testing the heater circuits of a triac/optocoupler system

advertisement

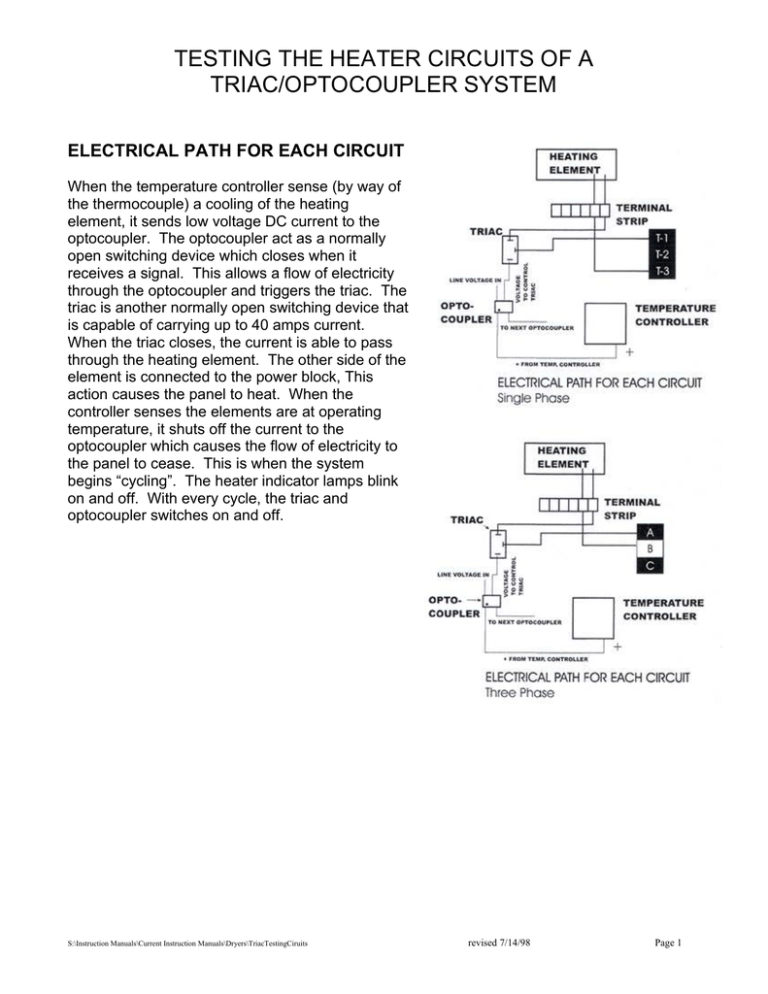

TESTING THE HEATER CIRCUITS OF A TRIAC/OPTOCOUPLER SYSTEM ELECTRICAL PATH FOR EACH CIRCUIT When the temperature controller sense (by way of the thermocouple) a cooling of the heating element, it sends low voltage DC current to the optocoupler. The optocoupler act as a normally open switching device which closes when it receives a signal. This allows a flow of electricity through the optocoupler and triggers the triac. The triac is another normally open switching device that is capable of carrying up to 40 amps current. When the triac closes, the current is able to pass through the heating element. The other side of the element is connected to the power block, This action causes the panel to heat. When the controller senses the elements are at operating temperature, it shuts off the current to the optocoupler which causes the flow of electricity to the panel to cease. This is when the system begins “cycling”. The heater indicator lamps blink on and off. With every cycle, the triac and optocoupler switches on and off. S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 1 TOOLS NEEDED: Volt/Ohm Meter In this instruction sheet, terminal strip refers to the white connecting strip inside the control box. Power block refers to the block where the incoming power lines connect. To check the Triacs: The triacs are located inside the control box on the aluminum heat sink in the upper left corner. There will be one triac for each heating element. Disconnect the power to the unit at the main breaker/fuse box so that you can make a visual inspection of the heater circuit wired and connections. You will need to reconnect the power later to make voltage checks. 1. Open the cover to the control box. 2. Visually and physically check the wires and connections at the terminal strip and at each triac. Replace any worn wire(s) with wire of the same type and rating. 3. With the power still disconnected, perform an ohms test on each circuit. Locate the two wires coming from the individual heaters. The wires connect into the strip starting at the right end. In a single phase unit, they will be labeled 1-1-, 2-2, 3-3, etc. In a three phase unit they will be labeled A-1 B-1, B-2 C-2, C-3 A-3, A-4 B-4, B-5 C-5, etc. Remove the two heater wires for each panel from the terminal strip. Place one lead from the ohmmeter to each of the incoming heater wires. (check only one set at a time and then reconnect to avoid mixing the wires with each other panels). There should be continuity at each panel. If a panel does not have continuity, then check the individual heater panels and/or crimps inside the heat chamber. 4. Reconnect the power at the breaker box. Be careful from this point on as the power will be live to the components you are checking. 5. Again, locate where the heater wires connect into the terminal strip. 6. Set the voltmeter to the 250 (or greater) AC volts range. 7. First check the voltages with the HEAT switch off. There should be NO voltage readings at this point. If there is voltage across a heater, then the triac for that heater circuit is stuck in the closed position and it should be replaced. S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 2 8. Turn the HEAT switch on and increase the temperature setting approximately 100 degrees above the normal setting. Again check the voltages, this time while the dryer is constantly heating. There should be a constant 208-240 volts (depending on the incoming voltages). If there is no voltage on any circuit, then that triac is stuck in the open position, or the optocoupler board is not sending the signal to the triac for it to close (see “Testing the Optocoupler Board” section). 9. Lower the temperature back to the normal operating temperature. Let the dryer heat up to operating temperature and the controller cycles. Check the voltages again. The readings should fluctuate between 0 volts and the incoming line voltage. 