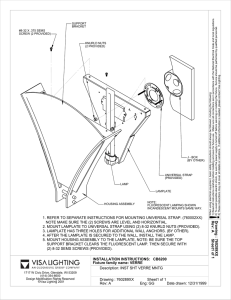

02454 Series Installation and Surface Mount Version

advertisement

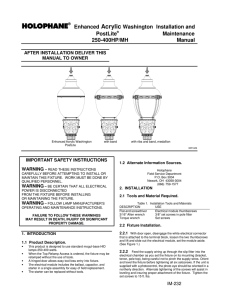

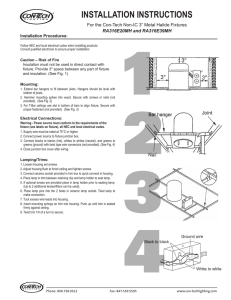

02454 Series Surface Mount Version AFTER INSTALLATION DELIVER THIS MANUAL TO OWNER IMPORTANT SAFETY INSTRUCTIONS WARNING - READ THESE INSTRUCTIONS Installation and Maintenance Manual 1 INTRODUCTION 1.1 Product Description. The 02454 Series lighting fixtures have been listed to applicable U.S. and Canadian safety standards by Underwriters Laboratories Inc. They are suitable for use in damp locations, and ambient temperatures up to 40 degrees Celsius. Fixture weight: 40 to 60 pounds. CAREFULLY BEFORE ATTEMPTING TO INSTALL OR MAINTAIN THIS FIXTURE. WORK MUST BE DONE BY QUALIFIED PERSONNEL. WARNING - BE CERTAIN THAT ALL ELECTRICAL POWER IS DISCONNECTED FROM THE FIXTURE BEFORE INSTALLING OR MAINTAINING THE FIXTURE. WARNING - FOLLOW LAMP MANUFACTURER’S OPERATING AND MAINTENANCE INSTRUCTIONS. FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN DEATH, INJURY OR SIGNIFICANT PROPERTY DAMAGE. 1.2 Alternate Information Sources. If additional questions arise relative to this lighting fixture that this document or your supplier cannot answer, please refer them to: Holophane Corporation Field Service Department P.O. Box 3004 Newark, OH 43058-3004 (866) 759-1577 2 INSTALLATIONS 2.1 Tools and Material Required. The following tools and materials are required during installation of 02454 Series lighting equipment: TABLE 1. Installation Tools and Materials DESCRIPTION USE Power drill Ceiling or girder mount Nutdrivers, Socket set or Flat-blade Screwdrivers Ceiling or girder mount Wiring box closure screw Access cover screws 1/8” Allen wrench Stem setscrew 1/4“ Hex Key Compact Fluorescent electrical cover 2.2 H.I.D. Installation. See Figures 1 & 2 next page. 2.2.1 For ceiling-mount and/or through wiring, the ceiling must be GR969 suitable for supporting a minimum of 75 pounds. Mount the quickinstall box to the ceiling or girder with four (4) #10 screws. Tighten the screws securely. Install conduit, conduit nuts and conduit bushings as required by code. WARNING DO NOT SUSPEND THE LUMINAIRE SOLELY FROM AN OUTLET BOX. THE LUMINAIRE WEIGHT EXCEEDS THE 50# CAPACITY OF OUTLET BOXES. FAILURE TO PROVIDE ADDITIONAL SUPPORT MAY RESULT IN INJURY OR DEATH OR SIGNIFICANT PROPERTY DAMAGE. GR1114 2.2.2 Hang the electrical assembly on the hinge of the quick-install box, and make the supply wire and ground wire connections. 2.2.3 Swing the electrical assembly up and secure it to the quickinstall box with the captive screw. 2.2.4 Loosen the two screws and remove the access cover from the swivel plate. 2.2.5 Pull the electrical assembly wires through the slot of the swivel plate. IM-159-A 2.2.6 Verify that the lamp type and wattage indicated on the relamp information label on the optical assembly matches the lamp type and wattage information on the nameplate label on the electrical assembly 2.2.7 Install the stem assembly to the optical assembly, tighten the conduit thread securely and tighten the setscrew. 2.2.8 Insert the stem fitting through the keyhole of swivel plate making sure the notch in the fitting mates to tab in swivel plate. 2.2.9 Splice the wires from the stem to the electrical assembly wires using the color-coding to match them. If the EM Option is provided there will be five splices. Figure 1 handles against the side of the lamp socket husk. While supporting the bottom of the glass refractor disengage the wire bails from the refractor and lower the refractor to expose the lamp socket. 2.2.12 Lift the glass access covers just enough to shift it sideways from the opening in which it is seated. Remove the cover by rotating it until it will slip out through the access hole in the bottom glass. 2.2.13 Install the proper lamp type (See the relamp information on the optical assembly) and tighten the lamp securely into the socket. 2.2.14 If the bottom glass includes the small removable glass access cover, insert the cover through the access opening, being careful not to break the lamp, and seat it into its original position. Otherwise, to close the optical assembly, position the glass refractor back in its original position and hold it in place with one hand while engaging the bails and closing the latches with the other hand. 2.3 Compact Fluorescent Installation. See Figures 2 & 3 WARNING IF INSTALLED IN CANADA THE LUMINAIRE MUST BE MOUNTED INDEPENDENTLY OF AN OUTLET BOX. Figure 3 Figure 2 GR769 GR1113 2.3.1 Attach the mounting bracket to the superstructure by inserting at least two screws through the holes in the mounting bracket. 2.3.2 Turn the mounting bracket counter-clockwise to lock into position and tighten the screws. 2.3.3 Install the stem assembly to the optical assembly, tighten the conduit thread securely and tighten the setscrew. 2.3.4 Pull the optical assembly wires through the keyhole of the mounting bracket. 2.3.5 Insert the stem fitting through the keyhole of mounting bracket GR1004 2.2.10 Secure the access cover to swivel plate with the two screws. 2.2.11 If the bottom of the optical assembly includes a small removable glass access cover, proceed to paragraph 2.2.13. Otherwise, to open the optical assembly, slowly release the latch making sure hole in the fitting matches up with the hole in mounting bracket. 