www.usa.siemens.com

Guide to machine safety standards

and safety terminology

White Paper | January, 2013

Objective of safety systems

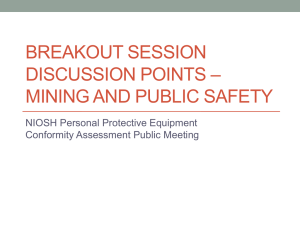

The objective of safety systems is to keep potential hazards

for both people and the environment as low as possible by

using suitable technical equipment, without restricting

more than absolutely necessary, industrial production,

the use of machines and thereby increasing productivity.

There are different concepts and requirements to guarantee

safety in the various regions and countries around the

globe. For example, in the EU, there are requirements

placed both on the manufacturer of a plant or system as

well as the operating company, which are regulated using

the appropriate European Directives, Laws and Standards.

On the other hand, in the US, requirements differ both at

a regional and even at a local level.

However, throughout the USA there is a basic requirement

that an employer must guarantee a safe place of work. In

the case of damage, as a result of the product liability laws,

a manufacturer can be made liable for damage caused by

his product. On the other hand, in other countries and

regions, other requirements apply.

A white paper issued by: Siemens.

© Siemens Industry, Inc. 2013. All rights reserved.

What is important for machinery manufacturers and plant

construction companies is that the legislation and rules of

the location where the machine or plant is being operated

always apply. For instance, the control system of a machine,

which is operated and used in the US, must fulfill US

requirements, even if the machine manufacturer (i.e. the

OEM) is based in Europe. Although the technical concepts

with which safety is to be achieved are subject to clear

technical principles, it is still important to observe as to

whether legislation or specific restrictions apply.

White paper | Guide to Machine Safety Standard | January, 2013

Safety systems and functional safety

From the perspective of the object to be protected, safety

cannot be segregated. The causes of danger and also the

technical measures to avoid them can vary widely. This is

the reason that a differentiation is made between various

types of safety, e.g. by specifying the particular cause of a

hazard. For instance, the term “electrical safety” is used if

protection has to be provided against electrical hazards

and the term “functional safety” is used if the safety is

dependent on the correct function.

To achieve this, specifically qualified technology is required,

which fulfills the requirements described in the relevant

standards. The requirements to achieve functional safety

are based on the following basic goals: Avoiding systematic

faults, controlling systematic faults and controlling random

faults or failures. The measure for the level of achieved

functional safety is the probability of the occurrence of

dangerous failures, the fault tolerance and the quality

that should be guaranteed by avoiding systematic

faults. Various terminology is used to express this in

the standards. In IEC 61508: “Safety Integrity Level”

(SIL) and EN ISO 13849-1 “Performance Level” (PL)

and “Categories.”

This differentiation is now reflected in the most recent

standards, in so much that there are special standards

that are involved with functional safety. In the area of

machine safety, EN ISO 13849 (derived from EN 954) and

IEC 62061 specifically address the requirements placed on

safety-related control systems and therefore concentrate

on functional safety. In the basis safety standard IEC

61508 (also EN 61508 and DIN EN 61508 / VDE 0803) IEC

addresses the functional safety of electrical, electronic

and programmable electronic systems, independent of

any specific application area.

Standards ensure safety

The demand to make plant, machines and other

equipment as safe as possible using state-of-the-art

technology comes from the fact that manufacturers

and users of equipment and products are responsible

for their safety. By maintaining and fulfilling the machine

safety standards, it can be ensured that state-of-the-art

technology is achieved – therefore ensuring that a

company, erecting a plant or a manufacturer producing

a machine or a device has fulfilled his responsibility for

ensuring safety.

In order to achieve the functional safety of a machine

or plant, the safety-relevant parts of the protective

and control systems must function correctly and must

respond in the event of a fault in such a way that the

system remains in a safe state or is brought into a

safe state.

