4.2.2 Error Message and Troubleshooting

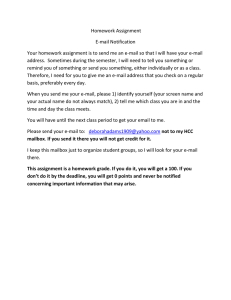

advertisement