Life-Cycle Assessment Modeling of Construction Processes for

advertisement

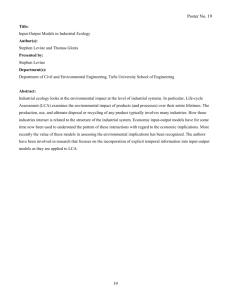

Life-Cycle Assessment Modeling of Construction Processes for Buildings Melissa M. Bilec1; Robert J. Ries2; and H. Scott Matthews, A.M.ASCE3 Abstract: This research examined the environmental impacts due to the construction phase of commercial buildings. Previous building research has often overlooked the construction phase and focused on the material and use phases, discounting the significant environmental impacts of construction. The research was conducted using life-cycle assessment 共LCA兲 methodology, which is a systematic environmental management tool that holistically analyzes and assesses the environmental impacts of a product or process. Life-cycle inventory results focused on particulate matter, global warming potential, SOx, NOx, CO, Pb, nonmethane volatile organic compounds, energy usage, and solid and liquid wastes. Results over the entire building life cycle indicate that construction, while not as significant as the use phase, is as important as other life-cycle stages. This research used augmented process-based hybrid LCA to model the construction phase; this modeling approach effectively combined process and input-output 共IO兲 LCA. One contribution was the development of a hybrid LCA model for construction, which can be extended to other sectors, such as building products. Including IO results, especially construction service sectors, is critical in construction LCA modeling. Results of a case study demonstrated that services had the highest level of methane emissions and were a significant contributor to CO2 emissions. DOI: 10.1061/共ASCE兲IS.1943-555X.0000022 CE Database subject headings: Construction; Life cycles; Environmental issues; Buildings, nonresidential. Author keywords: Construction; Life cycle; Environmental issues. Introduction Research on environmental impact of buildings has primarily focused on material manufacturing, energy use during building operation, and waste management when decommissioning buildings. On-site construction is often overlooked or incompletely modeled, leading to a gap in understanding the full spectrum of possible sources of environmental impacts from the life cycle of the built environment. Construction activities have an impact on air quality recently exemplified by China’s restrictions on construction projects prior to and during the 2008 Beijing Olympics in an effort to improve local air quality. When fully investigated, on-site construction activities are found to have a range of significant impacts. Service sectors such as design 共e.g., architects and engineers兲 and construction 共e.g., surveyors and construction firms兲 represent a noteworthy but often ignored source of environmental impacts. The research used life-cycle assessment 共LCA兲, a systematic environmental management tool that holistically analyzes and assesses the environmental impacts of a prod- uct or process. LCA can be used for decision making that inherently promotes stewardship by considering global, national, and regional impacts on social and environmental problems such as human health, resource depletion, and ecosystem quality. While LCA is a powerful tool, creating an accurate and inclusive model is often difficult. LCA practitioners are often faced with making difficult decisions related to selecting the appropriate scope or boundary of the analysis, the sources of data for lifecycle inventories, software, and impact assessment methods. Hybrid LCA frameworks that combine input-output 共IO兲 and process LCA modeling approaches are being explored to address some of these issues. This work focused on hybrid LCA for the construction phase of a commercial building. The hybrid framework, while developed for construction, can also be applied to analyze the life cycle of other products or processes. This paper discusses the motivation behind the research, provides a brief background and literature review on LCA and construction, presents the model development and its structure, examines a representative case study, and concludes with recommendations for improving the construction process and LCA modeling. 