required courses

advertisement

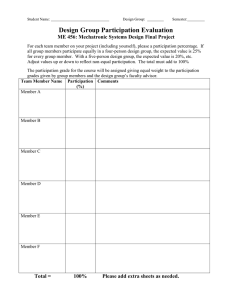

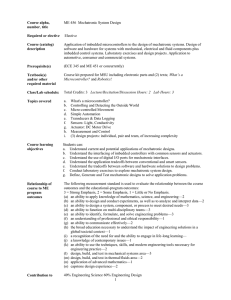

MECHATRONIC ENGINEERING ANNUAL PROGRAM IMPROVEMENT REPORT 2003-05 California State University, Chico Prepared by: Gregory A. Kallio, Professor & Chair Dept. of Mechanical Engineering, Mechatronic Engineering, and Manufacturing Technology California State University, Chico Chico, CA 95929-0789 Mechatronic Engineering Annual Program Improvement Report 2003-05 TABLE OF CONTENTS I. INTRODUCTION ………………………………………………………………………….. 3 1. Program Mission …………………………………………………………………… 3 2. Enrollment and Graduation Trends ………………………………………………… 3 II. ASSESSMENT OF PROGRAM OUTCOMES ………………………………………………… 5 1. Program Outcomes Summary ………………………………………………………. 5 2. Course-Program Outcomes Alignment ……………………………………………… 5 3. Course-Embedded Assessment Metrics and Measures……………………………… 6 4. Senior Exit Survey Results and Analysis……………………………………………. 8 5. Proposed Actions from Outcomes …………………………………………………... 13 6. Proposed Revision of Measures, Metrics, or Outcomes …………………………….. 13 III. ASSESSMENT OF PROGRAM EDUCATIONAL OBJECTIVES ………………………………. 14 1. Educational Objectives Summary …………………………………………………… 14 2. Alumni Survey Methodology and Results …………………………………………… 14 3. Employer Survey …………………………..………………………………………… 16 4. Advisory Board Feedback …………………………………………………………… 16 5. Proposed Revisions to Educational Objectives ……………………………………… 17 IV. APPENDICES ……………………………………………………………………………… 18 A. Senior Exit Survey – Major Specific Instrument .…………………………………… 18 B. Alumni Survey Instrument ………………………………..…………………………. 20 2 Mechatronic Engineering Annual Program Improvement Report 2003-05 I. INTRODUCTION This document, Mechatronic Engineering Annual Program Improvement Report, provides a summary of findings and actions resulting from implementation of the Mechatronic Engineering Program Improvement Plan in effect at the time of this report. The report is divided into two main sections, Assessment of Program Outcomes and Assessment of Program Educational Objectives. While some detailed data are reported here, complete data sets can be found in the assessment files in the file cabinet located in the Department storeroom. Program Assessment Reports normally address one academic year; however, this report summarizes assessment data from three sequential semesters, Spring 2004, Fall 2004, and Spring 2005, since a key assessment component (course embedded assessment) was not fully implemented until midway through the 2003-2004 academic year. Data from two complete years of graduating senior exit surveys and alumni surveys are provided. 1. Program Mission For reference, the current mission statement for the Mechatronic Engineering Program is given here: The Mechatronic Engineering Program has the primary mission of providing a highquality undergraduate engineering education with i. A curriculum that is firmly grounded in engineering fundamentals ii. A faculty that provides superior teaching and mentoring both in and out of the classroom iii. A faculty whose focus is undergraduate education iv. Class sizes that encourage student participation v. Project experiences that build on fundamentals and develop team skills vi. Facilities and equipment that are readily accessible vii. An environment that is conducive to learning and encourages students from different genders and backgrounds The faculty is committed to offer a broad undergraduate experience that will promote professional growth and prepare students for a variety of engineering careers, graduate studies, and continuing education. 2. Enrollment and Graduation Trends For reference, enrollment and graduation data for Mechatronic Engineering majors are presented for Fall1996 through Spring 2005 in Figures 1 and 2. It is evident that enrollment has increased steadily throughout most of this period since program inception in 1996. The last two years appear to show a leveling off in the 90-100 major range. 3 Mechatronic Engineering Annual Program Improvement Report 2003-05 100 83 79 Number of Majors 62 62 F00 S01 92 91 F03 S04 F04 93 84 80 60 92 77 57 60 44 40 46 37 35 18 20 11 0 F96 S97 F97 S98 F98 S99 F99 S00 F01 S02 F02 S03 S05 Semester Figure 1. Mechatronic Engineering Program Enrollment, Fall 1996 through Spring 2005. 20 16 Number of Gradautes 15 11 11 10 7 5 3 2 2 2 98/99 99/00 00/01 0 97/98 01/02 02/03 03/04 04/05 Academic Year Figure 2. Mechatronic Engineering Program Graduates, 1997-2005 Academic Years. 