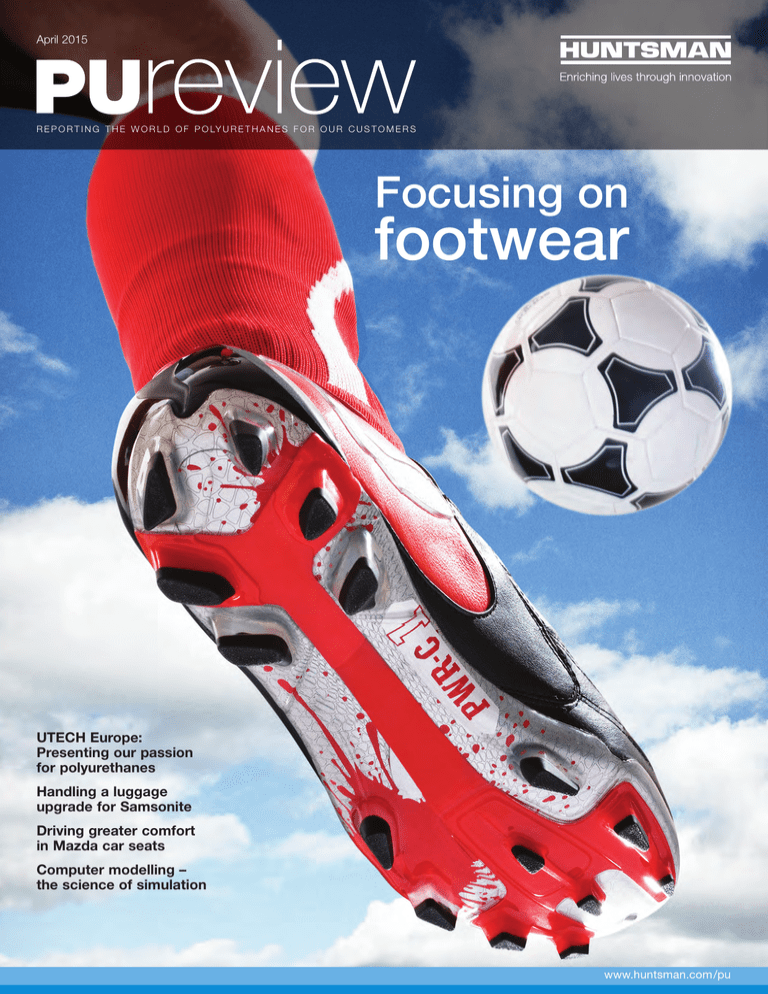

April 2015

R E P O R T I N G T H E W O R L D O F P O LY U R E T H A N E S F O R O U R C U S T O M E R S

Focusing on

footwear

UTECH Europe:

Presenting our passion

for polyurethanes

Handling a luggage

upgrade for Samsonite

Driving greater comfort

in Mazda car seats

Computer modelling –

the science of simulation

www.huntsman.com/pu

PU briefing April 2015

Encouraging signs for our industry in Europe

Tony Hankins, President, Huntsman Polyurethanes

This issue of PU review is being published to coincide with UTECH Europe 2015 in Maastricht, the prestigious polyurethanes

industry event which takes place every three years and which has sister events in America and China. I always find these

gatherings provide a good barometer of the industry mood and serve as a launch pad for new products and applications.

And of course, they provide an excellent opportunity to catch up with our valued customers and make new contacts.

In recent times, there has been a great deal of negative news about the European economy. The polyurethanes industry is

not immune from macroeconomic or geopolitical developments, but I have to say that I see many encouraging signs for our

industry. When you look at the stories in this issue, you’ll read about some exciting innovations that are coming through the

pipeline and which complement the enormous creativity of our European customers.

There is a particular focus on thermoplastic polyurethanes (TPU) – that most versatile range of products. The main feature

(pages 6 to 8) gives an interesting insight into footwear applications, which is a market that Huntsman first became involved

with in the 1970s, when AVALON® TPU was launched. Having led our global footwear business back in the early 1990s,

I still have a special affinity for AVALON®, and it’s great to see our footwear products thriving and our customers continuing to

introduce such cutting-edge innovations.

Huntsman’s presence at UTECH Europe will showcase how we are helping to address global challenges related to food,

energy and comfort. Twenty-five years after joining the industry, I remain as enthusiastic about the wide ranging benefits of

MDI-based polyurethanes as ever. I hope that after reading this magazine, you do too.

Demonstrating our passion for PU

In mid April, Huntsman will be at UTECH Europe 2015, showcasing its

passion for polyurethanes and the ways in which its knowledge of this

specialist chemistry is helping to enrich the lives of people worldwide.

Polyurethanes surround our daily lives – having a

positive impact on the way we move around the

planet; how comfortable we feel; our ability to

save time and energy; and even the food that we

eat. Focusing on these four elements, products

on display at Huntsman’s stand (1210) – within a

special circle of innovation – will include:

• A flexible foam to help optimize comfort in

bedding, furniture and seating applications

• A hydrophilic substrate that can be used in

hydroponic greenhouses and commercial

food growing environments

• A resin to enhance the manufacture of

automotive carbon fiber composite panels

• A new polyurethane resin system that is a

viable alternative to other thermoset-based

tooling products

• Polyurethane additives and catalysts to

improve the performance properties of

polyurethane-based systems

• TPU food contact materials (FCM) suitable

for use in harvesting and picking equipment,

processing and dispensing machinery,

conveyor belts and many other food and

drink-related applications.

2

The team will also be taking part in the

UTECH Europe 2015 conference program.

Tony Hankins, President of Huntsman

Polyurethanes, will deliver the conference

keynote address, discussing the challenges

and opportunities facing the polyurethanes

sector in the medium term, in both Europe

and beyond. Wim Gilis will give a presentation

on the company’s new VITROX ® EST resin

tooling technology. And Geert Dries will

present a paper on emissions limits for

vehicle interiors and how next generation

polyurethane additives and catalysts are

helping original equipment manufacturers

comply with legislative measures. |

ilse_vanden_brande@huntsman.com

Samsonite picks

Huntsman to handle

luggage upgrade

Samsonite, the world’s largest travel

luggage company, has chosen

Huntsman’s TPU to enhance several

lines in its prestigious collection.

At its European manufacturing

headquarters in Oudenaarde, Belgium,

Samsonite is using grades from

Huntsman’s IROGRAN® range to

produce parts for its Lite-Locked,

Lite-Cube, Cosmolite, Firelite and

Chronolite luggage carriers.

