Heating systems in buildings — Method for calculation of system

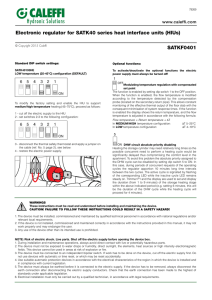

advertisement