1 Assistant Professor, Dept. of Civil and Environmental Engineering, Univ. of Pittsburgh, Pittsburgh, PA 15261 共corresponding author兲. E-mail: mbilec@pitt.edu 2 Assistant Professor, Rinker School of Building Construction, Univ. of Florida, Gainesville, FL. E-mail: rries@ufl.edu 3 Associate Professor, Civil and Environmental Engineering/ Engineering and Public Policy, Carnegie Mellon Univ. of Pittsburgh, Pittsburgh, PA 15213. E-mail: hsm@cmu.edu Note. This manuscript was submitted on April 14, 2009; approved on September 16, 2009; published online on October 2, 2009. Discussion period open until February 1, 2011; separate discussions must be submitted for individual papers. This paper is part of the Journal of Infrastructure Systems, Vol. 16, No. 3, September 1, 2010. ©ASCE, ISSN 10760342/2010/3-199–205/$25.00. Motivation The built environment contributes significantly to environmental impacts regionally, nationally, and globally. All phases of a building’s life cycle—design, raw material extraction and processing, manufacturing, construction, use and maintenance, and deconstruction—contribute to environmental impacts and energy use. A fair amount of research has focused on the material phase and the associated impacts from extraction and manufacturing. Some research has looked at end-of-life options for commercial buildings 共Guggemos and Horvath 2003兲. Existing research on the con- JOURNAL OF INFRASTRUCTURE SYSTEMS © ASCE / SEPTEMBER 2010 / 199 Downloaded 13 Jun 2012 to 128.237.190.83. Redistribution subject to ASCE license or copyright. Visit http://www.ascelibrary.org struction phase has assumed that the impacts are negligible 共Junnila and Horvath 2003兲, while others have indicated that the environmental impacts associated with construction are underestimated 共Hendrickson and Horvath 2000兲. LCA is an important method to determine and measure the environmental performance of a product or process. Guidelines for performing an LCA are delineated by International Organization for Standardization’s 共ISO兲 14040 series 关International Organization for Standardization 共ISO兲 2006兴. As defined by the ISO 14040 series, LCA is an iterative four-step process including goal and scope definition, life-cycle inventory 共LCI兲 analysis, lifecycle impact assessment 共LCIA兲, and interpretation. LCI is often where LCA studies terminate due to inconsistent framework, incomplete development, and subjectivity in the LCIA stage. Many construction LCAs utilize either process-based 共Keoleian et al. 2000兲 or IO techniques 共Ochoa et al. 2002兲; another option is hybrid LCA modeling, which is used in this research. This research combines the strengths of both techniques to develop a framework for hybrid LCA modeling. Background and Literature Review on LCA and Construction There are a limited number of published studies on LCA and commercial buildings. Few of these studies comprehensively considered on-site construction processes with the exception of Junnila and Horvath 共2003兲, Hendrickson and Horvath 共2000兲, Ochoa et al. 共2002兲, Guggemos and Horvath 共2005, 2006兲, Junnila et al. 共2006兲, and Sharrard et al. 共2008兲. Some studies stated that construction was included, but the definition of construction included various stages of material extraction, production, and transportation and not on-site construction processes 共Horvath and Hendrickson 1998; Treloar et al. 2004; Treloar et al. 2000兲. In summary, published research on LCA for the construction phase is limited and a consensus on methodology or approaches has not fully developed. Furthermore, a comparison between the relevant studies is difficult because the description of the building lifecycle phases is not consistent. For example, Ochoa et al. 共2002兲 included raw material acquisition, manufacturing, and transportation to the construction site as the construction phase. Conversely, Junnila and Horvath 共2003兲 considered the construction phase to include on-site activities and transportation. Guggemos and Horvath 共2005, 2006兲 and Junnila et al. 共2006兲 developed model for construction. The models created by Guggemos and Horvath 共2005, 2006兲 and Junnila et al. 共2006兲 include on-site energy, equipment utilization, transportation, and temporary materials. Athena Impact Estimator 4.0 includes primarily transportation and equipment combustion 共Athena Institute 2008兲. This model includes the aforementioned along with construction worker transportation, construction service sectors, equipment manufacturing, and fugitive dust generation. Model Development and Structure The model includes both the LCI and impact assessment stages. Process and IO methods are widely used and have strengths and limitations. Process LCA models the known environmental inputs and outputs by using a process flow diagram. Economic IO 共EIO兲 analysis, developed by Leontief 共1936兲, is an interdependency model that quantifies proportional interrelationships among sectors in an economy. IO LCA combines national sector-by-sector economic interaction data, which quantify the dependencies between sectors, with sector level environmental effects and resource use data 共Hendrickson et al. 1998; Lave et al. 1995兲. Minimal straightforward guidance for the LCA practitioner for selecting a modeling approach exists; the practitioner makes decisions based on the best available data and information. After considering the applicability of process only, IO only, and the range of hybrid LCA models, LCI was developed using an augmented hybrid approach. This modeling approach was chosen for the following reasons: to decrease reliance on the limited amount public data; to utilize available data within the