Advanced Noise Reduction Solution for Voice Capture Devices

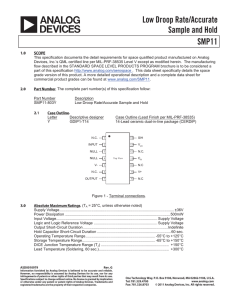

advertisement