abbreviations and symbols - Republic Doors and Frames

advertisement

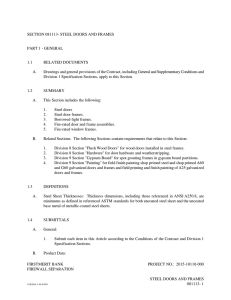

GENERAL NOTES 1. Fabrication of required material for this project will proceed only after receipt of signed approval by Architect. Also a signed approved copy of the finish hardware schedule and all necessary hardware templates will be required. 2. a) Doors and frames shall be properly reinforced, drilled and tapped for mortised hardware in accordance with the finish hardware schedule. Function holes shall be provided at the factory for locksets and exit devices. Trim mounting holes for hardware are to be drilled and tapped when required in the field by others. b) All doors and frames shall be properly reinforced for surface mounted hardware in accordance with the finish hardware schedule. Drilling and tapping for attaching of surface mounted hardware shall be done in the field by others. 3. Doors and frames shall be thoroughly cleaned, phosphatized and receive one coat of force-cured prime paint. 4. All frames shall be supplied with jamb anchors per sheet and base anchors per sheet . 5. All frames shall be supplied with three rubber silencers per strike jamb for single openings and/or two per head for double openings. 6. All glass and caulking shall be supplied and installed in the field by others. 7. All finish hardware shall be supplied by . 8. All doors and frames shall be marked with . 9. The hardware column on the door and frames schedule sheets is for manufacturing purposes. The headings are designated after receipt of the approved hardware schedule furnished by the hardware supplier. 10.The hardware locations indicated on the door and/or frame elevation sheets are Republic standard locations for the majority of builder's hardware. Special type hardware such as deadlocks, exit devices, etc., will also be located in accordance with Republic's standard locations for that specific hardware item and not at locations per the paper hardware templates received unless it is specifically advised by the Architect. 11.When hollow metal is used in conjunction with aluminum, plastic laminate, structural steel and/or wood products, it will be the responsibility of the general contractor to coordinate all hardware locations. ABBREVIATIONS AND SYMBOLS A 1 SECTION OR DETAIL SHEET NUMBERS ABO = ALUMINUM BY OTHERS CIBO=CHANNEL IRON BY OTHERS CO=CASED OPENING DA=DOUBLE ACTING (SINGLE) D=DOUBLE (PAIR) PROJECT Printed in U.S.A. Revised 5/00 DDA ME MH DM NIC WBO DL/DE DS DB P6 SE DG MG =DOUBLE ACTING (PAIR) =MITERED UNIVERSAL FRAME =MITERED DRYWALL FRAME =McKENZIE EDGE FLUSH DOOR =NOT IN CONTACT =WOOD BY OTHERS =SERIES 4 CHANNEL DESIGNATION =SERIES, STEEL STIFFENED, 4 CHNL DESIGNATION =BEVEL =EMBOSSED 6-PANEL DOOR =STICK MATERIAL =FULL GALVANIZED NON-PRIMED DOOR =FULL GALVANIZED NON-PRIMED FRAME 4= 1-3/4" (44mm) THICK DOOR 8= 1-3/8" (35mm) THICK DOOR TS= TRANSOM SIDELITE BL= BORROWED LITE SL= SIDELITE T= TRANSOM TFWOTB = TRANSOM FRAME WITHOUT TRANSOM BAR DATE DRAWN BY REVISION SHEET OF Form No. RBP 92-B