Elastomeric Material Solutions

www.rogerscorp.com

PORON® Materials for Protective Cases

Impact Protection for Portable Electronics

With portable electronics being designed smaller and becoming a larger part of our lives, protection for

these devices has never been so important.

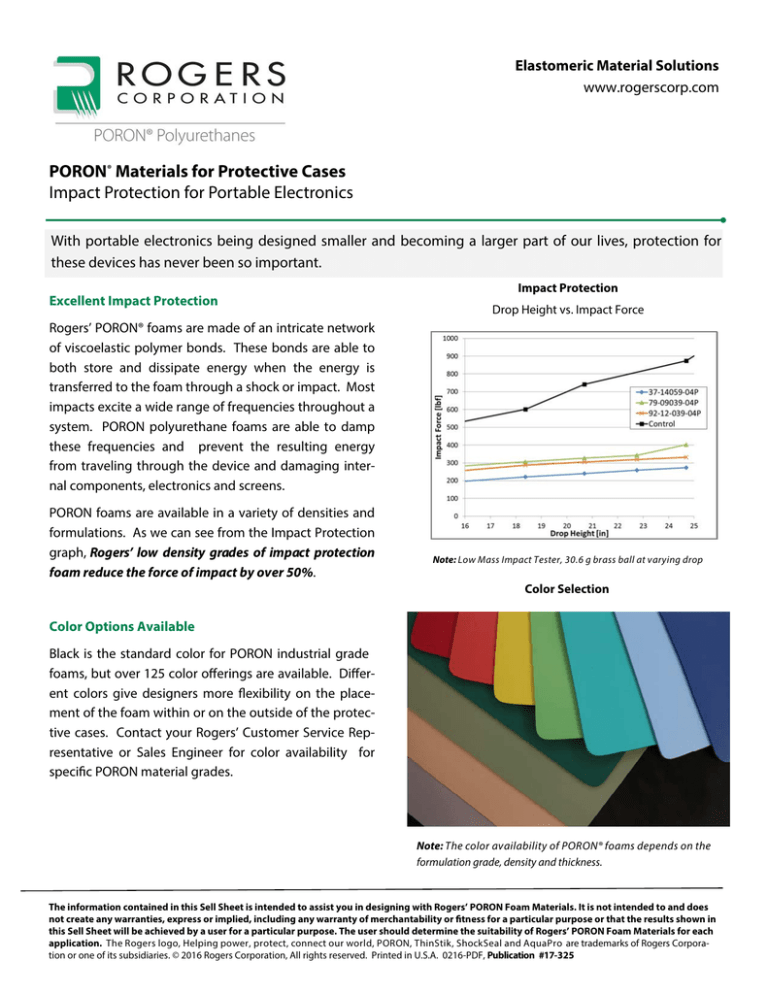

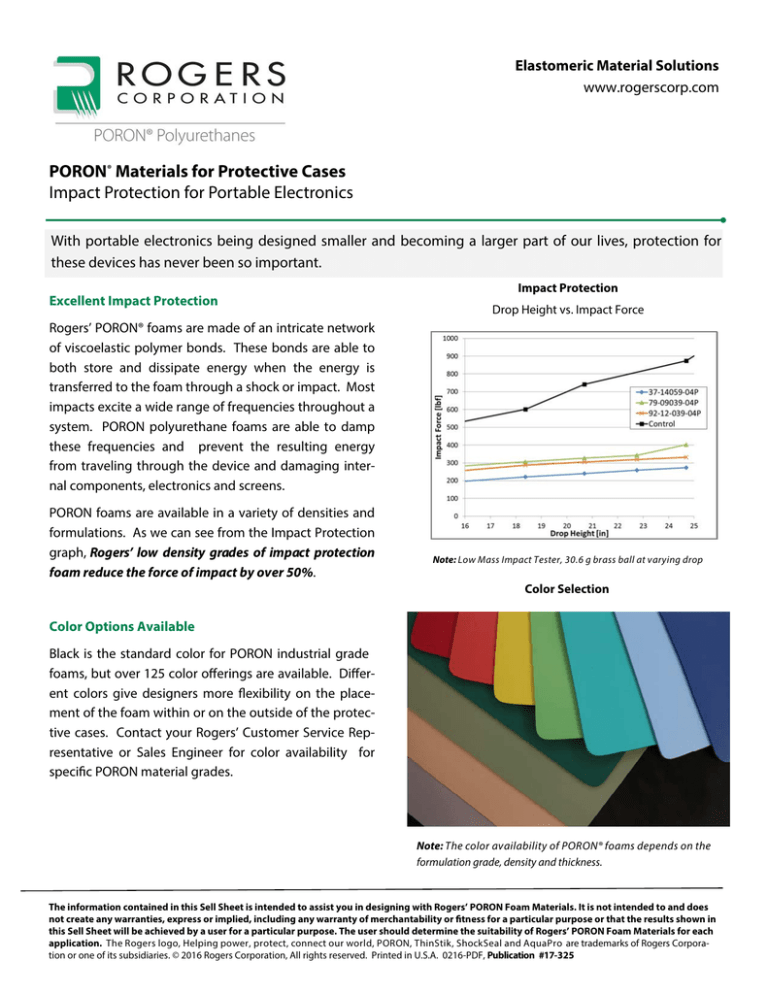

Impact Protection

Excellent Impact Protection

Drop Height vs. Impact Force

Rogers’ PORON® foams are made of an intricate network

of viscoelastic polymer bonds. These bonds are able to

both store and dissipate energy when the energy is

transferred to the foam through a shock or impact. Most

impacts excite a wide range of frequencies throughout a

system. PORON polyurethane foams are able to damp

these frequencies and prevent the resulting energy

from traveling through the device and damaging internal components, electronics and screens.