4 Mechatronic Engineering Annual Program Improvement Report 2003-05 II. ASSESSMENT OF PROGRAM OUTCOMES 1. Program Outcomes Summary ABET’s Criterion 3 for Accrediting Engineering Programs prescribes that the program must demonstrate that their graduates have achieved eleven specific proficiencies, also known as outcomes (a-k). For the purposes of assessment, these ABET proficiencies have been recast into eight Program Outcomes for Mechatronic Engineering at CSU, Chico: Mechatronic engineering graduates shall demonstrate the ability to: A. Apply knowledge of math, science, and mechatronic engineering to formulate and solve problems. B. Conduct experiments, and analyze and interpret the resultant data. C. Design components and systems to which integrate computers, sensors, and actuators in mechanical systems to meet desired needs, and design experiments to evaluate system performance with respect to specifications. D. Use current industry standard engineering tools. E. Communicate technical matters effectively in oral, written, and graphical form. F. Function effectively as members of multi-disciplinary teams. G. Understand their professional and ethical responsibilities, the impact of their activities on society and the environment, and appreciate contemporary issues facing society. H. Use information resources and recognize the importance of continued learning. These outcomes were assessed directly through course-embedded metrics. Indirect assessment methods was based upon Senior Exit Survey results. 2. Course-Program Outcomes Alignment Table 1 shows how the required courses within the Mechatronic Engineering curriculum align with the Program Outcomes. The categories of “Introduced”, “Practiced”, and “Assessed” indicate the degree to which an outcome is related to each course. Courses in which outcomes are “Assessed” include embedded, rigorous metric and measuring procedures that individually test student achievement. All required courses in Mechatronic Engineering contribute to the program outcomes to some degree. Outcomes that are not heavily supported by courses include F, G, and H. In particular, Outcome F: “function effectively as members of multi-disciplinary teams”, is probably the weakest due to the multi-disciplinary requirement. Outcome F is assessed in ME 238A/B, where students work on a year-long team project but not all teams are multi-disciplinary. At most, these teams consist of ME and MECA students. Outcome F is also assessed in ENGR 195 where one class project is done as a team and may have some combination of CE, ECE, ME, and MECA students. If multidisciplinary teams are meant to include students from majors other than engineering, then this outcome is not being satisfied. 5 Mechatronic Engineering Annual Program Improvement Report 2003-05 Table 1. Course-Program Outcomes Alignment Matrix REQUIRED COURSES PROGRAM OUTCOMES A B C D E F G H MATH 7A,B,C,D – Calculus, Differential Eqns CHEM 37 – General Chemistry (with lab) PHYS 4A,B,C – Physics (with lab) CE 35 – Statics CE 101 – Strength of Materials CE 121 – Engineering Economy and Statistics ECE 85 – Log Design Fundamentals (with lab) ECE 86 – Processor Architect/Assy Lang (with lab) ECE 90 – Algorithms and Programs for Eng. (with lab) ECE 95, 95L – Circuits and Devices (with lab) ECE 97 – Simulation and Analysis Tools (with lab) ECE 140 – Linear Circuits ECE 145 – Electronics I (with lab) ECE 146 – Electronics II (with lab) ECE 186 – Digital Systems Design (with lab) ECE 187 – System Architecture/Performance ECE 188 – Computer Interface Circuits ECE 236 – State Machine Design ME 25 – Engineering Graphics ME 45 – Materials Engineering (with lab) ME 135 – Dynamics ME 138 – Mechanical Engineering Design ME 201 – Control System Design MECA 238A – Mechatronic Eng. Design Project I MECA 238B – Mechatronic Eng. Design Project II ME 261 – Measurements & Instrumentation (with lab) ENGR 195 – Lifelong Development for Engineers General Education courses KEY: 3. Introduced Practiced Assessed Course-Embedded Assessment Metrics and Measures Table 2 gives the course metrics and measures for each embedded outcome, as well as the percentage of students achieving each metric. Refer to the Mechatronic Engineering Program Improvement Plan for details regarding the metrics, measures, and student achievement statistics. The Department has set a 100% compliance level on all course-embedded outcome assessments. This requires that all Mechatronic Engineering majors achieve proficiency in Program Outcomes B-H. Students that fail to achieve the course outcome metrics (i.e., typically a grade of “C”) do not pass or complete that particular course. The course instructor must assign either a failing grade (“F”) or an incomplete grade (“I”) in these instances. As seen in Table 2, this situation arises frequently; in most cases, students receive an incomplete grade and are given an opportunity to pass the metric during the following semester. 