European standards for safety of machinery

European machine safety standards are hierchically structured as follows:

Basic

safety

standards

Type A standards

Basic definitions

for all machinery

Group

safety

standards

Type B1 standards

Higher-level safety

aspects

Specialist

standards

EN ISO 12100

Safety of machinery

- Basic terminology, general principles for design

- Principles for risk assessment

Maximum gaps

to avoid crushing

of parts of the

human body

Safety-related

parts of control

systems

Safety distances

to prevent danger

zones being

reached by the

upper limbs

Electrical

equipment

of machines

Safety of

machinery

interlocking

devices with and

without tumbler

EN 349

EN 62061

EN ISO 13849-1

EN 294

EB 60204-1

EN 1088

Type B2 standards

Requirements for

safety devices

(Reference to

special protective

device/guards)

Two-hand control

device

Emergency stop

equipment, functions,

aspects

- Principles for design

Light barriers,

light curtains

EN 574

EN ISO 13850

EN 614961-1

Type C standards

Specialist standards for

specific requirements on

specific machines

Lifts

Injection

molding

machinery

Presses & shears

EN 81-3

EN 201

EN 692

EN 693

A white paper issued by: Siemens.

© Siemens Industry, Inc. 2013. All rights reserved.

Numerically

controlled

turning

machines

EN ISO 23125

White paper | Guide to Machine Safety Standard | January, 2013

Recommendation

Technology is progressing at a tremendous pace, which

is also reflected in changes made to machine concepts.

For this reason, especially when using type C Standards,

they should be checked to ensure that they are up-to-date.

It should also be noted that it is not mandatory to apply

the standard, but instead, the safety objectives must

be achieved.

If there are no harmonized European standards, or they

cannot be applied for specific reasons, then a manufacturer

can apply “National Standards”. All of the other technical

rules fall under this term of the machinery directive, e.g.

also the accident prevention regulations and standards,

which are not listed in the European Council Journal

(also IEC or ISO standards, which were ratified as EN). By

applying ratified standards, the manufacturer can prove

that recognized state-of-the-art technology was fulfilled.

However, when such standards are applied, this does not

automatically represent a presumption of conformity as

for a harmonized standard.

US machine safety standards

Understanding machine safety standards and terms

remains a challenging first step to spotting and reducing

risks and increasing profitability. Sources for help are

many. Standards organizations covering machine safety

include American National Standards Institute (ANSI),

National Fire Protection Association (NFPA), Robotics

Industries Association (RIA), and U.S. Occupational

Safety & Health Administration (OSHA), among others.

Requirements are numerous; some are more obvious

than others.

Watch for these common safety violations

When doing any plant walk-through, open your eyes

(behind safety glasses, of course) to the most common

safety violations, which may include:

• E-Stop pushbutton: Must be red palm or mushroom head with yellow background;

• Non-inspected fire extinguishers: approx. $1,200 fine;

• Fan guard opening greater than 1/2-in.: approx.

$1,500 fine;

• If a machine is modified, a new risk assessment is

required; and

Almost all new or revised US machine safety standards

require risk assessment to be done.

General information

The Occupational Safety and Health Act (OSHA) from

1970 regulates the requirements for employers to ensure

safe working conditions.

The core requirements of the OSH Act are administered

through the Occupational Safety and Health Administration

A white paper issued by: Siemens.

© Siemens Industry, Inc. 2013. All rights reserved.

(also known as OSHA). OSHA deploys regional inspectors

to check whether workplaces comply with the valid rules

and regulations.

The rules and regulations of OSHA – relevant for safety

at the workplace – are defined in OSHA 29 CFR 1910.xxx

(“OSHA Regulations (29 CFR) PART 1910 Occupational

Safety and Health”) (CFR: Code of Federal Regulations),

Subpart O - Machinery and Machine Guarding.

Additional information can be found in the Internet

(www.osha.gov).

Minimum requirements of the OSHA

The OSHA Rules under 29 CFR 1910 Subpart O, include

general requirements for machines (1910.212) and a

series of specific requirements for certain machine types.

OSHA regulations define minimum requirements to

guarantee safe places of employment.

However, they should not prevent employers from applying

innovative methods and techniques, e.g. “state-of-the-art”

protective systems in order to maximize the safety of

employees.