10. If the voltages are correct to all heater panels, then the problem is not in the electrical circuits controlling the heater(s). If there is a problem with the heater circuit, then you should check the optocoupler to make sure it is functioning properly. Each triac has an optocoupler than controls the switching action. IMPORTANT: Before making any electrical checks, visually inspects the optocoupler to make sure it is not cracked or damaged. The “dimple” must be in the lower left corner. Also, visually inspect each of the small resistors on the board. S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 3 Testing the Optocoupler Board: To check the input side of the optocoupler: 1. Set the voltmeter to DC volts (50 volts or less range). 2. Place the BLACK lead of the voltmeter to the negative (-) terminal on the terminal strip. 3. Place the RED lead of the voltmeter to pin #1 of the left most optocoupler. There should be approximately 7.5 volts DC at this position for a 5 heaters system; 6 volts for 4 heaters; 4.5 volts for 3 heaters; 3 volts for 2 heaters. 4. Move the red lead to pin #2 of the same optocoupler. There should be a 1-1/2 volt drop from the previous reading. 5. Move the red lead to pin #1 of the next optocoupler. The reading should be the same as pin #2 of the previous optocoupler. Check the voltage again at pin #2. There should again be a drop of 1-1/2 volts. 6. Check all optocouplers in this manner. The voltage at the #2 position of the last optocoupler should be 0. 7. if any optocoupler has a voltage reading at pin #1 but not at pin #2, then the optocoupler should be replaced. 8. if any optocoupler had no reading at pin #1 but the previous optocoupler had a reading at pin #2, then the whole board should be replaced. S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 4 To check the output side of the optocoupler: 1. Set the voltmeter to the 250 volts AC range. 2. Turn on the heat switch to the dryer. Make sure the temperature controller is calling for heat (the L1 light on the controller should be on). 2A. Single Phase Units: Place one lead of the voltmeter to pin #6, (see accompanying electrical drawings) place the other lead to T-3. There should be approximately 220 volts at this point. Move the lead from pin #6 to pin #4 and check. The voltage should be the same at this connection as it was at pin #6. Check all optocouplers using this procedure. If any optocoupler has a reading at pin #6 but no reading at pin #4, AND the controller is calling for heat, then the optocoupler should be replaced. If any optocoupler has no reading at pin #6, then the optocoupler board should be replaced. 2B. Three Phase Units: Place one lead to pin #6 (see accompanying electrical drawings) and the other lead to an opposing leg of the system; (check optocoupler #5 to C; #4 to B; #3 to A; #2 to C; and #1 to B). There should be 220 volts (or live voltage). Move the lead to pin #4 and check in the same manner. The voltage should be the same as at pin #6. Follow this procedures to check all optocouplers. If any optocoupler has a reading at pin #4 but not pin #6 AND the controller is calling for heat, then the optocoupler should be replaced. If there is no voltage at pin #6, then the board should be replaced. 3. If the voltage readings are correct at all optocouplers, leave the one lead on the opposing leg (see 2A and 2B for correct locations). Move the other lead to the 6 o’clock position of the triac to check the voltage at the triac. If there is no voltage, then check the wires and connections. If the connections are ok, then the board should be replaced. S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 5 S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 6 S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 7 S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 8 S:\Instruction Manuals\Current Instruction Manuals\Dryers\TriacTestingCiruits revised 7/14/98 Page 9