132kV Grid Substation Civil Engineering Specification

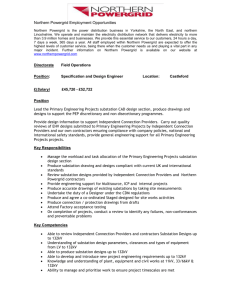

advertisement