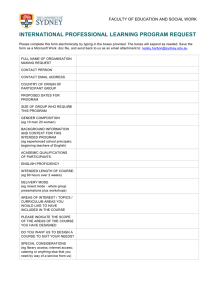

section 16130 - outlet boxes, junction boxes, and gutters (wireways)

advertisement

Copyright 2014 Ingenuity Engineers, Inc. / L3 Healthcare Design, Inc. 01/2014 SECTION 16130 - OUTLET BOXES, JUNCTION BOXES, AND GUTTERS (WIREWAYS) PART 1 - GENERAL 1.1 SCOPE: A. This section outlines the quality, type and installation of outlet boxes, junction boxes and gutters (wireways) for general and special use. PART 2 - PRODUCTS 2.1 GENERAL: A. All boxes and fittings shall be labeled by Underwriters' Laboratories, Inc. B. Interior outlet boxes shall be galvanized steel constructed with stamped knockouts in back and sides, and threaded holes with screws for securing box coverplates or wiring devices. C. Weatherproof outlet boxes shall be corrosion-resistant cast type suited to each application and having threaded conduit ends, cast face plate with spring-hinged waterproof cap suitably configured, gasket, and corrosion-proof fasteners. D. Provide outlet box accessories for each installation, including mounting brackets, wallboard hangers, extension rings, device rings, outlet boxes, and corrosion-resistant knockout closures compatible with outlet boxes being used and meeting requirements of individual wiring situations. E. Pull boxes and junction boxes shall be constructed of code gauge galvanized sheet steel. Provide pull boxes with screw-on covers of the type and size to suit each respective location and installation. Boxes shall have continuously welded seams and shall be equipped with steel nuts, bolts, screws, and washers. Provide cast metal, gasketed type pull boxes for outdoor locations. F. All boxes shall be sized by NFPA 70. G. NOTE: PVC junction boxes may be utilized for boxes located in elevated concrete decks. OUTLET BOXES: 2.2 A. Shall be standard type, with knockouts, made of hot dipped galvanized steel as manufactured by Steel City, Raco or Appleton. B. Ceiling outlet boxes shall be 4" octagon or square with plaster ring 1-1/2" deep or larger when required due to number of wires. C. Boxes shall be provided with approved 3/8" fixture studs where required. D. Except when located in exposed concrete block, switch and receptacle boxes shall be 4" square with plaster or masonry rings for single gang installation. Appropriate gang boxes shall be used for mounting ganged switches. E. When installed in exposed concrete block, switch and receptacle boxes shall be masonry type stamped steel boxes. OUTLET BOXES, JUNCTION BOXES, AND GUTTERS (WIREWAYS) 16130 - 1 Copyright 2014 2.3 Ingenuity Engineers, Inc. / L3 Healthcare Design, Inc. 01/2014 JUNCTION BOXES AND PULL BOXES (INTERIOR): A. Sheet Metal: Shall be standard NEMA 1 type with hinged lockable cover, with knockouts, made of hot dipped galvanized steel as manufactured by Steel City, Raco or Appleton. B. Cast: Shall be type FS, FD, JB, GS, or SEH for application. C. Mounting Panel: Provide removable plywood internal mounting panel for component installation. 2.4 JUNCTION AND PULL BOXES (EXTERIOR): A. 2.5 Shall be precast concrete for all below grade exterior use and where shown. All boxes installed above grade shall be NEMA 3R weatherproof and watertight, or as indicated on the drawings. CABINETS: A. Comply with UL 50, "Electrical Cabinets and Boxes" and NEMA ICS 6. B. Construction: Sheet steel, NEMA 12 class except as otherwise indicated. Cabinet shall consist of a box and a front consisting of a one piece frame and a hinged door. Arrange door to close against a rabbet placed all around the inside edge of the frame, with a uniformly close fit between door and frame. Provide concealed fasteners, not over 24" apart, to hold fronts to cabinet boxes and provide for adjustment. C. Provide flush or concealed door hinges not over 24" apart and not over 6" from top and bottom of door. For flush cabinets, make the front approximately 3/4" larger than the box all around. For surface mounted cabinets, make front same height and width as box. D. Doors: Double doors for cabinets wider than 24". E. Locks: Combination spring catch and key lock, with all locks for cabinets of the same system keyed alike. Locks shall be of a type to permit doors to latch closed without locking. All cabinets to be provided with locks. F. Mounting Panel: Provide removable plywood internal mounting panel for equipment and component installation. G. Provide color-coded identification nameplates for all junction boxes over 6" x 6” square per specification SECTION 16011 - ELECTRICAL SCOPE. H. Cabinets shall be Square D #24366, surface mounted with integral lockable cover and internal plywood backboard and ground bar. PART 3 - EXECUTION INSTALLATION: 3.1 A. Comply with applicable portions of the National Electrical Contractor's Association's (NECA) "Standard of Installation". OUTLET BOXES, JUNCTION BOXES, AND GUTTERS (WIREWAYS) 16130 - 2 Copyright 2014 Ingenuity Engineers, Inc. / L3 Healthcare Design, Inc. 01/2014 B. Install all boxes and fittings in compliance with NFPA 70, the manufacturer's written instruction, and with recognized industry practices. C. For locations exposed to weather or moisture (interior or exterior), provide weatherproof boxes and accessories. D. Install pull boxes in all raceways runs having more than 270 degrees total bending (all directions combined and each complete offset counting as 90 degrees) or in runs more than 200' long. E. Provide knockout closures to cap unused knockout holes where blanks have been removed, and plugs for unused threaded hubs. F. Boxes and conduit bodies shall be located so that all electrical wiring is accessible. G. All boxes shall be sized per NEC Article 370. H. Install pull boxes and wire troughs with front covers accessible per code requirements. I. All flush floor outlets shall be leveled and flush with floor; shall be parallel and perpendicular to building construction lines and shall be compatible with floor material used. Verify the exact location of floor boxes with Owner's Authorized Representative prior to concrete pour. Maintain the fire rating through floors. J. All recessed boxes shall be installed in a flush rigid manner with box lines at perpendicular and parallel angles to finished surfaces. Boxes shall be supported by appropriate hardware selected for the type of surface from which the box shall be supported. For example, provide metal screws for metal, wood screws for wood, and expansion devices for masonry or concrete. K. The Contractor shall coordinate work with that of all trades so that each electrical box is the type suitable for the wall or ceiling construction provided. L. Provide supporting channel and hardware as necessary to support boxes, enclosures, and cabinets. INSTALLATION OF OUTLET BOXES: 3.2 A. Outlet boxes shall be securely fastened to structural members and shall not be supported by dry wall, gypsum board, plaster, etc. The device or plate installed in conjunction with the outlet box shall not be used for support. B. Surface fixture outlet boxes shall be set so edge of cover comes flush with finished surface. C. There shall be no more knockouts opened in any outlet box than are actually required. D. Boxes shall be sealed during construction. E. Back-to-back boxes shall be staggered at least 3" or by UL listing for rated walls. F. Under no circumstances shall thru-the-wall boxes be used. OUTLET BOXES, JUNCTION BOXES, AND GUTTERS (WIREWAYS) 16130 - 3 Copyright 2014 G. 3.3 Ingenuity Engineers, Inc. / L3 Healthcare Design, Inc. 01/2014 Outlet boxes two gangs and wider shall not be supported by attachment clips or any means which supports the box from less than two opposite sides. Such outlet boxes in stud walls shall be supported securely by support members spanning between studs. INSTALLATION OF JUNCTION BOXES: A. Provide junction or pull boxes where shown on the drawings and to facilitate installing conductors. Such boxes shall be "Code" sized unless required to be larger by the plans or other sections of this specification. All junction boxes shall be accessible. B. Junction boxes shall be securely fastened to the building structure independent of ductwork, plumbing, etc. Junction boxes shall not be supported by conduit fittings. C. Boxes to be embedded in concrete shall be properly leveled and anchored in place before the concrete is poured. D. There shall be no more knockouts opened in any box than are actually required. E. Boxes shall be properly protected during construction and shall be cleaned of all foreign matter before conductors are installed. F. All junction boxes shall be located a minimum of 12” and maximum of 36” from ceiling grid. Overhead junction boxes may not be installed where accessibility is dependent on removal of a lighting fixture or access cover. No junction shall be located above drywall ceiling. All junction boxes’ locations shall be coordinated with all other trades such that all are accessible. G. Wall mounted junction boxes and terminal cabinets shall be mounted at a maximum height of 60” AFF. END SECTION 16130 OUTLET BOXES, JUNCTION BOXES, AND GUTTERS (WIREWAYS) 16130 - 4