In its relentless pursuit for innovation

and quality, Samsonite was keen to

start sourcing more of its raw materials

from Huntsman. Specifically it wanted

an extremely reliable new material

to bond to a polyamide handle.

Samsonite’s product development

experts were very clear about their

requirements. The material needed to

offer good tear strength that could

withstand cuts, abrasion and general

wear while being soft to touch and

aesthetically attractive.

Following recommendations by IMCD,

one of Huntsman’s key distribution

partners, Samsonite decided to run

trials with a plasticizer-free IROGRAN®

TPU that forms excellent bonds to

other materials.

The IROGRAN® TPU in question offered

all the processing properties Samsonite

required, including high shear rate

resistance in the tool during molding

and good strength at higher demolding

temperatures. As well as being soft to

touch with a matt, dry-feel surface

quality, the finished material has an

attractive appearance. It is also

resistant to scratching, marring and

doesn’t show sweat marks or residues.

Supported by Huntsman’s technical

development team, Samsonite ran

a series of product trials. Following

positive results, IROGRAN® TPU was

introduced for full-scale production of

handles for Samsonite’s premium

Lite-Locked and Lite-Cube models.

In addition, Samsonite has switched

to using the same IROGRAN® TPU

material for the production of hinges

on its Cosmolite, Firelite and

Chronolite models.

Rik Hillaert, Vice President,

Manufacturing and Development at

Samsonite, said: “Continual innovation

is key to Samsonite’s success. We are

constantly striving to improve our

products with new designs and

features, adapted to the needs of

consumers in different markets, while

staying true to the Group’s core values

of lightness, strength and functionality.

We have been very pleased with

Huntsman’s technical support and

delighted with the results achieved

with IROGRAN® TPU.” |

simone_richter@huntsman.com

New UV protected TPU grades developed for industrial cables

Huntsman has developed two ultraviolet (UV) protected grades of TPUs for use in offshore, oil and gas,

and mining wire and cable applications.

The polyether-based TPU materials – IROGRAN® A 85 P 4394 UV DP and IROGRAN® A 92 P 4637

UV DP – are part of Huntsman’s established IROGRAN® product range. Both are designed for

jacketing the cables of heavy duty pieces of equipment that have to function in harsh, abrasive and

outdoor environments, and are exposed to the elements.

Over time, exposure to UV light can cause cabling materials to degrade, losing performance in tensile

strength, abrasion and elongation. On oil rigs, offshore wind farms and in underground applications,

any form of deterioration in cable quality is unacceptable and could have costly consequences.

Huntsman’s latest wire and cable innovations were developed in response to requests from

customers in the Americas, who were asking for increasingly demanding performance levels from

their cable jacketing materials.

Easily processed and offering a wide temperature window, Huntsman’s new IROGRAN® materials

contain a UV package that is not listed as a substance of very high concern (SVHC) under REACH

regulations. Designed to increase cable longevity, the inclusion of this additive is beneficial for wire

and cable manufacturers who are looking to improve performance and comply with stringent

environmental standards. |

simone_richter@huntsman.com

www.huntsman.com/pu

3

Improving end caps for

charging electric vehicles

Worldwide, the market for electric cars is growing rapidly

with many leading automotive brands now offering

plug-powered and hybrid vehicles. UK-based think-tank,

the Institute of Economic Affairs (IEA) predicts there will be

1.1 million electric and plug-in hybrid electric vehicle sales

globally by 2015; 6.9 million by 2020; and 106 million by 2050.

Hand in hand with the growth of electric vehicles comes the

need to establish and manage an increasing number of

charging stations.

To improve the longevity of cables and

connectors used to charge electric and

plug-in hybrid vehicles, Mennekes, a leading

manufacturer of industrial plugs and sockets,

is using a TPU from Huntsman.

Headquartered in Kirchhundem, Germany,

Mennekes is employing an IROGRAN® TPU

grade to produce protective caps that fit on

the connector end of type 2 charging cables.

These coupling flexes are used to connect

cars to vehicle charging points, which are

now commonplace around city centres, in

municipal car parks, at petrol stations and by

the roadside. The end caps are put in place

when the cables are not in use, helping to

keep dirt and moisture out of the holes where

the sleeve contacts are inserted.

Mennekes specified IROGRAN® TPU for its end

cap application following recommendations

from Chemie Plast – one of Huntsman’s key

distribution partners. The product development

team at Mennekes were very clear about

their requirements. They needed to source

a material that would offer high wear and

abrasion resistance. The solution also had

to provide very good temperature flexibility.

Mennekes plugs and sockets for the electric

vehicle market have to withstand a range

of temperature extremes from sub-zero

conditions in Norwegian winters to hot and

humid Mediterranean summers.

Before approaching Chemie Plast, Mennekes

had tested other materials including rubber

and numerous thermoplastic elastomers (TPE).

However, they found that these moldings were

prone to leaving scuffmarks when they came

into contact with car paint. To overcome this

problem, Chemie Plast recommended a harder

grade of IROGRAN® TPU.

Mr Thomas Tigges, Plastic Technician at

Mennekes, said: “As ownership of electric

vehicles increases there will be a need for

more publicly accessible charging stations –

and of course more charging cables and end

caps. With new volumes coming through we

wanted to be sure that we were using the

very best material available for our cable caps.

The advice on offer from Chemie Plast,

combined with the quality of Huntsman’s

TPU, was a compelling proposition. We are

delighted with the support offered throughout

the decision making process and with the

end result.”

Mennekes is a family-run business with

subsidiaries and agencies in more than

90 countries, giving it global reach.

The business dates back to the 1930s

when Aloys Mennekes set up a small

electrical workshop. Today, the Mennekes

product portfolio comprises over 15,000

standardised CEE industrial plugs and

sockets in different shapes and designs

for multiple purposes. The business also

produces innovative components for the

increasing electric mobility market including

sockets, charging cables, vehicle plugs as

well as complete charging stations for

commercial and private use. |

simone_richter@huntsman.com

4

New reactor installed

at TEROL®

Performance Polyols site

Huntsman has installed a new reactor at its

TEROL® Performance Polyols manufacturing

facility in Houston, Texas.

The new aromatic polyol reactor, which has

significantly increased the site’s annual

production capacity, is enabling Huntsman to

better serve its customers and meet growing

demand for specialty polyols.

Huntsman offers one of the broadest ranges

of aromatic polyester polyols for rigid foam

applications, with hydroxyl values ranging

from 120 to 350. Its customized polyol

solutions can meet the most demanding

insulation applications from spray

polyurethane foam, boardstock, insulated

metal panels, structural insulated panels to

appliances and commercial refrigeration.

