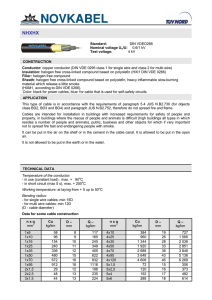

Railway Cables Rolling Stock

advertisement