6 Mechatronic Engineering Annual Program Improvement Report 2003-05 Table 2. Embedded Course Metrics and Measures with Results. Outcome B C C C D D E E E F F F G H H Course Measure Conduct lab experiment to validate design Microcomputer design ECE 186 project Individual & group ME 138 design projects (6) MECA Test Plan written report 238B AutoCAD or SolidWorks ME 25 tests (2) & final project Data acquisition ME 261 assignment using HP Vee Sketching tests (3) and ME 25 AutoCAD or SolidWorks final project MECA Oral presentations and 238B written reports Technical paper writing ME 261 assignment MECA Peer reviews, progress 238A memos, meetings MECA Individual contribution to 238B project (overall) Work on ENGR 195 multidisciplinary team ENGR 195 Weekly memos ME 138 Group design projects (3) Technical paper writing ME 261 assignment ECE 145 Metric Grade of C or better Grade of C or better % of Students Achieving S04 F04 S05 Not 88 96 measured 84 90 96 Average grade of C or better 100 Not taught 95 C grade or better 100 Not taught 94 Average grade of C or better 87 94 88 Grade of C or better 83 Not taught 93 Average grade of C or better 92 100 88 Average grade of C or better 100 Not taught 94 Grade of C or better 83 Not taught 93 Grade of C or better Not taught 94 Not taught Grade of C or better 100 Not taught Not measured Pass one of two standards 100 100 100 Pass one of two standards Average grade of C or better 100 100 100 Not taught 100 95 Grade of C or better 83 Not taught 93 The embedded measures used in these courses above are generally effective. The minimum “C” grade metric represents a unified approach to the measurement of Mechatronic Engineering outcomes. An overwhelming majority of students achieved the standards for each outcome measured. This may imply that the metrics chosen are too easy to achieve, however, a hidden factor is that some courses allow students to repeat or revise the instrument used to measure an outcome. This is an effective way to get students to work harder in achieving the outcome without the catastrophic effect of repeating a class and/or delaying graduation. Proposed improvements to outcome measure/metrics are included in Section 6. The necessity of measuring a given outcome in multiple courses is questioned. This occurs for Outcomes C, D, E, F, and H. In two cases (Outcome C and E), the multiple measurements are needed since no one course addresses all aspects of the given outcome. Outcome D is measured in two different courses for the purpose of sampling several types of “current industry standard engineering tools”; these included AutoCAD (now SolidWorks) in ME 25 and HP Vee in ME 261. The measurement of Outcome F 7 Mechatronic Engineering Annual Program Improvement Report 2003-05 in MECA 238A, MECA 238B, and ENGR 195 is deemed redundant. Likewise, multiple measurements of Outcome H in ME 138 and ME 261 are thought to be excessive. It is noted that no embedded course assessment exists for Program Outcome A. The original rationale was that Outcome A would be measured by the Fundamentals of Engineering Examination, but it is not known how many majors take this exam. Furthermore, there are no plans to make the FE exam required for graduation (as it is for Mechanical Engineering majors). It is proposed to embed assessment of Outcome A in at least one required course. 4. Senior Exit Survey Results and Analysis The Mechatronic Engineering program, as well as all other programs in the College of Engineering, Computer Science, and Construction Management (ECC), administer a Senior Exit Survey that is designed to meet the evaluative needs that are a consequence of implementing the ABET 2000 criteria. The results are tabulated annually in the College document, ECC Assessment Report – Senior Exit Survey Results, Summary Report and Evaluation. The surveys provide confidential information about student plans after graduation, their perceptions about learning and their level of satisfaction with various aspects of their education at CSU, Chico. In addition, the survey allows individual programs to add major-specific questions and written comments that focus on particular issues. The Major Specific instrument of the Senior Exit Survey is contained in Appendix A, which is the same for both Mechanical (ME) and Mechatronic (MECA) Engineering majors. The survey contains 44 questions that all ECC seniors answer, 10 supplemental questions that are specific to the ME and MECA programs, and space for written comments. Questions 1-14 address student demographics and post-graduation plans; they are not reported here. The responses reported here are divided into four groups: i) educational satisfaction (questions 15-30), ii) program outcomes, based on ABET Criterion 3a-k (questions 31-44), iii) major