holophane - Acuity Brands

advertisement

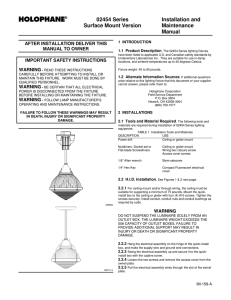

HOLOPHANE® Enhanced Acrylic Washington Installation and PostLite® Maintenance 250-400HP/MH Manual AFTER INSTALLATION DELIVER THIS MANUAL TO OWNER Enhanced Acrylic Washington PostLite with band with ribs and band, medallion GR1426 IMPORTANT SAFETY INSTRUCTIONS 1.2 Alternate Information Sources. WARNING – READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL OR MAINTAIN THIS FIXTURE. WORK MUST BE DONE BY QUALIFIED PERSONNEL. WARNING – BE CERTAIN THAT ALL ELECTRICAL POWER IS DISCONNECTED FROM THE FIXTURE BEFORE INSTALLING OR MAINTAINING THE FIXTURE. WARNING – FOLLOW LAMP MANUFACTURER’S OPERATING AND MAINTENANCE INSTRUCTIONS. FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN DEATH, INJURY OR SIGNIFICANT PROPERTY DAMAGE. 1. INTRODUCTION 1.1 Product Description. • • • • • Τhis product is designed to use standard mogul-base HID lamps 250-400 watts. When the Top Relamp Access is ordered, the fixture may be relamped without the use of tools. A hinged door allows easy tool-less entry into fixture. Τhe electrical module includes the ballast, capacitor, and starter in a single assembly for easy of field replacement. The starter can be replaced without tools. Holophane Field Service Department P.O. Box 3004 Newark, OH 43058-3004 (866) 759-1577 2. INSTALLATION 2.1 Tools and Material Required. Table 1. Installation Tools and Materials DESCRIPTION USE Flat-end screwdriver Electrical module thumbscrews 3/16" Allen wrench 3/8” set screws in pole fitter Torque wrench Set screws 2.2 Fixture Installation. 2.2.1 With door open, disengage the white electrical connector that is attached to the terminal block, loosen the two thumbscrews and lift and slide out the electrical module, set the module aside. (See Figure 1.) 2.2.2 Feed the supply wiring up through the slip fitter into the electrical chamber as you set the fixture on its mounting (bracket, tenon, pole top), being careful not to pinch the supply wires. Orient and level the fixture before tightening all six setscrews. If the unit is supplied with a photocontrol, the photo eye should be oriented in a northerly direction. Alternate tightening of the screws will assist in leveling and insuring proper attachment of the fixture. Tighten the set screws to 15 ft. lbs. IM-232 2.2.3 Secure the supply wires to the fixture by tying them or 3.1.2 Lamp Access installing a strain relief clamp. 2.2.4 Connect the electrical supply wires to the terminal block in the bottom of the electrical chamber. The terminals are marked “L1” (Line 1), “G” (Ground), and “L2” (Line 2). If one of the supply lines is electrically neutral, it should be connected to terminal “L2”. Dress the wiring neatly against the bottom of the chamber to allow the installation of the electrical module. 2.2.5 Lift the electrical module to the opening of the housing and slide the module into place and tighten the thumb screws. Plug in the keyed electrical disconnect, being certain that the snap lock engages on the disconnect latches. Figure 1 Standard Units: Note the orientation of the “Street Side” marking on the refractor. Loosen the optic mounting clips screws. Lift the refractor off of the electrical housing. See Figures 2 and 3 Units with top re-lamping access: Grip the finial on top of the fixture; rotate it counter clockwise until the bar is free from threads on shaft. Lift up on finial, shift bar to one side and remove lamp access cap. See Figure 4. 3.1.3 Remove the lamp and dispose of it in a safe and proper manner. 3.1.4 Install the proper lamp type. Tighten the lamp carefully but securely. 3.1.5 Re-install the lamp access cap by inserting the clamp bar under flange of refractor, rotate the finial clockwise until the clamp bar becomes tight against refractor. 3.1.6 Energize the fixture and check for proper operation. 3.2 Electrical Component Replacement 3.2.1 With door open, remove the starter and photocontrol if supplied. The starter is removed by lifting and sliding out and disconnecting the electrical connector, the photo control is removed by twisting it counterclockwise. If no other components are to be replaced go to section 3.2.6. Disengage the white electrical disconnect that is attached to the terminal block, loosen the two thumbscrews and lift and slide out the electrical module. (See Figure 1.) 3.2.2 Unplug the electrical disconnect, disengage the retaining hook from the housing bracket and remove the electrical module. Figure 2 LAMP ACCESS CAP GR1427 2.2.6 Close door and latch. 2.2.7 Install the proper lamp type through the opening in the top of the refractor. Tighten the lamp carefully but securely. OPTICS ORIENTATION NOTES Some of the fixtures in this series are equipped with optical components that produce distributions of light that are not symmetric and are intended to be aimed by orienting the prismatic refractor a specific direction. The “Street Side” marking on the housing should be pointed toward the street. 2.2.8 Install refractor onto electrical housing. Verify that the lip on the refractor slips past the optic mounting clips on the electrical housing. See Figures 2 and 3. Tighten the optics mounting clip screws 2.2.9 Energize the fixture and check for proper operation. 3. MAINTENANCE 3.1 Re-lamping and Cleaning STREET SIDE MARKING 3.1.1 Wipe off exterior dirt and debris from the plastic surfaces using a soft, clean cloth. CAUTION DO NOT USE ABRASIVE CLEANSERS ON OPTICAL SURFACES. THEIR USE MAY RESULT IN THE LOSS OF OPTICAL EFFICIENCY. GR1095 IM-232 Figure 3 Figure 4 GR1033 NOTE The entire electrical module can be replaced by another module, allowing maintenance on the original electrical module to be performed in the shop. If a complete replacement electrical module is being used, skip to step 3.2.5 3.2.3 Tag all leads that will be disconnected and note the orientation and position of all components that will be replaced and the fasteners holding them. Remove the component(s) to be replaced. NOTE The capacitor may be removed by disengaging the hook on the end of the coiled wire bracket from the top lip of the capacitor and lifting the capacitor out of the coiled wire bracket. 3.2.4 Use components supplied by Holophane. Place the new components exactly as were the original components and reuse the original fasteners to secure them. Check for pinched wires before tightening down the replacement components. Tighten all fasteners firmly. Bundle and secure the wiring in a manner similar to the way it was originally secured to avoid pinching of wires when reinstalling the module into the housing. Replace all shields/insulation as originally installed. 3.2.5 Re-install the electrical module by, lifting it to the opening of the housing, and slide module into place and tighten the thumbscrews. Plug in the keyed electrical disconnect, being certain that the snap lock engages on the disconnect latches. (See Figure 1). 3.2.6 If the unit was supplied with a starter or photo control reinstall them. 3.2.7 Close door and latch. 3.2.8 Energize the fixture and check for proper operation. GR840A 4. LIMITED WARRANTY AND LIMITATION OF LIABILITY The Holophane limited warranty and limitation of liability is published in the "Terms and Conditions" section of the current Holophane buyer's guide, and is available from your local Holophane sales representative. ® Acuity Lighting Group, Inc. 214 Oakwood Ave., Newark, OH 43055 IM-232 8/03 ©2003 Acuity Lighting Group Inc. Visit our web site at www.holophane.com Printed in USA IM-232