Steve Burns, Vice President, Americas,

Huntsman Polyurethanes, said: “Our

investment in the TEROL® Performance

Polyols manufacturing site illustrates our

continuing commitment to support the

growth of these specialty polyols and the

overall global MDI urethanes sector. By

increasing the site’s production capabilities,

we can drive growth in our downstream MDI

insulation systems business and expand

into new markets.” |

eric_stebel@huntsman.com

TEROL® Performance Polyols

site receives UL

Environment certification

Huntsman has become the first U.S. manufacturer to receive the

Underwriters Laboratories (UL) Environment certification for a polyol.

TEROL® 563 modified aromatic polyester

polyol is primarily used in polyisocyanurate

(PIR) insulation applications. When

formulated and processed properly,

insulation panels produced with TEROL® 563

polyol can pass the Factory Mutual 4450

Calorimeter and ASTM E-84 Tunnel tests.

The UL certification demonstrates that

Huntsman’s TEROL® Performance Polyols

business has the technological expertise

and logistical capabilities to provide an

independent, third party certified range of

recycled content and renewable content

polyols. Huntsman’s aromatic polyester

polyols incorporate both pre-consumer and

post-consumer recycled content, allowing

customers to design their insulation

products with confidence and meet

preferred purchasing protocols.

Les Yamato, Business Manager, TEROL

Polyols, Huntsman Polyurethanes, said:

“Receiving the UL Environment Certification

illustrates Huntsman’s continued commitment

to environmental excellence and providing

high-quality, sustainable insulation products

to our customers. We strive to be an

industry leader in sustainability, and the UL

Environment certification represents another

step toward that goal.” |

eric_stebel@huntsman.com

Brazil machine hall inaugurated

Huntsman has inaugurated a new machine hall for its polyurethanes business, adjacent to the

company’s Advanced Technological Centre (ATC) in Taboão da Serra, Brazil.

Designed to support commercial and technical polyurethanes growth in the Brazilian region, the facility is

being used to develop new polyurethane applications, simulate customer processes and carry out

demonstrations of Huntsman’s specialty systems.

Specialized equipment in the hall includes a high-pressure spray machine for elastomers, polyurea and spray

polyurethane foam; a mix head, high-pressure, injection device for rigid and flexible foam; and a lab scale

batch block machine for slab viscoelastic, high resiliency and rebound applications.

Alongside the new ATC (16,100 sqft.), the instruments in the machine hall will help Huntsman’s polyurethanes

business in Brazil grow strategically in automotive, insulated metal panels (IMPs), slabstock and ACE

(polyurea coatings) markets as well as other sectors. |

eric_stebel@huntsman.com

www.huntsman.com/pu

9

5

Focusing on footwear

Polyurethane chemistry touches all of our lives. Wherever

you are, whatever you are doing, this special material is

hard at work close by. Sometimes the presence of

polyurethanes is invisible. At other times, its benefits can

be clearly felt – for example in shoes and boots. To learn

more about one of the most tangible polyurethane

applications, PU Review spoke to Alfons Tremml,

Commercial Manager for Footwear in Europe at Huntsman.

PU Review (PU R): How long have

polyurethanes been used in the footwear

industry?

Alfons Treml (AT): Polyurethanes were first

introduced to the footwear industry in the late

1960s and have been a popular raw material

ever since – helping manufacturers make

lighter, more comfortable shoes and achieve

greater production efficiencies. Huntsman’s

involvement in the sector dates back to the

early 1970s and the launch of AVALON® TPU

– a range of premium materials developed

specifically for footwear applications.

PU Review (PU R): Is the AVALON® TPU

range still available today?

AT: Yes. More than forty years on, the

AVALON® TPU brand is still going strong.

Footwear manufacturers respect the caliber of

the material and the benefits it can bring to the

processing and performance of shoe soles,

and a variety of other footwear components.

Today, AVALON® TPUs are part of a much

wider portfolio of lightweight polyurethane

materials developed to meet the needs of the

footwear industry.

6

PU Review (PU R): How has the footwear

industry changed since the introduction

of polyurethanes?

AT: The footwear industry has changed

enormously since the 1970s. The last five

decades have been characterized by

tremendous growth. At the end of 2014, the

World Footwear Yearbook reported that more

than 22 billions pairs of shoes were produced

in 2013. While the last few years have been

tricky in some regions because of the global

downturn, industry revenue has continued to

grow overall thanks to continuing demand

from emerging markets such as India.

New fashions, modern manufacturing

techniques and more stringent environmental

standards have also brought about major

change across the industry. As styles have

shifted and production practices have

progressed, material providers have had to

keep pace. At Huntsman that’s meant evolving

our portfolio to create new polyurethanebased systems that continually raise the bar

in terms of material performance, comfort

and processability.

Feature

We’ve had to develop solutions for new

footwear applications that go beyond simply

soling, for example, gel liners and even film

coatings for shoe uppers. Expectations for

better performing materials in terms of

resistance to water, abrasion and static have

also increased.

PU Review (PU R): Can you give us some

specific examples of footwear innovation?

AT: There are many examples of innovation

but three achievements really stand out. In the

early 1990s, our footwear business – then part

of ICI – was the first company to introduce

water-blown polyether footwear systems,

eliminating the use of chlorofluorocarbons

(CFCs). Later that decade we broke new

ground with the first universal prepolymer

for use with both polyester- and polyetherbased systems. Around the millennium we

invented AVALON® Duo – a dual soling

solution that combines the benefits of TPU

and polyurethane.

PU Review (PU R): You mention three

different types of polyurethane: polyester,

polyether and TPU. What sets each apart?

AT: Polyester, polyether and thermoplastic

polyurethanes all have slightly different traits

and as such, lend themselves well to different

footwear applications. As a general rule,

polyester polyurethanes work well in safety

shoe applications. They have a high resistance

to chemicals, as well as substances such as

oil and petrol. They are also ideal for direct-on

processing and for casting unit soles – both

single and double density.

Polyether polyurethanes deliver good pattern

definition, whatever the processing technique

or desired density. They offer outstanding

flex-life properties and hydrolysis resistance.

With the ability to withstand moisture, they are

perfect for producing shoes and sandals worn

in humid, tropical climates where water ingress

and attack from microorganisms that thrive in

warm, damp environments is commonplace.