specific topics (questions 1-10), and iv) written comments. These survey questions are summarized here: Educational Satisfaction – At Chico State, how satisfied were you with the: Q15. Quality of teaching by faculty in department Q16. Quality of teaching by other faculty Q17. Access to faculty in your department Q18. Availability of courses in your department Q19. Quality of courses in your department Q20. Access to lab facilities and equipment Q21. Quality of laboratories and equipment Q22. Access to computer facilities Q23. Quality of computer facilities Q24. Academic advising from your major advisor Q25. Academic advising from the Advising Office Q26. Career advice from faculty in your department Q27. Availability of General Education (GE) courses 8 Mechatronic Engineering Annual Program Improvement Report 2003-05 Q28. Quality of General Education (GE) courses Q29. Overall quality of your education Q30. Overall experience at Chico State Program Outcomes – Based on your educational experience at Chico State, how well prepared are you to: Q31. Apply knowledge to solve problems Q32. Design and conduct experiments Q33. Analyze and interpret experimental data Q34. Design component or system to meet needs Q35. Function on multidisciplinary team Q36. Identify, formulate, and solve technical problems Q37. Communicate technical matters in writing Q38. Communicate technical matters orally Q39. Understand professional, ethical responsibilities Q40. Understand contemporary issues facing society Q41. Use modern tools and technology Q42. Enter the workplace Q43. Continued learning Q44. Recommend major program to others Major Specific - Based on your educational experience at Chico State, how well prepared are to: Q1. Produce a set of dimensioned engineering drawings Q2. Communicate manufacturing needs to a technician Q3. Create a Gantt chart for a project Q4. Discuss tolerances on manufactured parts Q5. Identify the critical path for a project Q6. Develop a detailed project budget Q7. Integrate a number of parts into a subsystem Q8. Prepare a design review Q9. Plan a test and verification program Q10. Order parts from a vendor The surveys were administered in May 2004 and May 2005 to 9 and 16 senior students, respectively, in the MECA 238B capstone course. Most these students graduate in May; a small fraction (typically less than 10%) graduate the following December. Survey participation rate for this cycle was above 90%. Figure 3 summarizes the educational satisfaction results for the current assessment cycle and preceding academic years 2001-02 and 2002-03. While there are some yearto-year variations, general trends exist and clear satisfaction is reported in the majority of categories. Particularly high levels of satisfaction are reported for access to faculty and access/quality of computing facilities. Indications of dissatisfaction are found in the areas of Quality of teaching by other faculty (Q16), Academic advising from the Advising Office (Q25), Career advice from faculty in your department (Q26), and Quality of GE courses (Q28). We know, from 9 Mechatronic Engineering Annual Program Improvement Report 2003-05 discussions with MECA students, that there exists dissatisfaction with the general quality of teaching and curriculum in the Department of Electrical & Computer Engineering (ECE). Specific problems candidly reported by students to the Chair are outdated curriculum, poor teaching, deficient English-speaking skills among some faculty, insufficient design content in key courses, course disorganization, and lack of rigor. Since the MECA curriculum contains 33 required units from ECE, this must be addressed immediately. While most major-specific academic advising is done and should be done by ME faculty, the University Advising Office often provides GE advising; this advising is complicated by waivers and substitutions for ME majors that may not be articulated well by the Advising Office staff. The staff includes part-time student help, who may not be familiar with all nuances of these waivers and substitutions. Career advice from our own faculty is notably lacking and needs to be addressed. The quality of general education is problematic due to the large class sizes and subject matter. ME majors may view these non-technical courses to be a diversion from their primary professional interests and thus affects their level of engagement. The department has little influence on the quality or availability of these courses. Marginal satisfaction is reported for Quality of laboratories and equipment (Q21), Academic advising from your major advisor (Q24), and Availability of GE courses (Q27). Deficiency in laboratory equipment is primarily a resource problem; however, it appears that academic advising by MECA faculty should be reviewed. 