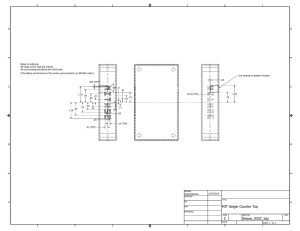

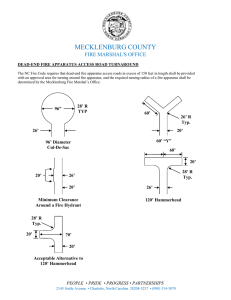

Addendum 3

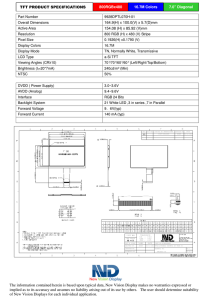

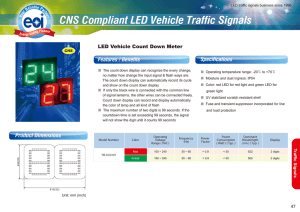

advertisement