Then there are TPUs – one of the best

performing footwear materials available in

terms of abrasion and impact resistance, flexlife and optical stability. TPUs can be used to

create unit soles, which are stuck straight to

the upper of a shoe in the latter stages of

manufacture. They can be combined with a

polyurethane midsole to create a dual density

solution. TPUs can also be precision

engineered to create footwear components

including top pieces and molded heels for

ladies fashion shoes; sports plates for soccer,

golf and baseball shoes; plus skates and

ski boots.

PU Review (PU R): What materials do

polyurethanes compete with in the footwear

sector and how does the chemistry compare?

AT: Polyurethanes are one of the only

materials that can be used in almost every

footwear application from outsoles and

midsoles to liners and uppers. This means

they have to compete with all standard

substrates such as ethylene-vinyl acetate

(EVA), vulcanized rubber, thermoplastic

rubbers, polyvinyl chloride (PVC), nylon and

leather. Performance wise, polyurethanes offer

a number of advantages. They enable

footwear manufacturers to produce lighter,

more comfortable shoes. They are easy to

process, helping to improve production line

efficiencies. Polyurethanes can also be

engineered to overcome yellowing and

hydrolysis issues, which can affect footwear

aesthetics and longevity.

PU Review (PU R): How do you see the

footwear manufacturing market developing?

AT: The balance of power in footwear

manufacturing is unlikely to change in the

immediate future. According to the World

Footwear Yearbook, Asia is responsible for

manufacturing an estimated 87% of the

world’s footwear. China remains the

undisputed leader, making almost two out of

every three pairs of shoes sold globally.

In China, it’s very much a numbers game.

Local manufacturers make millions of pairs of

shoes every year so unit prices can be kept

low, which is hard for manufacturers elsewhere

to compete with. Other regions are slowly

becoming more attractive again but this will

take time. Within Asia for example, footwear

companies are slowly starting to shift

production from China to Vietnam, Indonesia

and Taiwan. There is also growing interest in

manufacturing in Cambodia and Myanmar.

In Europe, where it’s more difficult to compete

on cost, the market is largely dominated by

small to medium sized companies making

shoes for niche applications such as safety

footwear – where material performance is

paramount.

It’s largely the same story in America.

According to the American Apparel and

Footwear Association, domestic footwear

companies manufactured just 1.4% of shoes

purchased in the U.S in 2011. Like Europe,

footwear production in the U.S is generally

more specialist, primarily safety footwear but

also military combat boots.

In terms of future growth, India is definitely

a market to watch. There is a big domestic

market for sandals and casual shoes,

which is growing quickly and the industry

is starting to wake up to what’s possible

with polyurethanes.

PU Review (PU R): You mentioned that other

regions are becoming more attractive again as

manufacturing locations – what’s driving this?

AT: There are two key factors. Import

procedures are becoming increasingly

complex – which means domestic

manufacturing is starting to have more

appeal. Processing techniques are also

becoming more automated – making

manufacture in other regions, outside of Asia,

more competitive.

www.huntsman.com/pu

7

Feature

PU Review (PU R): Are there any other

regional differences of note?

AT: Yes. The difference in regional production

levels is reflected in the use of materials and

manufacturing techniques employed around

the world. Polyurethanes and TPUs have a

global share of the footwear market of around

8%. In Europe this rises to approximately 18%

– echoing the emphasis on high quality,

specialist footwear applications.

We also offer customers practical advice to

reduce manufacturing costs and improve staff

training. In recent years we’ve worked with a

number of European manufacturers, helping

them to get new production lines up and

running. This kind of work will remain of high

value as the drive for automation continues as

mainstream footwear manufacturers consider

a return to production in Europe and the U.S,

and need to train more people locally.

In terms of techniques, unit sole casting is

widely used in Asia, South Europe and the

Middle East, where labour costs are generally

lower. While in central Europe and the U.S.,

where employment costs are typically higher,

and there is a move towards more automated

methods, which are far less labour intensive.

PU Review (PU R): Finally, can you tell

PU Review readers what Huntsman

does to support sustainability in footwear

manufacturing?

AT: In a fast paced industry, where so much

is in flux, making a positive sustainability

contribution is not just about making products

that have less environmental impact. That’s

important of course and something we take

very seriously. But sustainability in footwear

manufacturing is also about creating stability.

The footwear industry is highly pressurised, it’s

dominated by seismic seasonal shifts.

Manufacturers need to respond rapidly to

consumer demands. For big manufacturers

this can mean churning out thousands of

new styles every year. For smaller companies

it’s about keeping production sustainable

from a cost perspective so they can

remain competitive.

PU Review (PU R): In such a competitive

sector, how does Huntsman differentiate itself?

AT: We have many strengths; our time in the

market place, the breadth of our portfolio, and

our global capabilities. Customers tell us that

the quality of our technical partnerships also

help us stand out from the competition. From

our dedicated footwear development center in

Belgium, we undertake long-term research

projects into emerging footwear applications.

Liaising with customers we assess future

market trends and develop new materials –

producing samples in house on industry

standard machines that we’ve invested in.

8

We support sustainability by looking at

innovation and people alongside the planet.

It’s our duty to keep a pipeline of new

products coming through that enable

manufacturers to make high quality shoes

and boots at an acceptable cost and with

minimal environmental impact. DALTOPED®

Lite polyether material is one such

example. Launched three years ago, this

ultra-lightweight, cost-effective and highly

versatile alternative to ethyl vinyl acetate

(EVA) makes it possible to produce extremely

lightweight unit soles on existing polyurethane

machinery at a lower production cost

with less wastage.

Huntsman is also involved in corporate social

responsibility initiatives in countries such as

India, which are designed to make the local

footwear industry more sustainable over time.

In Kerala we work with the Footwear Design

and Development Center (FDDC) – a local

charity that helps equip people in rural

communities with the skills they need to enter

the footwear profession – helping to grow

the sector and improve prospects for

people locally.

These are just two examples of how we

are helping to improve sustainability in the

footwear sector. Countless other instances

exist and it’s this well-rounded approach

to supporting sustainability in the footwear

sector that our customers value and

which has given us such a high share of

the market worldwide. |

alfons_tremml@huntsman.com

The PU Review team would also like to thank

the following individuals for their editorial

contribution:

• Leon Chou, Technical Manager for

Elastomers and Regional Footwear Industry

Coordinator at Huntsman’s Asia

Technology Center

• Mark Kwek, Strategic Marketing Manager,

Great Asia

• Memphis Wei, Commercial Manager

Footwear, China

• Colin Tan, Sales Manager, TPU, Great Asia

• Jim McCloud, Senior Sales

Representative, PU

Huntsman TPU is sole choice for Panter

Huntsman’s footwear experts

have been working closely

with Panter (Industrial

Zapatera) – one of the largest

producers of safety shoes

and boots in Iberia.