context of the existing structure of the construction industry; and to ensure that the developed model has both depth and breadth. Since construction is a deregulated sector in the United States, environmental process data are limited. Process data were used in this model in conjunction with typical project records and practices when available. Additionally, the construction industry has existing financial construction data in estimating software and scheduling tools. In other words, available data are typically in monetary units 共cost estimates兲 and time 共schedules兲. These monetary data can be used in IO tools such as EIO-LCA without the need to collect additional data. Two main goals in hybrid LCA models are improving the time and cost associated with process-based LCAs and developing an inclusive boundary. Using an augmented process-based hybrid LCA approach achieves both of those goals. The hybrid LCA construction model blends the most important construction processes along with realistically assessing the availability and accuracy of data. An overall goal of the model was to respond to the construction industry’s need to ultimately improve, in terms of sustainability, what it can control—construction processes. Since each construction project is unique, the model allows for project specific user input, for example, project cost, which is important for usability. The construction industry is driven by schedule and cost, so the framework of the model centers on those two factors. Cost data are available from initial estimates, final costs, and cost databases 共e.g., R.S. Means兲 to name only a few. The user input and structure of the model follow the Construction Specification Institute format along with dollar units of demand with respect to IO information. Another important consideration in creating the model was determining data availability and data quality. This leads to including constructionspecific process information such as AP-42 emission factors 共EFs兲 共U.S. Environmental Protection Agency 2003兲 and the use of EFs and equipment fuel usage metrics from the Nonroad model 共U.S. Environmental Protection Agency 2005a兲. The structure of the model consists of three modules, namely, user input, detailed model, and results, each described in more detail below. Overview The hybrid LCA construction model was created in the software program Analytica, a visual modeling tool that can be used to create, analyze, and communicate decision models 共Lumina Decision Systems 2006兲. Analytica has been used to support other LCAs 共Thabrew et al. 2008; Lloyd and Ries 2009兲. The model combines several data sources, including process, EIO-LCA, and other data into one common LCA framework. The user inputs required are available from typical construction process variables, such as the dollar value of construction, the quantity of brick, and the hours of equipment operation. Face validity with industry was used to confirm usability and applicability of the model. The model also calculates LCIA and displays results by impact category that will not be discussed herein. 200 / JOURNAL OF INFRASTRUCTURE SYSTEMS © ASCE / SEPTEMBER 2010 Downloaded 13 Jun 2012 to 128.237.190.83. Redistribution subject to ASCE license or copyright. Visit http://www.ascelibrary.org Table 1. Environmental Impacts Included in the Hybrid LCA Construction Model Environmental impacts Data sources Dust from driving on paved roads Dust from driving on unpaved roads Dust generation during heavy construction operations Welding—hazardous metals and particulates Surface applications—application of paints, sealants, etc. Construction services—e.g., inspection, architects, engineers, and surveyors Equipment manufacturing Temporary materials Construction equipment—fuel combustion and usage Construction equipment—extraction and distribution Transportation of materials and workers—fuel combustion, extraction, distribution—diesel and gasoline truck, and diesel and gasoline tractor trailer Electricity—on-site usage, generation, distribution Concrete water and wastewater Model Boundaries and Major Construction Categories The model’s scope is bounded by transportation from the manufacturer’s, supplier’s, or waste handler’s gate and includes transportation to and from the construction site, on-site construction activities, and sectors that support construction such as construction services. The major sources of environmental impacts in construction are modeled in the categories listed in Table 1. Transportation can include both truck transportation for materials and equipment as well as worker transportation to and from the site. Electricity primarily represents on-site electricity usage for site office trailers, small equipment and tools, and lighting. Construction equipment includes not only fuel combustion but also fuel usage, production, and distribution; construction services represent sectors such as