In conjunction with specific applications, OSHA specifies

that all electrical equipment used to protect employees

must be certified for the intended application by a

Nationally Recognized Testing Laboratory (NRTL)

authorized by OSHA.

OSHA general duties clause section 5: It’s the LAW

Each Employer:

• Shall furnish to each of his employees employment and a place of employment, which are free from recognized hazards that are causing or likely to cause death or

serious physical harm to his employees;

• Shall comply with occupational safety and health

standards promulgated under this Act.

Each Employee:

• Shall comply with occupational safety and health

standards and all rules, regulations and orders issued

pursuant to this Act, which are applicable to his own

actions and conduct.

Application of other standards

In addition to the OSHA regulations, it is important to

carefully observe the up-to-date standards of organizations

such as ANSI, NFPA and RIA as well as the extensive product

liability legislation in the US. As a result of the product

liability, it is in the interest of manufacturers and operating

companies to carefully observe and maintain the regulations

– and they are more or less “forced” to fulfill the state-ofthe-art technology requirement.

White paper | Guide to Machine Safety Standard | January, 2013

Third-party insurance contracts generally demand that

the parties involved fulfill the applicable standards of the

standardization organizations. Companies who are selfinsured initially do not have this requirement. However,

|in the case of an accident, they must prove that they

had applied generally recognized safety principles.

NFPA 70 (known as the National Electric Code (NEC)) and

NFPA 79 (Electrical Standard for Industrial Machinery)

are two especially important standards regarding safety

in industry.

Both of these describe the basic requirements placed on

the features and the implementation of electrical equipment.

The National Electric Code (NFPA 70) predominantly applies

to buildings, but also to the electrical connections of

machines and parts of machines. NFPA 79 applies to

machines. The NFPA 79, 2012 is said to be the benchmark

for industrial machinery safety and is aligned with the

NEC and NFPA 70E.

NFPA 79

This standard applies to the electrical equipment of

industrial machines with rated voltages of less than

600 V. (A group of machines that operate together in a

coordinated fashion is considered to be a machine.)

• Original NFPA 79 1997 – Restricted machine safety t

electromechanical devices.

9.6.3 Where a Category 0 stop is used for the emergency

stop function, it shall have only hardwired electromechanical

components. In addition, its operation shall not depend

on electronic logic (hardware or software).

• NFPA 79 2002 – Allowed the use of safety PLC in

safety-related functions.

11.3.4 Use in Safety-Related Functions. Software and firmware-based controllers to be used in safety-related functions shall be listed for such use. [Annex to NFPA 79 2002,

A.11.3.4 IEC 61508]

• NFPA 79 2007 – Allowed drives as a final switching device.

9.2.5.4.1.4 Drives or solid-state output devices designed

for safety-related functions shall be allowed to be the final

switching element, when designed according to relevant

safety standards.

• NFPA 79 2012 – Allowed the use of cableless control,

see 9.2.7.1 below.

9.2.7.1* General. Cableless control (e.g., radio, infrared)

techniques for transmitting commands and signals

between a machine control system and operator control

station(s) shall meet the requirements of 9.2.7.1.1

through 9.2.7.1.4. The core requirements placed on

programmable electronics and buses include: System

requirements (refer to NFPA 79 2012 9.4.3.4.2).

A white paper issued by: Siemens.

© Siemens Industry, Inc. 2013. All rights reserved.

Control systems incorporating software- and firmware

based controllers performing safety related functions shall

be self-monitoring and conform to all of the following:

(1) In the event of any single failure, the failure shall:

– Not lead to the loss of the safety-related function(s)

– Lead to the shutdown of the system in a safe state

– Prevent subsequent operation until the component failure has been corrected

– Prevent unintended startup of equipment upon

correction of the failure

(2) Provide protection equivalent to that of control systems incorporating hardwired/hardware components

(3) Be designed in conformance with an approved

standard that provides requirements for such systems.

