Liquid level measurement - Basics 101

White Paper

Liquid level measurement - Basics 101

Part 2

John Schnake

Executive Summary

The perfect level technology that works for every liquid level and point level application does not exist. Hydrostatic pressure has been around, it seems forever, and is proven in many applications. Non-contact radar and guided wave radar level instrumentation are popular and growing. Capacitance and conductivity have long histories of success in certain applications. However, it is still true that certain level technologies work better for some applications than other level technologies. This paper will explore a number of technologies for measuring liquid level and point level and will allow the reader to understand the basics of each technology with its inherent advantages and disadvantages.

This paper is available in its entirety, or in three separate parts. The first part of this paper focuses on hydrostatic level measurement. The second part focuses on continuous liquid level measurement utilizing newer technologies and the third, and last part, focuses on point liquid level measurement.

About the Author

John Schnake is Manager, Marketing & Sales Support at Endress+Hauser GmbH+Co, Division Level+Pressure in

Greenwood, Indiana. He received his Bachelor of Science Degree in Chemical Engineering from the University of

Illinois and a Masters of Business Administration from Arizona State University.

John has 18 years of experience in the Automation and Instrumentation business holding positions in Applications

Engineering, Inside Sales, Outside Sales, Product Management and Marketing Management at Honeywell and

Applied Automation.

He is a member of ISA and has published several articles in instrumentation journals. John can be contacted at

Endress+Hauser (317) 535-1365 or via e-mail at: john.schnake@us.endress.com

CP 022F/24/ae/08.07

White Paper

US/INDD CS

2

Liquid level measurement - Basics 101 Part 2

Time of Flight technology

Time of flight devices are much newer technology than hydrostatic devices and consist of ultrasonic and radar devices

(non-contact and guided wave). Ultrasonic waves are not electromagnetic waves, they are mechanical sound waves. The speed of mechanical waves travel is well known

– about 1096 feet per second (334 meters/ second) through air at 68°F. The liquid level can be determined by measuring the amount of time it takes for the ultrasonic wave to travel to the liquid, reflect and travel back to the device.

Radar, an acronym for Radio Detection and Ranging, was patented by the British in 1935. The technology, based on radio waves, was used for locating aircraft.

Similar research for locating ships as well as aircraft using radio frequency was underway in the U.S. and Germany. Radar devices used today for level measurement operate with electromagnetic radiation at much shorter wavelengths – 1.5 to

26 gigahertz – commonly known as microwaves. Non-contact radar and guide wave radar operate using the same principle of microwaves; non-contact is considered free space (not contacting the media) while

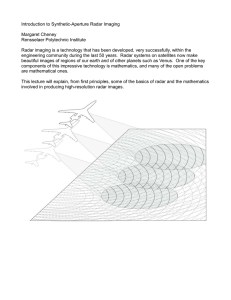

Diagram 6 – Time of Flight principle guided wave radar does contact the process media because it uses a long wave guide to better direct the microwave energy. Since the speed of light is well known like the speed of sound, the level of the liquid can be measured by measuring the amount of time it takes for the microwaves to travel to the liquid, and reflect back to the Radar device.

Diagram 6 provides an explanation of how

Time of Flight devices can measure the level of liquid in a tank.

Equation 3: L = E – D

L = liquid level

E = distance from measuring device to zero level

D = distance from measuring device to liquid

Equation 4: D = C x T/2

D = distance from measuring device to liquid

C = speed of sound or speed of light

T = amount of time for sound or light to travel from device to liquid and back

Based on Diagram 6 and Equations 3 and 4, the level of liquid can be determined from the time it takes for sound waves or light waves to travel from the measuring device to the liquid and back to the measuring device. One also needs to calculate E based on the size of the tank.