inspectors, architects, engineers, and surveyors. Environmental effects from manufacturing permanent materials are not included, but the full life cycle of temporary materials such as concrete formwork is included. Permanent materials are not included because they would typically be included in the “raw material” portion of a building LCA. Both on-site construction waste and concrete wastewater are included, along with emissions from welding and surface treatments such as paints and sealants. The category “paved and unpaved roads” captures particulate emissions from vehicles traveling over a surface, which is typically from brake wear, tire wear, and resuspended loose road materials. Dust generation from heavy construction operations is a particulate generation from the materials handled rather than directly from equipment or roads. User Input and Detailed Model The user can input project specific characteristics in nine categories, and data can be entered as a distribution or a single value. The nine categories are general project information, site preparation and deep foundations, concrete, masonry, steel, paints and surface applications, transportation 共not otherwise included兲, material handling, and generator usage. For example, for general project information, some categories include common construction information such as the dollar value of construction, project duration, and average travel distance 共one way兲 for a concrete truck. The detailed model module contains the main portion of the hybrid LCA model. In general, this module has two basic components: construction processes and data sources. The construc- AP-42, Section 13.2.1 AP-42, Section 13.2.2 AP-42, Section 13.2.3 AP-42, Section 12.9 User provided information EIO-LCA EIO-LCA EIO-LCA Nonroad Franklin; Idemat Franklin Franklin Independent laboratory results tion process section models the relevant construction processes while drawing from data sources as indicated in Table 1. Data Sources AP-42 AP-42 EFs were used for four different elements of the model: dust generation paved roads; dust generation unpaved roads; heavy construction operations; and welding. AP-42, Section 13.2.1—paved roads was used to determine dust generation from paved roads; AP-42, Section 13.2.2—unpaved roads was used to calculate dust from unpaved roads. AP-42 EFs for paved and unpaved roads are in units of mass of emissions per vehicle kilometer traveled. AP-42, Section 13.2.3—heavy construction operations are used to determine emissions from construction activities. Heavy construction activities have a significant temporary impact on local air quality from dust emissions, and both building and road construction activities have high emission potential. Table 13.2.3-1 provides information on the associated sources along with recommended EFs. An information process-specific approach, as outlined in Table 13.2.-1, was used. Specifically, information related to dozer equations in Section 11.9, western surface coal mining 共Tables 11.9-1 and 11.9-2兲. AP-42, Section 12.9—electric arc welding is used to determine the emissions factors related to welding. The emissions generated during welding are particulate matter and hazardous metals, and only electric arc welding generates the pollutants in significant quantities. Most of the particulate matter 共PM兲 generated is submicron in size, and all PM is considered to be PM-10. The EFs were used for shielded metal arc welding, gas metal arc welding, flux cored arc welding, and submerged arc welding: from Table 12.19-1 共PM-10兲, EFs for welding operations and for Table 12.19-2, hazardous air pollutant EFs for welding operations. EIO-LCA Inventory results from the EIO-LCA 共1997 benchmark model兲 were used for three major areas: construction equipment manufacturing; construction services; and temporary material manufacturing. The decision to use EIO-LCA as a data source was done for two reasons—obtaining process data was not feasible and pro- JOURNAL OF INFRASTRUCTURE SYSTEMS © ASCE / SEPTEMBER 2010 / 201 Downloaded 13 Jun 2012 to 128.237.190.83. Redistribution subject to ASCE license or copyright. Visit http://www.ascelibrary.org cess data were not reliable. Since construction equipment is a major component of construction and it is used in the construction process, manufacturing of construction equipment is included. Different modeling approaches were considered for this category. For example, one option is to enter the dollar value of total project construction equipment into the associated IO sector. This option proved to have too many variables such as the age of the equipment and the depreciated value and required knowledge of specific manufacturer’s makes and models. The second option, which was used in the model, is to enter the total value of construction in the associated IO sector and manually identify the construction equipment sectors. These sectors are used to estimate the impact