5 5.0 - Very Satisfied Average Response 4 AY 2001-02 3 3.0 - Neutral AY 2002-03 AY 2003-04 AY 2004-05 2 1 1.0 - Very Dissatisfied 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Question Number Figure 3. Senior Exit Survey - Educational Satisfaction Results, Mechatronic Engineering, 2001-05. 10 Mechatronic Engineering Annual Program Improvement Report 2003-05 When comparing current assessment cycle data with that of 2001-2003, satisfaction improvement is indicated in Access to computing facilities (Q22) and Quality of computing facilities (Q23). This is probably due to the purchase of new computers and software in our Computer-Aided Design Laboratory, and a new after-hours lab access policy. Decreases in satisfaction are noted for Questions 15, 16, 19, 24, 25, 28, 29, and 30. Significance and reasons for these results are unknown at this time, except for those previously mentioned. Figure 4 summarizes the program outcomes results for the current assessment cycle and preceding academic years 2001-02 and 2002-03. Responses indicate a high degree of preparedness in all categories and give indirect measure of Program Outcomes achievement. Marginal preparedness is reported for Understand contemporary issues facing society (Q40). The only significant decrease is found in Recommend major program to others (Q44); reasons for this result are unknown. Figure 5 summarizes the supplemental major specific results for the current assessment cycle and preceding academic years 2001-02 and 2002-03. The results indicate a positive degree of preparedness in all categories, but some are marginal. The most significant observation is that the 2004-05 results are lower in all categories compared to the 2002-03 and 2003-04 results. This appears to indicate weakness in our graphics course (ME 25) and capstone design course sequence (MECA 238A and MECA 238B), since many of the questions relate to the learning objectives of these courses. The lowest-scoring categories for AY 2004-05 are Create a Gantt chart for a project (Q3), Discuss tolerances on manufactured parts (Q4), and Identify the critical path for a project (Q5). It appears that these topics need more coverage in MECA 238A/B. 5 5.0 - Very Well Prepared 5.0 - Strongly Agree 3.0 - Neutral 3.0 - Neutral Average Response 4 AY 2001-02 3 AY 2002-03 AY 2003-04 AY 2004-05 2 1.0 - Very Unprepared 1.0 - Strongly Disagree 1 31 32 33 34 35 36 37 38 39 40 41 42 43 44 Question Number Figure 4. Senior Exit Survey - Program Outcome Results, Mechatronic Engineering, 2001-05. 11 Mechatronic Engineering Annual Program Improvement Report 2003-05 5 Very Well Prepared Average Response 4 AY 2001-02 3 AY 2002-03 Neutral AY 2003-04 AY 2004-05 2 1 Very Unprepared 1 2 3 4 5 6 7 8 9 10 Question Number Figure 5. Senior Exit Survey - Major Specific Results, Mechanical & Mechatronic Engineering, 2001-05. Written comments were solicited from students in this survey instrument, framed by the request to “provide additional comments that will help the faculty to improve the quality of the education”. As expected, comments were diverse in subject matter and depth, but common threads were evident. Some written comments offered praise to the quality of instruction and overall quality of the MECA program. Table 3 presents a summary of the comments from AY 2003-04 and AY 2004-05 that addressed needed improvements to the program. Table 3. Senior Exit Survey - Summary of Written Comments, Mechatronic Engineering, 2003-05. Comment Topic Improve EE curriculum and/or EE faculty instruction Add true mechatronics courses that bridge EE-ME disciplines Add topics in machine automation and robotics to curriculum Add drawing standards and parts selection to curriculum Improve communication between MEM and ECE departments Some professors lack sufficient English-speaking skills Thermal Packaging course covers too much for 2 units credit Student is unhappy about the performance of a certain professor Student feels he/she is not prepared for industry No. of Comments 8 3 1 1 1 1 1 1 1 12 Mechatronic Engineering Annual Program Improvement Report 2003-05 The overriding theme of the written comments is student dissatisfaction with both the curriculum and teaching quality in ECE. Again, this feedback emphasizes the need for immediate action. The need for courses that integrate mechanical, electrical, and computer engineering is also noted. 