Ultrasonic

The principle of ultrasonic devices is based on the amount of time it takes to send and receive a reflected ultrasonic sound wave from the media. Ultrasonic waves are similar to audible sound waves in that they are mechanical waves. Most ultrasonic transmitters and receivers operate from 10

KHz to 70 KHz, well above the frequency of audible sound waves. The speed of sound in air is well known at (1096 feet per second (334 meters/second) through air at 68°F). In order for ultrasonic waves to be reflected, they need a media with a certain mass (density). In level measuring applications, there must be enough mass in the liquid (density) to reflect the sound waves. Using audible sound waves as an analogy, you can think of your ear drums and what happens to them when hearing a noise. Since the noise is traveling through air (very low density compared to most solids and liquids), there must be enough difference in the mass of the reflector to reflect the waves. In this case, it is your ear drum. It has enough mass and the drum vibrates when the sound is received. The speed of ultrasonic waves can be more easily influenced than the speed of light.

The temperature and type of gaseous media have a tremendous effect on sound waves. The temperature of the gaseous media influences the speed of the wave.

The higher the temperature, the faster the sound waves travel. While the temperature at the level device can be compensated by a temperature sensor in the ultrasonic device, the level measurement will only be accurate if the entire space between the sensor and liquid are the same temperature. The type of gaseous media also influences the speed of the sound waves. For example, sound travels almost three times faster in helium than it does air. Most ultrasonic devices can be programmed for the type of gaseous media the sound waves will travel through.

See Diagram 7 below for Advantages and

Things to know.

Advantages

• Non-contact (lowest cost)

• Installation at top

• Accuracy independent of density changes, dielectric or conductivity

• No calibration with medium required

Things to know

• Minimum density required

• Foam is an issue

• Blocking Distance

• Turbulent surfaces

• Vapors/gas above the liquid

• Temperature difference between liquid and sensor

• No vacuum (10 psia), no high pressures (44 psia)

Diagram 7 – Ultrasonic level devices – Advantages and Things to know

Advantages of ultrasonic include: the device is non-contact; it can be installed at the top of the tank as a compact device or remote.

Measurement accuracy is not affected by density, dielectric number or conductivity changes. While ultrasonic level devices are used in many liquid and solid applications, they are traditionally used more in the wastewater industry. There are things to keep in mind though. Foam is an issue since it is like air and does not have enough mass to deflect the sound waves. Turbulent surfaces can affect the angle of incidence of the sound waves and therefore cause multiple reflections. Large temperature difference between the level of the product and where the sensor is located is an issue since temperature changes the speed of sound. Remember too that different gases affect the speed of sound. And, last but not least, sound cannot travel through a vacuum and most ultrasonic devices are designed to only operate up to 45 – 50 psi.

Radar (non-contact)

Non-contact radar devices use microwaves in the 6 to 26 gigahertz range to measure liquid level in tanks. Like the speed of sound, the speed of light (electromagnetic radiation) is well known – 186,000 miles per second. Based on equations 3 and

4 above, the level can be calculated by knowing the dimensions of the tank and measuring the amount of time it takes for the microwaves to reflect off the process media. Why do radar level devices use microwaves compared to other types of energy in the electromagnetic spectrum?

Microwaves have little effect from type of gases, temperature, pressure, buildup and condensate. However, the ability for the process medium to reflect or not reflect microwaves needs to be taken into account. One can determine this ability to reflect light or microwaves by looking at the dielectric number of the media.

The dielectric number is a measure of the polarization power of an insulating material or how much charge can be stored in a type of material vs. air. Water has a dielectric number of 80 and is considered a great reflector of microwaves. Air has a dielectric number of 1 and is considered a poor reflector of microwaves. Aqueous mixtures tend to work well with radar due to the high dielectric number. However, while hydrocarbon based liquids can be measured, the measuring ranges may be lower due to lower dielectrics numbers. Petroleum oil has a dielectric number of 2 while gasoline has a dielectric number between 2 and

3. Because, ambient conditions have little effect on microwaves, radar devices are generally accepted as the most accurate level devices – some can measure level to

±0.5 mm or ±0.02 inches. This is one of the main reasons why suppliers, processors and sellers of crude oil and other high cost materials will use a radar device as part of their tank gauging equipment to accurately measure level. See Diagram 8 for a typical non-contact radar device.