Requirements placed on programmable equipment (see

NFPA 79 2012 9.4.3.1) Software and firmware-based

controllers to be used in safety-related functions shall be

listed for such use. (OSHA states listed as being certified

by an NRTL)

UL

In order to implement the requirements listed in NFPA 79:

2007, UL has defined a special category “Programmable

Safety Controllers” (code NRGF). This category involves

control devices that contain software and are intended

to be used for safety-related functions.

IEC 62061 or EN ISO 13849-1 should also be considered

when taking into account functional safety and when

using new technologies, e.g. wireless-based suspended

operator panels incorporating electronic shutdown devices.

A precise description of the categories as well as a list of

the devices that fulfill these requirements are provided

in the Internet:

www.ul.com –> certifications directory –> UL Category

code / Guide information –> search for category “NRGF”

In addition to Underwriters Laboratories Inc. (UL), TÜV

SÜD Product Services GmbH (TUVPSG) and TUV Rheinland

of North America, Inc. (TUV) are also NRTL’s for these

applications.

UL functional safety mark program

With the advent and evolution of functional safety

standards in North America and Europe, UL is now

offering a UL Functional Safety Listing Mark that can be

added for those qualifying companies in the process of

getting a traditional Listing from UL. For more details visit

www.ul.com/functionalsafety

White paper | Guide to Machine Safety Standard | January, 2013

ANSI B11

The ANSI B11 standards are common standards, which

have been developed by associations -– e.g. the Association

for Manufacturing Technology (AMT), National Fire

Protection Association (NFPA) and the Robotic Industries

Association (RIA). For more details, visit www.ansi.org

Cooperation between OSHA and ANSI

The ANSI and OSHA memorandum of understanding

allows ANSI to use its technical resources to assist OSHA in

carrying out its responsibilities. Some applicable standards

and guidance follow.

ANSI B11.19 - 2010: Performance criteria for

safeguarding

Standards below are referenced in and are intended to be

used with “ANSI B11.19 - 2010: Performance Criteria for

Safeguarding.” Standards always are subject to revision;

investigate the possibility of applying the most recent

editions of any standard referenced.

• ANSI / NFPA 79 - 2007: Electrical Standard for Industrial Machinery.

Some standards below are for informative reference and

are included for information only, for full list see pages

9-11 of the ANSI B11.19 - 2010

• CFR 1910.147 ISO 13849-1 – 2008, IEC 60204-1, IEC 61496-1/2/3 ANSI / NFPA 70 – 2008,

• ANSI B11.1/.2/.3/.4/.5/.6/.7/.8/.9/.10/.11/.12/.13/.14/.15/.

16/.17/.18/.19/.20/.21/.22/.23/.24

See the appropriate ANSI B11 machine tool safety standard

for safeguarding selection requirements based on a

specific application. (See examples below.) Selection of

the safeguarding requires task and hazard identification,

and the application of risk assessment and risk reduction

of the total production system. (See ANSI B11.TR3 on risk

assessment and risk reduction).

• ANSI B11.3 – 2002 (R2007): Power Press Brakes

• ANSI/RIA 15.06: Safety Requirements for Industrial

Robots and Robot Systems

• ANSI B20.1: Conveyors

• TR-3 - 2000: Risk Analysis

• TR-4 - 2004: Failsafe PLC Application

• TR-6 - 2010: Safety Control Systems for Machine tools

• ANSI B11.19 - 2010 - 4.2.3: The user shall ensure that

when any change of the tooling, process or procedure occurs, the safeguarding continues to meet the

requirements of the standard and the ANSI B11.

“base” standard (the standard dealing with the specific

machine), see ANSI B11-0. Changes in the production system that may affect the safeguarding include, but

are not limited to tooling changes, addition or removal

A white paper issued by: Siemens.

© Siemens Industry, Inc. 2013. All rights reserved.

of auxiliary equipment, modification to the machine

systems, operation method (program) change in operation

personnel, adjustment location of safeguarding, and

part configuration. Adjustments to the safeguarding or

supplemental safeguarding may be necessary.

ANSI B11.19 - 2003 - 5: Hazard Control: Hazards associated

with the use of the safeguarding shall be identified and

controlled as part of the overall risk reduction strategy.