5. Proposed Actions from Outcomes Based upon the foregoing results and analysis, the following actions are proposed to improve the Mechatronic Engineering program: • • • • • • • Develop a plan for improving the EE courses taken by MECA students. Develop a plan for improving teaching quality in the ECE Department. Develop a plan for better integrating mechanical, electrical, and computer engineering in the curriculum. Work with University Advising Office to improve quality of advising. Review effectiveness of MECA academic advising. Develop a plan for upgrading laboratory equipment where applicable. Provide resources within Department for students to explore career opportunities and placement. In May 2005, seven senior MECA students met with Chair Greg Kallio of MEM and Chair Larry Wear of ECE to discuss ECE curriculum problems. The students critiqued each ECE course in the MECA program and comments were recorded by Chair Wear. This critique was communicated to the new ECE Chair Adel Ghandakly in Fall 2005. 6. Proposed Revision of Measures, Metrics, or Outcomes From instructor input and faculty discussions, several revisions to the embedded Program Outcomes assessment procedure are proposed: • Add course embedded assessment of Outcome A in one required course. • Simplify course embedded assessment by removing redundancies: o Delete MECA 238A and 238B from embedded assessment of Outcome F o Delete ME 138 from embedded assessment of Outcome H • In the replacement course for ME 25 (i.e., MECH 100), eliminate take-home project as an outcome measure and replace with in-class assignments. • Devise better instruments to measure teamwork, Outcome F, in capstone design course sequence (MECA 238A/B). 13 Mechatronic Engineering Annual Program Improvement Report 2003-05 III. ASSESSMENT OF PROGRAM EDUCATIONAL OBJECTIVES 1. Educational Objectives Summary In accordance with ABET Criterion 2, all graduates of the MECA program should accomplish eight educational objectives within the first few years of professional practice after leaving CSUC; some may be accomplished by the time of graduation. Mechatronic engineering graduates will: 1. 2. 3. 4. 5. 6. 7. 8. Be effective interdisciplinary engineers and problem solvers. Be well-educated in the basic engineering sciences and fundamentals of mechanical, electrical, and computer engineering. Be able to use engineering tools that will enhance their productivity. Be able to design, analyze, and test “intelligent” products or processes that incorporate suitable computers, sensors, and actuators. Be effective oral, written, and graphical communicators. Be able to function effectively as members of multi-disciplinary teams. Have an appreciation for the individual, society, and human heritage, and be aware of the impact of their designs on humankind and the environment. Be prepared for a variety of engineering careers, graduate studies, and continuing education. The objectives were last reviewed in December 2003 by the ME/MECA faculty and Industrial Advisory Board. It was decided to split the former Objective 5 (which addressed both communication and teamwork) into the current Objective 5 (communication) and Objective 6 (teamwork). 2. Alumni Survey Methodology and Results The department uses an Alumni Survey instrument, administered annually, to verify that graduates with three to seven years of experience meet the Educational Objectives. For this assessment period, two alumni surveys were conducted: i) alumni who graduated during AY 1996-97 and AY 1999-2000, surveyed in Summer 2003; and ii) alumni who graduated during AY 1997-98 and AY 2000-01, surveyed in Summer 2004. A hardcopy or electronic survey was sent to alumni for whom addresses (email included) were known. A copy of survey instrument is found in Appendix B. In addition to demographics, fifteen survey questions (Q11-Q25) reflected the degree to which the alumni considered that the Program Outcomes and Educational Objectives of the program had been met. The questions asked for the degree of preparedness, ranging from “Unprepared” to “Well Prepared” in five levels. These qualitative responses were translated into quantitative scores 1-5. Because the Educational Objectives are phrased in broad terms, the survey questions were written more specifically and are thus similar to the Program Outcomes statements. Table 4 shows the alignment between the fifteen survey questions and the eight Educational Objectives. Figure 6 presents the survey results for this assessment cycle. Only four responses were obtained – primarily due to the low number of MECA 14 Mechatronic Engineering Annual Program Improvement Report 2003-05 graduates during these years (no responses for 1996-1997 and 1997-98). Scores above 3.0 are deemed acceptable and all categories had average scores of 4.0 or higher. Thus, no weak areas were detected from this survey. Table 4. Alumni Survey – Educational Objectives Alignment. Question Topic Educational Objective Apply knowledge of math, science, engineering, and