ Scenarios Collaborative Learning Cooperative learning Demonstration Experiments Five Plus one (5+1) Games Group investigation Guest Speaker Guided Practice Instructional Technology Laboratory/ Shop Exercise Lecture, Lecture/Demonstration Note Taking PBL (Problem based Learning) Work Based Learning Work Sheets PPE in sufficient quantity for class numbers PowerPoint presentations Handouts Textbook, online and print Modules Online Technical Reference (AllData, Mitchell) Computers, laptop and desktop LCD Projectors Unit Assessment: Student will take written tests, demonstrate knowledge of system operation, and successfully complete applied skills performance tasks (hands on). Unit/Course CTSO Activity: Continue SkillsUSA Professional Development Program. SkillsUSA activity appropriate to tasks being taught Review SkillsUSA Technical Standards. Unit/Course Culminating Product: Student will demonstrate knowledge of system being taught; provide accurate diagnosis of system and industry standard repairs. Removing repairing and replacing components of a vehicle located in the laboratory Accomplishment of appropriate NATEF performance standards Course/Program Credential(s): X Credential Other: Certificate Postsecondary Degree University Degree Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I. Automotive Electrical and Electronic Systems I Gauge, Warning Device, and Driver Information System Diagnosis and Repair Unit: 10 Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): Students will: 10. Describe gauges, warning devices, and driver information system operations. • Demonstrating operation tests for diagnosis and repair of gauges, warning devices, and driver information system operations Students will: 1. Diagnose and repair gauge and warning devise system malfunctions. 2. Diagnose the cause of brighter than normal, intermittent, dim, or no light operation; determine necessary action. 3. Inspect, replace components as determined. 4. Summarize the process of inspecting, replacing components. Are driver information devices a necessity or a convenience? Content Knowledge Gauges Warning devises Device inspection Components Device replacement Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Brainstorming/Discussion Case Studies/ Scenarios Collaborative Learning Cooperative learning Demonstration Experiments Five Plus one (5+1) Games Group investigation Guest Speaker Guided Practice Suggested Materials, Equipment and Technology Resources Laboratory Shop Equipment Tools, Supplies adequate for class numbers PPE in sufficient quantity for class numbers PowerPoint presentations Handouts Textbook, online and print Modules Online Technical Reference (AllData, Mitchell) Computers, laptop and desktop LCD Projectors Instructional Technology Laboratory/ Shop Exercise Lecture, Lecture/Demonstration Note Taking PBL (Problem based Learning) Work Based Learning Work Sheets Unit Assessment: Student will take written tests, demonstrate knowledge of system operation, and successfully complete applied skills performance tasks (hands on). Unit/Course CTSO Activity: Continue SkillsUSA Professional Development Program. SkillsUSA activity appropriate to tasks being taught Review SkillsUSA Technical Standards. Unit/Course Culminating Product: Student will demonstrate knowledge of system being taught; provide accurate diagnosis of system and industry standard repairs. Removing repairing and replacing components of a vehicle located in the laboratory Accomplishment of appropriate NATEF performance standards Course/Program Credential(s): X Credential Other: Certificate Postsecondary Degree University Degree Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I. Automotive Electrical and Electronic Systems I Horn, Wiper, and Washer Diagnosis and Repair Unit: 11 Content Standard(s) and Depth of Knowledge Level(s): Students will: 11. Demonstrate diagnostic procedures for horn, wiper, and washer control problems. Students will: 1. Diagnose and repair horn, wiper, and washer control problems. 2. Diagnose the cause of horn, wiper, and washer control problems 3. Inspect, replace, horn, wiper, and washer components and control components Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): Can students diagnose and repair wiper systems? Content Knowledge 1. 2. 3. 4. 5. 6. 7. 8. Horn components Horn controls Wiper parts Wiper controls Wiper blades Washer systems Washer controls Washer parts Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Brainstorming/Discussion Case Studies/ Scenarios Collaborative Learning Cooperative learning Demonstration Experiments Five Plus one (5+1) Games Group investigation Guest Speaker Guided Practice Instructional Technology Laboratory/ Shop Exercise Suggested Materials, Equipment and Technology Resources Laboratory Shop Equipment Tools, Supplies adequate for class numbers PPE in sufficient quantity for class numbers PowerPoint presentations Handouts Textbook, online and print Modules Online Technical Reference (AllData, Mitchell) Computers, laptop and desktop LCD Projectors Lecture, Lecture/Demonstration Note Taking PBL (Problem based Learning) Work Based Learning Work Sheets Unit Assessment: Student will take written tests, demonstrate knowledge of system operation, and successfully complete applied skills performance tasks (hands on). Unit/Course CTSO Activity: Continue SkillsUSA Professional Development Program. SkillsUSA activity appropriate to tasks being taught Review SkillsUSA Technical Standards. Unit/Course Culminating Product: Student will demonstrate knowledge of system being taught; provide accurate diagnosis of system and industry standard repairs. Removing repairing and replacing components of a vehicle located in the laboratory Accomplishment of appropriate NATEF performance standards Course/Program Credential(s): X Credential Other: Certificate Postsecondary Degree University Degree Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I. Automotive Electrical and Electronic Systems I Accessory Diagnosis and Repair Unit: 12 Content Standard(s) and Depth of Knowledge Level(s): Learning Objective(s) and Depth of Knowledge Level(s): Essential Question(s): Students will: 12. Utilize diagnostic and repair procedures for accessories. Students will: 1. Diagnose and repair accessory system problems. 2. Diagnose the cause of accessory system problems. 3. Inspect and replace accessory system components. 4. Explain the process of inspecting and diagnosing incorrect turn signal or hazard light operation. Can students diagnose and repair turn signal system malfunctions? Content Knowledge 1. Accessory system components 2. Turn signals 3. Hazard lights 4. Accessory controls 5. Accessory system inspection 6. Accessory system parts replacement Suggested Instructional Activities Rigor & Relevance Framework (Quadrant) Brainstorming/Discussion Case Studies/ Scenarios Collaborative Learning Cooperative learning Demonstration Experiments Five Plus one (5+1) Games Group investigation Guest Speaker Guided Practice Instructional Technology Laboratory/ Shop Exercise Suggested Materials, Equipment and Technology Resources Laboratory Shop Equipment Tools, Supplies adequate for class numbers PPE in sufficient quantity for class numbers PowerPoint presentations Handouts Textbook, online and print Modules Online Technical Reference (AllData, Mitchell) Computers, laptop and desktop LCD Projectors Lecture, Lecture/Demonstration Note Taking PBL (Problem based Learning) Work Based Learning Work Sheets Unit Assessment: Student will take written tests, demonstrate knowledge of system operation, and successfully complete applied skills performance tasks (hands on). Unit/Course CTSO Activity: Continue SkillsUSA Professional Development Program. SkillsUSA activity appropriate to tasks being taught Review SkillsUSA Technical Standards. Unit/Course Culminating Product: Student will demonstrate knowledge of system being taught; provide accurate diagnosis of system and industry standard repairs. Removing repairing and replacing components of a vehicle located in the laboratory Accomplishment of appropriate NATEF performance standards Course/Program Credential(s): X Credential Other: Certificate Postsecondary Degree University Degree Based on NATEF Standards Articulates with AUM110 or ASE110 when taken with Electrical and Electronics II and Auto Engine Performance I.