The two companies have been collaborating on a series of soling projects that have helped

to improve productivity on Panter’s production lines and enhance the performance of its

technical workwear.

Panter has the capacity to produce thousands of pairs of safety shoes every day. Its manufacturing

facility in Alicante, Spain is operational 24 hours a day, six days a week, and employs only the very

best footwear materials.

With help from Huntsman, Panter has switched to using TPU to create soles for a range of its

professional safety boots, which are used in meat processing and butchery environments. Panter

employs Huntsman’s TPU to form a blue transparent outsole with a white mid sole. The material

also offers Panter higher cycle times and good abrasion and slip resistance – a winning combination

over conventional soling options.

Panter has also been working with Huntsman to improve the design of a wellington boot that it

manufactures for a leading Spanish supermarket chain. Employees who work in the supermarket’s

fish / seafood department and distribution depots used to wear boots made from other materials.

However, high levels of humidity and the fact that the boots were heavy and uncomfortable to wear,

meant employees’ feet were prone to sweat.

Together, Panter and Huntsman developed a solution that would perform well in harsh environments

for a long period of time. Lightweight and offering good anti-slip resistance, excellent hydrolysis

resistance and decent cold temperature protection for the wearer – this has been a major step

forward in terms of the safety, comfort and wellbeing of the supermarket’s workers. |

footwear@huntsman.com

Stepping up safety

shoe production

Using a specialist polyurethane material from Huntsman, SCHÜTZE-SCHUHE – an Austrian manufacturer of

premium quality, professional footwear – has developed a next generation soling solution for a new range

of light, fashionable, safety shoes that have electric static discharge (ESD) properties.

SCHÜTZE-SCHUHE is a family-run business,

best known for making hardwearing boots that

enable construction employees to work on hot

asphalt for more than an hour. The organization

also has an established range of roofing shoes

that offer exceptional grip.

When SCHÜTZE-SCHUHE decided to diversify

and create a range of ESD safety shoes, the

business began looking for a new polyurethane

supplier to work flexibly with. The ideal partner

had to be located in central Europe; willing to

develop a double-density soling solution

tailored to specific requirements; and capable

of providing hands-on technical support.

SCHÜTZE-SCHUHE contacted Huntsman and

together the two companies embarked on the

development of a bespoke soling solution

based on Huntsman’s DALTOPED® DUAL

DENSITY technology. Following a period of

rapid product development and successful

trials at Huntsman’s footwear technology

center in Belgium, SCHÜTZE-SCHUHE began

using the DALTOPED®-based material to

create a compact polyurethane outsole with

a foamed, soft polyurethane midsole.

Thomas Schützeneder, CEO of SCHÜTZESCHUHE, said: “Our business is renowned for

making shoes and boots that are tough and

have a long working life but are comfortable

enough to be worn eight hours a day, week

after week. We only pick the very best

materials and never compromise quality – two

values we carried through to our work with

Huntsman. Forging new supplier relationships

can be daunting but the transition to working

with Huntsman was a really positive

experience. They took a flexible approach

to innovation, provided exactly the kind of

material we needed and the technical support

they gave was invaluable.”

Following completion of its dual density soling

project for SCHÜTZE-SCHUHE, Huntsman

is now supplying the business with additional

products for other aspects of its production

set up – including the lines where its

highly insulated asphalt boots and slip

resistant roofing shoes are manufactured. |

footwear@huntsman.com

www.huntsman.com/pu

9

Polyurethane shows different

side to exterior cladding

Polyurethane chemistry is used extensively across the

construction industry. Typically it’s found in insulation to make

buildings more energy efficient and in adhesive, coating and

elastomer products, where it can help enhance durability,

toughness and overall aesthetics.

Now, polyurethanes are also proving their

benefits in siding, cladding and exterior trim

applications thanks to the efforts of Boral –

an international building and construction

materials group.

Combining a proprietary polyurethane

chemistry that utilizes Huntsman products with

fly ash (a by-product of coal-fired electric

generating plants), Boral has developed

TruExterior™ Siding and Trim – a new category

of products for exterior building applications

such as cladding, sofits, fascias, door casings

and window surrounds, which have historically

employed wood.

Less susceptible to the elements

Described by Boral as a poly-ash structure,

TruExterior™ products are engineered to look

like traditional wood-based siding and trim

solutions. Similar in weight but far less

susceptible to degradation from insects or

exposure to the elements, TruExterior™ requires

very little maintenance. It can be painted

any color and is easy to cut, route, drill and

mill using traditional woodworking tools

and methods.

Unlike other exterior trim solutions such as

wood, wood composites, fiber cement, or

vinyl/PVC, TruExterior™ products maintain a

high level of dimensional stability during periods

of moisture and temperature change. They are

also suitable for ground contact and do not

require end-sealing, special adhesives or other

costly installation techniques.

More than 70% recycled content

Furthermore, the TruExterior™ material has

excellent sustainability credentials. Consisting

of more than 70% recycled content blended

with a relatively low level of polyurethane

component, TruExterior™ is manufactured in

a LEED® Silver facility using a proprietary low

emission and low energy usage production

process. As a result, the products can

contribute to a building’s LEED® pursuits.

It can also help reduce lifecycle costs.

Boral’s development of TruExterior™ Siding

and Trim is indicative of a wider shift in the

construction market towards man-made

materials that are more resource efficient

and have greater potential to reduce energy

consumption and environmental impact.

Brian Below, President of Light Building

Products at Boral, said: “Across the

construction industry, the last two decades

have seen enormous change in the use of

building materials. Government mandates

and legislative measures, designed to boost

the energy efficiency of buildings, have led

to the evolution of existing technologies and

the development of many new alternative

products. Several years ago we spotted a

gap in the exterior trim market for a new type

of material. Industry feedback told us that

engineered wood, PVC and fiber cement

solutions were working well as wood

substitutes – but still had their drawbacks.

Moisture resistance, stability during

temperature fluctuations, and workability

challenges were just some of the issues

raised by users.”

10

“Realizing that no single material offered exactly

the right mix of attributes we decided to

develop a solution that would work as a true

replacement for wood trim. With builders and

homeowners accustomed to the workability

of wood we knew we needed to develop

a product that would look good, and offer

excellent durability, but be easy to cut and

fasten. We did just that, testing and trialing

all aspects of the TruExterior™ material over a

six year period and creating a product unlike

anything else available.”