Diagram 8 – Typical non-contact radar device

Great accuracy and contact-less measurement are not the only positives of non-contact radar. See Diagram 9 below for Advantages and Things to know. Noncontact radar devices can be installed in the top of the tank (unlike hydrostatic) and are not affected by liquids with changing dielectric number, conductivity or density.

When using non-contact radar, you must also take into account the tank shape.

Nozzles and other devices protruding into the tank can have some affect on measurement. The liquid level should be smooth and foamless. Agitated surfaces and foam can have some affect on level measurements. Similar to ultrasonic, some radar devices will experience a blocking distance. However, some other radar designs

(pulsed radar) do not experience blocking distances. Blocking distance is when the level gets too close to the radar device; the reflections cannot be received while the radar is emitting microwave pulses.

Last but not least, the liquid must have a minimum dielectric number. Minimum dielectric for free space installation is generally 2. A radar device with a stilling well or bypass tube can be used down to

1.6.

Advantages

• Very accurate - ± 0.5 mm (0.02 inches)

• Installation at top

• Non-contact

• Accuracy independent of dielectric constant, density and conductivity

• No re-setup required when changing liquids

Things to know

• Must take into account tank design

• Foam can be an issue

• Blocking distance

• Turbulent surfaces

• Minimum dielectric constant

Diagram 9 – Advantages & Things to know with radar devices

Guided wave radar

Guided wave radar devices use the same principle as non-contact radar devices

– it has the ability to transmit and receive reflected microwave energy. Guided wave

(sometimes called TDR – Time Domain

Reflectometry) operates at 1.5 GHertz.

While the electronics are mostly the same as non-contact radar, the big difference is the wave guide. The wave guide is a metal rod or rope which guides the energy to the process media. See Diagram 10 below. The wave guide directs approximately 80% of the available energy down the guide within an 8” radius.

Diagram 10 – Guide wave radar devices – cable and rod versions

3

Why would getting more energy directed on the process media be of help? It’s all about the signal to noise ratio. Even with interferences from nozzles or point level devices, more energy can be reflected back to the measuring device. More energy also means being able to work better with lower dielectric liquids as well as applications that might have foam.

Just like non-contact radar, guide wave radar devices are very accurate ±2 mm and the accuracy is independent of the liquid’s conductivity, density and dielectric number. No re-configuration is needed if changing measuring liquids in the tank. See

Advantages and Thing to know in Diagram

11 below. The following things should be remembered. Just like non-contact radar, you must take into account tank design. Agitators are an issue with guided wave because the probe/cable protrudes into the tank. While light foam is not an issue, heavy foam can effect the level measurement. Guided wave radar devices work particularly well in a tank bypass.

Advantages

• Very accurate - ± 0.2 mm (0.04 inches)

• Works with some foam

• Installation at top

• Accuracy independent of dielectric constant, density and conductivity

• No re-setup required

Things to know

• Must take into account tank design

• Heavy foam can be an issue

• Blocking Distance

• Turbulent surfaces

• Minimum dielectric constant

Diagram 11 – Guide wave radar devices –

Advantages and Things to know

Capacitance level measurement

Commercial capacitance level transmitters are proven devices and were first introduced in the 1950’s. They are also extremely versatile in that they can measure the continuous level and point level of liquids, slurries, liquid-liquid interface as well as point level of solids. Capacitance technology for level devices has also become known as reactance, admittance or RF technology.

The theory for capacitance level transmitters can be credited to Michael Faraday through his work in electromagnetic induction, electric generators and transformers. Part of his work resulted in the measure of capacitance which is defined as electric charge per voltage. The SI engineering unit for capacitance, farad, was named after him. A capacitor consists of two electrode plates and an electrical insulator

(dielectric). Charge can be stored in a capacitor by directing direct current across the electrodes. The amount of charge stored or capacitance is dependent on the distance between the electrodes, the area of the electrode plate and type of dielectric. See

Equation 5 and Diagram 12 below.