technology to solve problems Design and conduct experiments Analyze and interpret experimental data Design a component or system to meet desired needs Function on a multidisciplinary team Identify, formulate, and solve technical problems Communicate technical matters in writing Communicate technical matters orally Communicate graphically Understand professional and ethical responsibilities Understand contemporary issues facing society Use modern tools and technology Enter the workplace Continue learning Change positions/companies/career as desired 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 1,2 4 4 1,4 6 1 5 5 5 7 7 3,4 8 8 8 5 Well Prepared Mean Response 4 3 Neutral 1999-2000/200001 grads 2 1 Unprepared 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Question Number Figure 6. Alumni Survey Results for MECA Alumni Graduating AY 1999-2000 and AY 2000-2001; Total Reponses = 4. 15 Mechatronic Engineering Annual Program Improvement Report 2003-05 3. Employer Survey Prior to AY 2003-04, the department administered an alumni employer phone survey to supervisors of the surveyed alumni. Due to the low number of alumni responses and some reluctance from their supervisors to provide evaluations, the response rate was deemed too small to produce significant assessment. Consequently, alumni employer surveys were not conducted during this assessment cycle. 4. Advisory Board Feedback Three Industrial Advisory Board meetings took place during this assessment cycle: December 2003, May 2004, and February 2005. Useful feedback from these meetings is summarized below: • • • • • • • Educational Objectives for the MECA program were reviewed and revised to the current form. Board members served as judges for the Fall 2003 MECA 238A Critical Design Review and offered constructive suggestions that pertained to the grading of the presentations, design of test fixtures, and the up-front need for sponsored funding. Board encouraged department to establish a method of tracking retention and attempt to improve retention by using an organization like Tau Beta Pi to provide tutoring to freshman and sophomores. Board developed a list of items to help secure industrial sponsorship of senior projects. Board members gave presentations to faculty on their vision of mechanical and mechatronic engineering in the current economy and desired skills for BS graduates. Board members see fundraising as critical to the future of engineering programs. Board notes a disconnect between University career placement services and ME/MECA programs; encourages department to improve connection or become more proactive in helping place our own graduates in industry. During the February 2005 meeting, the Board met with senior Mechatronic Engineering (MECA) students to discuss the program. Observations and recommendations by the Board were submitted to Dean Ken Derucher on March 1, 2005 and are summarized as follows: Observations 1. The students had unusually harsh criticism of the ECE courses and faculty. This included a lack of design content in ECE 186, poor teaching methods, unprepared instructors, course coverage not aligned with catalog descriptions, and a feeling that ECE faculty do not support the MECA program. 2. MECA program has no real “home” and lacks autonomy. 3. Little integration of mechanical and electrical engineering in MECA program. 16 Mechatronic Engineering Annual Program Improvement Report 2003-05 Recommendations 5. 1. Create a study lounge area for MECA students. 2. Add content to the MECA curriculum that better integrates software, controls, mechanical, and electronic topics before the senior year. Consider a manufacturing course that includes electronic circuit board fabrication. 3. Fix the teaching problem in ECE. Consider hiring new faculty with mechatronic expertise. Proposed Revisions to Program Objectives No revisions to the MECA program Educational Objectives are proposed at this time. 17 Mechatronic Engineering Annual Program Improvement Report 2003-05 Appendix A Senior Exit Survey – Major Specific Instrument 18 Mechatronic Engineering Annual Program Improvement Report 2003-05 Graduating Senior Survey – Supplemental Questions College of Engineering, Computer Science, and Technology, CSU Chico Major: CE Graduation Date: CIS CM CMPE Semester: CSCI Spring EE Summer ME Spring 2005 MECA MFGT Fall Other 2003 2004 Major Specific Questions – ME / MECA: Based on your educational experience here at Chico State, how well prepared are you to: Preparation Very Unprepared Very Well Prepared Q1. Produce a set of dimensioned engineering drawings Q2. Communicate manufacturing needs to a technician A. B. C. D. E. Q3. Create a Gantt chart for a project Q4. Discuss tolerances on manufactured parts please answer these Q5. Identify the critical path for a project questions on scan form ! Q6. Develop a detailed project budget Q7. Integrate a number of parts into a subsystem Q8. Prepare a design review Q9. Plan a test and verification program Q10. Order parts from a vendor In the space below, please provide additional comments that will help the faculty to improve the quality of the education we provide. Your responses will be kept confidential. Thank you for completing this survey and please stay in touch with us ! 