Proven performance

Before its launch, the TruExterior™ material

underwent rigorous internal and third party

tests to verify its performance and durability,

even in the harshest of climates. Third-party

certification group MBDC has assessed

TruExterior™ Siding and Trim for its overall

impact to health and the environment and

certified it with a Cradle to Cradle™ Silver rating.

Scientific Certification Systems (SCS) Global

have also certified that the products have

greater than 70% recycled content. |

eric_stebel@huntsman.com

For more information:

www.BoralAmerica.com/TruExterior or

Nadine.sizemore@boral.com

Automotive

focuses on reducing

A

growingteam

technology

noise, vibration and ride harshness

In the food industry, demand for fresh crops, all year round, is

increasing. Consumers are now accustomed to having ready access to

fruit and vegetables, regardless of season. With the global population

booming – and estimated to surpass nine billion by 2050 – pressure on

food supplies is set to intensify.

In the Netherlands there is a mature, high tech, hydroponics industry continually growing food to

meet national and international demand. To support this sector, Huntsman has developed a

special hydrophilic material. With a special affinity for water, the technology has been designed for

use in commercial greenhouses and food-growing environments, in the production of tomatoes,

peppers, cucumbers, eggplants and salad leaves.

The material, marketed as BVB SUBLIME® substrate, is produced in conjunction with

BVB Substrates – a Dutch specialist in greenhouse horticulture. Clean, inert and easy to use it has

a high pore volume that gives it an excellent water holding capacity. A well balanced water /air ratio

enables it to release moisture to plant roots slowly, over time.

Delivering a comparable performance to existing plant growing substrates, BVB SUBLIME ®

substrate is ideal for use in greenhouses employing traditional hydroponics growing systems, as

well as NFT – the nutrient film technique. Via this method, salad leaves grow in a watertight gully.

At the bottom of the channel, a shallow stream of water containing dissolved nutrients circulates

past the bare roots of plants. A continuous supply of oxygen is also provided, encouraging the

root system to establish on a substrate at the base of the waterway.

Growing plants using BVB SUBLIME® substrate has further advantages. With the need for soil

eliminated, greenhouse drains can be kept clear. In addition, the roots of salad plants such as

lettuce are kept clean – and require less preparation before distribution to retail outlets.

Huntsman and BVB Substrates have worked together for five years undertaking trials to ensure

that BVB SUBLIME® substrate complies with food safety standards. Tested by numerous growers

and research stations, the material is now used in commercial greenhouses worldwide and

interest in this ‘next generation substrate’ is increasing.

As well as commercial hydroponic growing mats, BVB SUBLIME® substrate can be shaped into

grow plugs and propagation blocks, supporting the different stages of the plant growth cycle –

and a growing industry with the potential to benefit everyone on the planet. |

dave_burge@huntsman.com

For further information about BVB SUBLIME® substrate, contact: psonneveld@bvb-substrates.nl

www.huntsman.com/pu

11

Bio-based foam chosen for car headrest

In the March 2014 edition of PU

Review we announced Huntsman’s

successful development of a

special polyurethane prepolymer

based on rapeseed oil. This major

achievement* was instigated to

enable the production of more

sustainable polyurethane materials

for the automotive sector, where

there is a major drive for resources

with a strong renewable element.

Image for illustration only.

This issue we can announce that the Windsor

Machine Group (WMG) is now creating

headrests for a leading automotive

manufacturer using a fully formulated,

polyurethane foam from Huntsman, based on

this novel chemistry.

The bio-based headrests are the first of their

kind to be produced in Europe and employ

RUBIFLEX® H Bio – the name given to

Huntsman’s rapeseed oil /MDI-based

foam system.

WMG works with some of the world’s bestknown automotive brands. Its design engineers

have a reputation for developing creative

solutions that can significantly improve the fuel

efficiency of cars and the manufacturing

processes used to create them. The headrests

are being manufactured by WMG in Slovakia,

at a facility that opened in 2014.

Rob Purves, Windsor Machine and Stamping

Supplier Quality Manager at WMG, said:

“It’s hard to believe that the foam system

developed by Huntsman is bio-based. Its

quality is excellent, outperforming many of the

other materials we’ve tested. Crucially, the

percentage of bio-based content it contains

is also significantly higher. When we first

contacted Huntsman we wanted to find a foam

with a minimum bio content of 5% – to meet

OEM requirements. Huntsman recommended

RUBIFLEX® H Bio foam system. With 9% bio

content; no adverse effects on performance

properties; and a better process window;

we knew instantly that it represented a major

leap forward in foam technology.”

12

Incorporating bio polyols into foam production

has proved complicated in the past. The

presence of sustainable ingredients has

negatively impacted on both the processing

and performance capabilities of the resulting

material. Bio polyols are typically incompatible

with standard polyether-polyol combinations

used in the manufacture of flexible molded

polyurethanes. As a result the bio polyol can

separate very quickly. If this occurs, re-mixing

with a different storage tank and pump is

needed – which can be costly and time

consuming. Some bio polyols can also have

a detrimental effect on curing and final

mechanical properties.

Huntsman’s innovation team worked to

overcome this problem, developing a bio polyol

that has been pre-polymerized with specific

MDI isomers. As a result, RUBIFLEX® H Bio

foam system offers a better process window –

enabling the production of different foam parts

of a different hardness, density and shape.

Demold times are also short. The complete

cycle time is around three minutes.

Huntsman and WMG began discussions in

November 2013. The conversation was timely.

Huntsman had just initiated conversations with

Oleon about its bio prepolymer development

project. Impressed by what it heard,

WMG decided to work with Huntsman in

February 2014.

Huntsman’s first task was to define the right

prepolymer / polyol formulation based on

WMG’s specification and process conditions.

With parameters agreed, Huntsman created

foam prototypes at its technical development

center in Deggendorf, Germany. Once WMG

were happy, Huntsman offered additional

support, performing quality checks including

PPAP (Production Part Approval Process) –

a common standard developed by the

Automotive Industry Action Group (AIAG) that

establishes confidence in component suppliers

and their production processes. As production

commenced, Huntsman helped WMG further,

carrying out an audit of its health and safety

practices and delivering the polyurethane

industry’s Walk the Talk training program.

Continuing, Rob from WMG, said: “In addition

to supplying a top quality bio-based foam,

Huntsman’s full service package had strong

appeal. We’ve been producing headrests in

other parts of the world for many years but as

a relative newcomer to Europe, we needed an

MDI partner that was prepared to offer more

than just materials. With a new site to bring

online, equipment to install and people to train,

Huntsman’s development, prototyping and

technical support was invaluable – and an

added bonus alongside its bio-based system.”