from construction machinery manufacturing per dollar of construction. Sectors relevant to construction equipment manufacturing selected included a range from construction machinery manufacturing to motor and generator manufacturing. In the model, the user inputs the dollar value of construction, which is then multiplied by the construction equipment manufacturing results described above. Construction services 共e.g., architects, engineers, and surveyors兲 were modeled using the same approach as construction equipment manufacturing. The results from EIO-LCA’s Commercial and Institutional Building sector were reviewed to determine whether the sector was deemed a construction service. Temporary materials are included because these materials are used directly and exclusively in the construction process. The temporary materials for this model are related to concrete forms. Within each of the concrete construction processes, a submodule of concrete forms was created. Temporary materials used in formwork included in the model are wood, steel, fiberglass, and cardboard. Unlike construction equipment and services, temporary materials cannot be selected from commercial and institutional construction sectors because they are identical to permanent construction materials. Detailed material cost information on temporary materials was available from R.S. Means. Individual EIOLCA results were generated for four materials. Because R.S. Means cost data were from 2006 and the EIO-LCA data were from 1997 model 共the most recent available at the time of this research兲 adjustments were made for deflation with one single value. Nonroad Output and Model Details NONROAD2005 共U.S. Environmental Protection Agency 2005a兲 was used to model emissions from primarily nonroad equipment combustion. While Nonroad provides several estimating and reporting capabilities, the EF information was used the most. EFs used included grams per operating hour by source classification codes 共SCCs兲, grams per operating hour by horsepower 共hp兲 and SCC, grams per day by SCC; grams per day by hp and SCC, grams per hp hour by SCC, and grams per hp hour and SCC 共U.S. Environmental Protection Agency 2005b兲. EFs are based predominately on emission tests that were adjusted for in-use operation that differs from typical testing conditions 共U.S. Environmental Protection Agency 2004兲. The equipment ranges from loaders to aerial lifts. Process LCA from Existing Databases SimaPro, an LCA software package, allows users to conduct an LCA with preexisting unit processes, built-in impact assessment methods, and end-of-life options. SimaPro 5.0 is supported by several databases with ETH-ESU 共Frischknecht and Jungbluth 2001兲 and Franklin 共Norris 2001兲 being the most extensive. Many unit processes are available varying from “paint” to “production of paper bags.” SimaPro, which was developed by a European firm, contains more European-based process data. The unit processes from SimaPro that were incorporated into the hybrid LCA model were primarily from the Franklin database, which focuses on United States’ processes. ETH-ESU 共Frischknecht and Jungbluth 2001兲 and Idemat 共Delft University of Technology 2001兲 were also used on a minimal basis when Franklin information was not available. The three categories where process data are used are transportation, worker transportation, and electricity. Several Franklin database transportation processes were used with respect to transportation, including one truck and one tractor trailer with two fuel options. Worker transportation is modeled using an ETHESU process since the U.S. Franklin passenger car information was not available. Electricity is modeled using the “electricity average kilowatt hour USA” process from the Franklin database. The model can be adjusted for specific regional electricity modeling by changing the existing unit process if required by the user or the project. The unit process includes generation and distribution and accounts for line losses of about 8%. Construction Processes Modeling the construction process was a major portion of this research. The basic structure of the model and data are based on R.S. Means 共2006兲. Preprocessing R.S. Means information was done in Microsoft Excel before additional model development in Analytica. The available construction processes in the hybrid LCA construction model are aggregated into eight main categories of site preparation, deep foundations, concrete, masonry, steel, paints and sealants, general hauling and material handling, and energy. Information within each construction process draws from the references previously mentioned. Construction has a multitude of processes, and modeling every process was not practical. The selected construction processes represent the major core and shell processes. While building fit out is not included, it is possible for the user to input information related to this phase or the building