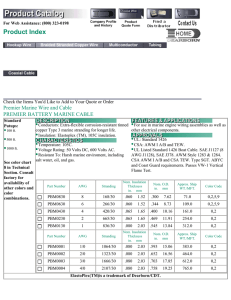

Belden Hook-Up and Lead Wire Catalogue

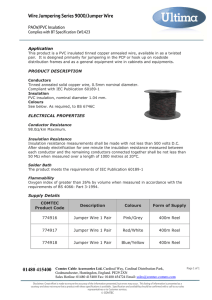

advertisement