PORON foams are available in a variety of densities and

formulations. As we can see from the Impact Protection

graph, Rogers’ low density grades of impact protection

foam reduce the force of impact by over 50%.

Note: Low Mass Impact Tester, 30.6 g brass ball at varying drop

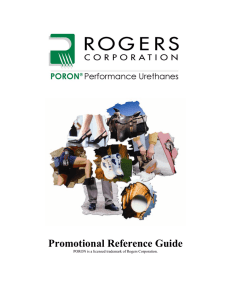

Color Selection

Color Options Available

Black is the standard color for PORON industrial grade

foams, but over 125 color offerings are available. Different colors give designers more flexibility on the placement of the foam within or on the outside of the protective cases. Contact your Rogers’ Customer Service Representative or Sales Engineer for color availability for

specific PORON material grades.

Colors! Note: The color availability of PORON® foams depends on the

formulation grade, density and thickness.

The information contained in this Sell Sheet is intended to assist you in designing with Rogers’ PORON Foam Materials. It is not intended to and does

not create any warranties, express or implied, including any warranty of merchantability or fitness for a particular purpose or that the results shown in

this Sell Sheet will be achieved by a user for a particular purpose. The user should determine the suitability of Rogers’ PORON Foam Materials for each

application. The Rogers logo, Helping power, protect, connect our world, PORON, ThinStik, ShockSeal and AquaPro are trademarks of Rogers Corporation or one of its subsidiaries. © 2016 Rogers Corporation, All rights reserved. Printed in U.S.A. 0216-PDF, Publication #17-325

Elastomeric Material Solutions

www.rogerscorp.com

Compression Set

Consistent and Reliable Performance

Compression set testing indicates how a material will

perform in an application while compressed over a long

period of time.

Two Rogers’ foams and a competitive material were

measured for thickness and then aged for 22 hours at

50% compression in a 70°C oven. After aging, the

heights of the materials were recorded. PORON materials lost between 4-5% of their total height while the

competitive material collapsed and only returned to

half of its original height.

Aged Performance

The SEM images below show a clear image of the difference between PORON foams and the competitor material.

Reliable Impact Protection Over Time

The decrease in thickness over time in the competitive

material will affect its ability to provide impact protection. On average, Competitor A impact protection will

decrease 37% while PORON foams will only decrease

between 3-8% depending on the grade of material.

PORON® Polyurethane Foam

Competitor A

Before

After

Before

After

The information contained in this Sell Sheet is intended to assist you in designing with Rogers’ PORON Foam Materials. It is not intended to and does

not create any warranties, express or implied, including any warranty of merchantability or fitness for a particular purpose or that the results shown in

this Sell Sheet will be achieved by a user for a particular purpose. The user should determine the suitability of Rogers’ PORON Foam Materials for each

application. The Rogers logo, Helping power, protect, connect our world, PORON, ThinStik, ShockSeal and AquaPro are trademarks of Rogers Corporation or one of its subsidiaries. © 2016 Rogers Corporation, All rights reserved. Printed in U.S.A. 0216-PDF, Publication #17-325

Elastomeric Material Solutions

www.rogerscorp.com

PORON® Protective Case Product Offerings

Typical Physical Properties

Rogers offers a wide range of PORON materials to solve challenging impact protection problems. Each of the

grades indicated below have excellent compression set resistance and sealing over time. These product lines have

unique attributes that can help designers choose the best solution for every application with specific design challenges.

Product Line

Density

Range*

Thickness

Range*

Product Description

ThinStik® 4790-92TS1

9 - 12 pcf

0.020 - 0.030”

Highly compressible foam manufactured with

a pressure sensitive adhesive layer

ShockSeal® 4790-79

12 - 20 pcf

0.021 - 0.375"

Specially formulated for impact protection in

demanding applications

PORON® AquaProTM 37

14 pcf

0.053 - 0.5"

Versatile foam that specialized in durable,

long-term performance applications

PORON® 4790-92

9 –30 pcf

0.012 - 0.120"

Extra soft, slow rebound material with a very

low closure force

* Thickness availability depends on the density and the formulation of PORON® products.

Note: Typical values are a representation of an average value. Additional technical information is available.

The information contained in this Sell Sheet is intended to assist you in designing with Rogers’ PORON Foam Materials. It is not intended to and does

not create any warranties, express or implied, including any warranty of merchantability or fitness for a particular purpose or that the results shown in

this Sell Sheet will be achieved by a user for a particular purpose. The user should determine the suitability of Rogers’ PORON Foam Materials for each

application. The Rogers logo, Helping power, protect, connect our world, PORON, ThinStik, ShockSeal and AquaPro are trademarks of Rogers Corporation or one of its subsidiaries. © 2016 Rogers Corporation, All rights reserved. Printed in U.S.A. 0216-PDF, Publication #17-325