WMG commenced production of the new

headrests in Q4 2014 (October). At the time

of going to press, Huntsman was the only

MDI supplier offering a bio-based prepolymer

technology to automotive OEMs in Europe. |

christophe_ponce@huntsman.com

* Huntsman’s bio-based prepolymer

was realized with support from French

agribusiness Sofiproteol)

Driving comfort in the new Mazda2

An all-MDI automotive seating system based on Huntsman’s

polyurethane chemistry is being used to drive greater comfort

levels in the brand new Mazda2, also known as the Mazda Demio.

Developed for Mazda by Huntsman and Toyo

Seat & Takaya – a Japanese car seat and

headrest supplier – the automotive seating

system is being used in the cushion and back

panel of the vehicle’s front seats.

The Mazda2 is a sporty, 1.3 liter, compact car.

Voted World Car of the Year in 2008, the

vehicle has exceptional fuel economy and is

widely regarded as sleek, stylish and fun to

drive. Awarded five stars in the Euro NCAP

safety ratings, the latest model of the Mazda2

is lighter than previous versions and has CO2

emission levels as low as 115g/km. It has a

carefully considered interior and according to

claims on the Mazda website, the company

has perfected the ergonomics of the car’s

seats and steering wheel.

Takaya introduced Huntsman to Mazda in

2013. Following a series of meetings to discuss

the benefits of using Huntsman’s polyurethanes

in automotive seating systems, Mazda agreed

that Takaya and Huntsman could work

together to develop a brand new system for

the latest Mazda2 model.

Over the following year, a team lead by Sansan

Wu, Technical Manager, at Huntsman’s Asia

Technical Center (ATC) in Shanghai, worked to

develop the system. Supported by Huntsman’s

automotive experts in the EAIME region, and

working closely alongside the Takaya team,

Huntsman ran a number of evaluations and

demonstrations at Takaya’s production line

in Japan.

Mazda sign off was secured in early 2014

and mass production of the system began

in October 2014. Today, Huntsman, Toyo

Seat & Takaya and Mazda are continuing

towork closely together to evaluate how

Huntsman’s all-MDI system could be

employed in other vehicles in the automotive

manufacturer’s range.

Julian Young, Japanese Transplant Manager,

Automotive and Flexible Industry at Huntsman

said: “The use of our all-MDI seating system in

the Mazda2 is a huge achievement for our

automotive team and represents a major

milestone for our Japanese business. Mazda

is one of the world’s major automotive

manufacturers. It has been a real honor to

work on a project that is so central to the

experience of people driving one of its most

popular vehicles. For most people, buying

a car is a major financial and emotional

investment, so ride quality can be a deciding

factor in the purchasing process. Polyurethanes

have been used across the automotive industry

for many years to help improve vehicle

performance and comfort. We are delighted

that Mazda has recognized the benefits of this

chemistry and is realizing the value it can add

to its vehicles worldwide.” |

ada_xu@huntsman.com

Huntsman wins Johnson Controls performance award

Huntsman has received a bronze Supplier Performance Award from Johnson Controls, Inc.

(JCI) for demonstrating excellence in all aspects of its supplier / customer relationship.

Every year, JCI – the largest global supplier of automotive interiors and seating in terms of market share – evaluates the

services it receives from its suppliers via a comprehensive review and sustainability survey.

The award is judged on six categories: quality, commercial (which includes cost-saving objectives), supply team

management, service and general expectations, social and environmental sustainability, and general performance.

The top performers are subsequently awarded prizes in categories that focus on quality; commercial activity; supply chain

management; service and general expectations; social and environmental sustainability; and general performance.

Huntsman has been supplying its MDI RUBINATE® products to JCI’s automotive interiors and seating

businesses for many years. The business received its prize – one of just twenty-four trophies given out –

at JCI’s annual North American Supplier Performance Awards ceremony in Plymouth, Michigan. |

eric_stebel@huntsman.com

www.huntsman.com/pu

13

New PU tooling technology breaks the mold

Huntsman has made a major tooling technology breakthrough. The business has

developed a new polyurethane resin system that cures extremely quickly and allows

the production of high heat stable modeling, tooling and rapid prototyping boards.

The availability for the first time of an effective, high temperature stable polyurethane will open up a world of

new opportunities in a wide range of sectors including aerospace, automotive, marine and shipbuilding.

With a glass transition temperature (Tg) of 200°C and higher, the new generation VITROX® EST system offers

product designers, tooling manufacturers and mold-makers a viable polyurethane alternative to other

thermoset-based tooling products – with a number of additional advantages.

The fast cure features of Huntsman’s VITROX® EST system make it possible to significantly reduce demolding

and manufacturing cycle times. This can help manufacturers increase productivity, reduce energy costs and

cut carbon emissions. The VITROX® EST system can also be precisely formulated to suit specific

requirements – offering added flexibility and broadening scope for innovation.

VITROX® EST system’s high Tg properties mean a constant coefficient of thermal expansion (CTE) from room

temperature to 200°C is achievable. This enables the creation of products and tooling boards with improved

long-term stability when exposed to high temperatures. Products and tooling boards made with the VITROX®

EST system also demonstrate better impact resistance and good machinability. Processing benefits include a

long, tunable pot life (5-20 minutes) and a low viscosity. Furthermore, the system is processable on low

pressure casting machines. |

wim_gilis@huntsman.com

Encouraging model behavior

Using computer-modeling techniques to understand how a material,

object or structure will behave over time, or when exposed to different

environments or circumstances, is now a fundamental part of the product

design process – regardless of application or end market.

Employing established modeling methods –

adapted for its own purposes – Huntsman

uses the science of simulation to gain a deeper

understanding of what it is possible to achieve

with polyurethanes. This strategic approach is

delivering major benefits for Huntsman

customers across a range of sectors, inspiring

innovation. PU Review spoke to Jan

Vandenbroeck to discover more.

“Architects and structural engineers would

never dream of constructing a high-rise

building without investigating how it would

cope in an adverse weather event or natural

disaster. Similarly, automotive manufacturers

would never approve new car concepts

without exploring every aspect of its design,

from aerodynamics to its performance on

different surfaces.

Diving deeper into polyurethane chemistry

“When it comes to road testing polyurethanes

and creating new MDI-based systems for

specific applications, we apply the same rules.