use phase in the general hauling, material handling, paints, sealants, and energy categories. While each construction process is unique, the structure of the model is consistent. Results Result options were developed in submodules for presenting and comparing results in both LCI and LCIA. The LCI has several options in the LCI stage represented in seven submodules that range from total LCI and LCIA results to local and regional inventory impacts. In summary, the hybrid LCA construction model is a complex model that draws from many data sources. Creating the structure of the model and finding and integrating the appropriate data sources were challenging from a larger scale in both framework and structure and a smaller scale in terms of consistent units and unit conversions. The processes created for individual construction activities are in some ways unique to each activity but in other ways are similar. Most of the construction processes involved calculating equipment combustion and associated fuel usage and emissions, determining transportation impacts, and estimating the amount of temporary materials. The model’s structure and readability were validated through face validity, which is an assessment method for the relevance of the model by using 202 / JOURNAL OF INFRASTRUCTURE SYSTEMS © ASCE / SEPTEMBER 2010 Downloaded 13 Jun 2012 to 128.237.190.83. Redistribution subject to ASCE license or copyright. Visit http://www.ascelibrary.org 25 15 SO2 NOx P M10 10 5 6,000 5,000 4,000 Energy 3,000 CO2 2 Emissions (kg/m2 ) 20 Energy (MJ/m ) and CO2 (kg/m2 ) 7,000 \ 2,000 1,000 0 Materials Construction Use and Maintenance End-of-Life Materials Construction Use and Maintenance Life Cycle Stages End-of-Life Life Cycle Stages Fig. 1. Emissions by life-cycle stage—steel case study construction results 关materials, use, and end-of-life data from Guggemos and Horvath 共2005兲兴 knowledgeable opinions from individuals. While the model is unique to construction, the framework and approach can translate to other applications of hybrid LCA. A LCIA calculation module is included; however, the results are not presented in this paper. Case Study A steel frame structure representing a typical office building is presented as a case study. As mentioned earlier, the material and manufacturing phases are not included in the boundary of the model except for temporary materials. The case study is a 17, 280-m2 core and shell office building completed in 2005 with a steel frame. The six-story structure has a brick and curtain wall exterior and exposed architectural and structural steel. The primary data sources for project data were construction drawings and the construction schedule. Storm water run-off quantity and quality were not included in this analysis since a management plan was implemented. The storm water management plan was approved by the County Conservation District and included elements such as inlet basin covers, silt fencing, and rock construction entrances. Case study results from this research 共SO2, NOx, PM10, energy, and CO2兲 from the construction phase were compared with other life-cycle stages 共material production, use and maintenance, and end of life兲 to determine the significance of the construction phase to the other phases. Data from the life-cycle stages 共material production, use and maintenance, and end of life兲 were obtained from Guggemos and Horvath 共2005兲; data from this case study were used because they are also a steel framed structure. The data from Guggemos and Horvath 共2005兲 were normalized on a square meter basis. For PM10, construction is relatively high, illustrating the importance of construction for local and regional impacts 共see Fig. 1兲. PM10 is primarily due to vehicles and equipment traveling on paved and unpaved roads and earth moving activities. SO2 emissions from construction 共2%兲 are lower than the other phases except end of life. For NOx, construction and end of life 共8%兲 have the lowest emissions of all the phases with the highest at 70% from the use phase. In terms of CO2, construction is the third highest 共Fig. 2兲. Energy, materials, and construction are almost the same in terms of percentage of energy use. Sensitivity Analyses Sensitivity analyses were performed on key components of the model to better understand elements of uncertainty and key vari- Fig. 2. Energy and CO2 by life-cycle stage—steel case study construction results 关materials, use, and end-of-life data from Guggemos and Horvath 共2005兲兴 ables that can greatly impact the results. Varying levels of analyses were performed ranging from broader factors to specific variables in equations. In total 13 scenarios were investigated and grouped into several categories 共see Table 2兲. The service sectors to include in the model from EIO-LCA results are somewhat subjective and therefore, a sensitivity analysis was performed. The model takes a fairly broad view of service sectors, which