Equation 5: C = (0.0884 * Er insulator

A = area of the electrode plates

* A) / d

C = capacitance

Er = dielectric number of the electric

D = distance between the electrode plates

Diagram 12 – Simple capacitor

This theory of capacitors can be applied to a cylindrical tank. For non-conductive liquids, the metal capacitance probe is one electrode, the metal tank wall acts as the second electrode and the liquid is the dielectric. Capacitance probes can also be used with conductive liquids. The metal probe will be insulated with a dielectric

– Teflon ® as an example. The metal probe is one electrode, the liquid in the tank coupled with the metal tank wall is the second electrode and the probe insulation is the dielectric. See Equation 6 and Diagram 13 below.

Equation 6: c

C = capacitance v

( Er 24 L ) /(log

Er = dielectric number of the electric insulator

L = length of the capacitance probe

D = diameter of the tank d = diameter of the capacitance probe

D / d )

Diagram 13 – Capacitance theory applied to a cylindrical tank

Both the capacitance of the probe using air as the dielectric (empty tank) and the capacitance of the probe in the media to be measured (full tank) must be calculated.

Equation 5 should be used for both of these calculations – only the dielectric of the liquid to be measured will affect the second calculation. This provides the change in capacitance from empty tank (zero) to full tank (full span). See Diagram 14 for a summary of the Advantages and Things to know. In general, capacitance devices work well with non-conductive liquids that have dielectric numbers less than 10. They also work well with conductive liquids which are considered to be conductive when the dielectric is over 10. Capacitance probes are far from expensive compared to radar or ultrasonic. They are a well established technology and operate with a fast speed of response. See Diagram 14 for Advantages and Things to know. A fast speed of response is important when quickly filling small tanks. Capacitance probes are quite versatile and can be used for interface measurement of oil/water mixtures. They are also used in high pressure and high temperature applications and can be used in some applications with foam depending on the conductivity of the foam. Things to know include: There are many versions of capacitance probes based on media type (is the liquid conductive or non-conductive) and tank wall material. A probe coating

4

must be used with conductive liquids and you will need to take into account material chemical compatibility with the liquid. The capacitance calculation for empty and full is important because a minimum change of capacitance of about 10 pF is needed for measurement. Last but not least, foam can be tricky with capacitance probes. If the foam is conductive, the capacitance probe will see the liquid and the foam as the complete level. Check with your supplier for other cases.

Source +

Source container

Advantages

• Very cost effective

• Established principle

• Fast speed of response

• Interface measurement possible

• High temperatures and pressures possible

Things to know

• Many versions

• Conductive/insulator

• Probe coating - chemical compatibility

• Ground reference tube

• Non-metallic

• Re-calibration with different media

• 10 pF minimum span

• Foam can be an issue

Diagram 14 – Advantages and Things to know for capacitance level measurement

Radiometric (gamma) level measurement

Similar to radar devices, gamma level devices use electromagnetic radiation emitters and receivers to measure the level of liquids in tanks. However, gamma devices use electromagnetic radiation at a different part of the electromagnetic spectrum. They use gamma rays which have much higher frequency and therefore smaller wavelengths vs. microwaves. See

Diagram 15. A source of gamma radiation, usually Cesium 137 or Cobalt 60 depending on the application, is placed in a lead source container. The container can be closed

(emitting no radiation) or open (emitting gamma radiation). A detector, capable of measuring the amount of radiation from the source, is installed on the other side of the tank. If the tank is empty, the detector receives most of the available gamma radiation. If the tanks starts to be filled with liquid, the liquid level will attenuate (absorb) some of the available gamma radiation. When the tank is full, the detector receives very little radiation compared to the empty tank scenario.