Several years ago we decided to invest in

computer modeling and dive deeper into

polyurethane chemistry.

“At our R&D headquarters in Belgium we

formed a dedicated computer modeling team

14

to study how polyurethanes perform in certain

scenarios. This five-strong group applies

algorithms and equations to help fine tune

chemical formulations and achieve the product

properties our customers want. Sometimes the

projects we work on are customer specific.

Some are driven by our own ideas. Others are

run in conjunction with world-renowned

universities and institutions including the

Belgian and Dutch governments, and the

European Union.

Layering additional information

“Computer modeling in the polyurethanes

industry has been around for a while but we’re

taking it a step further. Take flexible foams as

an example. In the past, computer modeling

helped define the structure of a polyurethane

foam. Today, we can simulate what the perfect

foam would look like and layer that information

with data about external influences and their

impact on processing and performance

properties. These extra insights are helping us

create innovative polyurethane-based products

that are truly fit for purpose.

“In recent years, we helped develop

ACOUSTIFLEX® S – a special form of sound

insulation. Going beyond conventional R&D

techniques, we explored the chemical /

acoustic relationship of the system to maximize

its ability to muffle sound. To help improve

building energy efficiency, we are using our

computer modeling capabilities to investigate

how the thermal properties of insulation can be

improved to develop super insulating materials.

And in the automotive industry, we are helping

vehicle manufacturers define what comfort –

delivered by polyurethane foams – should feel

like. Many manufacturers already run their own

tests to help quantify what is ultimately a

subjective area. Our work builds on this,

translating their requirements into specific

product parameters. We’ve also recently

introduced a CT scanner to our research lab,

enabling the 3D analysis of foam and

composite structures.” |

jan_vandenbroeck@huntsman.com

RUBIFLEX® Cocoon technology

creates cool comfort

RUBIFLEX® Cocoon technology is a new technology from Huntsman that’s been

developed with human wellbeing top of mind. Used to manufacture cool,

breathable, flexible foams, RUBIFLEX® Cocoon technology can significantly

enhance comfort in bedding, furniture and seating applications by reducing the

build up of heat and moisture that transfers from the body when it is at rest.

The availability of RUBIFLEX® Cocoon

technology makes it possible to fabricate

foams that combine the very best attributes of

existing memory and high resilience foam

solutions, with a number of additional benefits.

The resulting foam slabs provide excellent

support and good pressure distribution – gently

cradling the body and minimizing pressure

points to maximize blood flow and promote

quality sleep and relaxation.

With an open cell structure, the natural

increase in humidity produced by the body is

dispersed very effectively. Airflow permeability is

also high – helping to transport heat way from

the body’s surface. Tests show that the

temperature build up in a RUBIFLEX® Cocoonbased foam is more than 1.5°c lower than in a

comparable memory foam solution. Combined,

these qualities help support the body’s natural

thermoregulation mechanisms.

With RUBIFLEX® Cocoon technology, comfort

is heightened further still thanks to the unique

moisture management properties of the

system. Special hygrothermal attributes help

dissipate the natural accumulation of heat and

moisture generated by the body when it comes

into contact with mattresses, pillows, toppers,

armchairs, sofas and car seats.

RUBIFLEX® Cocoon technology is now in

commercial use. Spanish company Colchones

y Componentes Aspol is using it to produce

a range of mattresses for one of the

biggest department store chains in Europe,

El Corte Inglés.

The polymer structure of RUBIFLEX® Cocoon

technology offers a good balance of hydrophilic

and hydrophobic segments – enabling water

vapor permeability and moisture transmission.

foams also have an excellent wet compression

set and good tear strength. Conforming to

LGA and CertiPUR standards they meet low

VOC requirements. Furthermore, they can be

vacuum packed and are suitable for use in

adjustable mattresses.

andy_walton@huntsman.com

Foams based on RUBIFLEX® Cocoon

technology have a dry yet silky feeling and

work well in all climates. They are durable and

resilient, retaining their original feel, thickness

and shape over time – despite changes in

temperature conditions. RUBIFLEX® Cocoon

Forthcoming events and

technical presentations

List of forthcoming events:

European Coatings Show, Nürnberg, Germany (21-23 April)

Ligna, Hannover, Germany (11-15 May)

Chinaplas, Guangzhou, China (20-23 May)

2015 Polyurethanes Technical Conference, Orlando, Florida

(5-7 October)

Fakuma, Friedrichshafen, Germany (13-17 October)

WoodEx, Moscow, Russia (24-27 November)

Leathertech, Dhaka, Bangladesh (26-28 November)

Find us on:

Facebook: www.facebook.com/huntsmancorp

Twitter: www.twitter.com/Huntsman_Corp

LinkedIn: www.linkedin.com/company/huntsman

Google Plus: www.plus.google.com/106818920361803832093

YouTube: www.youtube.com/user/HuntsmanCorp

For more information on the subjects covered in PU Review

magazine, please contact the editor:

Ilse Vanden Brande, ilse_vanden_brande@huntsman.com,

+32 (0) 2 7589420

While all the information and recommendations in this publication are to the best of

our knowledge, information and belief accurate at the date of publication, nothing

herein is to be construed as a warranty, express or otherwise.

ACOUSTIFLEX®, AVALON®, DALTOPED®, IROGRAN®, RUBIFLEX®,

RUBINATE®, TEROL® and VITROX® are registered trademarks of Huntsman or

an affiliate thereof in one or more, but not all, countries. BVB SUBLIME® is a

registered trademark of Bas van Buuren B.V. LEED® is a registered trademark of

U.S. Green Building Council (ISGBC). Boral TruExterior ® Trim boards is a

registered trademark of Boral Composites Inc.

Copyright © 2015 Huntsman Corporation. All rights reserved.

Designed and produced by: Chris Pearson creative communications.

www.huntsman.com/pu

15

We create better comfort and durability.

Together.

At Huntsman Polyurethanes, we believe that working in true collaboration with customers is

the only way to solve complex problems and find the solutions that will deliver real innovation.

So, we strive with a passion and determination to build the deep understanding of our

customers that’s required to get to the heart of their needs and establish lasting partnerships.

We provide customers with a wide choice of footwear solutions, based on many different

polyurethane chemistries. From fully formulated grades and tailor-made polyesters to

polyether-based systems and TPU grades, we give footwear companies the freedom to

design innovative shoes, boots and sandals in step with the latest fashion trends,

manufacturing techniques and environmental concerns. Combine our knowledge of

polyurethanes with your expertise, and we'll create better footwear… together.

www.huntsman.com/pu