results in service sectors representing about $4,330,000 or 33% of the $13,000,000 construction cost. A more narrow interpretation of service sectors such as architects and engineers only results in service sectors representing 22% of the construction cost. Global warming potential 共GWP兲 results indicate that service sector selection range has relatively minimal impact 共see Fig. 3兲. The major impacts related to on-site construction were captured in the traditional service sectors. Detailed processes positively impacted the results; however, it would be very difficult to determine the quantitative level of the impact. Conclusions The foci of this research were construction, hybrid LCA modeling, and context. First, in terms of commercial core and shell construction in the United States, the research determined the LCI and impact assessment of the construction processes of a typical steel-framed commercial building in the U.S. LCI results included 292 substances but focused on PM emissions, GWP, SOx, NOx, CO, Pb, nonmethane volatile organic compounds, energy usage, and solid and liquid wastes. The model results were compared Fig. 3. Global warming potential comparison from an example sensitivity analysis of broad and narrow service sectors from inputoutput life-cycle assessment results JOURNAL OF INFRASTRUCTURE SYSTEMS © ASCE / SEPTEMBER 2010 / 203 Downloaded 13 Jun 2012 to 128.237.190.83. Redistribution subject to ASCE license or copyright. Visit http://www.ascelibrary.org Table 2. Sensitivity Analysis Scenarios 1 2 3 4 5 6 7 Ratio between diesel and gasoline equipment Ratio between diesel and gasoline transportation fleets Transportation distance for concrete supplier Transportation distances with respect to vehicle weight Number of construction workers and distance traveled Vehicle weights traveling on paved and unpaved roads Service sector selection with building life cycle results from published work. The comparison indicated that construction, while not as significant as the use phase, is as important as the other life-cycle stages and that PM emissions are significant in the construction phase. Second, with regard to hybrid LCA modeling, the augmented process-based LCA proved to be effective in modeling construction. A framework that allowed for efficiently combining process and IO modeling, especially for the construction sectors, is critical in construction LCA modeling. In the steel case study, services had the highest level of methane emissions, and they were a significant contributor to CO2 emissions. Third, hybrid LCA modeling requires both breadth and depth. For example, the model not only includes construction processes from site preparation to painting but also includes detailed modeling of construction equipment combustion. Modeling a diverse mix of construction equipment improves the usability and applicability of the construction LCA and improves the accuracy of the results. The research found that it is critical to include service sectors in LCAs and EIO-LCA is an effective source for service sector data. This finding pertains not only to construction but can also extend to LCAs in other domains as well; for example, this approach is currently being used to model construction products, such as insulating concrete forms and pultruded composites 共Rajagopalan et al. 2009兲. With respect to on-site construction and GWP, emissions from electricity are insignificant since electricity accounts for less than 6% of overall CO2. While this research focused on commercial construction in the United States, the framework can be extended to other construction types and countries, including developing countries. The framework allows for considerable flexibility with minimal effort to make changes to data sources. Examples of changes to the model in developing countries may include changes to combustion emissions for construction equipment, fuel usage, and equipment types. Developing countries may also employ different construction practices and levels of equipment use. The model may also be used to compare not only the entire project but also different construction activities, such as comparing the environmental impacts of augercast piles versus driven steel piles. The overall body of knowledge of construction LCAs needs to be further developed and expanded, and this research contributed to its development. The model will be posted online in the future. Additional research and especially case studies are needed so that deeper and more in-depth comparisons can be made to further refine the results. Acknowledgments Financial support for this research was provided by National Science Foundation Grant No. CMS-0327878. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the writer共s兲 and do not necessarily reflect the views of the National Science Foundation. The writers would also like to thank Dr. Aurora L. Sharrard for helpful discussions and the reviewers. References Athena Institute. 