The overall hazard identification and risk reduction strategy

is identified in each ANSI B11 “base” standard or in ANSI

B11.0 (B11.TR3). These documents are used to select

safeguarding appropriate to the foreseeable tasks and

identified hazards.

Risk assessment standards

The risk analysis is used to assess the hazards that a machine

presents. Risk analysis is an important requirement

according to NFPA 79 - 2012, ANSI/RIA 15.06 1999, ANSI

B11.0 2010 and SEMI S10. A suitable safety technology/

system can be selected using the documented results of

a risk analysis - based on the specified safety class of the

particular application.

As a result of their design and functionality, machinery

and plants represent potential risks. Therefore, the

machinery directive requires a risk assessment for every

machine and, if relevant, risk reduction, so that the

remaining risk is less than the tolerable risk.

The following standards should be applied for the

techniques to evaluate and assess these risks:

• For Europe:

EN ISO 12100 “Safety of machinery – basic terminology, general principles for design – risk assessment and risk reduction”

EN ISO 12100 mainly describes the risks to be

considered and design guidelines to minimize risk

and also focuses on the iterative process with risk

assessment and risk reduction to achieve safety.

• For USA:

ANSI B11.0 - 2012, Safety of Machinery; General

Requirements and Risk Assessment

This standard applies to new, modified or rebuilt power driven machines, not portable by hand, used to shape and/or form metal or other materials by cutting, impact, pressure, electrical or other processing techniques, or a combination of these processes. Incorporates the bulk of ANSI B15.1-2000 (R2008) and ANSI B11.TR3

Safety standards reduce operating costs

By now it is well understood, as shown by numerous

safety research studies, customer application case studies

and testimonies that not only does safety protect plant

personnel but increases productivity and provides a cost

saving of at least 30%. Companies that implement safety

functions, perform functional safety evaluations, and

implement safety in manufacturing processes by following

the guidelines mentioned in the machine safety standards

and complying with their requirements are finding

benefits where few expected to – on the bottom line.

There are other financial benefits of implementing safety

standards. One, is global acceptance which opens up

the more global opportunities. Another important one is

insurance companies have started to recognize machine

safety compliance, its benefits and that can reflect

favorably on the insurance premiums.

Additional organizations and links:

For more information on these topics, reference the

following links.

Siemens Industry Inc. http://www.usa.siemens.com/safety

ANSI

(American National Standards Institute)

http://www.ansi.org

OSHA

(Occupational Safety and Health Administration)

http://www.osha.org

NFPA

(Occupational Fire Protection Association)

http://www.hfpa.org

TUV

Rheinland of N.A. Inc.

http://www.us.tuv.com

UL

(Underwriter Laboratories)

http://www.ul.com

CSA

(Canadian Standards Association)

http://www.csa.ca

CCOHS

(Canadian Center for Occupational – Health and Safety)

http://www.ccohs.ca

NIOSH

(National Institute of Occupational Health and Safety)

http://www.cdc.gov/niosh/homepage.html

NSC

(National Safety Council)

http://www.nsc.org

ASSE

(American Society of Safety Engineers)

http://www.asse.org

RIA

(Robotic Industries Association)

http://www.robotics.org

http://www.tuv-sud.com

A white paper issued by: Siemens.

© Siemens Industry, Inc. 2013. All rights reserved.

White paper | Guide to Machine Safety Standard | January, 2013

Machine safety definitions explained

Actuating control(s): An operator control(s) used to initiate or maintain machine motion(s) or other machine function(s).

Automatic start: A safety function is automatically restored (without an ON button). This for example is only permissible

for moving protective guards that cannot be bypassed.

However this is not permissible for an Emergency Stop

device. This start type is only permissible after the hazard

has been assessed.

B10: The B10 value for devices subject to wear is expressed in the number of switching cycles. The failure rate of

electromechanical components can be calculated using the B10 value and the operating cycle.

Blanking: Bypassing a portion of the sensing field of a presence-sensing safeguarding device (light curtain).

