Temperature Sensor Interface Module for

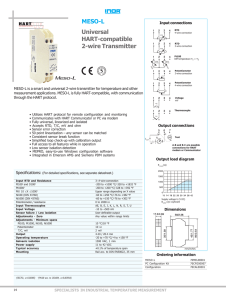

advertisement