Compacttransmitter

(Detector)

Diagram 15 - Gamma level measurement device

While the thought of having nuclear material in one’s plant can concern many, gamma level devices have been proven to be safe and reliable if safety procedures and regulations are followed. The sale of these devices is heavily regulated by the governments (Nuclear Regulatory

Commission in the U.S. or Canadian

Nuclear Safety Commission in Canada for example) of each country. There are piles of documentation and procedures that describe how qualified manufacturers can safely build, store and distribute the gamma devices, how qualified buyers can safely use them, and how qualified service personnel can safely commission, maintain or decommission the devices. The safety of personnel is number one and the amount of radiation over time that one can receive is well known and documented. All of this must be taken into account when purchasing gamma level devices. However, used safely, some of the most critical level measurements can be made with a gamma device. See Diagram 16 for Advantages and

Things to know.

Advantages

• Very versatile

• Non-invasive, no-contact

• No moving parts

• When all else fails!

Things to know

• Most expensive level device

• Is gamma safe? Yes

• Agencies track all sources

• Requires extra documents/paperwork

• Swipe tests

• Regulations dependent on country

Diagram 16 – Advantages and Things to know for

Gamma

Gamma is a versatile technology that can be used to measure continuous level, point level, density of the media or interface.

Gamma’s biggest advantage is that it is not only non-contact measurement, it is non-invasive; it is mounted on the side of the tank and there is no intrusion into the tank. Gamma devices have no moving parts and are often only considered when all other level technologies have failed.

Things to know include: You should expect to pay more for a gamma device than any other level measurement device. Also, you should understand gamma radiation and the precautions that your company will need to take to make sure the product is working safely. This includes performing swipe tests, documenting them and being prepared to be audited. It also includes documenting the amount of radiation that operation or maintenance personnel would receive when working close to the gamma level device.

And lastly, radiation safety and regulations to use gamma devices are country dependent. If you are a global company with operations in different countries, you may need to implement different procedures and process depending on which country you are using the equipment in.

This paper is the second of three parts.

For the complete paper, please request

CP024F/24/ae.

5

References

“Level Measurement and Inventory Tank Gauging”, Control Engineering, May, 2006

“Application Information of Radar Level Measurement for Hydrocarbon Measurement”,

Endress+Hauser White Paper, Alexander Roettcher & Dieter Markanic, March 2006

“In Control Part III – Liquid Level Measurement”, Ask Tom! 2001, http://www.waterandwastewater.com/www_services/ask_tom_archive/in_control_part_

3.htm

“Capacitance Level Measurement – How it Works”, Endress+Hauser White Paper, Robert A.

Green

“Capacitor Theory”, http://www.ece.uwaterloo.ca/~lab100/ls1notes.pdf

“The Theory and Practice of Level Measurement” Endress+Hauser Inc., Wim van de Kamp

“504-1200 Series Installation and Operating Instructions”, Ametek- Drexelbrook.

http://new.ametek.com/content-manager/files/STD//504-1200-000-LM2.pdf

USA

Endress+Hauser, Inc.

2350 Endress Place

Greenwood, IN 46143

Tel: 317-535-7138

Sales: 888-ENDRESS

Service: 800-642-8737

Fax: 317-535-8498 inquiry@us.endress.com

www.us.endress.com

Canada

Endress+Hauser Canada

1075 Sutton Drive

Burlington, ON L7L 5Z8

Tel: 905-681-9292

800-668-3199

Fax: 905-681-9444 info@ca.endress.com

www.ca.endress.com

Mexico

Endress+Hauser México S.A. de C.V.

Fernando Montes de Oca 21 Edificio A Piso 3

Fracc. Industrial San Nicolás

54030 Tlalnepantla de Baz

Estado de México

México

Tel: +52 55 5321 2080

Fax: +52 55 5321 2099 eh.mexico@mx.endress.com

www.mx.endress.com

International

ISO 9001:2000 Certified

08.07/SCUSA

For international locations visit: www.endress.com/worldwide

CP 022F/24/ae/08.07

White Paper

US/INDD CS