Cable-operated Switch: This is mainly used in EMERGENCY STOP protective safety devices and is a signal transmitter whose switching state changes if a cable / line - connected to the switch - is pulled or the line / cable breaks. This

device is used to monitor long lengths (for example, along conveyor belts).

Cascading input – Safety Relay: Safety, single-channel input of a safety relay that is internally evaluated just like a sensor signal; logical and operational with the other signal

transmitter / sensor inputs. If a voltage is not connected, the safety relay safely disables the enable circuits (outputs).

CCF (Common Cause Failure): Failure with a common cause (short-circuit).

Contact less electro-sensitive protective device (laser scanners, light grids, and light curtains). Contact less / electro-sensitive protective devices that essentially comprise

the sensor function and the associated control monitoring

function with output switching element – also known as

OSSD (output safe switching device).

Control reliability: The capability of the machine control system, the safeguarding, other control components and related interfacing to achieve a safe state in the event of a

failure within their safety-related functions.

Cross-circuit fault: This can occur for multi channel control circuits for equipment/devices and is a short circuit between channels (e.g. in a two-channel sensor circuit)

Cross-circuit fault detection: This is the ability of the safety device to detect cross-circuit faults – either immediately or as part of a cyclic monitoring routine: The device goes into a safe condition after the fault has been detected.

Discrepancy time: The discrepancy time monitoring tolerates, within a defined time window that associated signals

not available at the same time.

Diversity: The use of different means, such as use of different

processors or other hardware such as relays, storage media,

programming languages and software to perform the

same function.

A white paper issued by: Siemens.

© Siemens Industry, Inc. 2013. All rights reserved.

Emergency stop: A manually actuated control device that can be used to initiate an EMERGENCY STOP function (red mushroom button with yellow background). Note: The EMERGENCY STOP function is initiated by a single action

of a person and must always be available and capable of

functioning irrespective of the operating mode.

Enabling switch: An enabling switch is a manually operated signal transmitter which can be actuated to withdraw the protective effect of protection equipment. It is not possible or permissible to initiate hazardous states using the enabling

switch alone – a “second, conscious” start command is

required for this.

Energy source: Any electrical, mechanical, hydraulic, pneumatic, chemical, thermal, potential, kinetic or other sources of power / movement.

Feedback circuit: This is used to monitor controlled

actuators (e.g. relays or load contactors with positively-driven

contacts). The evaluation unit can only be activated when the

feedback circuit is closed. Note: The NC contacts (these are

positively-driven contacts) of the load contactors to be

monitored are connected in series and integrated into the

feedback circuit of the safety controller/relay. If a contact

welds in the enable circuit, then it is no longer possible to

re-activate the safety controller/relay because the feedback

circuit remains open. The (dynamic) monitoring of the feedback circuit does not have to be safety-related because it is

only used for fault detection. The ON button is generally

switched using the positively-driven contacts of the actuator

in series (fault detection when starting)

Hand tool: Any device used for manual feeding or removal or a work piece, freeing of a jammed work piece or removal of scrap.

Harmonized standard: Type A (Basic Standards), Type B (Group Standards) and Type C (Products Standards) are listed in the Machinery Directive and therefore allow an assumption to be made that the Machinery Directive is complied with.

Hazard: The hazard (as the result of a specific event)

represents danger for the user and can result in injury (potential source of damage).

Hazard assessment: Evaluation of a danger (resulting from a

hazard) for the user.

Interlocking equipment and devices: This is a mechanical, electrical or another interlocking device that has the function

of preventing the operation of a machine under certain

specific conditions (generally as long as a guard is not closed).

Life cycle of a machine: The phases of a machine including design and construction, transport and commissioning,

re-assembly, installation, initial adjustment, relocation, use (such as setting, teaching / programming or process change- over, operation) and care (cleaning, trouble shooting,

maintenance (planned or unplanned) de-commissioning, dismantling and, as far as safety is concerned, disposal.

