907.2.1.1 System initiation in Group A occupancies with an occupant

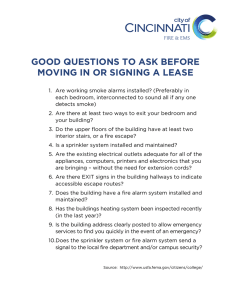

advertisement