2.3.6 Secure the stem in place by tightening the screw from the stem as shown in figure 3. 2.3.7 Splice the wires from the stem to the electrical assembly wires using the color-coding to match them. If the EM Option is provided there will be five splices. 2.3.8 If the bottom of the optical assembly includes a small removable glass access cover, proceed to paragraph 2.3.11. Otherwise, to open the optical assembly, slowly release the latch handles against the side of the lamp socket husk. While supporting the bottom of the glass refractor disengage the wire bails from the refractor and lower the refractor to expose the lamp socket. 2.3.9 Lift the glass access cover just enough to shift it sideways from the opening in which it is seated. Remove the cover by rotating it until it will slip out through the access hole in the bottom glass. 2.3.10 Install the proper lamp type (See the relamp information on the optical assembly) and tighten the lamp securely into the socket. IM-159-A 2.3.11 If the bottom glass includes the small removable glass access cover, insert the cover through the access opening, being careful not to break the lamp, and seat it into its original position. Otherwise, to close the optical assembly, position the glass refractor back in its original position and hold it in place with one hand while engaging the bails and closing the latches with the other hand. 3.3.11 Check the interior of the housing for evidence of damage or potentially hazardous conditions. 3.3.12 Reassemble closure plate to the electrical assembly; install the original 1/4-20 screws and torque to 55-65 in.-lbs. Be sure screws are fully seated and are not cross threaded. 3 MAINTENANCE INSTALL THE PROPER CLOSURE SCREWS USING THE PROCEDURES AS INSTRUCTED ABOVE. FAILURE TO DO SO MAY RESULT IN INJURY OR DEATH. WARNING 3.1 H.I.D Removal of the Electrical assembly. WARNING REMOVE THE ELECTRICAL ASSEMBLY TO A HORIZONTAL WORK SURFACE BEFORE ATTEMPTING TO REMOVE EITHER OF THE TWO LARGE SCREWS SECURING THE CLOSURE PLATE TO THE HOUSING. FAILURE TO DO SO MAY RESULT IN INJURY OR DEATH. 3.1.1 Disconnect electrical power to the fixture. 3.1.2 Loosen the two screws and remove the access cover from the swivel plate. 3.1.3 Disconnect the electrical wire splices and remove the stem fitting from the keyhole opening in the swivel plate and lay the optical assembly aside. 3.1.4 Back out the captive screw securing the electrical assembly to quick install box, and swing electrical assembly down on hinge. 3.1.5 Disconnect the supply wires and ground wire. 3.1.6 Remove electrical assembly from quick install box hinge. 3.2 Compact Fluorescent Removal of Electrical assembly. 3.2.1 Disconnect electrical power to the fixture. 3.2.2 Remove set screw from cover holder and slide electrical assembly cover down the stem. 3.3.13 Reinstall the fixture as instructed in paragraphs 2.2.2 through 2.2.12 or 2.3.1 to 2.3.10 3.4 Relamping and Cleaning. 3.4.1 Disconnect electrical power to the fixture. 3.4.2 Brush off loose dirt and debris. The optical assembly may be cleaned with water and mild detergent to assure maximum optical performance. Dry the assembly with a soft cloth. 3.4.3 To access the lamp, see paragraphs 2.2.11 and 2.2.12. 3.4.4 Remove the old lamp and discard in a safe and legal manner 3.4.5 Install the proper lamp type (see the relamp information on the optical assembly) and tighten the lamp securely into the socket. 3.4.6 To close the optical assembly, see paragraph 2.2.14. 3.4.7 Check the exterior of the housing for evidence of damage or potentially hazardous conditions. 3.4.8 Re-connect electrical power to the fixture and check for proper operation. 4 Limited Warranty and Limitation of Liability The Holophane limited warranty and limitation of liability is published in the "Terms and Conditions" section of the current Holophane buyer's guide, and is available from your local Holophane sales representative. 3.2.3 Remove the screw that connects the stem to the mounting bracket. 3.2.4 Securing the unit, turn the stem until the key at the end of the stem slides out of the mounting bracket. 3.2.5 Disconnect the supply wires and ground wire. 3.2.6 Remove mounting bracket from superstructure. ® 3.3 Electrical Component Replacement. Electrical components located inside the electrical assembly can be replaced as follows: 3.3.1 Disconnect electrical power from the fixture and remove the electrical assembly according to paragraph 3.1 or 3.2. 3.3.2 Place the electrical assembly on a horizontal work surface. Note: Steps 3.3.3 to 3.3.13 for H.I.D. only. 3.3.3 Open the housing by removing the 1/4-20 screws (2) securing the closure plate. Keep the screws for reassembly. 3.3.4 Tag all electrical leads for identification when installing the new components. 3.3.5 Break the electrical connections. 3.3.6 Remove the attaching hardware and retain it for re-use. 3.3.7 Remove the electrical components. 3.3.8 Place the new components into position being sure not to pinch any wires. 3.3.9 Install the attaching hardware. Tighten the fasteners securely. 3.3.10 Make electrical connections in accordance with wire tags and proper wiring practices. Acuity Lighting Group, Inc. 214 Oakwood Ave., Newark, OH 43055 IM-159-A 1/03 ©2003 Acuity Brands Inc. Visit our web site at www.holophane.com Printed in USA IM-159-A