19 Mechatronic Engineering Annual Program Improvement Report 2003-05 Appendix B Alumni Survey Instrument 20 Mechatronic Engineering Annual Program Improvement Report 2003-05 Mechanical Engineering Alumni Survey Summer 2004 Dear Alumnus: You can help us improve our program. Please take a few minutes to give us your reflections on your educational experience at Chico State and your career. Your responses will be kept confidential. I also encourage you to periodically log onto our website (www.csuchico.edu/mem) and help keep our alumni database current. Thank you for completing this survey and please stay in touch. Ron Roth, Department Chair Name: __________________________________________ Graduation Date: _______________________ Home Address: __________________________________________________________________________ City: ____________________________________________ State: ____ Zip Code: _________________ Email: ___________________________________________ Phone: _______________________________ 1. Current Employment Your job title:___________________________________________________________________________ Employer: ___________________________________________________________________________ Supervisor: ___________________________________ Supervisor’s phone: _____________________ Supervisor’s title: _______________________________ Supervisor’s email: _____________________ 2. Which of the following describe your primary job responsibilities? (check all that apply) Analysis Manufacturing Sales Design Research and Development Consulting Testing Quality/Reliability Other – Describe: Programming Management ____________________________ 3. Which of the following describe your primary business area? (check all that apply) Energy Systems Electronics or Optics Transportation Systems Machine/Mechanical Design Automation or Control Other – Describe: Computer or Information Systems Manufacturing Systems ____________________________ 4. What is your annual salary? Initially after graduation Currently <$40K <$40K $40-50K $40-50K $50-60K $50-60K $60-70K $60-70K $70-80K $70-80K >$80K >$80K 1-5 6-10 11-20 21-30 >30 4 5 >5 4 5 >5 5. How many employees do you supervise? 0 6. How many different companies have you worked for since you graduated? 1 2 3 7. How many different positions have you held since you graduated? 1 2 3 8. What, if any, degrees have you completed since you obtained your BS degree in Mechanical Engineering? Degree: __________ Major: _____________________ Institution: _____________________________________ 9. Since you obtained your BS degree have you taken any professionally related: yes no where: ___________________________________________ Graduate courses Short courses or in-house courses yes no description: ___________________________________________ Other professional training yes no description: ___________________________________________ 21 Mechatronic Engineering Annual Program Improvement Report 2003-05 0. Did you take: Fundamentals of Engineering (EIT) Exam? Professional Engineering (PE) Exam? yes – passed yes – passed yes - did not pass yes - did not pass Based on your Chico experience, how well prepared are you to: 11. Apply knowledge of math, science, engineering, Well Prepared and technology to solve problems 12. Design and conduct experiments 13. Analyze and interpret experimental data 14. Design a component or system to meet desired needs 15. Function on a multidisciplinary team 16. Identify, formulate and solve technical problems 17. Communicate technical matters in writing 18. Communicate technical matters orally 19. Communicate graphically 20. Understand professional and ethical responsibilities 21. Understand contemporary issues facing society 22. Use modern tools and technology 23. Enter the workplace 24. Continue learning 25. Change positions/companies/career as desired no no Unprepared 26. What are the strengths of the Chico State Mechanical Engineering Program? 27. What are the weaknesses of the Chico State Mechanical Engineering Program? 28. Additional comments that will help us improve the quality of the education we provide would be appreciated? Strongly Agree Strongly Disagree 29. I would recommend the Chico State ME Program to others. 22