共2008兲. Athena impact indicator (version 4.0) 关computer software兴, Ont., Canada. Delft Univ. of Technology. 共2001兲 Idemat database manual, Delft, The Netherlands. Frischknecht, R., and Jungbluth, N. 共2001兲. Database manual, the ETHESU 96 Library, ESU-Services and PRe Consultants, Vster, Switzerland. Guggemos, A., and Horvath, A. 共2003兲. “Strategies of extended producer responsibility for buildings.” J. Infrastruct. Syst., 9共2兲, 65–74. Guggemos, A., and Horvath, A. 共2005兲. “Comparison of environmental effects of steel-and concrete-framed buildings.” J. Infrastruct. Syst., 11共2兲, 93–101. Guggemos, A. A., and Horvath, A. 共2006兲. “Decision-support tool for assessing the environmental effects of constructing commercial buildings.” J. Archit. Eng., 12共4兲, 187–195. Hendrickson, C., and Horvath, A. 共2000兲. “Resource use and environmental emissions of U.S. construction sectors.” J. Constr. Eng. Manage., 126共1兲, 38–44. Hendrickson, C., Horvath, A., Joshi, S., and Lave, L. 共1998兲. “Economic input-output models for environmental life-cycle assessment.” Environ. Sci. Technol., 32共7兲, 184A–191A. Horvath, A., and Hendrickson, C. 共1998兲. “Steel versus steel-reinforced concrete bridges: Environmental assessment.” J. Infrastruct. Syst., 4共3兲, 111–117. International Organization for Standardization 共ISO兲. 共2006兲. “International standard: Environmental management—Life cycle assessment—Principles and framework.” 14040, Geneva, Switzerland. Junnila, S., and Horvath, A. 共2003兲. “Life-cycle environmental effects of an office building.” J. Infrastruct. Syst., 9共4兲, 157–166. Junnila, S., Horvath, A., and Guggemos, A. A. 共2006兲. “Life-cycle assessments of office building in Europe and the United States.” J. Infrastruct. Syst., 12共1兲, 10–17. Keoleian, G., Blanchard, S., and Reppe, S. 共2000兲. “Life-cycle energy, costs, and strategies for improving a single-family house.” J. Ind. Ecol., 4共2兲, 135–156. Lave, L. B., Cobasflores, E., Hendrickson, C. T., and McMichael, F. C. 共1995兲. “Using input-output-analysis to estimate economy-wide discharges.” Environ. Sci. Technol., 29共9兲, 420A–426A. Leontief, W. 共1936兲. “Quantitative input and output relations in the economic systems of the United States.” Rev. Econ. Stat., 18共3兲, 105– 125. Lloyd, S., and Ries, R. J. 共2009兲. “Spatial and temporal life cycle assessment: Ozone formation potential from natural gas use in a typical residential building in Pittsburgh, USA.” Dynamics of regions and networks in industrial ecosystems, M. Ruth and B. Davidsdottir, eds., The MIT Press, Cambridge, Mass. Lumina Decision Systems. 共2006兲. Analytica 关computer software兴, Los Gatos, Calif. Norris, G. 共2001兲. Database manual, the Franklin US LCI, Sylvatica and Pre Consultants, York, Me. Ochoa, L., Hendrickson, C., and Matthews, H. S. 共2002兲. “Economic input-output life-cycle assessment of U.S. residential buildings.” J. Infrastruct. Syst., 8共4兲, 132–138. Rajagopalan, N., Landis, A. E., and Bilec, M. 共2009兲. “Environmental impacts of insulating concrete forms.” Proc., 2009 IEEE Int. Symp. on Sustainable Systems and Technology, IEEE, New York. R.S. Means. 共2006兲. Building construction cost data, R.S. Means Company, Inc., Kingston, Mass. Sharrard, A. L., Matthews, H. S., and Ries, R. J. 共2008兲. “Estimating construction project environmental effects using an input-outputbased hybrid life-cycle assessment model.” J. Infrastruct. Syst., 14共4兲, 204 / JOURNAL OF INFRASTRUCTURE SYSTEMS © ASCE / SEPTEMBER 2010 Downloaded 13 Jun 2012 to 128.237.190.83. Redistribution subject to ASCE license or copyright. Visit http://www.ascelibrary.org 327–336. Thabrew, L., Lloyd, S., Hamilton, J., Cypcar, C., and Ries, R. J. 共2008兲. “Life cycle assessment of industrial and institutional water-based acrylic floor finish maintenance programs.” Int. J. Life Cycle Assess., 13共1兲, 65–74. Treloar, G. J., Love, P. E. D., and Crawford, R. H. 共2004兲. “Hybrid life-cycle inventory for road construction and use.” J. Constr. Eng. Manage., 130共1兲, 43–49. Treloar, G. J., Love, P. E. D., Faniran, O. O., and Iyer-Raniga, U. 共2000兲. “Note: A hybrid life cycle assessment method for construction.” Constr. Manage. Econom., 18共1兲, 5–9. U.S. Environmental Protection Agency. 共2003兲. AP-42, Vol. I, 5th Ed. U.S. Environmental Protection Agency. 共2004兲. “Exhaust and crankcase emission factors for nonroad engine modeling—Compressionignition.” Assessment and Standards Div., EPA Office of Transportation and Air Quality. U.S. Environmental Protection Agency. 共2005a兲. NONROAD2005 关computer software兴, Ann Arbor, Mich. U.S. Environmental Protection Agency. 共2005b兲. User’s guide for the final NONROAD2005 model, Assessment and Standards Div., Office of Transportation and Air Quality, Ann Arbor, Mich. JOURNAL OF INFRASTRUCTURE SYSTEMS © ASCE / SEPTEMBER 2010 / 205 Downloaded 13 Jun 2012 to 128.237.190.83. Redistribution subject to ASCE license or copyright. Visit http://www.ascelibrary.org