White paper | Guide to Machine Safety Standard | January, 2013

Listed for use: Equipment, materials or services included in a list published by a Nationally Recognized Testing Laboratory

(NRTL) and concerned with evaluation of products or services,

that maintains periodic inspection of production of listed

equipment or materials or periodic evaluation of services,

and whose listing states that either the equipment, material

or services meets identified standards or has been tested and

found suitable for a specified purpose.

Positively-opening: For positively-opening contacts, the contacts separate as a direct result of a defined motion of the switch actuator using non-spring mechanical linkage. For the electrical equipment of machinery, the positively-

opening contacts are expressly specified in all safety circuits.

Note: Positively-opening contacts are designated according

to IEC 60947-5-1 by the symbol (arrow in a circle) (function

to protect persons).

Manual reset: A function to restore one or several safety functions before the machine restarts. After a stop command

has been initiated by a protective device, the stop state must

be maintained until a manual reset device is actuated and the

safe state has been reached for a restart.

Presence-sensing device: A device that creates a sensing

field, area or plane to detect the presence of an individual

or project.

Mirror contact: A typical application of mirror contacts is to provide high reliable monitoring of the switching state in the

control circuits of machinery.

Monitored start: The safety function is restored by

monitoring a dynamic signal change, e.g. using an ON

pushbutton. This is absolutely mandatory to achieve a higher

safety level for an emergency stop protective device since it

provides protection against manipulation. This start type is

only permissible after a hazard has been assessed.

Muting: A type of bypass function: The safety-related

function is correctly and deliberately disabled using

additional sensors for a limited time. Note: This is used in the field to make a differentiation between persons and objects.

Performance level: Capability of safety-relevant parts to

execute a safety function under predictable conditions (that should be taken into account) to fulfill the expected risk minimization. From PLa (the highest probability of failure) to PLe (the lowest probability of failure)

Proof test: Repeated test that is executed to detect faults in a SRECS so that – if necessary – the system can be brought into an “as new state”, or as close as is practically possible to an “as new state.”

Protective device: Device (other than a guard), which reduces a risk, either alone or associated with a guard (does not

include personal protective equipment).

Residual risk: That risk that remains after safeguarding

devices have been applied and a risk assessment performed.

Risk: A combination of the probability and the degree of the possible injury or damage to health in a hazardous situation in order to select appropriate safeguards.

Risk assessment: The process by which the intended use of the machine, the tasks and hazards, and the level of risk are performed.

Safeguarding: Guards, safeguarding devices, awareness

devices, safeguarding methods and safe work procedures.

Safety distance: The calculated distance between a hazard

and its associated safeguard.

PES (Programmable Electronic System): A system for

control or monitoring using one or more programmable

electronic devices, including all elements of the system, such

as power supplies, sensors and other input devices, data links

and other communication paths, and actuators, and other

output devices.

Safety function: Function of a machine, the malfunction of

which would increase the risk of harm.

Positively-driven contacts: For positively-driven contacts

of a relay/contactor, the NC contact and the NO contact may never be simultaneously closed over the complete lifetime

of the device. This also applies if the relay/contactor is in an incorrect state (faulted). E.g. If a NO contact is welded, then all of the other NC contacts of the relay/contactor involved remain open no matter whether the relay/contactor is

energized or not.

Tolerable risk: Risk that is accepted for a given task and

hazard combination (hazardous situation).

Siemens Industry, Inc.

3333 Old Milton Parkway

Alpharetta, GA 30005

www.siemens.com

Order No. SIWP-SSTDS-0113

All rights reserved. All trademarks used are

owned by Siemens or their respective owners.

A white paper issued by: Siemens.

© Siemens Industry, Inc., October 2013. All rights reserved.

SIL: One of three possibilities to define safety integrity

specifications of the safety function that can be assigned

to an SRECS. Safety integrity level 3 (SIL 3) is the highest

possible level and level 1 (SIL1) is the lowest.

Two hand control device: An actuating control that requires

the concurrent use of the operators hands to initiate machine

motion during the hazardous portion of the machine cycle.

Validation: Confirmation by examination and testing that the

particular requirements for a specific intended use are met.

Verification: The process or act of confirming that a device or

function conforms or performs to its design.